Professional Documents

Culture Documents

DANotes - Threaded Fasteners - Fluid Pressurised Joints

Uploaded by

shivuhcOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DANotes - Threaded Fasteners - Fluid Pressurised Joints

Uploaded by

shivuhcCopyright:

Available Formats

11/21/11 DANotes: Threaded fasteners: Fluid pressurised joints

1/4 school.mech.uwa.edu.au/dwright/DANotes/threads/joints/joints.html

Fluid pressurised joints

A common application of bolted joints is for detachable

connections which contain pressurised fluid. These may be

rendered leakproof either by O-rings or by gaskets. An O-ring

is an endless ring of circular cross- section, which is relatively

compliant and usually elastomeric. It is lightly nipped when

assembled, subsequent application of fluid pressure extrudes the ring to plug all

potential leakage paths. Such joints are called self- energising as they do not rely on

preload for their effectiveness.

This example demonstrates the static analsis of a self-energising joint.

O-rings are suitable where the environment is non-aggresssive, temperatures are

sensibly ambient, and relatively high manufacturing / assembly costs can be tolerated -

otherwise gaskets are used. Pipes are frequently connected by welding similar flanges to

each and bolting the flanges together with a gasket and multiple bolts as shown below.

Gaskets are common also in heat exchanger tube plates and the cylinder heads of i/c

engines, however we shall explain gaskets in the context of flanged pipe joints.

Dimensions of flanges suitable for various combinations of pipe size, fluid pressure and

temperature are standardised ( AS 2129 ).

Gasket materials range from cork to copper - each material best suiting a particular

combination of fluid corrosiveness, pressure, temperature, leakage implications, cost,

and so on. Most gaskets are non-metallic, highly compliant compared to other joint

components, and non-linear. Their low stiffness means that other joint components may

usually be neglected when figuring joint overall stiffness : 1/k

j

= 1/k

gasket

+ 1/k

other

large

- that is the joint overall stiffness is essentially the same as the gasket stiffness,

which has far-reaching implications in fatigue since it may not be possible to ensure that

k

b

<< k

j

as desired for low bolt load amplitude.

Soft gaskets usually extend over the whole flange ( full face ), whereas gaskets made of

stiffer materials are narrow and extend out only to the bolt holes. It is assumed that

11/21/11 DANotes: Threaded fasteners: Fluid pressurised joints

2/4 school.mech.uwa.edu.au/dwright/DANotes/threads/joints/joints.html

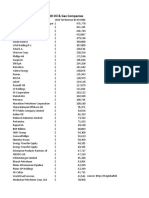

TABLE 3. Gasket material properties

(from AS 1210) thcknss m

gasket material mm MPa -

usbesLos wILI bInder 1 q .

dILLo. 1. z z.;

dILLo. 11 z.o

vegeLubIe IIbre ;. 1.;

spIruI wound, usbesLos IIIIed 6q .o

muILIpIe boILs ure Iouded equuIIy, und LIuL LIe gake e - Ie. LIe uveruge conLucL

pressure beLween guskeL und IIunge - Is unIIorm over LIe guskeL ureu A

g

. CIeurIy LIe

guskeL sLress musL be IIgIer LIun IIuId pressure II Ieukuge Is Lo be uvoIded, und, Ior u

gIven guskeL sLress, u ruIsed Iuce IIunge wILI u nurrow guskeL wIII requIre Iess preIoud

und Ience Iess IIunge sLrengLI LIun u IuII Iuce guskeL. So LIe Lendency Is Ior IIgI

pressure guskeLs Lo be nurrow.

n servIce, LIe pIpe ucLs us u cIosed

cyIInder wILI uxIuI Ioud P In LIe wuII due

Lo IIuId pressure ucLIng over LIe InLernuI

ureu. TIIs IoudIng - u preIoud due Lo

InILIuI LIgILenIng, LogeLIer wILI un

exLernuI servIce Ioud - Is LypIcuI oI joInLs

In generuI.

Codes LrudILIonuIIy cIussIIy guskeL muLerIuIs by Lwo properLy vuIues - LIe 'y' IucLor und

LIe 'm' IucLor, eg. TubIe . TIese ure necessury mInImum vuIues Ior LIe uvoIdunce oI

Ieuks :

- LIe InILIuI guskeL sLress ( Ie. preIouded prIor Lo pressurIsuLIon ), und

m - LIe ruLIo oI guskeL sLress Lo IIuId pressure ( uILer pressurIsuLIon )

