Professional Documents

Culture Documents

TS5 BW 108 109

Uploaded by

Brett HeinzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TS5 BW 108 109

Uploaded by

Brett HeinzCopyright:

Available Formats

By Bob Warnke

here are speed bumps for traffic control and speed bumps in transmission work. The small bumps entering an intersection are unavoidable, similar to those of transmission diagnosis and inspection. We have posted the following check lists, which are like

the SLOW, 5 MPH speed limit bumps, so you can avoid the impact of a BIG transmission problem. KEY:

VEHICLE = In the Vehicle, preliminary testing (scanner or DVOM) BENCH = Inspection of related parts on the bench

VEHICLE: Monitor release psi., P1, P2 Cross leaks of 20 psi. + trip P2 P2 indicates control valve position Movie of input/turbine RPM Variation of 8-10 RPM is ok. (Highway) Movie of MAF, TPS TCC duty % must rise w/load High slip w/low 30-40 % duty, a concern; Verify duty % rise to at least 70% Low TCC duty %? Brain dead PCM, 1st Low TCC duty %? reflash or new PCM Slip in 4th, no slip in 3rd, is not TCC Slip RPM over 10% of engine RPM ? High slip RPM, with code 730 = ratio Perform TCC command stall test, at 180F min. Install SonnaFlow, verify TCC control, valve strokes: Premature stroke = bad solenoid; Valve cycling = bad bore TCC PWM ohms test 10.8 at 68F

BENCH: Refer to 4T65-E repairs (pages 56-57) ISS retainer location/retention (see Figure 1) ISS reluctor end-play, pin wear (see Figure 2) Case cover sleeve index/wear (see Figure 3) Converter blow-off dirty (Case cover) (see Figure 3) Inspect #1 check ball seat (see Figure 3) Converter hub bushing wear Internal converter leakage Sprocket or differential ratio Test TCC PWM solenoid for cross-leakage OSS reluctor application Pump bearing and seal Drive sprocket bearing wear Air test converter apply circuit

Figure 2 Figure 3

Check-ball seats on the other side, and on plate. Clean TCC blow-off. Scanner movie hopefully identified worn pins, bent teeth or runout caused by endplay.

4T65-E

Figure 1

Monitor ISS and TCC/PWM solenoid. Bad solenoid will apply TCC before signaled. Sensor retainer must fold outward. Insure magnet is tight and clean.

Inspect AFL bore wear. AFL is torque signal, torque signal is line rise, line rise is TCC apply.

Inspect sleeve for wear and index. Thrust washer and reluctor surface for wear.

2003 Sonnax

VEHICLE: No restrictions allowed in cooler circuit! Sonnaflow diagnostics (see pages 180 & 181) Re-test with auxillary cooler, by-pass OEM Remove anti-drainback ball, re-retest Monitor TCC signal, Trans temp. TPS, VSSs Tap into TCC release circuit (special fittings) Set line pressure 65 psi. drive, idle Retorque all valve body bolts Install 727 screen filter Use synthetic ATF

BENCH: Use, 22771A-01, -02K, 22771-09 instructions and refer to pages 184, 185, 187 & 191 No wear allowed in pressure regulator bore (see Figure 4) WAT TCC apply circuit with pump, turbine shaft into converter TCC piston can be applied through pump WAT turbine shaft sealing rings (see Figure 5) Install 2 stiff-plastic turbine shaft seals (Torlon or Peak Material). Resurface the pump, seal surfaces with Loctite #518 Converter cover alignment affects TCC, due to shaft alignment (see Figure 6) Inspect dowel pins, crank wear and flex-plate Clean TCC solenoid feed orifice. .030" pin gauge must fit into solenoid feed hole in valve body casting. Test/replace TCC solenoid assembly

46/47RH/RE

Figure 4

Wear/Cross Leakage Causes: 1. Reverse high line psi. or buzz from instability

2. High line psi. 3. Low line psi., late upshifts 4. & 5. High line psi, valve instability 6. & 7. Low line psi 8. Elevated converter psi 9. Low converter pressure, delayed engagement

Figure 5

Note: The direct drum & forward clutches have been removed for this photo. They must be fully assembled with thrust washers to get the proper WAT test results!

Figure 6

Use improved plasticsealing rings here, separating TCC apply from release oil.

Should never be air or fluid bubbles coming from suction or line, during any WAT.

Pump suction Pump line psi. Direct/front clutch Forward clutch Converter release Converter apply With converter full of ATF, supply 30-50 psi. into apply port. Minimal to no leakage from release. No leaks into forward. Remove your air supply slowly as the converter will push the fluid back out!

Should never be oil/air leakage between halves. If so, resurface both, chamfer the thread pockets & seal w/Locktite #518. Air into release, plug apply. Cross leaks from release to forward? Inspect turbine shaft sealing rings & stator bore.

