Professional Documents

Culture Documents

Kashmiri Et Al

Uploaded by

Sathya VrathanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kashmiri Et Al

Uploaded by

Sathya VrathanCopyright:

Available Formats

African Journal of Biotechnology Vol. 5 (10), pp. 878-882 16 May 2006 Available online at http://www.academicjournals.

org/AJB ISSN 16845315 2006 Academic Journals

Full Length Research Paper

Production, purification and partial characterization of lipase from Trichoderma Viride

M. Akram Kashmiri, Ahmad Adnan* and Beenish Waseem Butt

Department of Chemistry, G C University, Lahore, Pakistan

Accepted 14 February, 2006

A new strain of lipolytic Trichoderma viride was isolated from the soil on a selective medium that contained olive oil as the only source of carbon and energy. The isolated strain was o cultivated for lipase production in shake flasks at 301 C and the fermentation pattern was studied. The maximum extracellular lipase activity of 7.3 U/mL and the maximum intracellular activity of 320 U/g mycelium were noted after 48 h. Although maximum fungal biomass was present at 13.6 g/L at 60 h but highest specific growth rate was observed between 6 and 18 h. The extracellular lipase present in the broth was purified 134-folds with an overall yield of 46% through purification procedure of ammonium sulphate precipitation, ion exchange and gel permeation chromatography. The Km value of the purified enzyme for triolein hydrolysis was found to be 1.229 m.mole/L. Key words: Fermentation, specific growth rate, fungal lipases, Michaelis constant, yield. INTRODUCTION: Lipases are glycerol ester hydrolases (E.C. 3.1.1.3), which hydrolyze ester linkages of glycerides at water-oil interface. During hydrolysis lipases pick acyl group from glycerides forming lipase-acyl complex, which then transfers its acyl group to OH group of water. However, in non-aqueous conditions, these naturally hydrolytic enzymes can transfer acyl groups of carboxylic acids to nucleophiles other than water (Martinelle and Hult, 1995). Thus lipases can acylate alcohols, sugars, thiols and amines synthesizing a variety of stereo-specific esters, sugar esters, thioesters and amides (Singh et al., 2003; Dellamora-Oritz, 1997). To employ a lipase on synthetic job, it must be immobilized because soluble lipases lose their activity in non-aqueous reaction media (Bruno, 2004; Dosanih and Kaur, 2004). These synthetic properties allow wide spread applications in various field of biochemical and organic conversions (Poonam et al.,

*Corresponding authors Email:adnan_biochem@yahoo.com. Tel: 0092-42-111 000 010 ext. 266. Abbreviations: Vmax, Maximum velocity; Km, Michaelis Constant; YX/S, Growth yield; , Specific growth rate; U, Lipase unit; LSD, Least significant difference; DEAE, Diethyl amino ethyl.

2005; Hsu et al., 2002). It is well known that lipases are the most widely used enzymes in organic synthesis and more than 20% biotransformations are performed with lipases (Gitlesen et al., 1997). In addition to their role in synthetic organic chemistry, these also find extensive applications in chemical, pharmaceutical, food and leather industries (Gulati et al., 2005; Gunstone, 1999). Promising fields for the application of lipases also include the biodegradation of plastics (Gombert et al., 1999) and the resolution of racemic mixtures to produce optically active compounds (Muralidhar et al., 2001). These functions of lipases owe to their broad specificity for a wide spectrum of substrates, stability in organic solvents and enantioselectivity (Snellman and Colwell, 2004; Fadnavis and Deshpande, 2002). In view of the variety in applications, there has been a renewed interest in the development of sources of lipases. Numerous species of bacteria, yeasts and moulds produce lipases with different enzymological properties and specificities but moulds are known to be more potent lipase producer (Choo et al., 1998). These microorganisms produce lipases both by solid substrate and submerged fermentations (He et al., 2004). Because of huge variation in applications, the availability of lipases with specific characteristics is still a limiting factor. Thus to search for new lipases with different characteristics

Kashmiri et al

879

and improve lipase production continue to be important research topics. Trichoderma viride, a mould of family Hypocreaceae, order Hypocreales and class Ascomycetes, is well known for the biological control and the production of cellulase and chitinase (Bailey et al., 2004; Castle et al., 1998). In this paper we reported the existence of a lipase producing strain of T. viride. The paper also describes the relation between lipid consumption and formation of biomass and lipase.

