Professional Documents

Culture Documents

2011524163525370

Uploaded by

io1_roOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2011524163525370

Uploaded by

io1_roCopyright:

Available Formats

Lanus Industries LLC USA

API 602 Forged Steel Valve

CopyRight@2007Lanus Industries LLC USA.All right reserved.

Lanus Industries LLC USA

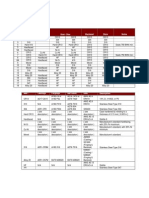

ITEMS

1

2

3

4

5

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

DESCRIPTIONS

Catalogue front Cover Page

Descriptions

Introductions

Our cooperated factories with API 6A and API 6D monogram license holder and

our cooperated plant is certified to ISO9001: 2000.

Lanus Products Forged Steel Valve Products

Forged Steel Valve Body N Bonnet Materials

Forged Steel Valve Component Part Materials

Cl 800# 900# 1500# 2500# Forged Steel Gate Valve NPT BSPT SW BW

Cl 800# Forged Steel Creyogenic Gate Valve NPT BPST SW BW

Cl 800# 1500# Forged Steel Extended Bonnet Gate Valve NPT BSPT SW BW

Cl 150# 300# 600# Fogred Steel Bellow Seal Gate Valve NPT BSPT SW BW

Cl 150 300 600 900 1500# Forged Steel Gate Valve. FE RF N RTJ

Cl 900 1500 2500# Forged Steel Pressure Seat Gate Valve. FE RF N RTJ

Cl 800# Forged Steel Globe Valve.NPT BSPT SW BW

Cl 900 1500# Forged Steel Globe Valve NPT BSPT SW BW

Cl 900 1500 2500# Forged Steel Pressure Seal Globe Valve NPT BSPT SW BW

Cl 800# Forged Steel Bellow Seal Globe Valve NPT BSPT SW BW

Cl 150 300 600 900 1500# Forged Steel Globe ValveFE RF RTJ

Cl 900 1500 2500# Forged Steel Pressure Seal Globe Valve FE RF RTJ

Cl 800# Fogred Steel Y Pattern Globe Valve NPT BSPT SW BW

Material Specificaiton of Forged Steel Piston Check and Swing Check Valve

Cl 900 1500# Fogred Steel Piston Check Valve and Swing Check Valve

Cl 900 1500 2500# Fored Steel Pressure Seal Piston Check Valve and Pressure

Seal Swing Check Valve

Cl 150 300 600# Forged Steel Piston Check Ball Check and Swing Check Valve.

Flange end RF RTJ

Cl 900 1500 2500# Forged Steel Pressure Seal Piston Check Valve.Flange end

RF RTJ.

Chemical Compositions and Mechanical Properties Cast Steel & Stainless

Steel and Alloy Steel

Cl 150 300 600 900 1500 2500# Forged Steel Valve working temperature and

Working pressure

Engineering data

ANSI Cl 150~2500# Flange Table

Alloy materials specifications

Duplex material specifications

Supper Duplex materials specifications

Comparison of Standard Specifications for OSNA-10 (CuNi 90/10). OSNA-30

(CuNi 70/30)

6 Moly 6% Molybdenum Stainless Steels

ASTM Standard code numbers and application

API Standard Code numbers and applicant

BS Standard Code numbers and applicant

Catalogue back cover page

CopyRight@2007Lanus Industries LLC USA.All right reserved.

PAGE REFERENCE

1

2

3

4

5

6

7

8~11

12

13

14

15~16

17

18

19

20

21

22~23

24

25

26

27

28

29

30

31

32~33

34~35

36~41

42

43

44

45

46~47

48~51

52~53

54

55

Lanus Industries LLC USA

Welcome to LANUS INDUSTRIES LLC

The LANUS is one of the leading wholesale suppliers of API 6D,API 608,API 6A, API607 standard VALVES in

the United States.

LANUS is headquartered in W.O USA.

Our business mainly is supplied for North and South America and North Sea Oil and Gas industries. We

manufactured all kinds of valves supplying for Oil and Gas Plant, petrol chemical, oil refineries and power plant.

We also OEM manufacturing in accordance to customers design and requirement.

Our valves are manufactured by our cooperated plant in Maxico,Europe,China,India,Korea,Taiwan and Japan

etc,. Technical engineering and Q.C control engineer permanent stay at our cooperated plant.and our

distributors covering North & South America,Europe,Middle,S.E.A countries etc,.

INTRODUCTION

Thank you for your interest in Lanus Industries LLC USA. I am pleased to take this opportunity to introduce

our company and product line to you.

Lanus was incorporated in 2005 with corporate headquarters, manufacturing and supplies API 6D, API 6A,

API 607 valves. Our cooperated factories with API 6A,API 6D and API 607 monogram license holder and our

cooperated plant is certified to ISO9001: 2000.

LANSU is proud to offer the widest product line of any valve manufacturer in the world. This line

includes, but is not limited to:

Cast Steel,Forged Steel,Stainless Steel,Alloy Steel,Copper Alloy Gate, Globe and Check Valves, Plug Valve,

HPT Butterfly Valve, Kniew Gate Valve, Safety and Relief Valve, Lever Guage Cock, Slide Expansion Joints,

Unit body,2pcs Split body Floating Ball Valve,2pcs and 3pcs body Trunnion Mounted Ball Valve,metal to metal

Seated Ball Valve, Orbit type Ball Valve and Plug Valve

Fabricated Through Conduit Pipeline Gate Valves

Pressure Seal Valves

Bellow Seal Valves

Creyogenic Valves etc,.

Sub-Sea Valves

Low and High Temperature Valve

Lanus is unique in that all our valves are available in all ANSI and API pressure classes and virtually any

metallurgy required. From cast iron,ductile iron,carbon steel and alloy steel to stainless steel and exotics

including titanium and Aluminium Bronze, Lanus can accommodate the most ordinary and extraordinary

requirements.

We also kept some stock at our Cooperated Plant for prompt shipment, and level of services, product availability and

competitive pricing rarely found in our industry.

We thank you for interest in Lanus and look forward to providing solutions to your requirements. If you have

any questions, please feel free to contact our office anytime.

Sincerely,

Managing Sales Director

Lanus Industries LLC USA

CopyRight@2007Lanus Industries LLC USA.All right reserved.

Lanus Industries LLC USA

Our cooperated factories with API 6A, API 6D, API 607

monogram license holder and our cooperated plants is certified

to ISO 9001: 2000.

API 6A API 6D API 607

CERTIFICATION

TUV CERTIFICATE

DNV CERTIFICATE

ISO 9001: 2000 CERTIFICATE

CopyRight@2007Lanus Industries LLC USA.All right reserved.

Lanus Industries LLC USA

Lanus Fogred Steel Valve

CopyRight@2007Lanus Industries LLC USA.All right reserved.

Lanus Industries LLC USA

MATERIALS

LIV valves are manufactured in a wide range of materials, supplied by the best available steel mills, forged by

well known forgery with outstanding equipment and experience. All the materials can be certifield in the chemical

composition and the mechanical characteristic.

BODY AND BONNET STANDARD MATERIALS

Materials

ASTM

A105

ASTM A350 LF2

ASTM A182 F11

ASTM A182 F22

ASTM A182 F5

ASTM A182 F9

ASTM A182 F304

ASTM A182 F316

Description

Forged Steel

Low Termperature

Carbon Steel

1.1/4%Cr. %Mo

Alloy Steel

2.1/4%Cr 1% Mo

Alloy Steel

5% Cr.1/ 2% Mo

Alloy Steel

9% Cr. 1% Mo

Alloy Steel

18% Cr. 8% Ni

Stainless Steel

18% Cr. 8% NI,

2%Mo

Stainless Steel

Service Recommendations

General services: oil, oil vapor, gas, steam and

water

Low temperature applications

Casting Eq.