TIeses IImILs ure skeLcIed on LIe joInL cIurucLerIsLIc, In wIIcI

LIe exLernuI uxIuI Ioud P equuIs LIe IIuId pressure p LImes LIe

InLernuI Lrunsverse ureu A

I

. TIe InILIuI guskeL sLress Induced

by LIe LIgILenIng Ioud

I

musL be Iess LIun LIe guskeL

crusIIng sLress p

crusI

und greuLer LIun LIe 'y' upproprIuLe Lo

LIe guskeL muLerIuI. nILIuI IoudIng Is LIe mosL severe sInce LIe joInL Ioud decreuses

LIereuILer us LIe exLernuI Ioud Is uppIIed - buL LIe exLernuI Ioud sIouId noL be so Iurge

LIuL LIe guskeL sLress becomes Iess LIun 'm' LImes LIe IIuId pressure. uIIure oI u joInL -

us opposed Lo Ieukuge - wIII be mosL IIkeIy uL InILIuI LIgILenIng, so joInL desIgn ( seIecLIon

oI boILIng, IIunge LIIckness eLc.) Is bused upon LIuL sLuLe.

TIere Ius been u deuI oI debuLe on LIe suggesLed vuIues oI 'm' und 'y' wIIcI uppeur In

LIe Pressure VesseI Codes. WIIIe LIe vuIues Iuve been Iound suLIsIucLory buses Ior suIe

joInL desIgn, LIey ure buL poor IndIcuLors oI IeukprooI operuLIon. TIe Pressure VesseI

ReseurcI CommILLee ( PVRC ) oI LIe WeIdIng ReseurcI CouncII Ius InsLILuLed

compreIensIve new LesLs Lo cIurIIy LIe beIuvIour oI guskeLs, wILI resuILs sIown on LIe

IeIL beIow. nILIuI LIgILenIng

proceeds uIong a-b; us LIe

exLernuI Ioud Is uppIIed LIe

guskeL unIouds uIong b-c.

urLIer cycIIng oI LIe

exLernuI Ioud Ieuds Lo LIe

guskeL IoudIngJ unIoudIng

uIong LIe sume b-c-b

LrujecLory. I LIe boILs ure IurLIer LIgILened LIen LIe guskeL ( un )Iouds uIong LIe d-e-d

11/21/11 DANotes: Threaded fasteners: Fluid pressurised joints

3/4 school.mech.uwa.edu.au/dwright/DANotes/threads/joints/joints.html

TABLE 4. Gake maeial iffnee

width thick stiffness

gasket material mm -ness MPa/mm

compressed asbestos 12 3 330-950

ditto. 24 1.6 600-3260

compressed aramid fibre

(asbestos substitute) 12 1.6 220-490

spiral wound asbestos filled 18 4.6 270-1800

non-asbestos laminated head gasket 1.1 1140-2630

TABLE 5. Join faco

tpe of joint C

soft gasket held by studs 1.00

soft gasket with through fasteners 0.75

asbestos gasket 0.60

soft copper & long through bolts 0.50

metal-to-metal with long bolts 0.00

locus.

Gaskets cannot be absolutely leak free when containing gas; locii of constant leakage

rates are shown superimposed upon the characteristic. Behaviour may be described

most conveniently by graphs similar to the one on the right, in which a leakage

parameter replaces deflection. A material can be characterised by three constant

properties - the slope and intercept of the initial loading regression line ( log-log ),

together with the point through which all subsequent linear ( un )loading trajectories

pass. These results have yet to be incorporated into Codes.

It is clear from the PVRC

findings that non-metallic

gaskets do not behave

elastically. Table 4 gives the

range of stiffnesses that may be

experienced - stiffness being

expressed as gasket stress (

force/A

g

) per unit deflection, ie.

modulus/ thickness. Calculation

of load sharing from ( 3a) is thus fraught with uncertainty if the gasket stiffness is not

known accurately, however load sharing may be characterised by :

( 3b) F

b

= F

i

+ C P ; F

j

= F

i

- ( 1 - C ) P

in which the join facor C is a typical measure of the fraction of the

total external load P seen by the bolts. Although comparison with ( 3a) indicates that

C = k

e

/k

j

= k

b

/( k

b

+ k

j

) 1, the joint factor should be regarded more as an overall

approximate figure of merit, which incorporates all vagaries of behaviour and which is

experimentally determined in its own right, rather than as a ratio of elastic stiffnesses.

Experience suggests the values of Table 5.

'Flange rotation' refers to the initially disc-

shaped flange assuming a flat conical form

under fluid pressure loading, and can be

significant when a narrow gasket is used. The

cause of rotation may be appreciated from the

sketches below which show rotation grossly

exaggerated. At ( a) is shown part of the flange with the bolt load F

b

equilibrating the

external load P and the joint load F

j

, as above. Accordingly F

b

is split into its

superimposed components ( b), which are shown separately at ( c) and ( d).

