Professional Documents

Culture Documents

63 sw01 106

Uploaded by

Grace A RahhalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

63 sw01 106

Uploaded by

Grace A RahhalCopyright:

Available Formats

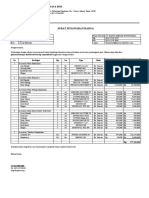

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

SPECIFICATION CONTENTS

A B C D 1.0 1.1 1.2 1.3 1.3.1 1.3.2 1.4 1.5 1.6 1.7 1.8 1.9 1.10 1.11 1.12 1.13 1.14 2.0 2.1 2.2 2.3 2.3.1 2.3.2 2.4 2.4.1 2.4.2 2.4.3 2.5 2.6 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 DESCRIPTION General technical requirement Standards Service conditions General arrangement and constriction Type of switchgears General conditions Primary Busbar and connections Circuit-breakers SF6 circuit-Breakers Vacuum circuit Breakers Operating mechanism Isolating devices and shutters Interlocking gear Locking facilities Earthling and earthing devices Testing facilities Control and indications Auxiliary switch Anti-condensation heaters Current transformers Voltage transformers Protective equipment General Relays Feeder over current and earth fault protection Overcorrect and earth fault protection Sensitive earth fault protection Transformer protection Over all differential protection Transformer restricted earth fault protection Stand by earth fault protection Frame leakage Breaker failure protection (for 33 kV switchgear only) Control and relay panels and auxiliary apparatus General Control switch Instruments Indications and alarms Indicating lamps Synchronizing apparatus Relays, fuses, links and auxiliary apparatus Earthing arrangements PAGE No 3 3 3 4 4 4 5 5 6 6 7 9 9 10 10 11 11 12 12 12 13 15 15 15 18 18 18 19 19 19 20 20 21 21 21 22 22 23 24 25 27 28

Rev 2- May. 2011

63

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

DESCRIPTION PAGE No 4.0 4.1 4.2 4.3 Small wiring and terminations General Identification of wiring Terminal boards 29 29 30 30

Rev 2- May. 2011

64

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

SPECIFICATION FOR 11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

Specification NO. SW-01 SCOPE

A GENERAL TECHNICAL REQUIREMENT: To be mentioned according to the specified design required of the substation. BSTANDARDS:

Unless another standard is specifically mentioned in this specification all materials and equipment supplied and all design calculations and tests shall be in accordance with International Standard Organizations (ISO) for mechanical equipment and international elector-technical Commission (IEC) recommendations for electrical equipment. CSERVICE CONDATIONS:

Equipment shall be suitable to ensure satisfactory operation for the following altitude, climatic and atmospheric site conditions: a Altitude: from sea level up to 2300m will be subjected to lightning strokes b Ambient temperature: 5C up to 50C. 2 c Wind pressure (kg/m ): 80 130 d Seismic acceleration: (g) 0.12 0.05 e Isokeraunic level: 10-18 f Relative humidity: 5-100 % g Atmosphere: Heavy salt and dust laden pollution in coastal areas, moderate sandstorm exposure and dust pollution in low to mid altitude and region and light to heavy dust pollution a t high altitudes.

Rev 2- May. 2011

65

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

D- GENERAL ARRANGEMENT AND CONSTRICTION 1.0 TYPE OF SWITCH GEARS: The equipment shall be of either the SF6 gas insulated, vacuum insulated or air insulated metal-clad type formed up into complete switchboards. 1.1 GENERAL CONDITIONS: The switchboards shall be built up of circuit breaker units. All units which shall be of horizontal type, when built up into a complete switchboard, shall be such that the completed switchboard is of flash fronted design having a neat and clean appearance and is readily extensible. The complete switchboards shall be designed to give maximum reliability in service, having regard to the need for speed of operation and ease of inspection and maintenance. All components shall be accessibly mounted in the switchboard and shall not impede access to wiring or terminals. All faults occurring within any individual unit shall be contained within that unit and except for busbar faults shall not cause shut down of any section of board other than the unit it self all equipment shall be constructed of non-hygroscopic and non-flammable material. Insulating barriers and bus supports shall be of an approved material. The design shall cater for the interconnection of busbars, both primary and secondary, between adjacent units. The apertures for secondary bus wires between adjacent units and for wiring in individual units shall be bushed to the approval of the PEC, to prevent damage to wires on sharp adages of metal. The switchboards shall consist of dust and vermin-proof cubicles, segregated into single or multi-tier compartments. They shall be made from sheet steel of thickness not less than 2.5 mm. The construction shall be robust and be designed to prevent the spreading of damage due to fire, short-circuits or other causes. The switchboards shall be designed to prevent accidental contact with live parts. A door shall be provided at the front of each compartment to give full access to apparatus and compartments. Bolted on rear and top covers shall be designed to give access to individual circuits without exposing other circuits, which may be live. Cubicles provide provided with forced ventilation in order to achieve the specified current rating are not acceptable 1.2 PRIMARY BUSBAR AND CONNECTIONS: Primary busbars and connections between the several pieces of apparatus forming the equipment of a cubicle shall be of electrolytic copper and all in accordance with IEC recommendations 60298 Primary busbars shall be contained in a separate compartment within the switchboard and access shall be possible only by means of bolted-on sheet covers, which shall clearly be marked Busbars Busbars and busbar connection shall not be exposed when covers and doors are opened for access to the remainder of the switchgear. Each phase conductor of the primary busbars, including all through joints and tapping connections shall, in addition to being spaced at such interval to give the necessary air clearance for the voltage rating, be completely insulated in an approved manner. Taping will not be accepted.

