Professional Documents

Culture Documents

Archit Agro 2nd Scrutiny R2 - 13.12

Uploaded by

Vipin KatariaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Archit Agro 2nd Scrutiny R2 - 13.12

Uploaded by

Vipin KatariaCopyright:

Available Formats

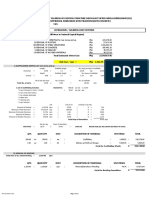

TECHNICAL SCRUTINY FORMAT 2nd Scrutiny Date: - 12. 12.

2011

S. No. A

Item Description

Proposal in DPR

Technical Deviations & observation

Promoter Replay/ Consultants Comments.

Identification Name of cold storages Ref. of DPR

Archit Agrotech India Pvt. Ltd.

NHB/LOI/09BLK/ OCS/0000161/2011-12 Dated 24.08.2011

Basic Cold Store Design consideration i).Commodity Storage Requirement Potato Type of produce 2 to 4 deg. C. Temp. in 0 C 90% & Above. Humidity in RH% 40 CMH/MT Air Circulation (CMH/MT)

OK OK. This should be 90 to95% 90 to 95 % OK

This should be 85 CMH / MT

as per standard. This is essentially mainly during loading and pull down and hence system must have that capacity. In holding it can be reduced with help of VFD. OK. OK. This should be (during loading to pull down) up to 10 Deg. C. in 1 day & then up to 3 Deg. C. in 8days from second day. OK. OK

85 CMH/MT OK

Ventilation (air changes/day)

2 to 6 Air Changes/Day 4000 PPM 2 Deg. C.

CO2

range(PPM) Produce cooling rate (0C/day)

Accepted

OK

Freezing point 0C Daily loading rate Special Provision CIPC : MA/Eth. Control etc. ii). Fresh air Ventilation system ii) Fresh air & ventilation system

(-) 0.6 deg C 4% to 5% N. A. Ethylene control.

OK. OK

Ventilation

Capacity (Max Air Changes/Day): 21000 CFM Design Considerations for Energy Recovery and Preventing Wetting

This should be in no. of air changes / day

2 to 6 air change/day OK

OK.

iii). Cold store Chamber size & capacity iv) Anti Room & Process Area

of Produce: Heat recovery wheel 21.00 x 17.50 x 13.30 (m) for 1437MT X 4 Rooms. Total capacity 5748 MT. (5 floors ) 35.69x 3.65 x 13.30 m ht: Anteroom has been shown to have 25 deg C. Processing area :Sorting & Grading Area ( Ground floor) 46.47 X 15.00 X 5.00 M Loading/ unloading dock. As per site requirement Sorting & grading area has shown to have 30 Deg.C

As per 3.4 cu.m / MT, capacity is OK. OK. Give stair case in ante room for entrance in cold chambers at least on alternate floors OK Accepted OK

OK. Pl. give dimensions & this should be under proper shed. OK. OK OK OK OK. OK. Provide proper strength & proper waterproofing. OK Please mention. .

(46.47 X 15.00 X 5.00) M OK

v) Machine room utility area

M/c room : 15.23 m x 9.14 m x 4.88 m ht Office: 11.00 x 4.00 x 4.00. Toilets & changing rooms: 4.00 x 3.00 x 4.00.

vi). bu ilding construction details

External

& Internal Walls: 230 mm brick wall Type of roof /ceiling. RCC slab. Internal Structure given as RCC Columns & RCC beams. Mezzanine grating: Not mentioned

Complete proper strength & proper waterproofing. OK

treated for termites.Wooden rack & column, beam strength material maurang, gitti, cement, ratio 1:2:3 OK

vii). Insulation & Vapour Barrier

Material: - EPS. Thickness 150 mm.for external walls, ceiling 75 mm for internal walls. & 125 mm for floor. Density: - 15 kg. /cu. mt. overall Water adsorption % by mass:-IS - 4671 Vapour barrier: - Al. foil of 50 microns for external / internal walls & ceiling and polythene sheet of 250 micron for floor. Cladding: For External walls, Internal walls & Ceiling: FRP Sheet. For floor Tar felt &

OK. OK OK. OK. But it should be as per BIS standard. OK. BIS standard code -4671 OK

OK. For Insulation work please follow NHB standard.

