Professional Documents

Culture Documents

ACSR Current Capacity Calculations

Uploaded by

christophe_guntzOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACSR Current Capacity Calculations

Uploaded by

christophe_guntzCopyright:

Available Formats

OVERHEAD ALUMINIUM

CONDUCTORS

All Aluminium Conductors

All Aluminium Alloy Conductors

Aluminium Conductors Steel Reinforced

Need Power Connections? We Have The Solutions!

70

BS 215:PART 1

REFERENCE CODE : AAC

ALL ALUMINIUM CONDUCTOR FOR OVERHEAD POWER TRANSMISSION

CODE NAME

NOMINAL EQUIVALENT CONDUCTOR

ALUMINIUM

COPPER CONSTRUCTION

AREA

AREA

APPROX.

OVERALL

DIAMETER

CALCULATED

AREA

APPROX.

WEIGHT

NOMINAL

BREAKING

LOAD

MAX. DC

RESISTANCE

AT 20C

CURRENT

RATING

mm2

mm2

No./mm

mm

mm2

kg/km

/km

Amp

MIDGE

22

14.2

7/2.06

6.2

23.3

64

4000

1.227

72

ANT

50

32.3

7/3.10

9.3

52.8

145

8300

0.5419

112

FLY

60

38.7

7/3.40

10.2

63.6

174

9900

0.4505

124

WASP

100

64.5

7/4.39

13.2

106.0

290

16000

0.2702

158

HORNET

150

96.8

19/3.25

16.3

157.6

434

24700

0.1825

190

CHAFER

200

129

19/3.78

18.9

213.2

587

32400

0.1349

215

COCKROACH

250

161

19/4.22

21.1

265.7

731

40400

0.10830

232

BUTTERFLY

300

194

19/4.65

23.3

322.7

888

48700

0.08916

247

CENTIPEDE

400

258

37/3.78

26.5

415.2

1145

63100

0.06944

262

BS 3242

REFERENCE CODE AAAC

ALL ALUMINIUM ALLOY CONDUCTOR FOR OVERHEAD POWER TRANSMISSION

NOMINAL EQUIVALENT CONDUCTOR

COPPER CONSTRUCTION

ALUMINIUM

AREA

AREA

APPROX.

OVERALL

DIAMETER

CALCULATED

AREA

APPROX.

WEIGHT

NOMINAL

BREAKING

LOAD

MAX. DC

RESISTANCE

AT 20C

CURRENT

RATING

mm2

mm2

No./mm

mm

mm2

kg/km

/km

Amp

ALMOND

25

16.1

7/2.34

7.02

30.1

82

8450

1.094

85

CEDAR

30

19.4

7/2.54

7.62

35.5

97

9950

0.9281

85

FIR

40

25.8

7/2.95

8.85

47.8

131

13400

0.6880

99

HAZEL

50

32.3

7/3.30

9.90

59.90

164

16800

0.5498

113

OAK

100

64.5

7/4.65

13.95

118.9

325

33300

0.2769

150

ASH

150

96.8

19/3.48

17.40

180.7

497

50600

0.1830

181

ELM

175

113

19/3.76

18.80

211.0

580

59100

0.1568

188

UPAS

300

194

37/3.53

24.71

362.1

997

101500

0.09155

209

CODE NAME

TNB SPECIFICATION

REFERENCE CODE ACSR

ALL ALUMINIUM ALLOY CONDUCTOR FOR OVERHEAD POWER TRANSMISSION

NOMINAL EQUIVALENT

ALUMINIUM COPPER

AREA

AREA

CODE NAME

mm

mm

300

197

BATANG

CONDUCTOR

CONSTRUCTION

ALUMINIUM

STEEL

No./mm

18/4.78

7/1.68

NOTES :

* THE RATINGS ARE BASED ON THE FOLLOWING CONDITIONS:

1. Wind speed

2. Ambient Temperature

71

0.447

35

m/s

C

3. Intensity of solar radiotion 1200

W/m2

4. Temperature rise

20

APPROX. CALCULATED

AREA

OVERALL

DIAMETER

APPROX.

WEIGHT

NOMINAL MAX. DC

CURRENT

BREAKING RESISTANCE RATING*

LOAD

AT 20C

mm

mm2

kg/km

/km

Amp

24.16

323.0

1010

69670

0.08914

178

BS 215:PART 2

REFERENCE CODE ACSR

NOMINAL EQUIVALENT

ALUMINIUM COPPER

AREA

AREA

CODE NAME

CONDUCTOR

CONSTRUCTION

ALUMINIUM

STEEL

APPROX. CALCULATED

AREA

OVERALL

DIAMETER

No./mm

APPROX.