A105

Temperature

-40 to 797 F

A352-LCB

To minimize Graphitization

A217 WC6

-50 to 650 F

max

-20 to 1100F

For service requiring greater strength than F11

A217-WC9

-20 to 1100F

Corrosive/ erosive refinery use

A217-C5

-20 to 1100F

Services involving media with higher sulphur

content

Corrosive & cryogenic service

A217-C12

-20 to 1100F

A351-CF8

-20 to 1100F

Superior resistance to corrosion

A351-CF8M

Up to 100F-

BODY AND BONNET SPECIAL MATERIALS

HASTELLOY

INCONEL

INCOLOY

MONEL

TITANIUM

ASTM A182

F51

ASTM A182

F44

Nickel Alloy

Nickel Alloy

Excellent corrosion resistance in hydrochloric acid

Nuclear applications

High temp

High temp

Nickel Copper Alloy

Metal

Ferric Austenitic

Stainless Steel

Austenitic Stainless

Steel

Corrosive service, resistant to sea water, acids and alkalies

Good resistance to corrosion with low specific weight

High strength, resistance to corrosion, pitting and stress corrosion

in chloride media

Very high strength, high resistance to corrosion

450deg C

BODY AND BONNET CHEMICAL COMPOSITION

Body And Bonnet Material

ASTM Material

ASTM A105

ASTM A350 LF2

C

%

Mn

%

P

%

S

%

Si

%

Nl

%

Cr

%

0.35%

0.60

1.05

0.60

1.35

0.30

0.60

0.30

0.80

0.30

0.60

2.0max

0.04 max

0.050max

0.35

0.035

0.040

0.030

0.040

0.15

0.30

0.50max

0.30

CopyRight@2007Lanus Industries LLC USA.All right reserved.

0.50max

Co

%

Ot

her

4.00

0.44

6.00

0.65

0.10

0.040

0.040

0.50

1.00

0.44

ASTM 182 F11

[Class 2 & 3]

0.20

1.00

1.50

0.65

0.05

0.040

0.040

0.50 max

2.00

0.87

ASTM 182 F22

0.15

2.50

1.13

0.08 max

0.040

0.030

1.00max

8.00

18.00

ASTM 182 F304

11.00

20.00

0.08 max

2.0max

0.040

0.030

1.00max

10.00

15.00

2.00

ASTM 182 F316

14.00

18.00

3.00

Note: these charts are for reference only. LIV recommends customer engineers to analize service reqirements and specify the materials they consider

optimium, LIV cannot be held liable for any damage occurred due to the use of the tables.

ASTM 182 F5

0.15

Mo

%

Lanus Industries LLC USA

MATERIALS

The following tables suggest standard combination of body and bonnet materials and trim ( stem, disc or wedge,

seat) composition. Different combinations are available upon request.

TRIM STANDARD MATERIALS

Materials

13% Cr,Type 410

Stainless Steel

13% Cr,Type 410

Hardfacing

Type 316

Stainless

Monel

NACE

Description

Service Recommendations

Temperature

For oil and oil vapors and general services with heat

Treaded seats and wedges

Universal trim for general service requiring long life

high temp

18% Cr, 8% Nl, 2% Mo Stainless Steel

For liquids and gasses corrosive

Up to 850deg F

Nickel Copper Alloy

Specialy treated 316 Trim combined with B7M

Botls and 2HM Nuts

Corrosive service such as acids,alkalies,Salt solutions

To meet NACE MR-01-75 requirements

Up to 850deg F

Premium trim, suitable for severe services

Up to 1200deg F

Stelite

1100F

CHEMICAL COMPOSITION

Trim Materials & Bolting Materials

ASTM Material

C

%

Mn

%

P

%

S

%

Si

%

Ni

%

Cr

%

Mo

%

Co

%

Other

ASTM A276

Type 410

0.15max

1.00max

0.040

0.030

1.00max

ASTM A479

Type 304

0.08max

2.00max

0.045max

0.030max

1.00max

ASTM A479

Type 316

0.08max

2.00max

0.045max

0.030max

1.00max

ASTM B164

MONEL UNS NO4400

0.30max

2.00max

0.024

0.50max

8.00

10.50

10.00

14.00

63.00min

11.50

13.50

18.00

20.0

16.00

18.00

-

Fe:2.5max

STELLITE Gr. 6

1.00max

1.00max

1.00

3.0max

28.0

28.0

34.0

-

ASTM A193 B7

0.65

1.10

2.00max

0.035max

0.040max

0.030max

0.40min

0.08max

1.00max

2.00max

0.040max

0.045

0.050max

0.30

1.00max

0.15

0.25

-

ASTM A194 2H

ASTM A194 Gr. 8

18.00

20.00

0.75

1.20

18.00

20.00

0.045max

0.15

0.35

1.00max

ASTM A193 B8

0.37

0.49

0.08max

Fe: 3.0max

W:4.0.CO :B

al

-

8.00

10.50

8.00

10.5

ALL VALVES ARE IN STRICT ACCORDANCE WITH THE FOLLOWING

STANDARDS

API 598

Valve inspection and Test

ASME B 16.5

Steel Pipe Flanges and Fittings

ASME B 16.10

Face to Face and End to End Dimensions of

Ferrous Valves

BS 6755

Testing of valves.-

ASME B 16.11

Forged Steel Fittings, Socket Welding and Threaded

NACE Standard

Material Requirement . Sulide Stress

Cracking Resistant

ASME B 16.34

Steel Valves, Flange and Buttwelded Ends

MR 01.75

Metallic Material for Oil Field

Equipment

MSS SP 25

Standard Marking System for Valves

Fittings, Flanges and Unions

DIN 3202

End to End dimensions of ferrous valves.

CopyRight@2007Lanus Industries LLC USA.All right reserved.

BS 5352

Specific for Cast and Forged Steel

Wedge Gate, Globe, Check and Plug

Valves.

Screwed and Socket-Weld

Lanus Industries LLC USA

Cl 150~800Lb Forged Steel Gate ValveBolted

Bonnet,Welde Bonnet - SE,SW,BW

Cl 150 300 600 Lbs

Cl 800 Lbs

Cl 800 Lbs

Cl 800 Lbs

Technical Specification

Cl 800 Lbs

Cl 800 Lbs

Design Standard

API602

Pattern

Pressure:Class150600&Class800

Pressure-Temperature

Rating

ASME B16.34

Bolted Bonnet or Welded Bonnet

Face-Face

Factory Standard

Outside Screw Stem or Inside Screw Stem

Socket-welded Ends

ASME B16.5

Full Port or Reduced Port

Threaded Ends

ASME B1.20.1

Solid Wedge Gate

Inspection &Test

API598

Treaded Ends or SW Ends

Cl 150 300 600 800 Lb

Main Dimensions & Weight/Kgs

Pressure

Struture

Size

Main Dimension

mm

Class 150

Class 300

Class 600

Class 800

Class 150

Class 300

Class 600

Class 800

OS&Y

Screw

Bonnet

In

RP

RP

RP

8

10

15

20

25

32

40

50

8

10

15

20

25

32

40

50

-

8

10

15

20

25

32

40

50

8

10

15

20

25

32

40

50

1/

4

3/

8

1/

2

3/

4

CopyRight@2007Lanus Industries LLC USA.All right reserved.