YES

OK

PCC 4 viii). C old Store Doors & Air curtains i) 12 doors with strip curtains. ii)Air curtains also mentioned. OK. For ante room entrance & process area extra insulated doors should be provided. Strip curtains to be used for cold room doors & air curtains to be used for ante room door & process area door. OK. OK YES OK

ix). Material Handling x). Grading, Sorting, washing & packing line(optional) Heat load calculations

Careers Manual

Cooling design

system

Summer dry bulb temp.:-40 Deg. C. Total refrigeration load:-399.124 KW. in peak period. (C.S.capacity 5748 MT.) Cooling system configuration i) Type of system given as Ammonia Over feed Type of comp.:Reciprocating. Type of capa. control:Automatic in steps Type of cond.:- atmospheric. Type of CT: N.A. Type of cooling coil: Ceiling suspended Type of defrosting:- Air /Water Humidification system & control: - Control on lower TD. ii)Comp. details Comp. capacity:- 295.19 KW. at (-) 2/ 38 Deg. C. (1 no. KC-4) & 226 KW. at (-) 2/ 38 Deg. C. ( 1 no KC-3.) iii) Condenser capacity:526.5 KW v) Air cooling units:- 39.92 KW at 2 Deg. C. SST. No of ACUS:- 12 Nos. Air flow given at free air flow conditions: 30600 CMH./unit

OK. OK.

OK OK. OK. OK. OK. OK. OK. OK.

OK. But make provision for stand by compressor during pull down / loading Suggested to go for 50% capacity x 3 nos as per standard OK. OK.TD should not be more than 4 Deg C. OK. Air flow should be given at specific static pressure drop. external static pressure. should be minimum 10 mm of water gauge. The CMH capacity is not adequate for 85CMH / MT. OK. OK. OK

YES Pl. give revised compressor details.

TD 40 C. OK

Fin spacing :- 6.4.0 mm. E Electrical installation Transformer:-250 KVA D. G. Set :- 160 KVA

External static pressure should be minimum 10mm WG. OK

Safety provisions

Mentioned.

G H I J

Codes & standard Energy saving equipments. Operation & maintenance. Estimated performance parameters

Mentioned. VFD for fans / comp.:- For Compressor Mentioned. COP :- Not mentioned.

OK. Ammonia masks &emergencies handling instructions to be display at prominent place in the machine room. Water shower to be provided over receiver. OK. VFD for fans also to be provided. OK. Pl. Mention

Accepted

OK

VFD for fans & compressor. OK

3.839 Peak Period 3.590 Holding Period 3.525 Lean Period OK. Pl. mention.

Elect.CostRs./day/ton:mentioned

Not

Pl. Mention

General: Data furnished is OK. Subject to they are giving revised compressor details & electrical cost / day / MT The proposal can be considered for LOI subject to other criteria as per NHB requirements being met. Drawing to be submitted to NHB, duly signed by registered architect, clearly showing plan & sectional views, with stair case in ante room. Condenser tank should be as close to plant room as possible.

ARVIND SURANGE. ACR PROJECT CONSULTANTS.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CMPM Reviewer Quiz 1: It Means The Demolition of A Structure Done With Some Equipment Without The Use of Any ExplosiveDocument3 pagesCMPM Reviewer Quiz 1: It Means The Demolition of A Structure Done With Some Equipment Without The Use of Any ExplosiveJCNo ratings yet

- Work Procedure For CCB Installation of Raised Floor 2Document13 pagesWork Procedure For CCB Installation of Raised Floor 2ResearcherNo ratings yet

- Singly Reinforced Concrete Beam Design ExampleDocument16 pagesSingly Reinforced Concrete Beam Design ExampleyamenNo ratings yet

- Mechanical Properties of Fly-Ash-Based Geopolymer Concrete: Aci Materials Journal Technical PaperDocument1 pageMechanical Properties of Fly-Ash-Based Geopolymer Concrete: Aci Materials Journal Technical PaperjoNo ratings yet

- Aluminium Tape: Lightning ProtectionDocument4 pagesAluminium Tape: Lightning ProtectionPradipa Aisyah Tri SyakinaNo ratings yet