Rev 2- May. 2011

66

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

Primary busbars, connections and their supports shall be of an approved type and shall be capable of carrying the shot-time current associated with their short-circuit ratings for a period of 3 seconds. Where busbar supports etc., use insulation of moulded or resin bonded material it shall have a durable anti-hygroscopic surface finish with high anti-tracking properties. The connections from busbars in individual units shall have a continues current rating of not less than that of the equipment comprising the unit. At all points where connections or joints occur, the busbars and connecting pieces shall be tinned or silver-plated. The resistance of any length of conductor containing a joint shall not be greater than that of an equal length without a joint. Clamps, where used, shall be phosphor bronze and all bolts for joints shall be of high tensile steel. Primary busbars and connections shall be clearly marked and shall be displaced for standard phase sequence Red (R), Yellow (Y), and Blue (B) or equivalent counting from front to rear, top to bottom or left to right as viewed from the switching device operating mechanism side. Busbars shall be readily extensible. 1.3 CIRCUIT-PREKEARS: All insulated circuit breaker units shall be horizontal draw out type and shall be suitable for a three-phase break, time delay, automatic re-closure cycle. Circuit breakers rated at 33kv or 11kv shall be either vacuum type Circuit breakers or SF6 as indicated in bill of quantity The moving portion of each circuit breaker unit shall consist of a three - pole circuit breaker with operating mechanism, primary and secondary disconnecting devices, auxiliary switches, position indicators and the necessary control wiring all mounted on a substantial steel framework. This framework and all metal parts of the moving portion apart form current carrying parts shall be solidly earthed via the fixed portion. The earthling of the moving portion shall be to the approval of the PEC. Means of registration shall be provided so that circuit breakers may be readily placed and secured in the correct position in the fixed portion. Circuit breakers of the same current and voltage rating shall be fully interchangeable one with another. Means shall be provided to prevent circuit breakers form being placed into fixed housings of different ratings. This device shall also prevent damage to isolating and other contacts. The fixed and moving contact systems shall comprise both main and arcing contacts, all parts of which shall be easily dismantled and replaced. 1.3.1 SF6 Circuit Breakers: Circuit breakers employing SF6 gas as an interrupting medium shall operate on the principle of self generated gas pressure for are extinction. The rate of gas leakage per annum shall be guaranteed and shall not be greater than 1% for any compartment. Means of confirming the existence of adequate gas density in the Rev 2- May. 2011

67

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

circuit breakers shall be available without removing the unit form service. The system of gas monitoring shall be temperature compensated and shall be to the approval of the PEC. Suitable facilities shall be included for replenishing the volume of SF6 gas should this be necessary due to leakage. Absorption of moisture and the decomposition products of the gas shall be achieved by integral filters. 1.3.2 Vacuum Circuit Breakers: Circuit breakers employing the vacuum interruption principle shall incorporate vacuum bottles of declared and established manufacture. Each interrupter shall be capable of individual adjustment for correct operation and easily removed for maintenance or replacement. Full instructions for monitoring the state of vacuum and contact life shall be provided to the approval of the PEC. Contacts shall be designed to ensure a long contact life at all currents up to the rated making and breaking current switching conditions. Contact materials having low current chopping levels shall be used to minimize the occurrence of excessive over-voltages when switching. Device shall be provided to limit over-voltages to a safe level. Details of such devices shall be submitted to PEC for approve. Vacuum bottles shall not require the addition of insulation or stress shielding to achieve the necessary dielectric strength externally and shall not be mechanically braced by components which may reduce the integrity of the isolation across the open gap latching against its rated making current.