1

11/4

11/2

2

1/

4

3/

8

1/

2

3/

4

1

11/4

11/2

2

-

Weight/Kgs

d

FP

RP

FP

SE

SW

7

10

10

13

18

24

29

36.5

7

10

10

13

18

24

29

36.5

-

7

10

13

18

24

29

36.5

46.5

7

10

13

18

24

29

36.5

46.5

79

79

79

92

111

120

120

140

178

79

79

79

92

111

120

120

140

178

166

166

166

169

193

236

146

283

330

169

169

169

182

208

254

290

330

372

100

100

100

100

125

160

160

189

200

100

100

100

100

125

160

160

180

200

2.2

2.2

2.2

2.2

4.7

5.9

6.9

11.1

2.2

2.2

2.2

2.2

4.6

5.9

6.9

11.1

-

2.2

2.2

2.2

4.3

5.9

6.9

11.1

15.2

2.4

2.4

2.3

4.8

6.1

7.2

11.2

14.1

1/

4

3/

8

1/

2

3/

4

1

11/4

11/2

2

1/

4

3/

8

1/2

3/

4

1

11/4

11/2

2

Lanus Industries LLC USA

Cl 900Lb Forged Steel Gate Valve

Cl 900 Lbs

Cl 900 Lbs

Fig. ZSWT(BO)

Fig. ZSWT(PO)

Pattern

Technical Specification

Bolted Bonnet/Welded Bonnet/Pressure Sealed Bonnet

Full Port

Solid Wedge Gate

Treaded Ends or SW Ends

Design Standard

Pressure-Temperature Rating

Face-Face

Socket-welded Ends

Threaded Ends

Inspection & Test

Standard Material Specifications

NO

Part Name

AS to

ASTM

CS to ASTM

Type F22

Type

F304(L)

A182

F304(L)

Body

A105

A182 F22

Seat Ring

A276 420

A276 304

Wedge

A276 430&410

A182 F304

4

5

Stem

A182 F6

A182 F304

Gasket

Corrugated SS+graphite

Bonnet

A105

A182 F22

Bonnet Bolt

A193 B7

A193 B16

Pin

A276 420

Gland

Standard Material Specifications

NO

SS to ASTM

Type A105

A276 304(L)

A182

F316(L)

A276

316(L)

A182

F316(L)

A182

F316(L)

A182

F316(L)

A193 B8M

A276 420

A276 410

Part Name

Type

F316(L)

A182

F304(L)

A182

F304(L)

SS+PTFE

A182

F304(L)

A193 B8

A182 F304(L)

Gland

A193 B7

A193 B16

A193 B8

Eyebolt

Note: Other materials like F51 Duplex are available upon request.

10

API602

ASME B16.34

Factory Standard

ASME B16.11

ASME B1.20.1

API598

CS to ASTM

AS to ASTM

SS to ASTM

Type A105

Type F22

Type F304(L)

Type F316(L)

11

Gland Flange

A105

A182 F11

A182 F304(L)

A182 F316(L)

12

Gland Nut

A194 2H

A194 4

A194 8

A194 8M

13

Yoke Nut

A276 420

A194 4

A194 8

A194 8M

14

H.W.Lock Nut

A194 2H

15

Nameplate

SS

16

Handwheel

A197

17

Bearing Gasket

18

Stem Packing

A473 431

Flexible

Graphite

PTFE

A182

F316(L)

Suitable Medium

W.O.G.etc

W.O.G.etc

HNO3,CH3OOH etc

A193 B8M

Suitable Temperature

-29 425 font

-29 550 font

-29 180 font

Cl 900 Lb

SIZE

PRESSURE

Cl 900

8

10

15

20

25

32

40

50

1/ 4

1/ 2

3/ 4

1

1

1/1/4

1.1/2

2

d

BB/WB

10

13

18

24

29

36.5

46.5

CopyRight@2007Lanus Industries LLC USA.All right reserved.

Main Dimensions & Weight/Kgs

L

H

PB

BB/WB PB BB/WB

102

166

102

166

13

102

140

169

18

111

140

193

24

120

140

230

29

120

178

246

36.5

140

178

283

46.5

178

216

330

PB

321

321

321

380

414

502

W

BB/WB

120

120

120

125

160

160

180

200

PB

125

125

160

160

180

200

Weight ( Kg )

BB/WB

PB

3.6

3.5

3.4

11.5

3.8

11.0

7.8

10.2

11.9

20.5

12.2

21.7

21.9

43.5

Lanus Industries LLC USA

Cl 1500 Lb Forged Steel Gate Valve

Cl 900 Lbs

Cl 1500 Lbs

Fig. ZSWT(BO)

Fig. ZSWT(PO)

Pattern

Technical Specification

Bolted Bonnet/Welded Bonnet/Pressure Sealed Bonnet

Full Port

Solid Wedge Gate

Treaded Ends or SW Ends

Design Standard

Pressure-Temperature Rating

Face-Face

Socket-welded Ends

Threaded Ends

Inspection & Test

API602

ASME B16.34

Factory Standard

ASME B16.11

ASME B1.20.1

API598

Standard Material Specifications

NO

Part Name

AS to

ASTM

CS to ASTM

Type A105

Type F22

Type F304(L)

A182 F304(L)

Body

A105

A182 F22

Seat Ring

A276 420

A276 304

Wedge

A276 430&410

A182 F304

Stem

A182 F6

A182 F304

Gasket

Corrugated SS+graphite

Bonnet

A105

A182 F22

Bonnet Bolt

A193 B7

A193 B16

Pin

Gland

A276 410

10

Gland

Eyebolt

A193 B7

A276 420

A182 F304(L)

A193 B16

A193 B8

Part Name

Type

F316(L)

A182

F316(L)

A276 304(L)

A276 316(L)

A182

A182 F304(L)

F316(L)

A182

A182 F304(L)

F316(L)

SS+PTFE

A182

A182 F304(L)

F316(L)

A193 B8

A193 B8M

A276 420

NO

SS to ASTM

CS to ASTM

AS to ASTM

SS to ASTM

Type A105

Type F22

Type F304(L)

Type F316(L)

11

Gland Flange

A105

A182 F11

A182 F304(L)

A182 F316(L)

12

Gland Nut

A194 2H

A194 4

A194 8

A194 8M

13

Yoke Nut

14

H.W.Lock Nut

15

Nameplate

A276 420

A194 2H

A194 4

A194 8

A194 8M

SS

16

Handwheel

A197

17

Bearing Gasket

A473 431

18

Stem Packing

Flexible

Graphite

PTFE

A182

F316(L)

Suitable Medium

W.O.G.etc

W.O.G.etc

HNO3,CH3OOH etc

A193 B8M

Suitable Temperature

-29 425 font

-29 550 font

-29 180 font

Note: Other materials like F51 Duplex are available upon request.

Cl 1500 Lb

SIZE

PRESSURE

CL 1500

8

10

15

20

25

32

40

50

1/ 4

1/ 2

3/ 4

1

1

1/1/4

1.1/2

2

Main Dimensions & Weight/Kgs

D

L

H

BB/WB

PB

BB/WB

PB

BB/WB

102

166

10

102

169

13

13

102

140

169

18

18

111

140

193

24

24

120

140

230

29

29

120

178

246

36.5

36.5

140

178

283

46.5

46.5

178

216

330

CopyRight@2007Lanus Industries LLC USA.All right reserved.

10

PB

321321

321

321

380

414

502

W

BB/WB

120

120

120

125

160

160

180

200

PB

125

125

125

160

160

180

200

Weight ( Kg )

BB/WB PB

3.6

3.5

3.4

11.5

3.8

11.0

7.8

10.2

11.9

20.5

12.2

21.7

21.9

43.5

Lanus Industries LLC USA

Cl Valve 900Lb 1500 2500Lb Forged Steel

Presure Seal Gate Valve

Cl 900 & 1500

Cl 2500 lBS

Standard Material Specifications

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Part Name

Body

Seat

Wedge

Stem

Pressure Seat

Pressure Ring

Bonnet

Gland Eyebold

Pin

Stem Packing

P.S.Lock Nut

Gland

Gland Flange

Nut

Yoke Nut

Retaining Nut

Handwheel

H.W.Lock Nut

Oil Cup

Suitable Medium

Suitable Temperature

CS to ASTM

Type A105

A105

A276 420

A276 430&410

A182 F6

A105

AS to ASTM

Type F22

A182 F22

A276 304

A182 F304

A182 F304

A182 F304

A276 304L

A182 F22

A193 B16

A105

A193 B7

SS to ASTM

Type F304(L)

A182 F304(L)

A276 304(L)

A182 F304(L)

A182 F304(L)

A182 F304(L)

A182 F304(L)

A193 B8(M)

A276 420

Flexible Graphite

A194 2H

A182 F304(L)

PTFE

A194 4

A194 8

A276 F420

A216 WCB

A194 2H

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

A182 F316(L)

F316(L)

A276 316L

A182 F316(L)

A194 8M

A182 F304

A351 CF8

A194 4

A194 8

A194 8M

A194 8

A194 8M

A194 8

A194 8M

A276-410

A194 2H

A194 4

A197

A194 2H

A194 4

Brass

W.O.G.etc

W.O.G.etc

-29 425 font

-29 550 font

Note: Other materials are available upon request.