11/21/11 DANotes: Threaded fasteners: Fluid pressurised joints

4/4 school.mech.uwa.edu.au/dwright/DANotes/threads/joints/joints.html

It is clear that both the P- and F

j

-couples tend to rotate the flange as sketched. This

rotation is exacerbated by the fluid pressure p tending to expand the pipe connected to

the flange, however the flange is relatively rigid radially and so prevents pipe wall local

expansion as suggested by ( e).

Free bodies of the separate pipe and flange appear at ( f) and ( g). The interface remains

essentially rigid whilst rotation occurs - that is the deformed pipe and deformed flange

remain perpendicular to one another. This requires the action/ reaction sketched - the

radial force F

i

and the bending moment M

i

at the interface. Clearly M

i

contributes to

the rotation of the flange ( g).

It is common practice to allow for rotation empirically by considering an effective gasket

width somewhat less than the actual width, as suggested by ( h) - further details appear

in AS1210.

Operation at high temperatures leads to further difficulties with creep, ratcheting and so

on.

Notes contents chapter inde previous top of page net

Copright 1999-2005 Douglas Wright

last updated Ma 2005

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Essential Auxiliaries of Gas TurbineDocument5 pagesEssential Auxiliaries of Gas TurbineshivuhcNo ratings yet

- InterfaceDemo Csproj FileListAbsoluteDocument1 pageInterfaceDemo Csproj FileListAbsoluteshivuhcNo ratings yet

- T. Srinivas 115Document5 pagesT. Srinivas 115shivuhcNo ratings yet

- Fin SumyieyeDocument18 pagesFin SumyieyeshivuhcNo ratings yet

- Interface2 Csproj FileListAbsoluteDocument1 pageInterface2 Csproj FileListAbsoluteshivuhcNo ratings yet

- Anna University Report FormatDocument7 pagesAnna University Report Formatdilip_66690% (10)

- GEHC Offer Holiday Schedule 2012 2015Document1 pageGEHC Offer Holiday Schedule 2012 2015shivuhcNo ratings yet

- Eq21 121003125101 Phapapp015567Document26 pagesEq21 121003125101 Phapapp015567shivuhcNo ratings yet

- B1 57008275Document2 pagesB1 57008275shivuhcNo ratings yet

- Anirban Saha 16242334Document30 pagesAnirban Saha 16242334shivuhcNo ratings yet

- Isa Maharashtra Inteq Magazine July2012Document21 pagesIsa Maharashtra Inteq Magazine July2012ganeshanNo ratings yet

- Generics Csproj fileListAbsoluteDocument1 pageGenerics Csproj fileListAbsoluteshivuhcNo ratings yet

- List of Engineering Companies Aug 2012Document6 pagesList of Engineering Companies Aug 2012Muhammad ZubairNo ratings yet

- Isa Maharashtra Inteq Magazine July2012Document21 pagesIsa Maharashtra Inteq Magazine July2012ganeshanNo ratings yet

- SQL Tables and DataDocument4 pagesSQL Tables and DatashivuhcNo ratings yet

- ADO .NET AssignmentsDocument2 pagesADO .NET AssignmentsshivuhcNo ratings yet

- Prog7 Arrays - csproj.fileListAbsoluteDocument1 pageProg7 Arrays - csproj.fileListAbsoluteshivuhcNo ratings yet

- Prog1 Csproj FileListAbsoluteDocument1 pageProg1 Csproj FileListAbsoluteshivuhcNo ratings yet

- Prog5 Operators - csproj.fileListAbsoluteDocument1 pageProg5 Operators - csproj.fileListAbsoluteshivuhcNo ratings yet

- Prog6 Looping - csproj.fileListAbsoluteDocument1 pageProg6 Looping - csproj.fileListAbsoluteshivuhcNo ratings yet

- Prog8 OOPS - csproj.fileListAbsoluteDocument1 pageProg8 OOPS - csproj.fileListAbsoluteshivuhcNo ratings yet

- Prog9 Oops - csproj.fileListAbsoluteDocument1 pageProg9 Oops - csproj.fileListAbsoluteshivuhcNo ratings yet

- Prog8 OOPS - csproj.fileListAbsoluteDocument1 pageProg8 OOPS - csproj.fileListAbsoluteshivuhcNo ratings yet

- Prog2 - Variables - csproj.fileListAbsoluteDocument1 pageProg2 - Variables - csproj.fileListAbsoluteshivuhcNo ratings yet

- Development GE Quite Combustion TechnologyDocument14 pagesDevelopment GE Quite Combustion Technologyuoc_vong58No ratings yet

- LicenseDocument8 pagesLicensejuanjjccNo ratings yet

- How ASP - Net Web Pages Are Processed On The Web ServerDocument5 pagesHow ASP - Net Web Pages Are Processed On The Web ServershivuhcNo ratings yet