1.4 OPERATING MEACHANISMS: The circuit- breaker mechanism shall be either motor wound spring or solenoid operated. The circuit breaker shall be capable of closing fully and latching against its rated making current. Facilities shall be provided to permit manual slow closing and slow opening of the circuit breaker for maintenance purposes. It shall not be possible to use this facility when the circuit breaker is in the service or earthling positions. Such manual closing shall be easily accomplished by one person. In the case of designs utilizing portable jacking devices, three devices per switchboard are required, subject to a minimum of one for each rating of equipment in the switchboard. Spring operated mechanisms shall have the following additional measures: 1.4.1 If the circuit breaker is opened and the springs charged the circuit breaker can be closed and then tripped.

Rev 2- May. 2011

68

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

1.4.2 If the circuit breaker is closed and the springs charged there shall be sufficient energy to trip, close and then trip the circuit breaker. 1.4.3 Mechanical indication and an auxiliary switch for remote electrical indication shall be provided to indicate the state of the spring. 1.4.4 Motor charged mechanisms shall be provided with means for charging the springs by hand, and also a shrouded push button for releasing the springs. An electrical release coil shall also be provided. 1.4.5 Under normal operation, motor recharging of the operating spring shall commence immediately and automatically upon copulation of each circuit breaker closing operation. The time required for spring recharging shall not exceed 30 seconds. 1.4.6 It shall not be possible to close a circuit breaker, fitted with a motor charged closing mechanism, whist the spring is being charged. It shall be necessary for the spring to be fully charged and the associated charging mechanism fully prepared for closing before it can be released to close the circuit- breakers. All circuit breaker operating mechanisms shall be fitted with an electrical shunt trip release coil and in addition a mechanical hand tripping device. The electrical tripping and closing devices shall be suitable for operation from a power supply as stated I this specification and shall operate satisfactorily over the ambient temperature range when the voltage a their terminal is any value within the voltage range stipulated in latest issue IEC standards 60056. All operating coils for use on the d. c supply shall be connected so that failure of insulation to earth does no cause the coil to become energized. Tripping and closing circuits shall be provided with a fuse in each pole on each unit and shall be independent of each other and all other circuits. Approved, positively driven mechanically operated indication devices shall be provided to indicate whether a circuit breaker is in the open or closed service, isolated or earth position. Locking facilities with padlocks shall be provided so that the circuit-breaker can be prevented from being closed when it is open and from being manually tripped when it is closed. These facilities shall not require the fitting of any loose components prior to the insertion of the single padlock required. It shall not be possible, without the aid of tools, to gain access to the tripping toggle or any part of the mechanism, which would permit defeat of the locking of the manual trip. It shall not be possible to lock mechanically the trip mechanism so as to render inoperative the electrical tripping.

Rev 2- May. 2011

69

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

1.5

ISOLATING DEVICES AND SHUTTERS:

All circuit beakers shall be connected to their associated busbars and cables through isolating devices which shall be of the off-load type but suitable for operation whilst the busbars or feeder circuits are live. The design shall be such that it is impossible for the isolating devices to be opened by forces due to current in the primary circuit and shall be interlocked with circuit- breakers so is impossible to make or break current with the isolating device. Attempted isolation shall not trip the circuit breaker. When isolation is effected by withdrawal of the circuit beaker provision shall be made for positively locating the circuit beaker in the service, isolated and, when fitted, earthling positions. Stops shall be provided to prevent over-travel and each position shall be clearly indicated. Preferably, a mechanical selector mechanism shall be utilized such that when a particular position is selected it is impossible to locate the circuit- breaker in any other position. Isolating devices shall incorporate self aligning contacts, the fixed contacts of which shall be such that access can readily be obtained for maintenance purposes. Metal shutters shall be provided to completely shroud fixed isolating contacts of the circuit-breaker busbar and feeder circuits. These shutters shall be opened and closed automatically by the movement of the circuit breaker carriage and shall prevent access to fixed isolating contacts when the circuit- breaker is withdrawn. The shutters for fixed isolating contacts connected to busbars and cables shall have independent operating mechanisms. All shutters shall have painted labels indicating whether they are busbar or feeder shutters. Self aligning plug and socket isolating devices of an approved design shall be provided for all auxiliary circuits. The position of these devices shall be such that individual circuits on different units are in the same relative physical positions. 1.6 INTERLOCKING GEAR:

Interlocks shall be of the mechanical or key operated type and shall be provided to prevent the following operations: 1.6.1 A moving portion from being withdrawn from or inserted into the isolating contacts when the circuit-breaker is closed. 1.6.2 The closing of the circuit -breaker unless the movable portion is correctly plugged in or isolated from the equipment. 1.6.3 The movable portion being plugged in without the circuit -breaker tank in position. 1.6.4 The circuit -breaker being closed in the "service" or "earth" location without completing the appropriate auxiliary circuits.