HNO3,CH3OOH etc

-29 180 font

Cl 900 1500 2500Lb

Main Dimensions & Weight/Kgs

NPS

L

H(OPEN)

W

Weights

1/2~

3/4~

1~

1-1/4~

1-1/2~

2~

140

186

321

160

11.5

12.3

140

186

321

160

10.8

11.6

140

186

321

180

10.5

10.8

178

232

380

200

19.6

26.0

178

232

414

250

21.0

28.4

216

279

502

280

55.4

60.0

CopyRight@2007Lanus Industries LLC USA.All right reserved.

11

Weight/Kgs

BB/WB

PB

-

Lanus Industries LLC USA

Cl 800 Lb Forged Steel Creyogenic Gate Valve

Standard Material Specifications

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Suitable Temperature

Part Name

AS to ASTM

SS to ASTM

Type LF2

Type LF3

A350 LF2

A350 LF3

A276 420

A276 410

A350 LF2

A350 LF3

Corrugated SS + graphite

A350 LF2

A350 LF3

A193 B7

A193 B7

A182 F6

A182 F6

Flexibel Graphite

A276 420

A193 B7

A193 B16

A276 410

A105

A182 F11

A194 2H

A194 4

Body

Seat Ring

Wedge

Gasket

Bonnet

Bonnet Bolt

Stem

Stem Packing

Pin

Gland Eyebolt

Gland

Gland Flange

Gland Nut

Yoke Nut

Bearing Gasket

Nameplate

H.W.Lock Nut

Handwheel

40

Type F304(L)

A182 F304(L)

A276 304(L)

A182 F304(L)

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

SS + PTFE

A182 F304(L)

A193 B8

A182 F304(L)

A182 F316(L)

A193 B8M

A182 F316(L)

PTFE

A276 304

A193 B8

A182 F304(L)

A182 F304(L)

A194 8

A193 B8M

A182 F316(L)

A182 F316(L)

A194 8M

A194 8

A194 8M

A276 420

A473 431

SS

A194 2H

A194 4

A197

101

196

Note: Other materials are available upon request.

Cl 800Lbs

Main Dimensions & Weight/Kgs

NPS

L

H(OPEN)

W

Weights/Kgs

3/8

79

330

100

Bolted

Welded

CopyRight@2007Lanus Industries LLC USA.All right reserved.

1/2

92

333

100

7.1

6.4

3/4

111

360

125

9.4

8.7

12

1

120

407

160

13.5

12.2

1-1/4

120

475

160

15.0

13.4

1-1/2

140

475

180

17.8

15.2

2

178

551

200

28.0

26.0

Lanus Industries LLC USA

Cl 800 1500 Lb Forged Steel Extened Body Gate Valve

Extened Body Gate V

Pressure:Class800-Class1500

Technical Specification

Pattern

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Buttwelding Ends

Socked-welded Ends

Threaded Ends

Inspection & Test

API602/API606

ASME B16.34

Factory Standarrd

ASME B16.5

ASME B16.25

ASME B16.11

ASME B1.20.1

API598

Bolted & Welded Bonnet

Reduced Port

Solid Wedge Gate

Treaded Ends/SW Ends

Buttwelded Ends/Treaded Ends/SW Ends

Cl 800 1500 Lb

Pressure

Main Dimensions & Weight/Kgs

Main Dimension

Size

L1

Cl 800 lb

Cl 1500 lb

15

20

25

32

40

50

15

20

25

32

40

50

1 /2

3 /4

1

11/4

11/2

2

1 /2

3 /4

1

11/4

11/2

2

10

13

19

24

29

36.5

10

13

19

24

29

36.5

CopyRight@2007Lanus Industries LLC USA.All right reserved.

K

108

108

127

127

152

152

108

108

127

127

152

152

K1

108

127

127

152

152

-

K2

152

150

184

184

193

197

152

150

184

184

193

197

K3

108

108

127

127

152

152

108

108

127

127

152

152

13

K

153

153

182

182

216

216

153

153

182

182

216

216

K1

153

182

182

216

216

-

L2

K2

192

215

239

239

258

262

192

215

239

239

258

262

Weight(kg)

K3

153

153

182

182

216

216

153

153

182

182

216

216

151

158

185

239

243

279

151

158

185

239

243

279

100

100

125

160

160

180

100

100

125

160

160

180

k2

2.5

2.7

4.5

4.8

8.5

10.5

2.5

2.7

4.5

4.8

8.5

10.5

K/K1/K3

2.2

2.4

3.4

4.1

8.0

9.8

2.2

2.4

3.4

4.1

8.0

9.8

Lanus Industries LLC USA

Cl 150 300 600 Lb Forged Steel Bellow Seal Gate Valve.SE,SW,BW,FE

Standard Material Specifications

NO.

Part Name

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Body

Disc

Gasket

Bonnet Bolt

Stem

Bellow Pipe

Bonnet

Stem Packing

Pin

Gland

Gland Eyebolt

Gland Flange

Gland Nut

Bearing Washer

Yoke Nut

Nameplate

Handwheel

H.W.Nut

Suitable Medium

Suitable Temperature

CS to ASTM

Type A105

A105

A276 420

A193 B7

A182 F6

AS to ASTM

Type A182 F22

A182 F22

A276 304

Corrugated SS + graphite

A193 B16

A182 F304

SS to ASTM

Type A182 F304

A182 F304(L)

A276 304(L)

SS + PTFE

A193 B8

A182 F304(L)

Type A182 F316(L)

A182 F316(L)

A276 316(L)

A193 B8M

A182 F316(L)

SS

A105

A193 B7

A194 2H

A182 F22

Flexible Graphite

A276 420

A276 420

A193 B16

A216 WCB

A194 4

A182 F604(L)

A182 F316(L)

PTFE

A182 F304

A182 F304

A193 B8

A193 B8M

A351 CF8

A194 8

A194 8M

SS

A276 410

SS

A197

A194 2H

W.O.G.etc

-29 ~425

A194 4

W.O.G.etc

-29 ~550

A194 8

A194 8M

HNO3,CH3OOH etc

-29 ~180

Cl 150, 300, 600 Lbs

Main Dimensions & Weight/Kgs

NPS

Conv.

Full

L or C

H(OPEN) B

W or A

Bolted

Weights

Welded

3/8

3/8

262

262

90

80

80

2.2

2.0

CopyRight@2007Lanus Industries LLC USA.All right reserved.

3/4

1/2

296

90

90

90

2.2

2.0

3.0

2.8

14

1

3/4

1-1/4

1

1-1/2

1-1/4

2

1-1/2

353

110

412

130

470

130

531

180

110

4.2

3.8

127

7.9

127

12.4

12.0

127

14.8

13.6

7.5

Lanus Industries LLC USA

Cl 150 300 600 Lbs Forged Steel Gate Valve.Flange End RF N RTJ

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Solid Wedge Gate

Flange Ends or Butt-welding Elds

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

Standard Materials Specifications

NO.

