Professional Documents

Culture Documents

Multiple VFD TX Failure Investigation

Uploaded by

Justan MendezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multiple VFD TX Failure Investigation

Uploaded by

Justan MendezCopyright:

Available Formats

ACS 1000 Transformer Failure Investigation

Nathan Schachter, Peng

ACS 1000 Transformer Failure

Objectives

Learn what happened Explain why it happened Discuss solutions Suggest remedies so it does not happen again Prevention is the key to success

2

29.10.2006

ACS 1000 VFD TRANSFORMER FAILURE

What happened?

The plant experienced several transformer and VFD failures with the medium voltage drives supplied for Line 2 installation between November 1999 and January 2001.

3

29.10.2006

ACS 1000 VFD transformer failures

The equipment involved includes the following: -1000kVA - kiln bypass fan -3000kVA - pre-heater ID fan -4500kVA - raw mill ID fan -2250kVA - filter bag-house fan, which sustain damage to the electronic components - some of the smaller drives lost fuses and diodes (ACS600)

4

29.10.2006

ACS 1000 VDF tranformer failures

5

29.10.2006

ACS 1000 VFD transformer failures

6

29.10.2006

ACS 1000 Transformer Failure

7

29.10.2006

ACS 1000 Transformer Failure

8

29.10.2006

ACS 1000 Transformer Failure

9

29.10.2006

ACS 1000 Transformer Failure

Possible causes Physical design of the transformer for the application of non-linear load characteristics Impedance specification to limit the secondary current. (Commutating reactance) Electromagnetic forces withstand capability for core and windings Shape of the coils- rectangular or round Cooling and oil circulation between the coils

10

29.10.2006

ACS 1000 Transformer Failure

What actually happened?

Indications are that the windings did not fail turn to turn at first, which would be an indication of insulation failure due to an external surge The rectification process of the AC waveform itself subjects the windings to near short-circuit conditions every half cycle. All failures occurred on the Y winding connection of the secondary - ungrounded

11

29.10.2006

ACS 1000 Transformer Failure

The secondary windings deformed first as a result of the electromagnetic force which is proportional to I. The deformation of the windings also changes the mutual inductance of the windings, which in turn reduces the reactance component - a cascading effect to increase secondary current. Secondary of the transformer is not fused, the drive is a fuse-less design. It relies on the primary protection and the electronic protection supplied with the drive.

12

29.10.2006

ACS 1000 Transformer Failure

Other possible causes for failure It has been suggested that switching transients from the capacitor banks were the root cause of the failure. - not likely although repeated switching of shunt capacitors can give rise to over-voltages under certain conditions. A high secondary current is also likely a result of a diode failure because of forward current handling. Surge protection of the diode bridge and high DC bus voltage remain a potential weak link.

13

29.10.2006

ACS 1000 Transformer Failure

Re-energizing the transformer with a faulted winding Power system transients due to the breaker dropping out under load is to be expected in an industrial power system Switching transients of 1.8 to 2.0 per unit voltage are not desirable but are expected in an industrial power system.

14

29.10.2006

ACS 1000 Transformer Failure

Electrostatic shields provide adequate isolation between the primary and secondary steep waveforms such as a surge voltage

Independent analysis of the mode of failure arrived to similar conclusions: - Sunbelt report, Van-Koy and BBXs reports ,etc.

15

29.10.2006

ACS 1000 Transformer Failure

What has been done to date Interim transformers have been secured through ABB and installed temporarily until the new drive transformers arrive at the plant. These units remain in service at this time. Damaged drive parts have been replaced with spare parts. These were purchased by the plant. Three new transformers have been delivered to the plant: 2250kVA, 3000kVA and 4500kVA.

16

29.10.2006

ACS 1000 Transformer Failure

The 1000kVA powering the bypass fan was the first to fail. At the advise of ABB an available transformer was purchased by the plant from Monarch Cement. All the new transformers have been supplied also with surge arresters on the HV side. The original transformers did not have.

17

29.10.2006

ACS 1000 Transformer Failure

The priorities until now was to secure adequately designed replacement transformers.

The next steps require fine tuning of the power distribution system.

We require every ones participation.

18

29.10.2006

ACS 1000 Transformer Failure

Outstanding issues with the drives Replace temporary transformers with new units. There were discrepancies with the impedance specifications and winding temperature class for all of the new transformers. These were only recently partially clarified. - Short circuit type test verification for the prototype coil design (VT /ABB to confirm) - Insulation class of the windings. ABB to confirm

19

29.10.2006

ACS 1000 Transformer Failure

A proposal from ABB to enhance the surge protection across the diode rectifier section of each drive remains on the table. ABB to confirm requirements

20

29.10.2006

ACS 1000 Transformer Failure

The plant is concerned that the 1000kVA transformer was designed with aluminum windings and want it replaced. Also it was designed for a higher temperature rise (65C) than the other units (55C). Also it has larger impedance than the other units - 8.84 vs 7.34. Supplied with 6kV arrester vs 3kV arresters for the new units. Spare parts for the ACS1000 drives. The plant depleted their resources.