MATERIALS AND METHODS Isolation of producer microorganism Fungal species producing lipases were isolated from soil samples by using a selective medium in which olive oil was the only source of carbon and energy. The medium consisting of (g/L) ammonium sulphate, 1.0; potassium chloride, 0.7; dipotassium phosphate, 1.0; iron (II) sulphate heptahydrate, 0.05; olive oil, 100, was spread over TLC plates and was sterilized by exposure to U.V. radiations. Samples were dusted over the plates and the plates were incubated at 301oC for four days. The microbial colonies were developed which were picked up and purified by streaking. The isolated cultures were screened for lipase production in 250 mL shake flasks. The medium used for screening was consisted of (g/L) olive oil, 20 (emulsified in 2% gum acacia); egg yolk, 10; ammonium chloride, 4.0; magnesium sulphate heptahydrate, 0.25; dipotassium phosphate, 0.5; calcium carbonate, 5.0. The flasks were incubated at 301C for 48 h. A green colonies forming culture with a significant lipase activity was selected and identified to be Trichoderma viride (Bissett, 1991). The culture was maintained on potato dextrose agar slants. Fermentation The fermentation was carried out in shake flasks using a complex medium consisting of (g/L) olive oil, 20 (emulsified in 2% gum acacia); egg yolk, 10; ammonium chloride, 4.0; magnesium sulphate heptahydrate, 0.25; dipotassium phosphate, 0.5; calcium carbonate, 5.0. The flasks containing 40 mL fermentation medium were inoculated by 18 h old vegetative inoculum. The vegetative inoculum was developed from spore suspension prepared from 48 h old culture slants. The inoculum development and the fermentation were carried out at 30 1C with orbital shaking at l00 rpm.

MEASUREMENT OF PROTIEN CONCENTRATION The protein concentration was determined by the method of Bradford (1976) using bovine serum albumen (Sigma chemical Corp.) as the standard. Measurement of lipid contents Total lipid contents of the fermentation medium were determined by the method of Drochioiu (2005). Dry cell mass determination To determine the fungal biomass the mycelium was filtered through filter paper (Whatman No. 40). It was washed first with 0.I mol/L HC1 to remove CaCO3, followed by washing with distilled water. The washed mycelium was dried at 1051 to constant mass. It C was placed in the desiccator and then the mass was determined. Specific growth rate To determine the specific growth rate (), natural log of biomass (ln X) was plotted against time (t). The slope of the line at any moment gives the specific growth rate at that moment. Growth yield Biomass growth yield was determined on the basis of lipid consumption. A graph was plotted between changes in mycelial dry weight and changes in the amount of the lipids consumed. The slope of the graph was YX/S. Purification procedure Step 1: Solid ammonium sulphate was added to the extract with stirring to bring the saturation to 35% and after standing it for 4 h at 4oC, the precipitates were removed by centrifugation. Lipase activity both in precipitate and supernatant was determined. Additional ammonium sulphate was added to the supernatant to bring the saturation to 60% and the mixture was left overnight. The precipitates were collected, dissolved in distilled water and the solution was dialyzed against water for 36 h using a bladder membrane. Step2: The dialyzed solution was concentrated under vacuum and applied to a column (15 x 1.5 cm) of DEAE cellulose. The lipase was allowed to bind to the gel for 1 h. The column was eluted with linear gradient of NaCl (0.05-1.0 mole/L: 250 ml) in phosphate buffer at a flow rate of 120 mL/h. The eluent was collected in 5 ml fractions. Step 3: The eluent was concentrated under vacuum and the concentrate was applied to a column (15 x 1.5 cm) of Sephadex G100, which was pre-equilibrated with sodium phosphate buffer pH 7.0 and eluted with same buffer. The fractions were collected and analyzed. Determination of Vmax and Km The purified lipase was incubated with various concentrations of emulsified triolein. The final concentration ranged from 0.5 m.mol.L1 to 4.0 m.mol.L-1. The Michaelis constant (Km) was calculated by

Lipase assay Lipase activity in the broth or mycelia was determined titrimetrically on the basis of olive oil hydrolysis (Macedo et al., 1997). One mL sample solution or 10 mg mycelial powder was added to the assay substrate containing 10 mL of 10% homogenized Olive oil in 10% gum acacia, 2 ml of 0.6% CaCl2 solution and 5 ml of 0.2 mol/L citrate buffer, pH 7.0. The enzyme substrate mixture was incubated on orbital shaker with a shaking speed of 100 rpm at 37C for 1 h. To stop the reaction, 20 ml ethanol acetone mixture (1:1) was added to the reaction mixture. Liberated fatty acids were titrated with 0.1 mol/L NaOH. Intracellular lipase activity was expressed as units per gram mycelium and extracellular lipase activity as units per mL of the broth. One lipase unit (U) was defined as the amount of the enzyme that released one mole fatty acid per min.