WEIGHT

NOMINAL MAX. DC

CURRENT

BREAKING RESISTANCE RATING

LOAD

AT 20C

mm

mm2

kg/km

/km

Amp

1/2.36

7.08

30.62

106

9600

1.093

77

6/2.59

1/2.59

7.77

36.88

128

11400

0.9077

84

6/3.00

1/3.00

9.00

49.48

172

15200

0.6766

98

32.3

6/3.35

1/3.35

10.05

61.70

214

18400

0.5426

112

45.2

12/2.59

7/2.79

13.95

116.2

538

61200

0.3936

148

100

64.5

6/4.72

7/1.57

14.15

118.5

394

32700

0.2733

153

mm

mm

GOPHER

25

16.1

6/2.36

WEASEL

30

19.4

FERRET

40

25.8

RABBIT

50

HORSE

70

DOG

WOLF

150

96.8

30/2.59

7/2.59

18.13

194.9

726

69200

0.1828

162

DINGO

150

97.9

18/3.35

1/3.35

16.75

167.5

506

35700

0.1815

179

LYNX

175

113.0

30/2.79

7/2.79

19.53

226.2

842

79800

0.1576

178

CARACAL

175

113.7

18/3.61

1/3.61

18.05

194.5

587

41000

0.1563

205

PANTHER

200

129

30/3.00

7/3.00

21.00

261.5

974

92200

0.1363

191

BISON

226

54/3.00

7/3.00

27.00

431.3

1444

120900

0.07571

208

JAGUAR

200

130

18/3.86

1/3.86

19.30

222.3

671

46600

0.13670

197

ZEBRA

400

258

54/3.18

7/3.18 28.62

484.5

1621

131900

0.06740

202

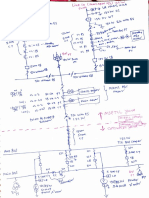

CURRENT RATING CALCULATION

FOR ALUMINIUM CONDUCTOR STEEL REINFORCED

The following equations can used to

Calculate the current rating for ACSR.

Continuous Current Rating (Calculation)

ALUMINIUM CONDUCTOR STEEL

REINFORCED FOR

OVERHEAD POWER TRANSMISSION

{hw + (hr - [Ws/0])n} D0

Amp - eqn.(1)

Ra

Current rating I =

cross sectional view

Where,

Galvanised

Steel Core

1) Heat dissipated due to wind velocity,

0.00572

{273 + T + (0/2)} 0.123

hw =

:

:

:

:

D

T

0

W/C cm2

Wind velocity

Conductor diameter

Ambient temperature

Permissible temp. increase

Ws

Ra

:

:

:

Where,

273 + T + 0

100

273 + T

100

W/C cm2

0

solar radiation = 0.1 W/cm2

Black body radiation coefficient = 0.9

ac resistance of conductor, /cm

Ra = K1 K2 Rd

Rd: dc resistance of conductor converted to R at (T + 0)

Rd = Rto{1+ (t-to)};

t = (T + 0)

to

Rto

:

=

:

Aluminium

wires

Skin effect constant:K1 = 0.99609 + 0.018578 - 0.030263

4

m/s

cm

C

C

2) Heat dissipated due to radiation,

hr = 0.000567

Temperature coefficient at 20C = 0.004

20C

dc resistance at 20C

(D+2d) x 0.01 x

(D+d)

+ 0.020733

8 f (D-d)

(D+d) Rd

Frequency in Hz

Iron loss constant:K2 = 0.99947 + 0.028895 - 0.0059348

+ 0.00042259

For ACSR with 3 layers of Aluminium

Ra = K1K2Rd

I

Where I = current from eqn.(1)

=

S

S = (D2 d2) mm2

4

72

73

You might also like

- Calculation For Induced Voltage in CableDocument1 pageCalculation For Induced Voltage in CablePramod B.Wankhade50% (2)

- DSLP Calculation by LMDocument8 pagesDSLP Calculation by LManilmarturiNo ratings yet

- Zebra Current Capacity Calculation SheetDocument1 pageZebra Current Capacity Calculation Sheetbinode100% (1)

- DSLP Calculation by VikasDocument7 pagesDSLP Calculation by Vikasvikasrajput1989100% (2)

- Bus Duct Calculations For 4000A Rated CurrentDocument4 pagesBus Duct Calculations For 4000A Rated CurrentGnanavel GNo ratings yet

