Professional Documents

Culture Documents

Integration of 3D With Reservoir Simulation

Uploaded by

Ismail MohammedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Integration of 3D With Reservoir Simulation

Uploaded by

Ismail MohammedCopyright:

Available Formats

SPE 64746 Integration of 3D-Seismic With Reservoir Simulation for Reservoir Characterization and Assessment of Alternative Exploitation Schemes

of Field Development - A Case Study

C. S. Singh, B. Borgohain and D. Borgohain, Oil India Limited

Copyright 2000, Society of Petroleum Engineers Inc. This paper was prepared for presentation at the SPE International Oil and Gas Conference and Exhibition in China held in Beijing, China, 710 November 2000. This paper was selected for presentation by an SPE Program Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material, as presented, does not necessarily reflect any position of the Society of Petroleum Engineers, its officers, or members. Papers presented at SPE meetings are subject to publication review by Editorial Committees of the Society of Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Cross-discipline integration of data expertise and study has helped in accurate mapping of the minor faults and has provided a better insight into fault transmissibilities in the fluid flow simulation. Introduction Shalmari, a major oil producing field of Oil India Limited situated in the North-Eastern India was discovered in 1986. The initial field development and exploitation of reserves was carried out on the basis of then available 2D-Seimic data (acquired in 1984-85). Based on results of 2D-seismic interpretation and subsequent drilling of wells, the field is subdivided into three major fault blocks viz. Northern, Southern and Well #19 Block reservoirs. The areal extent of the structure is 5.8 sq. km. Till date a total of 30 wells have been drilled in this area at approximately 40 acre well spacing with current production rate of around 690 m3/day from Oligocene sandstone reservoirs. The area of study in this case will be confined to Northern Block reservoir which has 11 wells of which 6 are producing at the rate of 485 m3/day. The Northern Block reservoir has an estimated oil-in-place of 6.4859 MM m3 and recovery till date has been 28% of OOIP. Preliminary material balance and reservoir engineering studies indicated that the Northern Block reservoir was in immediate need of pressure maintenance possibly due to higher productivity of the wells and limited water influx from the aquifer(s). A detailed simulation study using a geological model based on 2D-seismic data was carried out in 1994 to assess the pressure maintenance requirement and to formulate an optimum field development plan. Based on the results of the study, few locations were identified for drilling as injectors and producers as infill/extension wells for adequate drainage of the reservoir (refer Figure 1(a)). Acquisition and Interpretation of 3D-Seismic Data 3D seismic survey was carried out in Shalmari and its adjoining areas covering 149.88 sq. km in March-May 1994. Processing of the data was completed in February 1995, of which only 118.38 sq. km of processed data were available for interpretation. A 3D seismic profile in NW-SE direction showing major structural style is shown in Figure 2(a). The broad objective of the study included detailed structural mapping and delineation of the areal extent of oil/gas pools for

Abstract This paper deals with a study where integration of 3D-seismic survey and reservoir simulation has aided in reservoir characterization which in turn have led to better and effective implementation of reservoir development schemes. Shalmari, one of the major oilfields in Assam-Arakan geological province of North-East India was discovered in 1986 and the initial field development was carried out on the basis of then available 2D-seismic data. During the course of initial field development, the area of major concern was the rapid decline of reservoir pressure. A detailed simulation study was carried out in 1994 for assessment of the pressure maintenance requirements and field development. A 3D-seismic survey was carried out in 1994 in this area to obtain additional information on the reservoir geometry and structural configuration. The processing and interpretation of 3D-seismic data resulted in identification of additional faults thus bringing about a change in the structural configuration of the reservoir. The presence of identified faults was corroborated by pressure transient surveys. This necessitated in carrying out of another detailed reservoir simulation study by building up a geological model based on 3D-seismic data. The basic objective of the study was to carry out a more accurate and reliable reservoir characterization apart from identifying the prominent direction of aquifer support and reassessment of the hitherto planned reservoir development scheme including ongoing pressure maintenance scheme. The results of the study carried out in 1997 also indicated possible increase in gross ultimate recovery as a result of water flooding. The financial analysis of the development schemes envisaged in this study was also found to be attractive.

