Professional Documents

Culture Documents

2.methods 2.1 Assays and Product Quantitation

Uploaded by

Nurrahmi Putri Anggraeni LaguligaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.methods 2.1 Assays and Product Quantitation

Uploaded by

Nurrahmi Putri Anggraeni LaguligaCopyright:

Available Formats

Scope of this chapter with the proviso that methods adopted in the early stages of development should ideally

be robust and adaptable to manufacturing scales. Our chapter mainly focuses on pilot-scale fermentation and downstream process development. In its simplest form, scale-up can be achieved by merely increasing the scale of compound production and subsequent purification. There are times when this approach is the most practical route to getting a compound quickly. There is an inevitable risk, however, that any increase in scale, without sufficient process development, will not be successful. An alternative and generally preferable approach is to increase the concentration of the target compound relative to unwanted compounds (impurities) in the material to be processed. This in turn can significantly improve the ease of downstream purification and ultimately result in enhanced yields. The latter course is usually undertaken with microbial product in the form of an integrated program of process development to improve both the fermentation and DSP processes. Cost and process efficiency become more important as the scale increases, and there will always be some scope for improving the purification method itself. The initial compound isolation will, in most cases, have been bioassay guided, with speed of identification the major objective, and is therefore highly unlikely to have been efficient in terms of either compound production levels or purification step yields. As the scale of operation increases, for fermentation products at least, so does the proportion of the overall scale-up process taken up by DSP activities. The importance of the relationship between the production and the DSP of the target compound, and the potential for the latter activity by improving the former, cannot be stressed too highly. 2.methods 2.1 assays and product quantitation The importance of reliable, quantitative assay as tools for directing the development of scale-up process, by measuring target compound concentration in fermentation and in concentrated extracts or eluates during various stages of purifications, should not be understated. They allow the accurate determination of step yields, thus providing a means of measuring and improving efficiencies. Appropriate assays are usually chromatographic and should be capable of high throughputs (typically 10-100 of samples per day). Reversed-phase highperformance liquid chromatography (HPLC) method with UV/ visible or occasionally mass spectrometric detection are used most frequently. Evaporative light scattering detector (ELSDs) allow the detection of all compound in a sample, including those with no UV absorbance, and add an extra dimension when assessing purity. These chromatographic methods are preferred to assays based on biological activity, through which many natural products are first detected and discovered , as such assays measure a total response to all of the active compounds present in a sample. Given that the majority of secondary metabolites are produced mixtures of

closely related compounds with varying degrees of activity, biological activity assays will deliver a composite response that could be misleading in respect of a particular compound. There is also scope for synergistic or antagonistic effects between components of a mixture in such biological assays. Compound-specific chemical assays are thus useful for separately quantifying different compounds within a series. There is a danger, however, in relying too much on an assay that is highly product specific. For fermentation development, at least, there is merit in running in parallel a product-specific HPLC assay with a steep gradient elution method that allows gross changes in the overall metabolite profile to be monitored. It is relatively common in process development to implement a desirable improvement in process characteristic (e.g., higher titer, better medium composition, to name a few) that also produces some unwanted impact on the process (e.g., a change in the profile of minor components, morphological change in the producing organism, and so on ). It is essential, therefore, that the analytical techniques applied be broad enough to pick up both desirable and undesirable change during the development phase. 2.2 fermentation development The general principles for process development were outlined in the first edition of this volume (1). Hence, we do not reiterate there principles here. Instead, we update and expand upon these initial comments and illustrate with recent references where appropriate. For instance, we cite a case study that exemplifies the more standard approaches to process development, and in addition, illustrates the value of having a taxonomically well-characterized culture collection, which can be explored not only for new secondary metabolites but also for other interesting biological properties such as organisms that may produce related compounds or possess useful enzymic activities that can be utilized to modify certain molecules. We also provide a brief basic introduction to the increasing application of recommendation techniques to process development. 2.2.1 reproducibility and inoculums The first step in process optimization typically involves some investigation into medium composition. Yields of will-tipe organisms are often around 1 mg/L or less, and medium optimization can be an effective means to rapidly improve yields to greater than 100 mg/L. These early stage optimization studies are typically carried out in shake flasks and tend to be based around statistical experimental methods such as Placked Burman, surface response, multivariate, and principal component analysis. Process reproducibility is a necessary prerequisite before process development and optimization can begin, or more properly it might be considered the first step, as it provides a reliable baseline against which to gage future improvements. This is particularly important when using statistical