- 4-D03108-0 - Conductor Sizing & BPI Cantilever Strength CalculationDocument13 pages4-D03108-0 - Conductor Sizing & BPI Cantilever Strength CalculationunnvishnuNo ratings yet

- ECSDocument58 pagesECSPradeesh Vijayan (v.prathi)No ratings yet

- Current Rating Calculation For ACSRDocument1 pageCurrent Rating Calculation For ACSRRomanistaPerSempreNo ratings yet

- Single Line Diagram of 132kv LILO SubstationDocument2 pagesSingle Line Diagram of 132kv LILO SubstationEr. Ajit Solanke100% (1)

- 33 KV TowerDocument4 pages33 KV TowerJayabalan R KNo ratings yet

- KEI Cable CatalogueDocument114 pagesKEI Cable CatalogueMousum100% (1)

- As D SW SP 4600 3Document9 pagesAs D SW SP 4600 3Odipiyo Paul100% (2)

- Acsr Panther Conductor Sizing Xls 0 PDFDocument6 pagesAcsr Panther Conductor Sizing Xls 0 PDFRavindra GoyalNo ratings yet

- Design of Insulator - 07.11.11Document1 pageDesign of Insulator - 07.11.11Natarajan RamakrishnanNo ratings yet

- DSLP CalculationDocument7 pagesDSLP Calculationravi shankar100% (1)

- Covergence of DC Resistance To Ac ResistanceDocument37 pagesCovergence of DC Resistance To Ac ResistanceBiswajit Naik100% (1)

- G I Stay Wire 7 - 10 SWGDocument1 pageG I Stay Wire 7 - 10 SWGAjay PatelNo ratings yet

- Calculation of Earthing System As Per Ieee 80Document10 pagesCalculation of Earthing System As Per Ieee 80Fateh Khemissi MilasNo ratings yet

- Substation Grounding Design - 50kgDocument7 pagesSubstation Grounding Design - 50kgsitifarhaniNo ratings yet

- Earthing CalculationDocument4 pagesEarthing CalculationNipuna Thushara WijesekaraNo ratings yet

- 132kv Malana Ekd-Section-Rev01 ModifiedDocument1 page132kv Malana Ekd-Section-Rev01 ModifiedannuvyasNo ratings yet

- REC Construction Standards: Name of The SpecificationDocument9 pagesREC Construction Standards: Name of The SpecificationJasmin ShethNo ratings yet

- EWT Earthing TransformersDocument4 pagesEWT Earthing TransformersSibolis NaburjuNo ratings yet

- CEADocument34 pagesCEAsubhra100% (1)

- Voltage Drop For 11KV CableDocument1 pageVoltage Drop For 11KV CableMohamed Anwar0% (1)

- Conductor SpecificationsDocument3 pagesConductor Specificationsdorababu2007No ratings yet

- Short-Circuit Currents - Calculation of Effects The Second Edition of Iec Publication 865Document10 pagesShort-Circuit Currents - Calculation of Effects The Second Edition of Iec Publication 865Hassan Bagheri100% (1)

- 1 Normal Tower 2 +3M Extn. Only 3 +6M Extn Only 4 StubDocument11 pages1 Normal Tower 2 +3M Extn. Only 3 +6M Extn Only 4 StubSrinivasarao MorampudiNo ratings yet

- Aluminium Pipe Bus PDFDocument6 pagesAluminium Pipe Bus PDFaviral mishraNo ratings yet

- Typical HT and LT Power Cable Sizing PDFDocument26 pagesTypical HT and LT Power Cable Sizing PDF1382ace100% (2)

- Technical Specification FOR 66kV, 132kV & 220 KV XLPE Insulated Single Core Power CableDocument13 pagesTechnical Specification FOR 66kV, 132kV & 220 KV XLPE Insulated Single Core Power CableGokul VenugopalNo ratings yet

- 33kV Line Loss Estimation - KaradikondaDocument8 pages33kV Line Loss Estimation - Karadikondasomdatta chaudhury0% (1)

- Type Tests On ACSR ConductorDocument1 pageType Tests On ACSR Conductorrajiv71No ratings yet

- Transmission Line Voltage and Conductor Selection Standard DatabaseDocument9 pagesTransmission Line Voltage and Conductor Selection Standard DatabaseKapil Mishra100% (1)

- IEC 60287 Current Capacity of Cables - Rated CurrentDocument1 pageIEC 60287 Current Capacity of Cables - Rated CurrentxsystemNo ratings yet

