Professional Documents

Culture Documents

Pressure Testing Safety

Uploaded by

api-26143956Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Testing Safety

Uploaded by

api-26143956Copyright:

Available Formats

SAFETY FEEDBACK

DGEP/SE & NOTICE 16-2002

DGEP/TDO/PJC

THE HAZARDS OF PRESSURE TESTING

Why this subject ?

During hydrotesting and pressure testing operations incidents sometimes happen. This

Safety Feedback Notice provides some typical examples which can be used as an aid

in highlighting the hazards and dangers involved are what are often seen as routine

operations.

Details of the 5 incidents

1. Hydro-test of a new vertical vessel

The root cause of the incident is not fully

known but there was some thought that hydro-

testing with "very cold" water was a

contributing factor.

Fortunately no injuries occurred.

Wall Thickness

2. Filling of a vertical tank

The filling of the tank was made with water from a fire hydrant.

The top of tank blew off because the

relief valve could not displace the air

fast enough for the volume of water

that was being pumped in.

Fortunately no injury happened, but an

operator was on

top of the tank a

few seconds

before.

For further information please contact Jean-Marc PECQUOIS ( + 33 (0)5 59 83 45 50

* jean-marc.pecquois@totalfinaelf.com

DGEP/SE 16/2002 October 2002 Page 1/4

SAFETY FEEDBACK

DGEP/SE & NOTICE 16-2002

DGEP/TDO/PJC

3. Emptying of a vertical tank

The collapse of this tank happened while it was being emptied. A plastic sheet protecting the

roof was trapped in the vent;

hence a vacuum was caused.

The plastic sheet

on top of the tank

There was no injury. It should be

noted that this type of incident

is not that unusual.

4. Sphere collapse

The accident happened during the filling of a

2000 m 3 LPG sphere. Its legs collapsed.

One person was killed and one seriously

injured.

At the time of the accident, the sphere was

approximately 80% full of fresh water.

The vessels last hydro-test was 10 years ago

and the last inspection of its legs was 5 years

ago.

Severe corrosion of the legs under the

concrete fire protection was the main cause.

The corrosion occurred due to water ingress

between the concrete and the steel legs.

The water protective cap located over the concrete was not sufficient to keep the water out.

After the accident, it was verified that the steel legs had thickness reductions of up to 8mm,

with pitting holes of up to 10cm2.

After analysis and tests, it has been found that the following factors caused the collapse:

♦ Water caps over the fire-proofing concrete were of poor design thereby letting

water penetrate between the steel beams and the concrete.

For further information please contact Jean-Marc PECQUOIS ( + 33 (0)5 59 83 45 50

* jean-marc.pecquois@totalfinaelf.com

DGEP/SE 16/2002 October 2002 Page 2/4

SAFETY FEEDBACK

DGEP/SE & NOTICE 16-2002

DGEP/TDO/PJC

♦ Vertical cracks in the concrete let water in.

♦ Repairs had been done to the concrete, but with poor workmanship.

♦ The new concrete had not adhered to the old concrete, again letting water in.

♦ The deluge system had been tested with salt water, increasing the possibility of

corrosion.

5. Emptying of a gear box

To speed up the removal of 250l of oil from a gear-box, the gauge hole was plugged and the

breather was connected to the 6 bar air network.

The gear box exploded, and threw missiles around seriously damaging surrounding piping

and structure. Fortunately there was no injury.

Breather connected

to air compressor

SPECIFIC RECOMMENDATIONS

For each case the specific recommendation are generally obvious :

1st incident : Water temperature is critical when hydro testing. TFE specification (GS

PVV 211) states that both metal and water temperature during pressure testing shall be

maintained at least at 16°C or at least 10°C above the impact test temperature of the

metal.

2nd and 3rd incidents : venting systems shall be inspected and checked before filling

and emptying operations.

4th incident : Is a maintenance problem ? Before testing an old vessel, a complete

inspection must be performed visually and with NDT. This inspection shall include the

vessel, nozzles, appurtenances, and supporting structures.

5th incident : obviously a gear-box is not a pressure vessel, but productivity may lead

to a risky attitude.