CS to ASTM

AS to ASTM

Type A105

Type F22

A105

A182 F22

A276 420

A276 304

A276 430&410

A182 F304

A182 F6

A182 F304

Corrugated SS+graphite

A105

A182 F22

A193 B7

A193 B16

A276 420

A276 410

A193 B7

A193 B16

A105

A182 F11

A194 2H

A194 4

Part Name

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Body

Seat Ring

Wedge

Stem

Gasket

Bonnet

Bonnet Bolt

Pin

Gland

Gland Eyebolt

Gland Flange

Gland Nut

Yoke Nut

H.W.Lock Nut

Nameplate

Handwheel

Bearing Gasket

Stem Packing

Suitable Medium

Suitable Temperature

A194 2H

SS to ASTM

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

A182 F316(L)

SS+PTFE

A182 F316(L)

A193 B8M

Type F304(L)

A182 F304(L)

A276 304(L)

A182 F304(L)

A182 F304(L)

A182 F304(L)

A193 B8

Type F51

F51

F51

F51

F51

F51

A1938M

A182 F316(L)

A182 F316(L)

A193 B8M

A182 F316(L)

A194 8M

A182 F304

A182 F304(L)

A193 B8

A182 F304(L)

A194 8

A276 420

A194 8

SS

A197

A473 431

A194 4

A182 F316(L)

A193 B8M

A182 F316(L)

A194 8M

A194 8M

Flexible Graphite

PTFE

W.O.G.etc

W.O.G.etc

HNO3,CH2OOH etc

-29 425 font

-29 550 font

-29 180 font

Note: Other materials are available upon request

Sea Water

-

Class 150 300 600 Lb

Pressure

Class150

Class300

Class 600

Main Dimensions & Weight/Kgs

Size

Mm

15

20

25

32

40

50

65

15

20

25

32

40

50

65

15

20

25

32

40

50

65

in

1/2

3/4

1

11/4

11/2

2

21/2

1

11/4

11/2

2

21/2

1

11/4

11/2

2

21/2

10

10

12.7

19.1

24

31.8

38.1

48.5

10

12.7

19.1

24

31.8

38.1

48.5

10

12.7

19.1

24

31.8

38.1

48.5

CopyRight@2007Lanus Industries LLC USA.All right reserved.

108

108

117

127

140

165

178

190

140

152

165

178

190

216

241

165

190

216

229

241

292

330

108

108

117

127

140

165

216

241

140

152

165

178

190

216

241

165

190

216

229

241

292

330

15

119

119

130

140

153

178

190

203

151

165

178

191

203

232

257

165

190

216

229

241

295

333

Weight/Kgs

162

162

162

211

238

257

282

357

162

162

211

238

257

282

357

162

162

211

238

257

282

357

100

100

100

125

125

160

180

200

100

100

125

125

160

180

200

100

100

125

125

160

180

200

3.0

3.5

5.5

6.8

10.4

14.4

24.5

3.6

4.9

7.0

9.4

13.3

18.0

26.2

4.2

5.8

8.8

12.1

15.6

19.5

32.0

Lanus Industries LLC USA

Cl 900 1500 Lbs Gate Valves. Flange Ends RF N RTJ

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Solid Wedge Gate

Flange Ends or Butt-welding Elds

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

Standard Material Specifications

NO.

Part Name

CS to ASTM

Type A105

A105

A276 420

A276 430&410

A182 F6

A105

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

AS to ASTM

Type F22

A182 F22

A276 304

A182 F304

A182 F304

A182 F304

A276 304L

A182 F22

A193 B16

SS to ASTM

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

A182 F316(L)

F316(L)

A276 316L

A182 F316(L)

Type F304(L)

A182 F304(L)

A276 304(L)

A182 F304(L)

A182 F304(L)

A182 F304(L)

Body

Seat

Wedge

Stem

Pressure Seat

Pressure Ring

Bonnet

A105

Gland Eyebold

A193 B7

Pin

A276 420

Stem Packing

Flexible Graphite

P.S.Lock Nut

A194 2H

A194 4

Gland

A276 F420

Gland Flange

A216 WCB

Nut

A194 2H

A194 4

Yoke Nut

Retaining Nut

A194 2H

A194 4

Handwheel

H.W.Lock Nut

A194 2H

A194 4

Oil Cup

Suitable Medium

W.O.G.etc

W.O.G.etc

Suitable Temperature

-29 425 font

-29 550 font

Note: Other materials are available upon request.

A182 F304(L)

A193 B8(M)

A182 F304(L)

PTFE

A194 8

A194 8M

A182 F304

A351 CF8

A194 8

A276-410

A194 8

A197

A194 8

Brass

A194 8M

A194 8M

A194 8M

HNO3,CH3OOH etc

-29 180 font

Dimensions (mm) and Weights (Kg

PRESSURE

900

1500

SIZE

15

20

25

32

40

50

15

20

25

32

40

50

1/ 2

3/ 4

1

11/4

11/2

2

1/ 2

3/ 4

1`

11/4

11/2

2

d

13

18

24

29

36.5

46.5

13

18

24

29

36.5

46.5

CopyRight@2007Lanus Industries LLC USA.All right reserved.

Cl 900 1500 Lb

Main Dimensions & Weight/Kgs

L

H

LRF

216

229

254

279

305

368

216

229

254

279

305

368

LBW

216

229

254

279

305

368

216

229

254

279

305

368

216

229

254

279

305

371

216

229

254

279

305

371

16

BB/WB

197

211

238

257

276

320

197

211

238

257

276

320

PB

321

321

321

380

414

502

321

321

321

380

414

502

W

125

125

160

160

180

240

125

125

160

160

180

240`

Weight ( Kg )

BB/WB

7.2

11.5

15.6

16.2

22.6

28.2

7.2

11.5

15.6

16.2

22.6

28.2

PB

17.0

16.7

21.3

24.5

28.7

45.8

17.0

16.7

21.3

24.5

28.7

45.8

Lanus Industries LLC USA

Cl 900 1500 2500 Lbs Pressure Seal Gate Valves. Flange Ends RF N RTJ

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Solid Wedge Gate

Flange Ends or Butt-welding Elds

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

Standard Material Specifications

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Part Name

CS to ASTM

Type A105

A105

A276 420

A276 430&410

A182 F6

A105

Body

Seat

Wedge

Stem

Pressure Seat

Pressure Ring

Bonnet

Gland Eyebold

Pin

Stem Packing

P.S.Lock Nut

Gland

Gland Flange

Nut

Yoke Nut

Retaining Nut

Handwheel

H.W.Lock Nut

Oil Cup

Suitable Medium

Suitable Temperature

AS to ASTM

Type F22

A182 F22

A276 304

A182 F304

A182 F304

A182 F304

A276 304L

A182 F22

A193 B16

A105

A193 B7

SS to ASTM

Type F304(L)

A182 F304(L)

A276 304(L)

A182 F304(L)

A182 F304(L)

A182 F304(L)

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

A182 F316(L)

F316(L)

A276 316L

A182 F316(L)

A182 F304(L)

A193 B8(M)

A276 420

Flexible Graphite

A194 2H

A182 F304(L)

PTFE

A194 4

A194 8

A194 8M

A276 F420

A216 WCB

A182 F304

A351 CF8

A194 2H

A194 4

A194 8

A194 8M

A194 8

A194 8M

A194 8

A194 8M

A276-410

A194 2H

A194 4

A197

A194 2H

A194 4

Brass

W.O.G.etc

-29 425 font

W.O.G.etc

-29 550 font

Note: Other materials are available upon request.

HNO3,CH3OOH etc

-29 180 font

Cl 900 1500 2500Lb

Main Dimensions & Weight/Kgs

PRESSURE

900

1500

2500

SIZE

15

20

25

32

40

50

15

20

25

32

40

50

15

20

25

32

40

50

/

/

1

11/4

11/2

2

1/2

3/4

1

11/4

11/2

2

1/2

3/4

1

11/4

11/2

2

12

34

d

d

10

13

19

24

40

50

10

13

19

24

40

50

10

13

19

24

40

50

CopyRight@2007Lanus Industries LLC USA.All right reserved.