21

29.10.2006

ACS 1000 Transformer Failure

Coordination of primary protection devices need to be revised for the electrical characteristics of the new transformers.

Review of the drive control scheme and interface to the DCS. The drive must trip the contactor under normal operation.( ABB 80-100ms)

22

29.10.2006

ACS 1000 Transformer Failure

Concern remains with the smaller drives ACS600 and the design of the isolation transformers. These were were built by the same manufacturer as for the larger units.(PTI Industries)

These units are fused and have slightly higher impedance values that that of the medium voltage drive transformers.

23

29.10.2006

ACS 1000 Transformer Failure

The secondary fuses have blown during the power system disturbance in December 2000. This is perhaps the reasons they have not failed.

Also denotes a lack of selectivity in coordination with the primary protective devices. This has to be reviewed in detail.

24

29.10.2006

ACS 1000 Transformer Failure

Other observations

There was lack of information on the original transformers and actual test data. Transformer damage curves. Commissioning reports for the drives, protection device settings (preliminary and final settings), etc.

25

29.10.2006

ACS 1000 Transformer Failure

Line 2 capacitor banks Requirement for having and also for switching the 800 and 1200kVAr capacitor whenever the 8000hp S-I motor is off line? If these are required the capacitor banks must be upgraded to include reactor de-tuned for 4.7th. This is the minimum requirement to mitigate harmonic effects from the utility. (IEEE)

26

29.10.2006

ACS 1000 Transformer Failure

Utility contract What are the contractual power factor requirements at the 138kV for Line 1 and Line 2 ? - above 90, 92 or 95 - firm demand or interruptible power contract? - what load factor? - coincidental billing?

27

29.10.2006

ACS 1000 Transformer Failure

Preventative measures Power system analysis -short circuit duties at equipment -Load flow analysis -power factor - (displacement and actual) - selective co-ordination and protection. The incident on December 2000 indicates that a complete review is required. In particular with the SI motor

28

29.10.2006

ACS 1000 Transformer Failure

Harmonic studies Modeling of harmonic sources Harmonic sensitivities and amplification factors Actual field measurements with the equipment operating - partial and full load. (measurements and spectrum analysis done at 138kV by the plant after Line 2 came on stream) First sign of harmonic amplification are blown fuses and capacitors.

29

29.10.2006

ACS 1000 Transformer Failure

Switching transients EMTP -electromagnetic transient program and modeling can give an indication if there are dynamic over-voltages in excess. If these were a problem other equipment would have been also affected. Switching capacitor banks and virtual current chopping is more of a problem when a capacitor bank is de-energized. -

30

29.10.2006

ACS 1000 Transformer Failure

Protection of fuse-less drives

Special attention is required with the primary interrupting devices and power electronic devices. ABB has to provide damage curves for the diodes, protection IGCTs. Selection and coordination of primary fuse to protect the transformer winding, the diode and the electronic protection IGCT.

31

29.10.2006

ACS 1000 Transformer Failure

Similar attention is required for the ACS600 drives.

32

29.10.2006

ACS 1000 Transformer Failure

Questions? For additional clarifications/requirements please contact the presenter at 1-(905)-336-2786, Ext 21

33

29.10.2006

You might also like

- Loop Test Sheet PDFDocument1 pageLoop Test Sheet PDFTrí NguyễnNo ratings yet

- Openphaseconditionsintransformersanalysisandprotectionalgorithm PDFDocument14 pagesOpenphaseconditionsintransformersanalysisandprotectionalgorithm PDFEmmanuel Entzana HdzNo ratings yet

- Open DeltaDocument3 pagesOpen DeltaRoshmith PurushothamanNo ratings yet

- Loop Test Sheet PDFDocument1 pageLoop Test Sheet PDFTrí NguyễnNo ratings yet

- Foxboro Magnetic Flow Transmitters IMT25Document20 pagesFoxboro Magnetic Flow Transmitters IMT25Justan MendezNo ratings yet

- Loop Test Sheet PDFDocument1 pageLoop Test Sheet PDFTrí NguyễnNo ratings yet

- SelectionGuide Foxboro Electrodeless 06-11Document2 pagesSelectionGuide Foxboro Electrodeless 06-11Justan MendezNo ratings yet

- HACH Particle Counter TAGSDocument2 pagesHACH Particle Counter TAGSJustan MendezNo ratings yet

- Broadway To San Fernando Hill - Google MapsDocument1 pageBroadway To San Fernando Hill - Google MapsJustan MendezNo ratings yet

- InspectNTrackfor Equip InspecDocument15 pagesInspectNTrackfor Equip InspecJustan MendezNo ratings yet

- 871EC Series Electrodeless Conductivity Sensors and AccessoriesDocument28 pages871EC Series Electrodeless Conductivity Sensors and AccessoriesJustan MendezNo ratings yet

- Mvi56 MCMR User ManualDocument167 pagesMvi56 MCMR User ManualJustan MendezNo ratings yet