For further information please contact Jean-Marc PECQUOIS ( + 33 (0)5 59 83 45 50

* jean-marc.pecquois@totalfinaelf.com

DGEP/SE 16/2002 October 2002 Page 3/4

SAFETY FEEDBACK

DGEP/SE & NOTICE 16-2002

DGEP/TDO/PJC

RECOMMENDED ACTIONS FOR PRESSURE TESTING

Tests may be a routine operation pressure for you, however, do not forget that in fact

pressurisation is energy storage. Its instantaneous release works as a bomb and may cause

severe damage to persons and equipment.

M

As for most of the operations, good preparation is essential to avoid incidents. It is

recommended to use the following check list :

ð A detailed check list procedure must be prepared as per the standards and specifications. It

must cover the testing operation from filling up to emptying the vessel.

ð Good co-ordination is essential to avoid performing the hydro-test at the same time as other

operations. A work permit procedure / Job Hazard Analysis should be used,

ð The equipment should be in good condition and adequately maintained and certified,

ð Testing equipment must be as far as practicable from the recording and pumping station,

ð Testing equipment (even if brand new) must be checked.

ð The test area must be roped off,

ð During the test, from filling up until the end of depressurisation, all non-essential people

must be out of the test area,

ð The test crew must attend a toolbox talk,

ð All people must wear their appropriate PPE,

ð Inspection for leaks shall be performed at least 15mn after the test pressure has been

reached and only by designated personnel,

ð Never tamper with, or tighten any fittings (i.e. connections, bolts, hoses and the like) while

under pressure or during pressure-up stages.

M

Also do not forget that as pipeline pigging is similar to pressure testing. As a minimum the

same checklist should be used.

For further information please contact Jean-Marc PECQUOIS ( + 33 (0)5 59 83 45 50

* jean-marc.pecquois@totalfinaelf.com

DGEP/SE 16/2002 October 2002 Page 4/4

You might also like

- Perpetuum Mobile - Penguin Café OrchestraDocument1 pagePerpetuum Mobile - Penguin Café OrchestrajxaytvgvdgfaNo ratings yet

- 7 Anabolic Abs WorkoutsDocument28 pages7 Anabolic Abs WorkoutsjosemfcNo ratings yet

- Samsung engineering construction work method statementDocument7 pagesSamsung engineering construction work method statementgururaj100% (1)

- Fine Motor SkillSDocument52 pagesFine Motor SkillSHemant Kumar100% (1)

- Pneumatic TestDocument10 pagesPneumatic Testchitobarba19726762100% (3)

- PTW Check ListsDocument30 pagesPTW Check ListsRoshin99100% (1)

- 0051-1104 Method Statement Pneumatic TestingDocument9 pages0051-1104 Method Statement Pneumatic TestingHasif Mohammed67% (3)

- EVA RPG NERV White Paper English - TextDocument219 pagesEVA RPG NERV White Paper English - TextBuran 1942100% (2)

- شبكات المياه والصرف الصحيDocument124 pagesشبكات المياه والصرف الصحيWalif Dababat100% (3)

- KU-TWK-00-QA-PRO-0001 - 0 - Hydrostatic Pressure Testing ProcedureDocument29 pagesKU-TWK-00-QA-PRO-0001 - 0 - Hydrostatic Pressure Testing Procedurebmanojkumar16No ratings yet

- Pressure Test - Hydrostatic and Pneumatic Test RequirementsDocument6 pagesPressure Test - Hydrostatic and Pneumatic Test RequirementslorenzoNo ratings yet

- تقنيات الطرقDocument126 pagesتقنيات الطرقWalif Dababat100% (5)

- LEAK PRESSURE TEST TITLEDocument68 pagesLEAK PRESSURE TEST TITLEJayaraman KamarajNo ratings yet

- Hazard Identification and Risk AssesmentDocument4 pagesHazard Identification and Risk AssesmentSkipper SkyNo ratings yet

- Advanced Oilfield Technology Company LLC: Work ProcedureDocument6 pagesAdvanced Oilfield Technology Company LLC: Work ProcedureAhmed M. AbdelazizNo ratings yet