experimental design techniques, where process variability may be misinterpreted as a statistically significant improvement. It is uncommon for organisms producing natural products to display a certain degree of physiological and metabolic instability which, in practice, may manifest itself in a lack of reproducibility-for instance, in activity in a downstream bioassay. Precious resources and much time cab be tied up both in fermentation and chemical isolation by trying to track down these lost or variable activities from wild-type isolates. It is therefore desirable in the first instance that the initial activity be reproduced in the same way as the original fermentation. A confirmed activity from such a refermentation will provide the scale-up scientist with the confidence to take the hit further. The first scale-up fermentation should preferably be performed in a system as close as possible to the fermentation system in which the hit was first detectedusing multiple units if necessary-to avoid unnecessary complications with scale-up issues. For example, if the initial hit was first detected in an extract obtained from 50 mL shake flask fermentation, then multiple shake flasks could be employed to produce volume up to 5-10 L. if the referment is successful, it adds to the growing confidence in the activity and increases the likelihood that the activity will scale-up into stirred fermenters. If the referment is unsuccessful, then this is likely indicates some issue with poor reproducibility rather than a scale-up issue. Alternatively, if the equipment is available, bench top fermenters may be used-if this stategy is adopted it is desirable that a confirmatory

You might also like

- Development and Validation of Dissolution ProceduresDocument7 pagesDevelopment and Validation of Dissolution ProceduresVenkatesh KoppuNo ratings yet

- Auto-Induction Screening Protocol For Ranking Clonal Libraries of Pichia Pastoris Mut StrainsDocument14 pagesAuto-Induction Screening Protocol For Ranking Clonal Libraries of Pichia Pastoris Mut StrainsAvijeet SinghNo ratings yet

- Fermentation Process KineticsDocument7 pagesFermentation Process KineticsDillip_subuNo ratings yet

- A Comprehensive Book on Experimental PharmaceuticsFrom EverandA Comprehensive Book on Experimental PharmaceuticsRating: 5 out of 5 stars5/5 (1)

- USP New Monograph Dissolution AutomationDocument28 pagesUSP New Monograph Dissolution AutomationSochib Ibe FiniarelNo ratings yet

- Cargill - Corn To Polylactic AcidDocument6 pagesCargill - Corn To Polylactic AcidI. Murali KrishnaNo ratings yet

- GadenDocument7 pagesGadenBenjamin HonorioNo ratings yet

- Why The Swab Matters in Cleaning ValidationDocument3 pagesWhy The Swab Matters in Cleaning ValidationYehuda Rahmanu PuteraNo ratings yet

- Simutis 2015Document18 pagesSimutis 201515041168No ratings yet

- Rapid Sterility Testing Using PallchekDocument29 pagesRapid Sterility Testing Using Pallchekvkumar6883No ratings yet

- DisolucionMaraton5 11181Document20 pagesDisolucionMaraton5 11181Alfred FonsecaNo ratings yet

- Solvent Extraction of PullulanDocument7 pagesSolvent Extraction of PullulananirbanNo ratings yet

- 17-31-ET-V1-S1 l-31 Theory Biological Assay of Fermentation ProductsDocument6 pages17-31-ET-V1-S1 l-31 Theory Biological Assay of Fermentation Productsuzma begum100% (1)

- Preformulation Studies WhoDocument20 pagesPreformulation Studies WhoparinafernsNo ratings yet

- Protein Purification HandbookDocument98 pagesProtein Purification Handbookkongster1No ratings yet

- Comparative Disso ProfileDocument5 pagesComparative Disso Profileabhijit_gothoskar6039No ratings yet

- Scaled Up Process DirectlyDocument8 pagesScaled Up Process DirectlyAnonymous 1XHScfCINo ratings yet

- Engineered Enzymes For Chemical ProductionDocument7 pagesEngineered Enzymes For Chemical ProductionAyyanar PeriasamyNo ratings yet

- A Review of Advanced Small-Scale Parallel Bioreactor TechnologyDocument13 pagesA Review of Advanced Small-Scale Parallel Bioreactor TechnologyHwee MuzyNo ratings yet

- Peer Reviewed: Microbiology: Approaching Microbiological Method Validation - IVTDocument18 pagesPeer Reviewed: Microbiology: Approaching Microbiological Method Validation - IVTPrashanth KumarNo ratings yet