880

Afr. J. Biotechnol.

16

Biomass (g/L)

plotting 1/V against 1/[S] in Lineweaver and Burk plot. Statistical analysis Experiments were performed in triplicate and the results were statistically analyzed using computer software Costat cs6204W.exe. The treatment effects were compared after Snedecor and Cochran (1980) and the significant difference among replicates has been presented as Duncans multiple range tests in the form of probability values.

12 8 4 0 -4 0 20 40

Time (h)

60

80

U/mL

Figure 1. Shows the rate of production of fungal biomass during lipase fermentation by Trichoderma viride at 301C.

10 5 0 -5 0 20 40 60 80

4 2

ln X

Time (h)

Figure 5. Extracellular lipase activity, showing maximum of 7.3 u/ml at 48 h.

0 -2 0 -4 -6

Time (h)

20

40

60

80

RESULTS AND DISCUSSION The rate of growth and enzyme production by microorganisms is quite important in understanding their fermentation pattern. Figure 1 shows the rate of production of fungal biomass during lipase fermentation by T. viride at 301C for 72 h of incubation. Maximum growth rate was observed between 12 and 48 h of fermentation. At 60 h 13.6 g/L fungal dry mass was present. After 60 h, there was a slight decrease in the mycelial dry mass. Figure 2 shows that 6 h lag phase was followed by a true exponential growth between 6 and 18 h, during which a constant specific growth rate () of -1 0.48 h was observed. After that, although the growth rate went on increasing but the specific growth rate (slope of the curve in Figure 2) decreased. After 18 h the growth showed divergence from the exponential because in place of homogeneous growth, mycelial pellets began to form in which nutrients and oxygen supply became the growth limiting. Total lipid content was measured throughout the experiments (Figure 3). It was observed that the fungus started using lipid source after 12 hours of inoculation but the utilization rate was low in the beginning. The extraordinary low utilization rate of lipids during early hours of fermentation and apparently very high YX/S (0.8) may be due to the utilization of nutrients other than lipids, like small amount of sugars and proteins present in the egg yolk. The most rapid utilization of the lipids was observed after 18 h. After 18 h, YX/S was almost constant (0.63 - 0.66 g/g). Statistical analysis showed that no significant lipid consumption was observed after 48 h and 5.7% of the total lipids were still unused at 72 h. Figure 4 shows the intracellular lipase activity during lipase fermentation. The intracellular lipase activity after 6

Figure 2. Specific growth rate of the fungal biomas, () of 0.48 h-1 between 6-18 h.

Residual Lipids (g/L)

30 20 10 0 0 20 40

Time (h)

60

80

Figure 3. Consumption of lipid source with time in h.

400 300

U/g

200 100 0 0 20 40 60 80

Time (h)

Figure 4. Intracellular lipase activity, showing maximum of 320 u/g at 48 h.

Kashmiri et al

881

Lipase (U/ml) ser 1 Protein (mic.g/ml) ser 2

2000 1500 1000 500 0 -500 0

Lipase (U/ml) Protein (mic.g/ml)

60% saturation. Precipitates were found to have 329 U/ml. These precipitates were dissolved in and dialyzed against distilled water and loaded on the DEAE cellulose column (Figure 6). Fraction numbers 17, 18 and 19 were lipase active. These fractions were pooled and found to

20

40

60

Fraction No.

Figure 6. Lipase purification by DEAE Cellulose Column Chromatography.

Lipase (U/ml) Ser.1 Protein (mic. g/ml) Ser. 2

300 200 100 0 -100 0

Lipase u/ml Protein (mic. g/ml)

Figure 8. Determination of Km of Lipase activity.

20

40

60

Fraction No.