- Hand Book BTS Site.Document28 pagesHand Book BTS Site.KUNDANNo ratings yet

- High Pressure CleaningDocument8 pagesHigh Pressure Cleaningmc chesterNo ratings yet

- Leak Test Procedure For SubDocument5 pagesLeak Test Procedure For Subpallav chatterjeeNo ratings yet

- Hydrotesting of ShellDocument4 pagesHydrotesting of Shellmsaqibraza93No ratings yet

- Pressure Testing Safety EssentialsDocument7 pagesPressure Testing Safety EssentialsSuleyman HaliciogluNo ratings yet

- Bristle - Blaster - Brochure SSPC SP 11Document6 pagesBristle - Blaster - Brochure SSPC SP 11yanuar iskhakNo ratings yet

- FR 002 Pressure Testing Inspection ChecklistDocument6 pagesFR 002 Pressure Testing Inspection Checklistum er100% (1)

- Hydro Testing FatalityDocument1 pageHydro Testing FatalityAnand Padmanaban100% (1)

- Classic Dungeon Designer's Netbook #4 - Old School Encounters Reference PDFDocument160 pagesClassic Dungeon Designer's Netbook #4 - Old School Encounters Reference PDFcaracallax100% (1)

- Equipment Nitrogen Purging Procedure PDFDocument13 pagesEquipment Nitrogen Purging Procedure PDFKUMAR100% (2)

- Confined Space Entry Procedure WorksheetDocument5 pagesConfined Space Entry Procedure WorksheetToma AdrianaNo ratings yet

- Re-Welding, Expansion & HT ProcedureDocument6 pagesRe-Welding, Expansion & HT Proceduresuria qaqcNo ratings yet

- Hydrostatic Pressure Test Safety ChecklistDocument3 pagesHydrostatic Pressure Test Safety ChecklistKyaw Kyaw AungNo ratings yet

- HSE Alert PDFDocument2 pagesHSE Alert PDFjavariam99No ratings yet

- Bulletin HSE SampleDocument4 pagesBulletin HSE SampleeliNo ratings yet

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- ادارة المشاريعDocument135 pagesادارة المشاريعWalif Dababat67% (3)

- Need for Effective HSE ManagementDocument59 pagesNeed for Effective HSE ManagementtissaanuradhaNo ratings yet

- HAZARDS Pneumatic TestDocument4 pagesHAZARDS Pneumatic TesthazopmanNo ratings yet

- Corrosion Cotrol ManualDocument36 pagesCorrosion Cotrol ManualNwosu AugustineNo ratings yet

- Tombo PackingDocument32 pagesTombo PackingghostinshellNo ratings yet

- Safety Alert Space HeatersDocument2 pagesSafety Alert Space HeatersRamadan KareemNo ratings yet

- AB-522 Standard Pneumatic Test Procedure RequirementsDocument16 pagesAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerNo ratings yet

- Earn BTC DailyDocument4 pagesEarn BTC DailyMaria AlfonsoNo ratings yet

- Method Statement DPE GL1 Cooling Water Line CleaningDocument15 pagesMethod Statement DPE GL1 Cooling Water Line CleaningDheeraj Chowdary DhanekulaNo ratings yet

- MEGHA ENGINEERING HYDRO TEST CHECKLISTDocument1 pageMEGHA ENGINEERING HYDRO TEST CHECKLISTjithin shankarNo ratings yet

- Pneumatic Test ProcedureDocument12 pagesPneumatic Test ProcedurePower Power100% (4)

- Measurement For SalwarDocument15 pagesMeasurement For Salwarsanjee2100% (1)

- Tyres Adam ThorpeDocument8 pagesTyres Adam ThorpeHow-Shin Tsao0% (1)

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDocument5 pagesCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNo ratings yet

- P3-PTP-001 R0 Piping Pressure Test ProceduresDocument8 pagesP3-PTP-001 R0 Piping Pressure Test ProceduresHengNo ratings yet

- SwimmingDocument12 pagesSwimmingkunalNo ratings yet

- David Lodge - Hotel Des BoobsDocument5 pagesDavid Lodge - Hotel Des BoobsAdelina TeodoraNo ratings yet