C. S. SINGH, B. BORGOHAIN, D.BORGOHAIN

SPE 64746

further development within and adjacent to the Shalmari oilfield. Synthetic seismograms generated from sonic and density logs of few wells were used for identifying the horizons of interests for tracking. The correlation between well logs, synthetic seismogram and 3D seismic data for Well #5 is presented in Figure 2(b). The structural interpretation of 3D-seismic data was carried out on six horizons from Paleocene/Lower Eocene to Mio-Pliocene reflectors in Tertiary sedimentary sequences. The major tectonic elements are NE-SW trending normal faults which are associated with structural highs and lows at Oligocene level. The Oligocene formation (locally known as Barails) is subdivided into five main sand groups interbedded with shale/clays. Starting from top of Barails, the Fourth sand group is the main producing horizon for the Shalmari oilfield. At the top of the producing horizon, the Shalmari structure trends along WNW-ESE, oblique to the most dominant fault trend (refer Figure 1(b)). Structurally, the Northern Block reservoir is a faulted anticline bound by normal faults and a downdip oil-water contact. Apart from the major faults established during 2D-seismic interpretation, small synthetic and antithetic faults were identified as a result of 3D-seismic survey. These smaller faults more or less tend to isolate the main part of the structure from the flanks. Figure 1(b) depicts limited continuity of these faults. These faults show small throws of 10-20 m compared to sand thicknesses of 30-40 m and hence communication across the faults cannot be ruled out due to sand-to-sand juxtaposition. Figures 1(a) and 1(b) depict the structural pattern of Shalmari oilfield before and after 3Dseismic data acquisition and interpretation. Locations A, B, C, D, E, F and G of Figure 1(a) have been drilled and completed as Wells #22, 23, 24, 25, 26, 27 and 28 respectively (refer Figure 1(b)). The producing reservoir is a fluvial channel deposit with the channel axes running mostly from NE-SW and sometimes from West to East. Broadly there are three channel systems separated by shale interbeds. The middle part of the sand-body (Channel B) is cleaner, thicker and better developed than the lower and upper sand-bodies (Channels A and C). The channel A has completely shaled out in the western part of the structure where Wells #17, 22 and 25 are located. The shale bed separating these sand-bodies with thicknesses ranging from 4m to 7 m in the northern part of the structure possibly act as local vertical barriers. However, towards the southeastern part of the structure, the thickness of shale bed gradually decreases and is expected to die out completely towards the crest of the structure. Hence, regionally within the Northern Block, these two sand-bodies (channels A and B) are expected to be in pressure communication forming a single reservoir unit. All the wells in the Northern Block have been completed in the middle sand body (channel B). Additionally, Wells #5, #7 & #18 have also been completed in the lower sand body (channel A). The producing sand is separated from the upper (Barail Third) and the lower (Barail Fifth) sands by impermeable shale beds. It is important to note that Barail Third sand has been tested to be oil bearing while Barail Fifth

Sand is mainly water bearing. Figures 3(a) and 3(b) show two schematic geological sections depicting sand development patterns in the Northern Block of Shalmari structure. Figure 4 shows an isopach map of the main producing channel B. It is evident from the Figure that Channel B is thicker around wells #7, #14, #24 adjacent to the channel axis and gradually thinning down towards the northern flank of the structure. Pressure-Production Behaviour Shalmari Northern Block reservoir has an estimated OOIP of 6.4859 MM m3. So far, 11 wells have been completed in this reservoir out of which 6 wells are on production contributing around 485 m3/day of oil with negligible water cut. One well has been plugged back and completed in higher up sand. Water injection was initiated through Well #20 in 1994 but had been suspended since January 1997 based on the interpretation 3D seismic data as the location appeared to be unsuitable for injection. Measured pressure data in this well suggests limited communication of the well with the main Northern Block reservoir and this corroborates the results of 3D seismic data1. As a substitute, Well #6 has been converted to a water injector in January 1997. Well #25 ceased to flow during June 1996 due to low tubing pressure and at present the well has been converted to a water injector based on combined evidences from 3D seismic, pressure data and results of reservoir simulation. The original pressure was 316 kg/cm2 at a datum of 3220 m bd which has declined to the present level of about 180 kg/cm2 corresponding to a cumulative oil production of about 1.84 MM m3. The peak production rate was around 900 m3/day during 1995 before the onset of decline. The initial pool GOR was around 250-300 sm3/m3 and has shown a distinct rising trend in the past 2-3 years (GOR of 600-700 sm3/m3) due to fall in reservoir pressure well below the bubble point pressure. Reservoir Simulation Model and History Matching Keeping in mind that the sand-bodies within the producing sand in the Northern Block from a single pressure unit and are relatively homogeneous in nature, a `layer cake model has been deemed to be adequate to identify the main controls on reservoir-fluid flow and production. The simplified layer-cake correlation of the reservoir units enabled determination of obvious lateral and vertical barriers to flow across the reservoir. Based on channel orientation, structural dip and well spacing, a 34 x 19 x 2 (100 m x 100 m) uniform grid system aligned along the NE-SW trending major faults has been used for the simulation study. The structure contour map superimposed with the simulation grid is shown in Figure 5. The oil-water contact of the model has been set at 3260 m bd based on the wireline log data, hydrocarbon indications obtained during drilling and side-wall cores of Wells #20, #22 and #25. Validation and refinement of the geological model was accomplished by first comparing the model in-place volumes with the previous volumetric estimates and then history-