- Making The Most of Affinity Tags: David S. WaughDocument5 pagesMaking The Most of Affinity Tags: David S. WaughmudapakajNo ratings yet

- EB Pesticide Residue Analysis LCGC ENDocument38 pagesEB Pesticide Residue Analysis LCGC ENFaiza BouchalaNo ratings yet

- Internasional RMBDocument5 pagesInternasional RMBkmx5h5ktwmNo ratings yet

- Biomolecules: Refolding Techniques For Recovering Biologically Active Recombinant Proteins From Inclusion BodiesDocument17 pagesBiomolecules: Refolding Techniques For Recovering Biologically Active Recombinant Proteins From Inclusion BodiesJaya SaputraNo ratings yet

- Novel Approach For Scale-Up of Fermentation Process PDFDocument8 pagesNovel Approach For Scale-Up of Fermentation Process PDFKUNALNo ratings yet

- BFS-FRIEDMAN - Contamination Case Studies Paper PDFDocument9 pagesBFS-FRIEDMAN - Contamination Case Studies Paper PDFipatoffNo ratings yet

- Literature Review - The Role of Chromatography in The Characterization and Analysis of Protein Therapeutic Drugs by C. David CarrDocument4 pagesLiterature Review - The Role of Chromatography in The Characterization and Analysis of Protein Therapeutic Drugs by C. David CarrRos Vincent AlvarezNo ratings yet

- Poster EstebanDocument3 pagesPoster EstebanaealarconoNo ratings yet

- Selection of DissolutionDocument5 pagesSelection of DissolutionGirishNo ratings yet

- Stability-Indicating Assays: LC TroubleshootingDocument3 pagesStability-Indicating Assays: LC TroubleshootingVivek SagarNo ratings yet

- Dorado Assingment #1Document2 pagesDorado Assingment #1MARISSE LYN DORADONo ratings yet

- ELMA KitDocument24 pagesELMA KitVrunda PatelNo ratings yet

- Biotechnology Progress - 2008 - Mandenius - Bioprocess Optimization Using Design of Experiments MethodologyDocument13 pagesBiotechnology Progress - 2008 - Mandenius - Bioprocess Optimization Using Design of Experiments MethodologyZahi DrawNo ratings yet

- Principles of Performance Testing of Laundry DetergentsDocument9 pagesPrinciples of Performance Testing of Laundry Detergents魏达铭No ratings yet

- LABORATORY MANUAL FOR A MINI PROJECT: MSCB 1113 BIOCHEMISTRY & MICROBIAL PHYSIOLOGYFrom EverandLABORATORY MANUAL FOR A MINI PROJECT: MSCB 1113 BIOCHEMISTRY & MICROBIAL PHYSIOLOGYNo ratings yet

- Process Development-Chapter-12Document20 pagesProcess Development-Chapter-12shalom.chen0602No ratings yet

- Approaching Microbiological Method Validation-1Document19 pagesApproaching Microbiological Method Validation-1Apar DholakiaNo ratings yet

- Quality of Test ResultsDocument12 pagesQuality of Test Resultsdharmendra gaurNo ratings yet

- Scale-Up of Protein Purification Downstream Processing Issues PDFDocument13 pagesScale-Up of Protein Purification Downstream Processing Issues PDFCapNo ratings yet

- CHAP1Document10 pagesCHAP1Andre HigginsNo ratings yet

- Summative Mass Closure: Laboratory Analytical Procedure (LAP) Review and IntegrationDocument14 pagesSummative Mass Closure: Laboratory Analytical Procedure (LAP) Review and IntegrationanurdiaNo ratings yet

- Et Iso 21187 2012Document18 pagesEt Iso 21187 2012leovenceNo ratings yet

- Scale Up FermentersDocument11 pagesScale Up FermentersLouella100% (1)

- Á1228Ñ Depyrogenation: First Supplement To USP 39-NF 34Document5 pagesÁ1228Ñ Depyrogenation: First Supplement To USP 39-NF 34deepanmb007No ratings yet

- In Process Quality Control Pharma PathwayDocument6 pagesIn Process Quality Control Pharma PathwayDeepakNo ratings yet

- Aseptic ProcessingDocument13 pagesAseptic ProcessingAshok Kumar100% (1)