LRF

216

229

254

279

305

368

216

229

254

279

305

368

264

273

308

349

384

451

L

LBW

216

229

254

279

305

368

216

229

254

279

305

368

264

273

308

349

384

451

H

216

229

254

279

305

371

216

229

254

279

305

371

264

273

308

352.2

387.2

454.2

17

BB/WB

197

211

238

257

276

320

197

211

238

257

276

320

197

211

238

257

276

320

PB

321

321

321

380

414

502

321

321

321

380

414

502

321

321

321

380

414

502

W

180

180

180

200

200

300

180

180

180

200

200

300

180

180

180

200

200

300

BB/WB

9.8

9.7

9.5

17.5

21.6

42.7

9.8

9.7

9.5

17.5

21.6

42.7

12.3

21.1

11.8

20.9

27.5

53.3

Weight ( Kg )

PB

11.5

11.2

10.8

18.0

22.0

44.0

11.5

11.2

10.8

18.0

22.0

44.0

13.0

12.7

12.5

21.8

29.3

55.4

Lanus Industries LLC USA

Cl 150,300,600,800 Lbs Forged Steel Globe Valve.SE SW BW

Material Specifications

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Solid Wedge Gate

Flange Ends or Butt-welding Elds

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

CS to ASTM

AS to ASTM

Type A105

Type F22

A105

A182 F22

A276 420

A276 304

A276 430&410

A182 F304

A182 F6

A182 F304

Corrugated SS+graphite

A105

A182 F22

A193 B7

A193 B16

A276 420

A276 410

A193 B7

A193 B16

A105

A182 F11

A194 2H

A194 4

Part Name

Body

Seat Ring

Wedge

Stem

Gasket

Bonnet

Bonnet Bolt

Pin

Gland

Gland Eyebolt

Gland Flange

Gland Nut

Yoke Nut

H.W.Lock Nut

Nameplate

Handwheel

Bearing Gasket

Stem Packing

Suitable Medium

Suitable Temperature

A194 2H

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

Type F304(L)

A182 F304(L)

A276 304(L)

A182 F304(L)

A182 F304(L)

A182 F304(L)

A193 B8

A182 F304(L)

A193 B8

A182 F304(L)

A194 8

A276 420

A194 8

SS

A197

A473 431

A194 4

W.O.G.etc

-29 425 font

:

:

:

:

:

Flexible Graphite

W.O.G.etc

-29 550 font

SS to ASTM

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

A182 F316(L)

SS+PTFE

A182 F316(L)

A193 B8M

A182 F304

A182 F316(L)

A193 B8M

A182 F316(L)

A194 8M

A194 8M

HNO3,CH2OOH etc

-29 180 font

Note: Other materials are available upon request

Cl 150 300 600 800 Lb

Main Dimensions & Weight/Kgs

NPS

Conv.

3/8

3/4

1-1/4

1-1/2

2.1

3/8

79

158

100

100

1/2

1/2

92

169

2.3

3/4

92

169

100

4.3

1

120

236

160

5.9

1-1/4

140

283

180

11.1

1-1/2

140

283

180

11.1

2

178

330

200

15.2

1.8

2.3

2.0

3.8

5.1

10.2

10.2

14.2

Full

Weights

L or C

H(OPEN) B

W or A

Bolted

Welded

CopyRight@2007Lanus Industries LLC USA.All right reserved.

18

Lanus Industries LLC USA

Cl 900 & 1500 Lbs Forged Steel Globe Valve.SE SW BW

Standard Material Specifications

Material Specifications

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Solid Wedge Gate

Flange Ends or Butt-welding Elds

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Part Name

Body

Seat Ring

Wedge

Stem

Gasket

Bonnet

Bonnet Bolt

Pin

Gland

Gland Eyebolt

Gland Flange

Gland Nut

Yoke Nut

H.W.Lock Nut

Nameplate

Handwheel

Bearing Gasket

Stem Packing

Suitable Medium

Suitable Temperature

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

CS to ASTM

AS to ASTM

Type A105

Type F22

A105

A182 F22

A276 420

A276 304

A276 430&410

A182 F304

A182 F6

A182 F304

Corrugated SS+graphite

A105

A182 F22

A193 B7

A193 B16

A276 420

A276 410

A193 B7

A193 B16

A105

A182 F11

A194 2H

A194 4

A194 2H

W.O.G.etc

-29 425 font

A194 4

Type F304(L)

A182 F304(L)

A276 304(L)

A182 F304(L)

A182 F304(L)

A182 F304(L)

A193 B8

A182 F304(L)

A193 B8

A182 F304(L)

A194 8

A276 420

A194 8

SS

A197

A473 431

Flexible Graphite

W.O.G.etc

-29 550 font

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

SS to ASTM

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

A182 F316(L)

SS+PTFE

A182 F316(L)

A193 B8M

A182 F304

A182 F316(L)

A193 B8M

A182 F316(L)

A194 8M

A194 8M

HNO3,CH2OOH etc

-29 180 font

Note: Other materials are available upon request

Cl 900 1500Lb

NPS

Conv.

Full

L or C

H(OPEN) B

W or A

Bolted

Weights

Welded

3/8

3/8

Main Dimensions & Weight/Kgs

3/4

1

1-1/4

1-1/2

1/2

1

1-1/4

92

169

100

2.5

2.4

111

197

125

4.3

4.2

111

197

125

4.2

4.0

CopyRight@2007Lanus Industries LLC USA.All right reserved.

120

236

160

6.6

6.3

120

246

160

8.8

8.7

19

140

283

180

12.5

12.1

2

1-1/2

2

2

178

330

200

17.2

17.2

210

354

240

23.5

22.0

Lanus Industries LLC USA

Cl 900 1500 2500 Lbs Forged Steel Pressure Seal Globe Valve.SE SW BW

Standard Material Specifications

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Solid Wedge Gate

Flange Ends or Butt-welding Elds

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

Material Specifications

NO.

Part Name

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Body

Seat Ring

Wedge

Stem

Gasket

Bonnet

Bonnet Bolt

Pin

Gland

Gland Eyebolt

Gland Flange

Gland Nut

Yoke Nut

H.W.Lock Nut

Nameplate

Handwheel

Bearing Gasket

Stem Packing

Suitable Medium

Suitable Temperature

Note: Other materials are available upon request

CS to ASTM

AS to ASTM

Type A105

Type F22

A105

A182 F22

A276 420

A276 304

A276 430&410

A182 F304

A182 F6

A182 F304

Corrugated SS+graphite

A105

A182 F22

A193 B7

A193 B16

A276 420

A276 410

A193 B7

A193 B16

A105

A182 F11

A194 2H

A194 4

A194 2H

SS to ASTM

Type F304(L)

A182 F304(L)

A276 304(L)

A182 F304(L)

A182 F304(L)

SS+PTFE

A182 F304(L)

A193 B8

A182 F316(L)

A193 B8M

A182 F304

A182 F304(L)

A193 B8

A182 F304(L)

A194 8

A276 420

A194 8

SS

A197

A473 431

A194 4

Flexible Graphite

W.O.G.etc

-29 550 font

W.O.G.etc

-29 425 font

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

A182 F316(L)

A182 F316(L)

A193 B8M

A182 F316(L)

A194 8M

A194 8M

HNO3,CH2OOH etc

-29 180 font

Cl 900 1500 2500Lb

Main Dimensions & Weight/Kgs

PRESSURE

SIZE

Cl 900

Cl 1500

Cl 2500

15

20

25

32

40

50

15

20

25

32

40

50

15

20

25

32

40

50

/

/

1

11/4

11/2

2

1/2

3/4

1

11/4

11/2

2

1/2

3/4

1

11/4

11/2

2

12

34

d

d

10

13

19

24

40

50

10

13

19

24

40

50

10

13

19

24

40

50

CopyRight@2007Lanus Industries LLC USA.All right reserved.