- ACSR Conductor Regulation CalculationDocument2 pagesACSR Conductor Regulation CalculationPramod B.Wankhade100% (1)

- Short Circuit Current Rating of ConductorsDocument1 pageShort Circuit Current Rating of ConductorsPradeep_VashistNo ratings yet

- Oil Soak Pit CalculationDocument2 pagesOil Soak Pit CalculationROHIT MCNo ratings yet

- Aluminium Busbar Sizing Software OutputDocument3 pagesAluminium Busbar Sizing Software Outputkapil100% (4)

- How To Determine Correct Number of Earthing Electroding FactorDocument14 pagesHow To Determine Correct Number of Earthing Electroding FactorumerNo ratings yet

- GTP of Insulator 132kV & 220kVDocument3 pagesGTP of Insulator 132kV & 220kVTarun AggarwalNo ratings yet

- Technical Specification: Odisha Power Transmission Corporation LimitedDocument55 pagesTechnical Specification: Odisha Power Transmission Corporation LimitedPritam SinghNo ratings yet

- Specification For BULL Conductor.Document4 pagesSpecification For BULL Conductor.boopelectra100% (2)

- ACSR ConductorsDocument118 pagesACSR Conductorssameerray12100% (1)

- Aluminium Tubular Busbar Sizing Calculations - 132kVDocument24 pagesAluminium Tubular Busbar Sizing Calculations - 132kVsitifarhani67% (3)

- Calculation For Earthing MatDocument11 pagesCalculation For Earthing Matpvpavan0% (1)

- Busbar Selection ChartDocument4 pagesBusbar Selection ChartArvind KumawatNo ratings yet

- Earthing Calculations For 66KV Switchyard - 32mm Dia Rod-7!3!12Document8 pagesEarthing Calculations For 66KV Switchyard - 32mm Dia Rod-7!3!12M.K.RameshNo ratings yet

- SS Earthing Mat Design 22 8 12Document7 pagesSS Earthing Mat Design 22 8 12Vishal ThakurNo ratings yet

- Quotation 11KV 33KV Electrical Equipment NESCL NTPC CS DA 628 DarlipaliDocument17 pagesQuotation 11KV 33KV Electrical Equipment NESCL NTPC CS DA 628 DarlipaliSharafat AliNo ratings yet

- Modern Survey For KPTCL 110 KV Transmission LinesDocument27 pagesModern Survey For KPTCL 110 KV Transmission Linesjoydeep_d3232No ratings yet

- AAC BULL & BERSIMIS Conductor - SpecificationDocument18 pagesAAC BULL & BERSIMIS Conductor - Specificationbalaeee123100% (2)

- Conductor SizingDocument5 pagesConductor Sizingzaidisofian100% (1)

- Busbar Size CalculationDocument5 pagesBusbar Size Calculationdermasdemo100% (6)

- 3VYN191246 - Busdesign CalculationsDocument9 pages3VYN191246 - Busdesign CalculationsManiKantNo ratings yet

- Parameters: Calculation For Al Bus Bar Suitable For 50ka Fault LevelDocument1 pageParameters: Calculation For Al Bus Bar Suitable For 50ka Fault Levelanand_girgaonkarNo ratings yet

- Earthing CalculationDocument14 pagesEarthing CalculationNatarajan Ramakrishnan100% (18)

- Electrical Cable GuideDocument12 pagesElectrical Cable GuidesunilwadekarNo ratings yet

- Design Cal IndoramaDocument13 pagesDesign Cal IndoramaKUNALJAYNo ratings yet

- FTPower Cable Size (1089 - 21)Document3 pagesFTPower Cable Size (1089 - 21)Nishu JainNo ratings yet

- Astm A153Document3 pagesAstm A153christophe_guntzNo ratings yet

- Astm A239Document3 pagesAstm A239christophe_guntzNo ratings yet

- Astm A143Document4 pagesAstm A143christophe_guntzNo ratings yet

- Astm A123Document7 pagesAstm A123christophe_guntzNo ratings yet

- ASTM A36 - 96 Standard Specification For Carbon Structural SteelDocument3 pagesASTM A36 - 96 Standard Specification For Carbon Structural SteelAnderson MatiasNo ratings yet

- Code For Design of Steel StructuresDocument136 pagesCode For Design of Steel Structureschristophe_guntzNo ratings yet

- Sag CalculationDocument20 pagesSag Calculationrahu111112000No ratings yet