Figure 7. Lipase purification by Gel permeation Chromatography.

h of incubation was 85 U/g. Then it gradually increased and reached to 320 U/g after 48 h. The rate of lipase accumulation inside the mycelia was significantly higher between 42 and 48 h. During this period the rate of lipase formation exceeded the rate of its secretion into the broth. After 48 h the secretion dominated over its formation and the cell-bound lipase activity fell down. Figure 5 shows the extracellular lipase activity during the fermentation. The rate of lipase secretion into fermentation broth was the highest between 18 to 24 h and then the rate gradually decreased. The level of extracellular lipase was the maximum till 48 h i.e. 7.3 U/mL. Then its level slightly decreased due to denaturation of the formed enzyme. The results are similar to that of Kamimura et al. (1999) and Burkert et al. (2004) who worked on Geotrichum sp. and reported that tin shake flasks maximum lipase activity was achieved in 48 h. However, Kamimura et al. (1999) also reported that only 10 h were needed to get maximum lipase activity in stirred fermenter using a complex medium containing corn steep liquor, olive oil and ammonium nitrate. Once the maximum extracellular lipase activity had been reached, the mycelium was filtered and the filtrate was found to have 7.3 lipase U/mL. The specific activity of the filtrate was noted to be 11.0 units/mg protein. The enzyme was salted out using ammonium sulphate at 35-

have the lipase activity 298 lipase U/ml. The specific lipase activity in these fractions was 328 U/mg proteins. The lipase active fractions were concentrated again under vacuum and were further purified by gel permeation. Fraction numbers 12, 13, 14 and 15 was lipase active as shown in the Figure 7. The purified enzyme had lipase activity 168 U/mL and a specific lipase activity in these fractions was 1479 U/mg protein. A representative profile is summarized in the Table 1. The purified lipase was incubated with various concentrations of triolein in the emulsion and the final concentrations of the triolein in the reaction mixture ranged from 0.5 to 4.0 mM. The Michaelis Constant (Km) was determined from the Lineweaver and Burk plot (Figure 8), by dividing the slope of the line with the intercept. The Vmax was determined as the reciprocal of the intercept. The enzyme was found to have Km of 1.14 -1 -1 -1 m.mol. L and Vmax of 0.056 m.mol.L min . ACKNOWLEDGMENT We are thankful to Higher Education Commission of Pakistan (Islamabad), for funding the research project entitled Production of Lipases and Lipase Mediated Synthesis of Valuable Esters.

REFERENCES: Bailey DJ, Kleczkowski A, Gilligan CA (2004). Epidemiological dynamics and the efficiency of biological control of soil-borne disease during consecutive epidemics in a controlled environment. New Phytologist161(2): 569-576. Issett J (1991). A revision of the genus Trichoderma. II. Infrageneric classification. Can. J. Bot. 69: 2357-2372. Bradford MM (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of proteindye binding. Anal. Biochem , 72: 248254.

882

Afr. J. Biotechnol.

Bruno Laura M, Filho Jose, L de Lima, de Melo, Eduardo H, de Castro, Heizir F (2004) Ester synthesis catalyzed by mucor miehei lipase immobilized on magnetic polysiloxanepolyvinyl alcohol particles. Appl. Biochem and Biotechnol 113:1-3, pp. 189-200. Burkert JFM, Maugeri F, Rodrigues MI (2004). Optimization of extracellular lipase production by Geotrichum sp. using factorial design. Bioresource Technol. 91: 1. pp.77-84. Castle, Alan; Speranzini, Donna; Rghei, Nezar; ALM, Glen; Rinker, Dan and Bissett, John. (1998) Morphological and molecular identification of Trichoderma isolates on North American mushroom farms. Appl. and Environ. Microbiol. 64(1): 133-137. Choo DW, kurihara T, Suzuki T, Soda K, Esaki NA (1998). cold adapted lipase of an Alaskan psychrotroph, Pseudomonas sp, Strain B 11-1: Gene cloning and enzyme purification and characterization. Appl. and Environ. Microbiol. 64(2): 486-491. Dellamora-ortiz gm, Martins RC, Rocha WL, Dias AP (1997). Activity and stability of a Rhizomucor miehei lipase in hydrophobic Media. Biotechnol. and Appl. Biochem vol. 26, pp.111-116. Dosanih NS, Kaur J (2002). Immobilization, stability and esterification studies of a lipase from a Bacillus sp. Biotechnol. and Appl. Biochem. vol. 36 pp. 7-12 Drochioiu, Gabi (2005). Turbidimetric lipid assay in seed flours. J. Food Lipids, 12: 1, p.12. Fadnavis NW, Deshpande A (2002). Synthetic applications of enzymes entrapped in reverse micelles and organo-gels. Curr. Organic Chem 6(4): 393-410. Gitlesen T, Bauer M, Adlercreutz P (1997). Adsorption of Lipase on polypropylene powder, Biochimica et Biophysica Acta. vol.1345, pp. 188-196. Gombert AK, Pinto al, Castilho LR, Freirc DMG (1999). Lipase by Penicillium restrictum in solid state fermentation using Babassu oil cake as substrate, Process Biochem., vol.35, pp. 85-90 Gulati Ruchi, ISAR Jasmine, Kumar Vineet, Parsad Ashok K, Parmar Virinder, S Saxena Rajendra K (2005). Production of a novel alkaline lipase by Fusarium globulosum using Neem oil, and its applications. Pure and Appl Chem, 77(1): 251-262.