SPE 64746

INTEGRATION OF 3D-SEISMIC WITH RESERVOIR SIMULATION FOR RESERVOIR CHARACTERIZATION AND ASSESSMENT OF ALTERNATIVE EXPLOITATION SCHEMES OF FIELD DEVELOPMENT - A CASE STUDY

matching the model production and pressure performance to the actual well/field data. The volume check was to ensure that no major problems existed with the 3D model and that the ratio of reservoir to non-reservoir volumes was reasonable. Production and pressure matching were the main qualitycontrol tools. It is pertinent to mention here that the nature of faults/barriers established from 3D data interpretation could not be established at the beginning of the study. The history matching for initial reservoir-model simulation was attempted by assuming a closed structure with very limited pressure support from the Barail Fifth sand as aquifer in an area southeast of Well #18 where shale thickness is minimum. Additionally, communication in Well #7 was assumed with the lower sand where CET log showed poor cement bonding against the same. No pressure match could be obtained under this scenario and several wells exhibited premature breakthrough of water which has not been experienced in the field. It has been mentioned earlier that water injection through Well #20 has been suspended since beginning of 1997 as no beneficial effect of water injection was realized in the nearby wells. To resolve the nature of reservoir geometry established from 3D seismic2, a series of static BHPs were planned in Well #20 (adjacent to fault F3) and in the shut-in well, Well #25 (adjacent to fault F6). Interestingly, static BHP recorded in these wells indicated gradual decline in static pressure, thereby, confirming non-sealing nature of the faults F3 and F6. However, based on pressure data the degree of communication of the reservoir under study with Well #20 appeared to be lower than that with Well #25. To sustain the required level of pressure support in the model, a Carter Tracy type analytical aquifer was introduced along the edges of the grid. Sensitivity runs to determine the predominant direction of aquifer support incorporating regional geology and detailed field data3, revealed that influx is from the E-NE direction and the support is probably being transmitted through the `leaky fault, F4. It is important to note that the neighbouring blocks have recorded water production and presence of a common aquifer to all these blocks cannot be ruled out. Modelling of water influx from other directions could not sustain pressure in the producers and led to premature breakthrough of water in some cases. With the above geological model, a reasonable match could be obtained for pressure and production histories. Summary of History Match Results The final accepted field-wide history match plots are shown in Figures 6(a) and 6(b). Except for GOR mismatch in Wells #6 and #25, which are situated at the edges of the channel and very close to faults, history match for the individual wells were satisfactory. The salient findings arising out of the history match are summarized below: 1. The E-W trending northerly fault (F3) adjacent to Well #20 is not entirely bounding/sealing and Well #20 is within the main reservoir through restricted communication through the leaky fault.