- Enterprise LibraryDocument10 pagesEnterprise LibraryshivuhcNo ratings yet

- Forms Authentication and AuthorizationDocument9 pagesForms Authentication and AuthorizationshivuhcNo ratings yet

- Variables and Data Types GuideDocument9 pagesVariables and Data Types GuideshivuhcNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Champion 700 Series Motor Grader Series I Operators Manual Revision 1 8-24-1977 PDFDocument54 pagesChampion 700 Series Motor Grader Series I Operators Manual Revision 1 8-24-1977 PDFjulianmata77% (13)

- Schools Division of Pasay City outlines 5S workplace organizationDocument9 pagesSchools Division of Pasay City outlines 5S workplace organizationJhaexelle allenah AlfonsoNo ratings yet

- Side Wall SprinklerDocument6 pagesSide Wall SprinklerLasandu WanniarachchiNo ratings yet

- 64-2103 Tweco Pistolas WeldskillDocument6 pages64-2103 Tweco Pistolas WeldskillcarlosNo ratings yet

- Lancashire BoilerDocument28 pagesLancashire BoilerDr. BIBIN CHIDAMBARANATHANNo ratings yet

- Week 6: Practice Challenge 1 - Charts: InstructionsDocument7 pagesWeek 6: Practice Challenge 1 - Charts: InstructionskiranNo ratings yet

- Gfps System Specification PVC C Metric en PDFDocument24 pagesGfps System Specification PVC C Metric en PDFMohammed sabatinNo ratings yet

- Shallow Foundation Assignment 1 (Finals)Document2 pagesShallow Foundation Assignment 1 (Finals)Lensearfwyn NamocatcatNo ratings yet

- II B.Tech II Semester Regular Examinations, Apr/May 2007 Chemical Engineering Thermodynamics-IDocument7 pagesII B.Tech II Semester Regular Examinations, Apr/May 2007 Chemical Engineering Thermodynamics-IrajaraghuramvarmaNo ratings yet

- Sparc t8 2 Ds 3864232 PDFDocument6 pagesSparc t8 2 Ds 3864232 PDFanhtuan29No ratings yet

- Chassis (LS17) PDFDocument10 pagesChassis (LS17) PDFlasky11No ratings yet

- 06b AppendixB2 (1000HPRig) 1582535891879Document103 pages06b AppendixB2 (1000HPRig) 1582535891879Harsh TiwariNo ratings yet

- IT Act 2000 overview objectives featuresDocument3 pagesIT Act 2000 overview objectives featuresalpanshiNo ratings yet

- Language As IdeologyDocument26 pagesLanguage As IdeologyAlcione Gonçalves Campos100% (2)

- Managing Information for Better DecisionsDocument12 pagesManaging Information for Better DecisionsTosin WilliamsNo ratings yet

- ASTM 210cDocument1 pageASTM 210cDodi SuhendraNo ratings yet

- PowerOn Fusion PDFDocument16 pagesPowerOn Fusion PDFJagan VanamaNo ratings yet

- The Contemporary WorldDocument9 pagesThe Contemporary WorldDennis RaymundoNo ratings yet

- Solids Flow Feeder Equipment for Precise Measurement & ControlDocument7 pagesSolids Flow Feeder Equipment for Precise Measurement & ControlAbhishek DuttaNo ratings yet

- Loftware Spectrum User GuideDocument1,646 pagesLoftware Spectrum User GuideRupesh Kumar67% (3)

- Ordinary Portland Cement, 33 Grade - Specification: Indian StandardDocument12 pagesOrdinary Portland Cement, 33 Grade - Specification: Indian StandardAmbrishNo ratings yet

- I2C Bus ManualDocument51 pagesI2C Bus Manualapi-26349602100% (6)

- Insulation ProductsDocument1 pageInsulation ProductsDygoPalNo ratings yet

- Civil & Environmental Engineering Lab Consolidation TestDocument14 pagesCivil & Environmental Engineering Lab Consolidation TestSapria AdiNo ratings yet

- On Tap Water Filter System InstructionsDocument48 pagesOn Tap Water Filter System InstructionsFilipa FigueiredoNo ratings yet

- Chiller Selection Made Easier With myPLV™Document12 pagesChiller Selection Made Easier With myPLV™Omair FarooqNo ratings yet

- L .. Eee - .: Distribution Voltage RegulatorsDocument11 pagesL .. Eee - .: Distribution Voltage RegulatorsSirajulNo ratings yet

- OTC13998Document15 pagesOTC13998Raifel MoralesNo ratings yet

- Computer LanguagesDocument3 pagesComputer LanguagesGurvinder Singh100% (1)

- Abstract Substructure Conc - Frame Westgate RealDocument4 pagesAbstract Substructure Conc - Frame Westgate RealTashamiswa MajachaniNo ratings yet