Gunstone, Frank D (1999). Enzymes as biocatalysts in the modification of natural lipids. J. Sci. Food and Agric. 79(12): 1535 1549. HE YQ, Wang BW, Tan TW (2004). Fermentation Production Technology of Lipase with Candida sp. Chinese J. Biotechnol. 20(6): 921-926. HSU An-Fei, Jones K, Foglia TA, Marmer WN (2002). Immobilized lipase catalyzed production of alkyl esters of restaurants grease as biodiesel. Biotechnol and Appl Biochem. vol. 36, pp.181-186. Kamimura ES, Mendieta O, Sato HH, Pastore, Maugeri F (1999) . Production of lipase from Geotrichum sp. and adsorption studies on affinity resin. Brazilian J Chemical Engr, 16(2):1-10 Macedo GA, Park YK, Pastore GM (1997) . Partial purification and characterization of an extracellular lipase from a newly isolated strain of Geotrichum sp. Rev. Microbiol. 28(2): 90-95. Martinelle M, Hult K (1995). Kinetics of acyl transfer reactions in organic media catalyzed by Candida antarctica lipase B. Biochimica Biophysica Acta. 1251(2): 191-197. Muralidhar RV, Marchant R, Nigam P (2001). Lipases in racemic resolutions. J. Chemical Technol & Biotechnol. 76(1): 3-8. Poonam, Prasad AK, Mukherjee Chandrani, Shakya Gaurav, Meghwanshi GK, Wengel Jesper, Saxena RK, Parmar Virinder S (2005). Selective transacylation reactions on 4-aryl-3-4dihydropyrimidine-2-ones and nucleosides mediated by novel lipases. Pure and Appl Chem. 77(1): 237-243. Singh SK, Felse AP, Nunez A, Foglia TA, Gross RA (2003). Regioselective enzyme-catalyzed synthesis of phospholipid esters, amides, and multifunctional monomers. J. Organic Chem. 68(14): 5466-5477. Snedecor GW, Cochran WG . Statistical Methods, 7th Ed.1980, Iowa State University, pp.32-43. Snellman EA, Colwell RR (2004). Acinetobacter lipase: molecular biology, biochemical properties and biotechnological potential. J. Industrial Microbiol and Biotechnol. 31(9): 391-400.

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Iotechnology RogressDocument22 pagesIotechnology RogressSathya VrathanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Effect of Maltodextrin, Glycerol Monostearate and Tricalcium Phosphate On Vacuum Dried Mango Powder PropertiesDocument10 pagesEffect of Maltodextrin, Glycerol Monostearate and Tricalcium Phosphate On Vacuum Dried Mango Powder PropertiesSathya VrathanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Jumo Tecline HD PH and Jumo Tecline HD RD: PH and Redox Combination Electrodes in Glass Shaft VersionDocument7 pagesJumo Tecline HD PH and Jumo Tecline HD RD: PH and Redox Combination Electrodes in Glass Shaft VersionSathya VrathanNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- BambangNur PhD2016Document177 pagesBambangNur PhD2016Sathya VrathanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- AmylaseDocument8 pagesAmylaseSathya VrathanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- For Xylanase 1Document11 pagesFor Xylanase 1Sathya VrathanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Effect of Drying Parameters On Moisture Content and Papain Enzyrne Activity of Dried PapayaDocument6 pagesEffect of Drying Parameters On Moisture Content and Papain Enzyrne Activity of Dried PapayaSathya VrathanNo ratings yet