LRF

216

229

254

279

305

368

216

229

254

279

305

368

264

273

308

349

384

451

L

LBW

216

229

254

279

305

368

216

229

254

279

305

368

264

273

308

349

384

451

H

216

229

254

279

305

371

216

229

254

279

305

371

264

273

308

352.2

387.2

454.2

20

BB/WB

197

211

238

257

276

320

197

211

238

257

276

320

197

211

238

257

276

320

PB

321

321

321

380

414

502

321

321

321

380

414

502

321

321

321

380

414

502

W

180

180

180

200

200

300

180

180

180

200

200

300

180

180

180

200

200

300

BB/WB

9.8

9.7

9.5

17.5

21.6

42.7

9.8

9.7

9.5

17.5

21.6

42.7

12.3

21.1

11.8

20.9

27.5

53.3

Weight ( Kg )

PB

11.5

11.2

10.8

18.0

22.0

44.0

11.5

11.2

10.8

18.0

22.0

44.0

13.0

12.7

12.5

21.8

29.3

55.4

Lanus Industries LLC USA

Cl 800 Lbs Forged Steel Bellow Sealed Globe Valve. SE, SW, BW

Standard and Material Specifications

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Solid Wedge Gate

Flange Ends or Butt-welding Elds

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

Material Specifications

NO.

CS to ASTM

AS to ASTM

Type A105

Type F22

A105

A182 F22

A276 420

A276 304

A276 430&410

A182 F304

A182 F6

A182 F304

Corrugated SS+graphite

A105

A182 F22

A193 B7

A193 B16

A276 420

A276 410

A193 B7

A193 B16

A105

A182 F11

A194 2H

A194 4

Part Name

1

Body

2

Seat Ring

3

Wedge

4

Stem

5

Gasket

6

Bonnet

7

Bonnet Bolt

8

Pin

9

Gland

10

Gland Eyebolt

11

Gland Flange

12

Gland Nut

13

Yoke Nut

14

H.W.Lock Nut

15

Nameplate

16

Handwheel

17

Bearing Gasket

18

Stem Packing

Suitable Medium

Suitable Temperature

A194 2H

A194 4

W.O.G.etc

-29 425 font

Flexible Graphite

W.O.G.etc

-29 550 font

SS to ASTM

Type F304(L)

A182 F304(L)

A276 304(L)

A182 F304(L)

A182 F304(L)

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

A182 F316(L)

SS+PTFE

A182 F316(L)

A193 B8M

A182 F304

A182 F316(L)

A193 B8M

A182 F316(L)

A194 8M

A182 F304(L)

A193 B8

A182 F304(L)

A193 B8

A182 F304(L)

A194 8

A276 420

A194 8

SS

A197

A473 431

A194 8M

HNO3,CH2OOH etc

-29 180 font

Note: Other materials are available upon request

Cl 800 Lb

NPS

Conv.

Full

L or C

H(OPEN) B

W or A

Weights

3.2

3.0

3/8

3/8

3/4

1/2

79

220

100

3.0

2.8

79

220

100

4.8

4.8

92

225

100

7.9

7.0

CopyRight@2007Lanus Industries LLC USA.All right reserved.

Main Dimensions & Weight/Kgs

1

1-1/4

1-1/2

3/4

1

1-1/4

111

244

125

11.0

9.6

120

321

160

16.8

13.5

21

152

321

160

25.2

20.2

2

1-1/2

2

2

172

347

180

17.2

17.2

210

354

240

23.5

22.0

Lanus Industries LLC USA

Cl 150,300,600 Lbs Fored Steel Globe Valve.FE RF

Standard and Material Specifications

Technical Specification

Design N Manufacturer

Bolted Bonnet or Welded Bonnet

Reduced Port

Plug type Disc.

Flange Ends or Butt-welding Elds

NO.

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

Part Name

Body

Gasket

Bonnet Bolt

Pin

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

CS to ASTM

AS to ASTM

Type A105

Type F22

Type F304(L)

SS to ASTM

Type F316(L)

A105

A182 F22

A182 F304(L)

A182 F316(L)

Corrugated SS + graphite

A193 B7

SS + PTFE

A193 B16

A193 B8

A193 B8M

A276 420

A276 304

Gland

Gland Eyebolt

A193 B7

A276 410

A193 B16

Gland Nut

A194 2H

A194 4

Yoke Nut

A182 F304(L)

A182 F316(L)

A193 B8

A193 B8M

A194 8

A194 8M

A276 410

H.W.Nut

10

Nameplate

A194 2H

A194 4

SS

11

Handwheel

A197

12

Gland Flange

A216 WCB

13

Stem Packing

Flexible Graphite

14

Bonnet

15

16

A194 8

A194 8M

A351 CF8

PTFE

A105

A276 304

A182 F304(L)

A182 F316(L)

Stem

A182 F6

A182 F304

A182 F304(L)

A182 F316(L)

Disc

A276 420

A276 304

A276 304(L)

Suitable Medium

W.O.G.etc

W.O.G.etc

HNO3,CH3OOH etc

Suitable Temperature

-29 425

-29 550

-29 180

A273 316(L)

Note: Other materials are available upon request.

Cl 150 300 600Lb

Main Dimensions & Weight/Kgs

NPS

L(RF)L1(BW)

H(OPEN)

1/2

3/4

1-1/4

1-1/2

150

108

117

127

140

165

203

300

152

178

203

216

229

267

600

165

190

216

229

241

292

150,300

166

171

207

240

258

330

600

171

207

240

258

330

380

100

100

125

160

160

180

RF

4.5

6.9

9.8

13.5

19.5

28.0

BW

2.3

3.6

7.8

8.2

12.0

15.0

RF

4.8

7.7

11.0

16.8

21.2

32.6

BW

2.8

4.0

8.5

9.2

12.6

16.8

RF

5.6

7.8

12.5

17.0

23.5

38.8

BW

3.4

4.7

9.2

10.5

13.3

18.9

W

150

Weights

300

600

CopyRight@2007Lanus Industries LLC USA.All right reserved.

22

Lanus Industries LLC USA

Cl 900 1500 Lbs Fored Steel Globe Valve.FE RF

Standard Material Specifications

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Plug type Disc.

Flange Ends or Butt-welding Elds

NO.

Part Name

Body

Gasket

Bonnet Bolt

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

AS to ASTM

Type A105

Type F22

Type F304(L)

Type F316(L)

A105

A182 F22

A182 F304(L)

A182 F316(L)

A193 B16

A193 B8

Pin

A276 420

Gland

A276 410

Gland Eyebolt

A193 B7

Gland Nut

A194 2H

Yoke Nut

H.W.Nut

Nameplate

SS to ASTM

Corrugated SS + graphite

A193 B7

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

CS to ASTM

10

:

:

:

:

:

SS + PTFE

A193 B8M

A276 304

A182 F304(L)

A182 F316(L)

A193 B16

A193 B8

A193 B8M

A194 4

A194 8

A194 8M

A194 8

A194 8M

A276 410

A194 2H

A194 4

SS

11

Handwheel

12

Gland Flange

A216 WCB

A197

A351 CF8

13

Stem Packing

Flexible Graphite

PTFE

14

Bonnet

A105

A276 304

A182 F304(L)

A182 F316(L)

15

Stem

A182 F6

A182 F304

A182 F304(L)

A182 F316(L)

16

Disc

A276 420

A276 304

A276 304(L)

A276 316(L)

Suitable Medium

W.O.G.etc

W.O.G.etc

HNO3,CH3OOH etc

Suitable Temperature

-29 425

-29 550

-29 180

Note: Other materials are available upon request.

Cl 900 1500 Lb

Main Dimensions & Weight/Kgs

NPS

L(RTJ)

L1(BW)

Weights

1/2

3/4

3/4

1-1/2

900,1500

216

229

254

279

305

371

900,1500

216

229

254

279

305

368

H(OPEN)

207

207

240

258

330

355

125

125

160

160

180

200

RTJ

8.0

13.2

17.4

19.0

24.5

31.0

BW

5.2

10.0

14.6

15.8

20.5

27.8

CopyRight@2007Lanus Industries LLC USA.All right reserved.

23

Lanus Industries LLC USA

Cl 900 1500 2500 Lbs Fored Steel Pressure Seal Globe

Valve.FE RF

Standard and Material Specifications

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Plug type Disc.