Release oil must flow across bushing or engine stumble, TCC apply during engagement to D-R.

Washer or bearing must flow oil.

2003 Sonnax

800/843-2600 802/463-9722 fax: 802/463-4059 www.sonnax.com info@sonnax.com

sonnax

109

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Truck PDFDocument218 pagesTruck PDFCharles Claycomb100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Timing Cover d13Document25 pagesTiming Cover d13SsNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Volkswagen New Beetle 1.8 Liter 4-Cyl. 5V Turbo OBD II Engine MechanicalDocument26 pagesVolkswagen New Beetle 1.8 Liter 4-Cyl. 5V Turbo OBD II Engine MechanicalHoopdub50% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

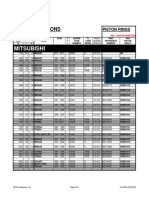

- Mitsubishi: U.S. ApplicationsDocument10 pagesMitsubishi: U.S. ApplicationsEdixo ReyesNo ratings yet

- 00602-17620-3xx TRD 1mz Supercharger ManualDocument24 pages00602-17620-3xx TRD 1mz Supercharger ManualSupaTouring60% (5)

- Crank Case Inspection ProcedureDocument6 pagesCrank Case Inspection ProcedureSid ACHARYANo ratings yet

- Vta28 G5Document2 pagesVta28 G5rohizat75% (12)

- Manual Peças MotorDocument31 pagesManual Peças MotorArildo Chaves de AndradeNo ratings yet

- Apl Komatsu s6dDocument8 pagesApl Komatsu s6dirawan budi santosaNo ratings yet

- Land Rover Ilustrated Parts Catalogue 101fcDocument399 pagesLand Rover Ilustrated Parts Catalogue 101fcDavid SeddonNo ratings yet

- Sulzer ZAV 40Document59 pagesSulzer ZAV 40Curtler Paquibot100% (1)

- K1156925544Document1 pageK1156925544dikki newNo ratings yet

- TE360 - (11Kw - 2001)Document2 pagesTE360 - (11Kw - 2001)rolandNo ratings yet

- LAB: TWO STAGE AIR COMPRESSOR TESTDocument4 pagesLAB: TWO STAGE AIR COMPRESSOR TESTAmit Singh DehuryNo ratings yet

- Ignition Control - Ignition Coils ControlDocument1 pageIgnition Control - Ignition Coils ControlMisa GamezNo ratings yet

- Amp PDFDocument48 pagesAmp PDFIlyaNo ratings yet

- Impulse Turbine and Reaction TurbineDocument5 pagesImpulse Turbine and Reaction Turbinerahul100% (1)

- CaT G3516LE HQ PDFDocument4 pagesCaT G3516LE HQ PDFzona amrullohNo ratings yet

- 40-Service Manual TDI Injection and Glow Plug System (6-Cyl 3 0 LTR 4-Valve Common Rail ASB &Document112 pages40-Service Manual TDI Injection and Glow Plug System (6-Cyl 3 0 LTR 4-Valve Common Rail ASB &hayabusarulezNo ratings yet

- Solex Vacuum PipesDocument5 pagesSolex Vacuum Pipesvanapeer100% (1)

- 2004 Volkswagen Jetta Sedán L4-2.0L Engine ControlsDocument4 pages2004 Volkswagen Jetta Sedán L4-2.0L Engine ControlsRogelio ArenasNo ratings yet

- Ship Survey Status Report: OnegatesystemDocument2 pagesShip Survey Status Report: OnegatesystemKadhafi AznurNo ratings yet

- Compressed Air Rotary Vane EngineDocument13 pagesCompressed Air Rotary Vane EngineSanjith KorutlaNo ratings yet

- SZ 150.1 MergedDocument116 pagesSZ 150.1 MergedArif MamunNo ratings yet

- Camshaft Recommendation FormDocument3 pagesCamshaft Recommendation Formcrower_scribdNo ratings yet

- 250 KVA Generator Technical SpecificationsDocument3 pages250 KVA Generator Technical Specificationscrawn06No ratings yet

- Dgca Module 15 Part 2Document24 pagesDgca Module 15 Part 2nishat529100% (1)

- What Is Air Fuel (Fuel Air) Ratio - Rich, Lean, Stoichiometric Mixture Used For Ic EngineDocument1 pageWhat Is Air Fuel (Fuel Air) Ratio - Rich, Lean, Stoichiometric Mixture Used For Ic EngineNopparat SvtNo ratings yet

- Engines and Power Units DatabaseDocument30 pagesEngines and Power Units DatabaseLuis Eduardo Albarracin RugelesNo ratings yet