2. The NE-SW trending fault (F6) adjacent to Well #25 is partially communicating and hence Well #25 is in the main Northern Block reservoir. 3. The NW-SE bounding fault (F4) on the eastern side of the structure is also partially communicating and the aquifer support for the reservoir is primarily from this direction. 4. Wells #12, #13 and #26 belong to a separate fault block lying to the south of the main reservoir separated by fault, F2. This fact is corroborated by 3-D seismic data and entirely different pressure-production behaviour. Additionally, the following important points also emerged to aid in future field development plans (Fig 1(b) refers): a) Loc. H, re-proposed for drilling in the Northern Block on the basis of 3D seismic, should be withheld due to expected high water saturation as indicated by fluid saturation distribution at the end of the history. Similarly, Loc. I (proposed earlier on the basis of 2D model) should be withdrawn due to deteriorating sand quality as evident in Well #20 and anticipated high water saturation. b) Locs. J and K originally proposed to be drilled for water injection on the basis of the earlier geological model, are now redundant and hence, should be withdrawn. No benefits of water injection are envisaged through these wells due to restricted communication through the faults F3 and F4. c) Loc. L already shifted to the present revised position on the basis of 3D seismic, is an ideal candidate for water injection for pressure maintenance in the block. d) Loc. M (re-proposed in this study with a shift of 288 m from its original proposed location in 2D model) should be prioritized for drilling as there is need for a drainage point in the unswept area towards the western part of the structure. Performance Prediction The model calibrated as above was used to forecast the ultimate production from the reservoir and to identify the optimum development scenario. After carrying out a number of prediction cases with a variety of combinations, the following important results emerged: 1. Peripheral water flooding/injection through Wells #6, #25, Loc. L and #22 and production from the current producers including Loc. M is expected to yield maximum recovery (42% of OOIP for a 10 year prediction period and about 55% of OOIP as GUR) from the reservoir. Well #22 was identified to be a key injector for better areal sweep for maximizing recovery. The optimum water injection volume was found to be around 600 m3/day at the current pool offtake rate. This scheme also indicated the workover needs for gas-lift completion in the wells in the near future. 2. Delay in water injection will entail substantial loss in oil production apart from contributing to rise in GOR and pressure reduction in the reservoir. 3. Based on full simulation prediction run till the field oil and water cut-off limits, the gross ultimate recovery (GUR) is expected to be 45% for the base case and 55% of the OOIP for the best/optimum case. This indicates that an estimated

C. S. SINGH, B. BORGOHAIN, D.BORGOHAIN

SPE 64746

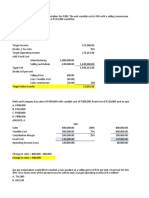

increase of 10% in GUR is possible through implementation of a suitable water-flooding programme. Conclusions The multidisciplinary approach has helped in establishing the nature of communication across the smaller faults identified in 3D seismic interpretation and in reviewing the hitherto planned development schemes of the reservoir bringing in necessary changes in the water injection and drilling programmes. The review has effectively saved drilling of at least three wells which were earlier proposed on the basis of 2D geological model. This study has also aided in proper planning for layouts and procurement of gas-lift and other production facilities for the future. Suitable candidates for injection were identified in the study and have been implemented in the reservoir. The benefits realized as a result of this are evident from Figures 7(a) and (b) where the decline in pressure and production has been arrested. The results of the study indicated an estimated 10% increase in GUR through implementation of suitable water flooding programme for a prediction period upto 2006-07. A financial analysis of alternative exploitation schemes for incremental revenue was carried out under two scenarios pessimistic and optimistic and the IRRs obtained were 20% and 68% respectively. Since the actual scenario will be between these two scenarios, the viability of the proposed water-flooding scheme was found to be financially attractive. Cross-discipline integration of data expertise and study has facilitated evaluation of detailed 3D Reservoir model of the Shalmari Northern Block. While 3D seismic have helped in accurate mapping of the minor faults and their distribution, it has also provided a better basis for assumptions about fault transmissibilities in the reservoir flow simulation. Development 3D seismic is key to better understanding of reservoir geometry and hence, a powerful tool for proper reservoir management. Integration of 3D seismic with fluid flow simulation, for the reservoir under study, has helped in resolving of more reliable reservoir geometry and formulating an optimum field development plan. Additionally, the recovery factor has been revised upwards to 55% as a result of this study. Acknowledgements The authors wish to express their thanks to the management of Oil India Limited for the permission to publish this paper in the proceedings of SPE International Oil & Gas Conference and Exhibition in China (IOGCEC'00) to be held in Beijing, China. Nomenclature bd = below datum (91.44 m asl) OOIP = Original Oil-In-Place GOR = Gas-Oil-Ratio GUR = Gross Ultimate Recovery IRR = Internal Rate of Return CET = Cement Evaluation Tool

References

1. Suarez, M, et al.: "Integration of Reservoir Data for Fault Identification: A Synergetic Approach", Paper SPE 23638 presented at the Second Latin American Petroleum Conference, II LAPEC, of SPE, Caracas, Venezuela, 8-11 March, 1992. 2. Benson, R. D. et al.: "Verification of Modern Three-Dimensional Seismic through Reservoir Simulation, Cedar Hill Field, San Juan Co., New Mexico, USA", Paper SPE 35627 presented at the Gas Technology Conference, Calgary, Alberta, Canada, 28 April - 1 May, 1996. 3. Grinde Per, et al.: "Low Cost Integrated Teamwork and Seismic Monitoring Improved Reservoir Management of Norwegian Gas Reservoir with Active Water Drive", Paper SPE 28876 presented at the European Petroleum Conference, London, UK, 25-27 October, 1994