- Installing and Operating a Thermal Relief ValveDocument12 pagesInstalling and Operating a Thermal Relief ValveHiren Panchal100% (1)

- Pipe Fabrication Brochure CompressedDocument2 pagesPipe Fabrication Brochure CompressedLeDzungNo ratings yet

- Typical Acid Cleaning Procedure For Compressor LinesDocument1 pageTypical Acid Cleaning Procedure For Compressor Linesrenjithv_4No ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: FacilityjoshuaNo ratings yet

- S104-PPT - Hydrostatic and Pneumatic TestsDocument60 pagesS104-PPT - Hydrostatic and Pneumatic TestsMohammad Arif100% (1)

- Pipeline Pigging Incident Injures WorkerDocument7 pagesPipeline Pigging Incident Injures WorkerSajid SattarNo ratings yet

- IENCSEPRO0007-2 - General Leak Test Procedure PDFDocument9 pagesIENCSEPRO0007-2 - General Leak Test Procedure PDFCatalinNo ratings yet

- HSE Leadership - DD LWD MWD PWDDocument3 pagesHSE Leadership - DD LWD MWD PWDAKOMOLAFE ABAYOMINo ratings yet

- Material Inspection ReportDocument5 pagesMaterial Inspection ReportAndreas SchlagerNo ratings yet

- Stress Relieving Procedure 01Document6 pagesStress Relieving Procedure 01VikasShelkeNo ratings yet

- WELDING MACHINE ChecklistDocument1 pageWELDING MACHINE Checklistsakthi venkatNo ratings yet

- Hydro Test ProcedureDocument2 pagesHydro Test ProcedureDhanushka B HerathNo ratings yet

- Air Testing TanksDocument2 pagesAir Testing TanksTatiana CruzNo ratings yet

- Lift Study ChecklistDocument3 pagesLift Study ChecklistIkhsan Awan0% (1)

- HYDROTESTDocument144 pagesHYDROTESTJean GheorgheNo ratings yet

- NRL Pipeline Hydrotest Format PDFDocument1 pageNRL Pipeline Hydrotest Format PDFJaved Mohammed100% (1)

- Pressure Equipment Hydro-Testing GuideDocument10 pagesPressure Equipment Hydro-Testing GuideJamalAhmedNo ratings yet

- ToolboxTalk 0715Document2 pagesToolboxTalk 0715Epifanio Jr Lagadan TorresNo ratings yet

- Notification of Incident/Hazard: Incident Report Ref: MLE/HSE/IRF/-03Document3 pagesNotification of Incident/Hazard: Incident Report Ref: MLE/HSE/IRF/-03Abdul-kadiri SulleyNo ratings yet

- Working at Heights ChecklistDocument3 pagesWorking at Heights ChecklistCristiane RibeiroNo ratings yet

- Piping Hydrostatic Testing (Overview)Document5 pagesPiping Hydrostatic Testing (Overview)ricosanojuanNo ratings yet

- ICI SAFETY NEWSLETTER No 91 PDFDocument8 pagesICI SAFETY NEWSLETTER No 91 PDFИванов ИванNo ratings yet

- Piping Hydrostatic Testing (Overview) - QA - QC ConstructionDocument11 pagesPiping Hydrostatic Testing (Overview) - QA - QC ConstructionSonNguyenNo ratings yet

- Disaster Case Studies PasadenaDocument6 pagesDisaster Case Studies PasadenaDarius DsouzaNo ratings yet

- Msf-Safety-Flash-06 24Document1 pageMsf-Safety-Flash-06 24gcaptain100% (1)

- 01.hazards of Trapped Pressure & Vacuum-29Document2 pages01.hazards of Trapped Pressure & Vacuum-29rahulNo ratings yet

- No. 127 More About Modifications and InstrumentsDocument8 pagesNo. 127 More About Modifications and InstrumentsLisa FosterNo ratings yet

- ورش كهربائية وصحيةDocument150 pagesورش كهربائية وصحيةWalif DababatNo ratings yet

- Basic Software Internet Programming (Networking EngineeringDocument3 pagesBasic Software Internet Programming (Networking Engineeringapi-26143956No ratings yet