- Activated Sludge Process Control and Troubleshooting Chart PDFDocument55 pagesActivated Sludge Process Control and Troubleshooting Chart PDFcassindrome100% (2)

- Best Practices For Cleaning Validation Swab Recovery StudiesDocument7 pagesBest Practices For Cleaning Validation Swab Recovery StudiesmujtabaNo ratings yet

- Raw Materials Selection and Medium Development For Industrial Fermentation ProcessesDocument10 pagesRaw Materials Selection and Medium Development For Industrial Fermentation ProcessesIsaacNo ratings yet

- Quantitative Hands-On Gas Chromatography Undergraduate Analytical Laboratory ExerciseDocument6 pagesQuantitative Hands-On Gas Chromatography Undergraduate Analytical Laboratory Exerciseho phong voNo ratings yet

- Enrichment Activity No. 1 (Unlayao)Document11 pagesEnrichment Activity No. 1 (Unlayao)Diana MaeNo ratings yet

- Wheat From Chaff Meta-Analysis As Quantitative Literature ReviewDocument7 pagesWheat From Chaff Meta-Analysis As Quantitative Literature ReviewaflspwxdfNo ratings yet

- Akash PDFDocument22 pagesAkash PDFry886450No ratings yet

- Best Practices For Effectively Implementing An ATP Sanitation Verification ProgramDocument16 pagesBest Practices For Effectively Implementing An ATP Sanitation Verification Programasbar salesNo ratings yet

- Essential Chemistry for Formulators of Semisolid and Liquid DosagesFrom EverandEssential Chemistry for Formulators of Semisolid and Liquid DosagesRating: 5 out of 5 stars5/5 (2)

- Physical-Chemical Properties of Foods: New Tools for PredictionFrom EverandPhysical-Chemical Properties of Foods: New Tools for PredictionNo ratings yet

- Handbook of Microbiological Criteria for FoodsFrom EverandHandbook of Microbiological Criteria for FoodsNo ratings yet

- Ultra-High Performance Liquid Chromatography and Its ApplicationsFrom EverandUltra-High Performance Liquid Chromatography and Its ApplicationsNo ratings yet

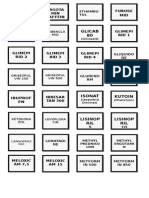

- Andala N 1 BLN Andala N 3 BLN Aquade S Antrai NDocument1 pageAndala N 1 BLN Andala N 3 BLN Aquade S Antrai NNurrahmi Putri Anggraeni LaguligaNo ratings yet

- Label Generik2Document1 pageLabel Generik2Nurrahmi Putri Anggraeni LaguligaNo ratings yet

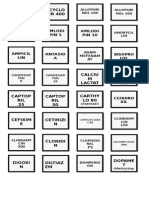

- Acyclo VIR 200 Acyclo VIR 400: Ambrox OL Amlodi PIN 10 Amlodi Pin 5Document1 pageAcyclo VIR 200 Acyclo VIR 400: Ambrox OL Amlodi PIN 10 Amlodi Pin 5Nurrahmi Putri Anggraeni LaguligaNo ratings yet

- Actos Amaryl 1 Amaryl 2 Amaryl 3: Diamicr On MRDocument1 pageActos Amaryl 1 Amaryl 2 Amaryl 3: Diamicr On MRNurrahmi Putri Anggraeni LaguligaNo ratings yet

- Aldisa SR Asvex Epexol Fartoli N: Flutamo L PlusDocument1 pageAldisa SR Asvex Epexol Fartoli N: Flutamo L PlusNurrahmi Putri Anggraeni LaguligaNo ratings yet

- Label AntibiotikDocument1 pageLabel AntibiotikNurrahmi Putri Anggraeni LaguligaNo ratings yet

- Alloris Cerini Cortid EX: Dextami NEDocument1 pageAlloris Cerini Cortid EX: Dextami NENurrahmi Putri Anggraeni LaguligaNo ratings yet

- Pelayanan ApotikDocument14 pagesPelayanan Apotikg_beewNo ratings yet

- Msds Acid WashDocument5 pagesMsds Acid WashNurrahmi Putri Anggraeni LaguligaNo ratings yet

- Action Ophthalmic: Decreases IOP by Constricting Pupil and Stimulating Ciliary Muscles To OpenDocument4 pagesAction Ophthalmic: Decreases IOP by Constricting Pupil and Stimulating Ciliary Muscles To OpenNurrahmi Putri Anggraeni LaguligaNo ratings yet