- Energy and FluctuationDocument10 pagesEnergy and Fluctuationwalid Ait MazouzNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Sawla - Laska (Lot - I) Road Project Hydrology - Hydraulics MDocument64 pagesSawla - Laska (Lot - I) Road Project Hydrology - Hydraulics Mashe zinab100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Zeolites and Ordered Porous Solids - Fundamentals and ApplicationsDocument376 pagesZeolites and Ordered Porous Solids - Fundamentals and ApplicationsHenrique Souza100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Version 2 Dog Legged Stair ES EN 1992-1-1 2015Document29 pagesVersion 2 Dog Legged Stair ES EN 1992-1-1 2015Khaja100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Project Final PDFDocument98 pagesProject Final PDFNgonidzashe MhukaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Omnivision Man lp06xx Rev0 0611Document18 pagesOmnivision Man lp06xx Rev0 0611ivan ramirezNo ratings yet

- Ap2 Safe ManipulationDocument5 pagesAp2 Safe ManipulationDarthVader975No ratings yet

- Risk Assessment Project Iosh - MsDocument2 pagesRisk Assessment Project Iosh - MsSanjeev Kumar75% (32)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Examination Speaking Assignments Term III - 2021Document2 pagesExamination Speaking Assignments Term III - 2021Khrystyna ShkilniukNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Kim, KDM, Sim, SDM PDFDocument12 pagesKim, KDM, Sim, SDM PDFKavan Gt12No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- I10 Workshop Manual - ADocument292 pagesI10 Workshop Manual - ANorthstartechnology Company82% (11)

- BMC IV - Module 02 Finishes 200912Document56 pagesBMC IV - Module 02 Finishes 200912Fidha SulfiNo ratings yet

- 11 Physical Fitness Assessment 1Document40 pages11 Physical Fitness Assessment 1Danilo Sare IIINo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Full List of Oil Companies in Nigeria & Websites - Nigerian Infopedia PDFDocument6 pagesFull List of Oil Companies in Nigeria & Websites - Nigerian Infopedia PDFBoma EvansNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- ASTM E 1066 - 95 Standard Practice For Ammonia Colorimetric Leak Testing PDFDocument5 pagesASTM E 1066 - 95 Standard Practice For Ammonia Colorimetric Leak Testing PDFАртем ТитовNo ratings yet

- Bioclim MaxentDocument9 pagesBioclim MaxentNicolás FrutosNo ratings yet

- Nelson Tables All in One PDFDocument618 pagesNelson Tables All in One PDFAmulya Ramakrishna100% (7)

- Seismic Retrofitting2.0 BY PRIYANSHUDocument30 pagesSeismic Retrofitting2.0 BY PRIYANSHUPriyanshu VarshneyNo ratings yet

- Agriculture Mcqs PDFDocument4 pagesAgriculture Mcqs PDFAbdul QudoosNo ratings yet

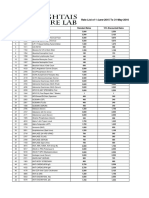

- Rate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesDocument25 pagesRate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesMirza BabarNo ratings yet

- Aqa Econ3 QP Jan12Document8 pagesAqa Econ3 QP Jan12api-247036342No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- MSDS Aradur 2965 PDFDocument9 pagesMSDS Aradur 2965 PDFkamalnandreNo ratings yet

- 03N - Top Level View of Computer Function and InterconnectionDocument38 pages03N - Top Level View of Computer Function and InterconnectionDoc TelNo ratings yet

- Spread of Hinduism To South East Asia by Land and Maritime RoutesDocument36 pagesSpread of Hinduism To South East Asia by Land and Maritime RoutesUday DokrasNo ratings yet

- 2017 Induction Programme V1Document3 pages2017 Induction Programme V1AL SolmiranoNo ratings yet

- German Din Vde Standards CompressDocument3 pagesGerman Din Vde Standards CompressYurii SlipchenkoNo ratings yet

- Roles and Responsibilities of ASHADocument3 pagesRoles and Responsibilities of ASHAmohanpskohli8310No ratings yet

- Assignment Class X Similar Triangles: A D E B CDocument2 pagesAssignment Class X Similar Triangles: A D E B CCRPF School100% (1)

- Questions and Answers About Lead in Ceramic Tableware: Contra Costa Health Services / Lead Poisoning Prevention ProjectDocument4 pagesQuestions and Answers About Lead in Ceramic Tableware: Contra Costa Health Services / Lead Poisoning Prevention Projectzorro21072107No ratings yet

- r315 Quick Start PDFDocument80 pagesr315 Quick Start PDFfdsfasdsfadsNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)