- العقود الهندسيةDocument237 pagesالعقود الهندسيةKhaled Rahim100% (1)

- ورش شدات وحديد التسليحDocument160 pagesورش شدات وحديد التسليحWalif Dababat100% (1)

- انشاءات معدنيةDocument134 pagesانشاءات معدنيةWalif Dababat100% (1)

- امن وسلامةDocument71 pagesامن وسلامةapi-26143956No ratings yet

- تقنية عمارةDocument130 pagesتقنية عمارةapi-26143956No ratings yet

- HPD262Document200 pagesHPD262api-26143956No ratings yet

- HPDL261Document116 pagesHPDL261api-26143956No ratings yet

- Exp GuideDocument583 pagesExp Guideapi-26143956100% (1)

- 05 Geotechnical EngineeringDocument5 pages05 Geotechnical Engineeringapi-26143956No ratings yet

- خواص واختبارات مواد البناء-عمليDocument126 pagesخواص واختبارات مواد البناء-عمليWalif Dababat100% (4)

- خواص واختبارات مواد البناء-عمليDocument126 pagesخواص واختبارات مواد البناء-عمليWalif Dababat100% (4)

- Kancil Dan MonyetDocument6 pagesKancil Dan MonyeticaNo ratings yet

- Timun MasDocument2 pagesTimun MasmaiyaNo ratings yet

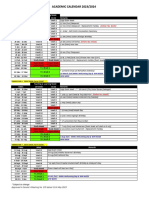

- Academic Calendar 23 24Document1 pageAcademic Calendar 23 24Jeff KokNo ratings yet

- Section Factors HPADocument16 pagesSection Factors HPATanmay GorNo ratings yet

- Winter Academic State ChampionsDocument2 pagesWinter Academic State ChampionsstprepsNo ratings yet

- En - HDL20-A Spec SheetDocument4 pagesEn - HDL20-A Spec SheetNiviNo ratings yet

- Attom - DC Power System-Brochure-en-2021v1.2Document5 pagesAttom - DC Power System-Brochure-en-2021v1.2Eleken Login2No ratings yet

- Tawara Adventures Newsletter: Uk Centres Family FunDocument2 pagesTawara Adventures Newsletter: Uk Centres Family FunAbril MendezNo ratings yet

- Old Quarter 1Document2 pagesOld Quarter 1Huy TrầnNo ratings yet

- Cultural Diversity and Influences Shaped Indonesian MusicDocument12 pagesCultural Diversity and Influences Shaped Indonesian MusicjhokenNo ratings yet

- Log Cat 1705805683197Document41 pagesLog Cat 1705805683197apatkalidNo ratings yet

- Technology in Education Technology Presentation in Blue Peach Illustrative StyleDocument37 pagesTechnology in Education Technology Presentation in Blue Peach Illustrative StyleAngel “Miley” SamileyNo ratings yet

- Rosario - Software ApplicationDocument12 pagesRosario - Software ApplicationJoan RosarioNo ratings yet

- Gymnastics Module2 1stsemDocument23 pagesGymnastics Module2 1stsemJhon Cleoh DiasaNo ratings yet

- 1 48Document48 pages1 48rdvreyNo ratings yet

- Item Material Description Qty UnitDocument18 pagesItem Material Description Qty UnitFroilan EspinosaNo ratings yet

- Curso: Ingles Ii Docente: Gina Antonella Buitriago Mendez Alumno: - Ayrton Fernando Torrejon Santillan Codigo: - U20249783Document3 pagesCurso: Ingles Ii Docente: Gina Antonella Buitriago Mendez Alumno: - Ayrton Fernando Torrejon Santillan Codigo: - U20249783Ayrton Fernando TorrejónNo ratings yet

- The Road Towards A Linux TSN Infrastructure: Jesus Sanchez-PalenciaDocument27 pagesThe Road Towards A Linux TSN Infrastructure: Jesus Sanchez-Palenciakrishna prasathNo ratings yet

- Sony Ericsson Xperia Play R800 Z1 Schematics - Electrical v2Document18 pagesSony Ericsson Xperia Play R800 Z1 Schematics - Electrical v2Mata RandallNo ratings yet