- 26 09 2021 SR Super60 & All Jee Adv2018 P1 GTA 29 Question PaperDocument19 pages26 09 2021 SR Super60 & All Jee Adv2018 P1 GTA 29 Question PaperVineel KrishnaNo ratings yet

- GEMSS-M-35 Rev 01 Painting & Coating Protection SystemDocument11 pagesGEMSS-M-35 Rev 01 Painting & Coating Protection SystemAzhar AliNo ratings yet

- Arcelor-Mittal Granite PVDFDocument1 pageArcelor-Mittal Granite PVDFZlatko KrsicNo ratings yet

- Hot Weather ConcretingDocument21 pagesHot Weather ConcretingDr Yousif HummaidaNo ratings yet

- Water Treatment: SolutionsDocument16 pagesWater Treatment: SolutionsrobinNo ratings yet

- Rumus Mifflin: Pengurangan KaloriDocument8 pagesRumus Mifflin: Pengurangan KaloriWindy oktriNo ratings yet

- Tutorial Questions 1111Document6 pagesTutorial Questions 1111Fahmy Muhd100% (1)

- Orion Cadmium Electrode - Bergman-NetDocument51 pagesOrion Cadmium Electrode - Bergman-NetHeberti FreireNo ratings yet

- Know Your Cooling SystemDocument103 pagesKnow Your Cooling SystemgustavoNo ratings yet

- Art 2Document15 pagesArt 2Solams CastilloNo ratings yet

- Seacure Gen W DT Dynagas PDocument46 pagesSeacure Gen W DT Dynagas PAlex KuvoricNo ratings yet

- Unstable Formation and Sand ControlDocument17 pagesUnstable Formation and Sand ControlHafiz AsyrafNo ratings yet

- IB Environmental Systems & Societies (ESS) SL: 1.5 Humans & PollutionDocument9 pagesIB Environmental Systems & Societies (ESS) SL: 1.5 Humans & PollutionAbed AlhamadehNo ratings yet

- Effect of HEDP On Copper Electroplating From Noncyanide Alkaline BathsDocument8 pagesEffect of HEDP On Copper Electroplating From Noncyanide Alkaline BathsDerdo ZulmuNo ratings yet

- Blonde Idol Color 14 Shade Chart Mini GLDocument2 pagesBlonde Idol Color 14 Shade Chart Mini GLlyly23748No ratings yet

- Chlorination of MethaneDocument11 pagesChlorination of MethaneEngr Abuzar KhanNo ratings yet

- TDS - Pipeclad HOT 120Document2 pagesTDS - Pipeclad HOT 120Long ChenNo ratings yet

- Energy Analysis of Pipes and FittingsDocument4 pagesEnergy Analysis of Pipes and FittingsEymann JalaNo ratings yet

- Journal Summary Phy592Document3 pagesJournal Summary Phy592Fatin Nur Syahirah AzharNo ratings yet

- Properties of Fatty AcidsDocument20 pagesProperties of Fatty AcidsMah NoorNo ratings yet

- Astm A510-20Document7 pagesAstm A510-20Ryan Zhang100% (2)

- Heat Transfer in Packed BedDocument12 pagesHeat Transfer in Packed BedKusmakarNo ratings yet

- Finite Element Technique: 7.1 Introduction and ScopeDocument34 pagesFinite Element Technique: 7.1 Introduction and ScopeSharon ShineNo ratings yet

- CarcinogensDocument85 pagesCarcinogensNidyaletchmy ReddyNo ratings yet

- 6 Mechanical Behaviour of MaterialsDocument44 pages6 Mechanical Behaviour of MaterialsArjun MahendraNo ratings yet

- 3D Effects of Taylor FlowDocument8 pages3D Effects of Taylor FlowShreyank Deepali GoelNo ratings yet

- Welding Fabrication Standards PDFDocument95 pagesWelding Fabrication Standards PDFYaronNo ratings yet

- What Is FrictionDocument3 pagesWhat Is FrictionJOLLIBEL LLANERANo ratings yet

- What Is Lithium CarbonateDocument8 pagesWhat Is Lithium CarbonateNurAneesaNo ratings yet

- Painting Inspection - SlidesDocument66 pagesPainting Inspection - SlidesVinoth Kumar SubramaniNo ratings yet