SPE 64746

INTEGRATION OF 3D-SEISMIC WITH RESERVOIR SIMULATION FOR RESERVOIR CHARACTERIZATION AND ASSESSMENT OF ALTERNATIVE EXPLOITATION SCHEMES OF FIELD DEVELOPMENT - A CASE STUDY

C. S. SINGH, B. BORGOHAIN, D.BORGOHAIN

SPE 64746

SPE 64746

INTEGRATION OF 3D-SEISMIC WITH RESERVOIR SIMULATION FOR RESERVOIR CHARACTERIZATION AND ASSESSMENT OF ALTERNATIVE EXPLOITATION SCHEMES OF FIELD DEVELOPMENT - A CASE STUDY

C. S. SINGH, B. BORGOHAIN, D.BORGOHAIN

SPE 64746

SPE 64746

INTEGRATION OF 3D-SEISMIC WITH RESERVOIR SIMULATION FOR RESERVOIR CHARACTERIZATION AND ASSESSMENT OF ALTERNATIVE EXPLOITATION SCHEMES OF FIELD DEVELOPMENT - A CASE STUDY

10

C. S. SINGH, B. BORGOHAIN, D.BORGOHAIN

SPE 64746

Oil Rate

1200

Water Rate

GOR

600

1000

500

800

400

600

300

400

200

200

100

0 May-1989

0 May-1991 May-1993 May-1995 May-1997 May-1999

Time

Figure 7(a) : Production Performance Plot of Northern Block Reservoir

Cum_Inj ('000 m3)

600

SBHP (ksc)

400 350

500 300 400 250

Cum. Injection

300

200 150

200 100 100 50 0 May-1989 0 May-1991 May-1993 May-1995 Time May-1997 May-1999

Figure 7(b) : Effect of injection on Reservoir Pressure of Northern Block Reservoir

SBHP

GOR(sm3/m3)/Water Rate(m3/day)

Oil Rate (m3/day)

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Practical Approach To Defining Reservoir Heterogeneity - SPE-3608-PADocument8 pagesPractical Approach To Defining Reservoir Heterogeneity - SPE-3608-PAIsmail MohammedNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Data Analytics in Reservoir Engineering Technical Report Open Comment VersionDocument101 pagesData Analytics in Reservoir Engineering Technical Report Open Comment VersionIsmail MohammedNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Oil and Gas BookDocument74 pagesOil and Gas BookIsmail Mohammed100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Chapter 1 Overview of Oil and Gas IndustryDocument33 pagesChapter 1 Overview of Oil and Gas IndustryIsmail MohammedNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Using Vorticity To Quantify - Relative ImportanceDocument2 pagesUsing Vorticity To Quantify - Relative ImportanceIsmail MohammedNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Uisng Soap To Revive Mature Oil FieldDocument2 pagesUisng Soap To Revive Mature Oil FieldIsmail MohammedNo ratings yet

- Achieving Effective Well Stimulation in PDFDocument18 pagesAchieving Effective Well Stimulation in PDFIsmail MohammedNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Factors to Achieving Effective Well Stimulation in the Niger DeltaDocument18 pagesFactors to Achieving Effective Well Stimulation in the Niger DeltaIsmail MohammedNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- SHGAs Forecasting PDFDocument39 pagesSHGAs Forecasting PDFIsmail MohammedNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Waterflood in Basement Reservoirs - White TigerDocument14 pagesWaterflood in Basement Reservoirs - White TigerIsmail Mohammed100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- IPRES Force EOR Presentation 26th May 2014Document36 pagesIPRES Force EOR Presentation 26th May 2014Ismail MohammedNo ratings yet

- Measurement and Impact FactorsDocument17 pagesMeasurement and Impact FactorsIsmail MohammedNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Res Evaluation Drive MechDocument17 pagesRes Evaluation Drive MechArief HidayatNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Undersaturated Oil-Gas Simulation - Impes Type Solution: o Os GS So oDocument10 pagesUndersaturated Oil-Gas Simulation - Impes Type Solution: o Os GS So oIsmail MohammedNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- RR ContestDocument6 pagesRR ContestIsmail MohammedNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Well TestDocument18 pagesWell Testgo25101992No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Iptc 13156Document7 pagesIptc 13156Ismail MohammedNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Fundamentals of ElectricityDocument49 pagesFundamentals of ElectricityIsmail MohammedNo ratings yet