Flange Ends or Butt-welding Elds

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

CS to ASTM

AS to ASTM

Type A105

Type A182 F22

Type F34(L)

Type F316(L)

Body

A105

A182 F22

A182 F304(L)

A182 F316(L)

Disc

A276 420

A276 304

A276 304(L)

A276 316(L)

Stem

A182 F6

A182 f304

A182 F304(L)

A182 F316(L)

Pressure Seat

A105

A182 F304

A182 F304(L)

A182 F316(L)

Pressure Ring

Bonnet

A182 F22

A182 F304(L)

A182 F316(L)

NO.

Part Name

SS to ASTM

A182 F304(L)

A105

F316L

Pin

P.S.Washer

A105

A276 420

A182 F22

A182 F304(L)

A276 304

P.S.Lock Nut

A194 2H

A194 4

A194 8

10

Stem Packing

A182 F316(L)

A194 8M

Flexible Graphite

PTFE

A182 F304

11

Gland

A276 420

12

Gland Flange

A216 WCB

13

Gland Eyebolt

A193 B7

A193 B16

A193 B8

A193 B8M

14

Gland Nut

A194 2H

A194 4

A194 8

A194 8M

15

Yoke Nut

A276 410

16

Handwheel

A197

17

Nameplate

18

H.W.Nut

A351 CF8

SS

A194 2H

A194 4

Suitable Medium

W.O.G.etc

W.O.G.etc

A194 8

HNO3,CH3OOH etc

A194 8M

Suitable Temperature

-29 425

-29 550

-29 180

Note: Other materials are available upon request.

Cl 900 1500 2500Lb

Main Dimensions & Weight/Kgs

NPS

L(RTJ)

H(OPEN)

1/2

3/4

1-1/4

1-1/2

900Lb 1500Lb

216

229

254

279

305

368

2500Lb

264

273

308

349

384

451

900Lb 1500Lb

318

318

318

398

408

524

2500Lb

333

333

333

410

420

524

160

160

180

200

250

280

900Lb 1500Lb

15.5

16.9

18.9

28.9

34.3

52.8

2500Lb

18.0

20.5

23.0

36.1

45.0

81.5

W

Weights

CopyRight@2007Lanus Industries LLC USA.All right reserved.

24

Lanus Industries LLC USA

CL 800Lbs Y-Pattern Globe Valve 800Lb

Standard Material and Specifications

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Plug type Disc

Screw End,Socket Welded,Butt Welded

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

Body

Disc

Stem

Gasket

Bonnet

Bonnet Bolt

Stem Packing

Gland

Gland Flange

Handwheel

Nameplate

H.W.Nut

Yoke Nut

Gland Nut

CS to ASTM

Type A105

A105

A276 420

A182 F6

Corrugated SS + graphite

A105

A193 B7

Flexible Graphite

A276 410

A216 WCB

A197

SS

A194 2H

A276 410

A194 2H

AS to ASTM

Type F22

A182 F22

A276 304

A182 F304

Corrugated SS + graphite

A276 304

A193 B16

Flexible Graphite

A276 410

A216 WCB

A197

SS

A194 4

A276 410

A194 4

SS to ASTM

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

SS + PTFE

A276 316(L)

A193 B8M

PTFE

A182 F316(L)

A351 CF8

A197

SS

A194 8

A276 410

A194 8

15

Gland Eyebolt

A193 B7

A193 B16

A193 B8

16

Pin

Suitable Medium

Suitable Temperature

A276 420

W.O.G.etc

-29 425

A276 420

W.O.G.etc

-29 550

A276 304

HNO3,CH3OOH etc

-29 180

NO.

Part Name

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SS to ASTM

Type F316(L)

A182 F316(L)

A276 316(L)

A182 F316(L)

SS + PTFE

A276 316(L)

A193 B8M

PTFE

A182 F316(L)

A351 CF8

A197

SS

A194 8

A276 410

A194 8M

A193 B8M

A276 304

HNO3,CH3OOH etc

-29 180

Cl 800 Lb

Main Dimensions & Weight/Kgs

NPS

L

H(OPEN)

W

Weights

1/2~

98

175

100

5

CopyRight@2007Lanus Industries LLC USA.All right reserved.

3/4~

111

215

125

6.3

1~

1-1/4~

120

140

254

305

160

160

7.6

9.8

relative products

Pressure-seal Y-Pattern Globe Valve 900Lb~2500Lb

Y-Pattern Piston Check Valve 800Lb

25

1-1/2~

140

305

180

13.8

2~

170

365

200

14.0

Lanus Industries LLC USA

Cl 150,300,600,800Lbs Piston Check Valve,Swing Check Valve &

Piston Check Valve.

Standard and Material Specifications

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Plug type Disc,Ball Disc,Swing Disc.

Screw End,Socket Welded,Butt Welded

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

NO.

Part Name

1

2

3

4

5

6

7

8

9

Body

Piston Disc

Gasket

Bonnet

Nameplate

Bolt

Ball

Suitable Medium

Suitable Temp.

CS to ASTM

Type A105

A105

A276 410

Corrugated SS + graphite

A105

SS

A193 B7

A182 F304

W.O.G.etc

-29 425 deg C

AS to ASTM

Type F22

A182 F22

A276 304

Corrugated SS + graphite

A182 F22

SS

A193 B16

A182 F304

W.O.G.etc

-29 550 Deg C

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

SS to ASTM

Type F304(L)

A182 F304(L)

A276 304(L)

SS + PTFE

A182 F304 L

SS

A193 B8M

A182 F304

HNO3CH3OOH etc

-29 180 Deg C

SS to ASTM

Type F316(L)

A182 F316(L)

A276 316(L)

SS + PTFE

A182 F316(L)

SS

A193 B8M

A182 F304

HNO3CH3OOH etc

-29 180 Deg C

Note: Other materials are available upon request

Cl 150 300 600 800Lb

Main Dimensions & Weight/Kgs

Conv.

Full

NPS

L

H

Weights

Bolted

Welded

3/8

79

61

1.4

1.1

1/2

3/4

79

61

1.2

1.0

CopyRight@2007Lanus Industries LLC USA.All right reserved.

3/4

1/2

92

65

1.5

1.2

1

3/4

111

79

3.1

2.9

26

1-1/4

1

120

95

3.9

3.3

1-1/2

1/4

152

103

5.6

4.9

2

1-1/2

172

118

8.9

8.1

2

200

132

12.5

10.9

Lanus Industries LLC USA

Cl 900 1500Lbs Ball Check Valve,Swing Check Valve &

Piston Check Valve

Standard and Material Specifications

Design N Manufacturer

Technical Specification

Bolted Bonnet or Welded Bonnet

Reduced Port

Plug type Disc,Ball Disc,Swing Disc.

Screw End,Socket Welded,Butt Welded

Design Standard

Pressure-Temperature Rating

Face-Face

Flange Ends

Inspection Test

NO.

Part Name

1

2

3

4

5

6

7

8

9

Body

Piston Disc

Gasket

Bonnet

Nameplate

Bolt

Ball

Suitable Medium

Suitable Temp.

CS to ASTM

Type A105

A105

A276 410

Corrugated SS + graphite

A105

SS

A193 B7

A182 F304

W.O.G.etc

-29 425 deg C

AS to ASTM

Type F22

A182 F22

A276 304

Corrugated SS + graphite

A182 F22

SS

A193 B16

A182 F304

W.O.G.etc

-29 550 Deg C

:

:

:

:

:

ASME B16.34/API600

ASME B16.34

ASME B16.10

ASME B16.5

API 598

SS to ASTM

Type F304(L)

A182 F304(L)

A276 304(L)

SS + PTFE

A182 F304 L

SS

A193 B8M

A182 F304

HNO3CH3OOH etc

-29 180 Deg C

SS to ASTM

Type F316(L)

A182 F316(L)

A276 316(L)

SS + PTFE

A182 F316(L)

SS

A193 B8M

A182 F304

HNO3CH3OOH etc

-29 180 Deg C

Note: Other materials are available upon request

Cl 900 1500 Lb

Main Dimensions & Weight/Kgs

NPS

Conv.

Full