- Tg3 Emc Compliant Installation 61348280 Rev DDocument44 pagesTg3 Emc Compliant Installation 61348280 Rev Diyilmaz1No ratings yet

- De-Energized Tap ChangerDocument3 pagesDe-Energized Tap ChangerJustan MendezNo ratings yet

- Amerlock 2Document3 pagesAmerlock 2Justan MendezNo ratings yet

- Technical Guide 6 HarmonicsDocument32 pagesTechnical Guide 6 HarmonicsLucian ConstantinNo ratings yet

- 1276-1997 - Insulation Material in Liquid Immersed Power TransformersDocument23 pages1276-1997 - Insulation Material in Liquid Immersed Power TransformersJustan MendezNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Experiment No 3 PDFDocument13 pagesExperiment No 3 PDFDiana NomilNo ratings yet

- SP8M3Document6 pagesSP8M3RjibNo ratings yet

- User Manual PDFDocument58 pagesUser Manual PDFsrinu1984No ratings yet

- CH 3 ProblemsDocument3 pagesCH 3 ProblemsDiogo Rodrigues0% (1)

- Aros FlexusDocument8 pagesAros FlexusfedericosanchezNo ratings yet

- OctoboxDocument12 pagesOctoboxSatadal GuptaNo ratings yet

- Characteristics of Logic Gates: A. ObjectivesDocument10 pagesCharacteristics of Logic Gates: A. ObjectivesManish KumarNo ratings yet

- Power Budget: Pre-Planning Detailed Planning Post - PlanningDocument39 pagesPower Budget: Pre-Planning Detailed Planning Post - PlanningHân TrươngNo ratings yet

- Snap Kit ChiquitoDocument2 pagesSnap Kit ChiquitoHugo EnriquezNo ratings yet

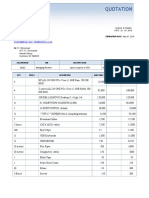

- Quotation: Techsols EnterpriseDocument2 pagesQuotation: Techsols EnterpriseJeffMuiaNo ratings yet

- Rssi On Pucch and Pusch Effect LteDocument2 pagesRssi On Pucch and Pusch Effect LteDpkKSingh50% (2)

- ALTEC LANSING 620A MonitorDocument3 pagesALTEC LANSING 620A MonitornraghunadhNo ratings yet

- Bks DPEng 0800 At01Document6 pagesBks DPEng 0800 At01NICOLAS ALEJANDRO BOADA BENITEZNo ratings yet

- Design of Millimeter Wavw Radio - RazaviDocument13 pagesDesign of Millimeter Wavw Radio - Razaviदीपक जोशीNo ratings yet

- DatasheetDocument24 pagesDatasheetLuis CordeiroNo ratings yet

- 6 Adc0804Document5 pages6 Adc0804esther_kakani919No ratings yet

- E WalletDocument15 pagesE WalletManoj Kumar Paras100% (1)

- VX 1700 Technical InformationDocument10 pagesVX 1700 Technical InformationHenry AlvaxNo ratings yet

- Interfacing LEDs With TMS320F2812 DSP - PD PDFDocument9 pagesInterfacing LEDs With TMS320F2812 DSP - PD PDFChakib KaNo ratings yet

- Evolution of Electronics and Its ApplicationsDocument11 pagesEvolution of Electronics and Its ApplicationsDebasish MishraNo ratings yet

- More Zapper Frequencies PDFDocument1 pageMore Zapper Frequencies PDFRobert MaximilianNo ratings yet

- SteelTongs ReadmeDocument3 pagesSteelTongs Readmealice1303No ratings yet

- PIC32-PINGUINO Development Board Users Manual: Designed by OLIMEX LTD, 2011Document16 pagesPIC32-PINGUINO Development Board Users Manual: Designed by OLIMEX LTD, 2011Bruno BrunocomNo ratings yet

- LC-10 LOAD CELL Trainer PDFDocument10 pagesLC-10 LOAD CELL Trainer PDFAvijitRoyNo ratings yet

- TD1501Document18 pagesTD1501Hernando GamaNo ratings yet

- CRODocument4 pagesCROboopathy566No ratings yet

- Myfreelap Scenarios: Freelap Sa Av. Daniel Jeanrichard 2 Ch-2114 Fleurier +41 (0) 32 861 52 42 Contact@Freelap - CHDocument6 pagesMyfreelap Scenarios: Freelap Sa Av. Daniel Jeanrichard 2 Ch-2114 Fleurier +41 (0) 32 861 52 42 Contact@Freelap - CHAnonymous 3BBuadJXr2No ratings yet

- PSRR and Measurement of PSRR in Class-D Audio Amplifiers and LDOs - An-135Document7 pagesPSRR and Measurement of PSRR in Class-D Audio Amplifiers and LDOs - An-135absalomlootNo ratings yet

- UV-5R MenusDocument4 pagesUV-5R MenusRikardoviskiNo ratings yet

- Bicsi Icttoday 20160506Document60 pagesBicsi Icttoday 20160506saldivaroswaldoNo ratings yet