- Well ControlDocument43 pagesWell ControlIsmail Mohammed100% (1)

- Fundamentals of ElectricityDocument49 pagesFundamentals of ElectricityIsmail MohammedNo ratings yet

- Well TestingDocument5 pagesWell TestingIsmail MohammedNo ratings yet

- Coupled Mode TheoryDocument5 pagesCoupled Mode TheoryRahul RoyNo ratings yet

- SEEPZ Special Economic ZoneDocument2 pagesSEEPZ Special Economic ZonetarachandmaraNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- CVP Solution (Quiz)Document9 pagesCVP Solution (Quiz)Angela Miles DizonNo ratings yet

- NVH Analysis in AutomobilesDocument30 pagesNVH Analysis in AutomobilesTrishti RastogiNo ratings yet

- DSP Lab Record Convolution ExperimentsDocument25 pagesDSP Lab Record Convolution ExperimentsVishwanand ThombareNo ratings yet

- CLC Customer Info Update Form v3Document1 pageCLC Customer Info Update Form v3John Philip Repol LoberianoNo ratings yet

- Troubleshooting Edge Quality: Mild SteelDocument14 pagesTroubleshooting Edge Quality: Mild SteelAnonymous U6yVe8YYCNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- FEM IntroductionDocument47 pagesFEM IntroductionShanmuga RamananNo ratings yet

- Hillingdon Health Visiting ServiceDocument12 pagesHillingdon Health Visiting ServiceAnnikaNo ratings yet

- Kuliah Statistik Inferensial Ke4: Simple Linear RegressionDocument74 pagesKuliah Statistik Inferensial Ke4: Simple Linear Regressionvivian indrioktaNo ratings yet

- Presentation Pineda Research CenterDocument11 pagesPresentation Pineda Research CenterPinedaMongeNo ratings yet

- Hindustan Coca ColaDocument63 pagesHindustan Coca ColaAksMastNo ratings yet

- Whats The Average 100 M Time For An Olympics - Google SearchDocument1 pageWhats The Average 100 M Time For An Olympics - Google SearchMalaya KnightonNo ratings yet

- Maximizing Revenue of IT Project DevelopmentDocument4 pagesMaximizing Revenue of IT Project DevelopmentJulius Mark CerrudoNo ratings yet

- Anomaly Sell Out Remap December 2019 S SUMATRA & JAMBIDocument143 pagesAnomaly Sell Out Remap December 2019 S SUMATRA & JAMBITeteh Nha' DwieNo ratings yet

- StrutsDocument7 pagesStrutsBatrisyialya RusliNo ratings yet

- Funded African Tech Startups 2020Document13 pagesFunded African Tech Startups 2020LoNo ratings yet

- Machine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILUREDocument5 pagesMachine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILURE9965399367No ratings yet

- Eship 1Document18 pagesEship 1Yash SoniNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- (EMERSON) Loop CheckingDocument29 pages(EMERSON) Loop CheckingDavid Chagas80% (5)

- Siyaram S AR 18-19 With Notice CompressedDocument128 pagesSiyaram S AR 18-19 With Notice Compressedkhushboo rajputNo ratings yet

- AssDocument9 pagesAssJane SalvanNo ratings yet

- Exercise Manual For Course 973: Programming C# Extended Features: Hands-OnDocument122 pagesExercise Manual For Course 973: Programming C# Extended Features: Hands-OnAdrian GorganNo ratings yet

- PNW 0605Document12 pagesPNW 0605sunf496No ratings yet

- Presentation of The LordDocument1 pagePresentation of The LordSarah JonesNo ratings yet

- Keynes Presentation - FINALDocument62 pagesKeynes Presentation - FINALFaith LuberasNo ratings yet

- ETP Research Proposal Group7 NewDocument12 pagesETP Research Proposal Group7 NewlohNo ratings yet

- Norms and specifications for distribution transformer, DG set, street light poles, LED lights and high mast lightDocument4 pagesNorms and specifications for distribution transformer, DG set, street light poles, LED lights and high mast lightKumar AvinashNo ratings yet

- Tambunting Pawnshop Vs CIR Re VATDocument7 pagesTambunting Pawnshop Vs CIR Re VATMark Lester Lee AureNo ratings yet

- The Power of Flexibility: - B&P Pusher CentrifugesDocument9 pagesThe Power of Flexibility: - B&P Pusher CentrifugesberkayNo ratings yet

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (33)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (5)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)