- SOP251 Proprietary Item Specifications by Inspector General 2013 July Attachment BDocument10 pagesSOP251 Proprietary Item Specifications by Inspector General 2013 July Attachment Bmalik macNo ratings yet

- Morning Report Mei 2023Document3 pagesMorning Report Mei 2023hmzh faqihNo ratings yet

- Earthing and Lightning Protection InstallationDocument16 pagesEarthing and Lightning Protection Installationwagwahkiabathe100% (1)

- 2 Cpccca3008 PP SlidesDocument42 pages2 Cpccca3008 PP SlidesRavinder BalhotraNo ratings yet

- Presentation On Offshore Geotechnical en PDFDocument13 pagesPresentation On Offshore Geotechnical en PDFDadang Kurnia100% (1)

- Proposed Pavilion at Cooray Play Ground Final BillDocument44 pagesProposed Pavilion at Cooray Play Ground Final BillSanjeewa Kulasooriya0% (1)

- 2 Weeks Look Ahead Schedule (Submitted On 10 Dec 2021)Document1 page2 Weeks Look Ahead Schedule (Submitted On 10 Dec 2021)Syazu StylzerNo ratings yet

- Two Storey Commercial Warehouse W Mezzanine (Semi-Concrete) - 17-024 - VeteransDocument21 pagesTwo Storey Commercial Warehouse W Mezzanine (Semi-Concrete) - 17-024 - VeteransJohn Michael TalanNo ratings yet

- Rectification of Accident Black Spot Preparation of Proposal and Sanction Approval Regarding On 26th August 2019.-MinDocument11 pagesRectification of Accident Black Spot Preparation of Proposal and Sanction Approval Regarding On 26th August 2019.-MinAshok Kumar SahaNo ratings yet

- 2 PDF 1522223349Document114 pages2 PDF 1522223349Инженер ДолинскоеNo ratings yet

- TrusSteel - Truss Design Manual (2017) PDFDocument78 pagesTrusSteel - Truss Design Manual (2017) PDFgrahambrasicNo ratings yet

- Alok Panday Design & Construction of SuperstructureDocument57 pagesAlok Panday Design & Construction of SuperstructureBalakumaran GunasekaranNo ratings yet

- Experienced Civil Engineer Seeking New OpportunityDocument3 pagesExperienced Civil Engineer Seeking New OpportunityAhmed SaadNo ratings yet

- FDAS Preventive Maintenance Checklist - Unit Monitoring Cluster 1-4Document4 pagesFDAS Preventive Maintenance Checklist - Unit Monitoring Cluster 1-4Kurt Ross RicamaraNo ratings yet

- User Guide Safety Harness With CuplokDocument6 pagesUser Guide Safety Harness With CuplokAbdul HameedNo ratings yet

- Phu Luc Cable of Drain Solution Instructions V1 - 10082017w32Document8 pagesPhu Luc Cable of Drain Solution Instructions V1 - 10082017w32KHOA NGUYEN DANGNo ratings yet

- SECTION 21 - MicropilingDocument8 pagesSECTION 21 - MicropilingTony JamesNo ratings yet

- Ecr58d - 20032818-B CHNDocument572 pagesEcr58d - 20032818-B CHNDiego MontenegroNo ratings yet

- Health, Safety, & Environment Manual: General Safety Requirement For Sub Structure Works (Foundation)Document4 pagesHealth, Safety, & Environment Manual: General Safety Requirement For Sub Structure Works (Foundation)rizal azizanNo ratings yet

- Finalproject MergedDocument85 pagesFinalproject MergedMICHAELDANE SALANGUITNo ratings yet

- Firex 2015 Price List - PART 1 - GENERALDocument51 pagesFirex 2015 Price List - PART 1 - GENERALeng_asayedNo ratings yet

- 0.4mm Ribtype Roof DesignDocument1 page0.4mm Ribtype Roof Designcrimson dinawanaoNo ratings yet

- 903 Assignment PDFDocument13 pages903 Assignment PDFabikeerthuNo ratings yet

- Composite PC Slabs and SCI P287 Release Note PDFDocument3 pagesComposite PC Slabs and SCI P287 Release Note PDFRobert GilbertNo ratings yet

- Plan of 3.5 KM Flowline ConstructionDocument1 pagePlan of 3.5 KM Flowline ConstructionRohit SharmaNo ratings yet