Rev 2- May. 2011

70

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

1.6.5 To apply an earth to busbars until all circuit -breakers, which can feed the busbars are locked open. When key interlocking is employed, any attempt to remove the trapped key shall not cause closing or opening of the associated equipment. Where. a circuit -.breaker or other switch gear is fitted with means for mechanical or electrical operation, Interlocks shall be provided so that it is impossible for the electrical and mechanical devices to operate simultaneously. The earthing devices shall be provided with interlocks to ensure correct operation in conjunction with the associated circuit --breaker. In the case of circuit -breaker earthing, the electrical tripping of the circuitbreaker shall be rendered inoperative during earthing operations both when closing and when closed in the earthed position. It shall not be possible to return to the service position and close the circuit -breaker until the electrical tripping is again operative. 1.7 LOCKING FACILITIES: In addition to any requirements already specified the following padlocking facilities shall also be included:1.7.1 Selector mechanisms on circuit -breaker -isolated and service positions. 1.7.2 Safety shutters on primary contact isolating orifices in closed position. All cubicle access doors, other than those, which are interlocked with a switching device, shall be provided with an integral type locking facility. 1.8 EARTHING AND EARTHING DEVICES: All metal parts other than those terming part of an electrical circuit shall be connected in an approved manner to a hard drawn, high conductivity copper earth busbar which shall run the full length, and be bolted to the main frame, of the switchboard. At the positions where joints occur, the earth busbar shall be tinned. The earth busbar shall be rated to carry currents equal in magnitude and duration to that associated with the short -circuit rating of the equipment. The design and construction of the equipment shall be such that all metal parts, other than current carrying parts, of withdrawal equipment are earthed before the primary connections are made. The cases of all instruments, relays or other associated components mounted on the switch gear shall be connected to the earthed busbar by conductors of not less than 2.5 mm2 cross- sectional area. When components are provided for mounting separately each shall be provided with an earthing terminal not less than 30 mm2 cross - sectional area. Rev 2- May. 2011

71

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

Earthing devices shall be provided on all circuit -breaker units whereby the circuit can be earthed. With the circuit earthed, shutters over unearthed fixed main isolating contacts shall be closed. Where circuit and busbar earthing is effected through the circuit - breaker it is preferred that the facilities shall be integral in the design and construction of the switch gear. Single phase earthing devices for attachment to the circuit -breaker are subject to approval and shall be positive in application and function and permit essential interlocking features to be retained. Earthing via a fault -making earth switch may also be acceptable subject to compliance with requirements for this type of switch and position of suitable interlocks, details of which shall be submitted for approval from PEC. " Feeder and busbar earthing devices shall have a short -circuit rating ) equal to that of their associated circuit -breaker. Padlocking facilities shall be provided for the purpose of preventing inadvertent earthing. Labeling shall be provided to show whether the equipment is prepared for "SERVICE", "BUSBAR EARTH' or CIRCUIT EARTH". Such indication shall be visible from the front of the equipment at all times. 1. 9 TESTING FACILITIES: All circuit -breaker units shall be provided with facilities to enable applied high voltage tests to be carried out. -Provision shall also be made for temporarily completing the auxiliary circuits when the circuit -breaker is isolated and withdrawn, to enable the functioning of the circuit -breaker to be tested. When current transformers and protective relays are fitted, facilities shall be provided for primary and secondary injection tests to be carried out. These facilities shall be such that wires and connections need not be disconnected for the tests to be carried out. 1.10 CONTROL AND INDICATION: Approved, positively driven mechanical indicating devices shall be provided on all equipment to indicate whether the primary equipment is in the open or closed position. Care shall be exercised in the design and fitting of these indicators to ensure that the indicating device and associated apparatus does not interfere with the correct operation of the circuit -breaker or isolator. Each circuit- breaker shall be provided with the necessary auxiliary contacts and internal wiring to facilitate remote indication, which may take the form of two Rev 2- May. 2011

72

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

indicating lamps, a discrepancy control switch or a semaphore indicator. The remote indication will operate on the 110 V d. c. battery supply. Indicating lamps and lamp-holders shall be arranged to that replacement of lamps and cleaning of reflectors and glasses employed can be readily effected, To reduce heating and fouling of the panels, lamps, which are continuously energized shall have the minimum consumption consistent with good visibility of indications in a brightly lit room.

1.11 AUXILIARY

SWITCHES:

Approved, positively driven auxiliary switches shall be provided on all circuit breakers and, where necessary, isolators and earthing switches for indication control and interlocking. Auxiliary switches shall be strong, have a positive wiping action when closing and shall be mounted in an accessible position clear of operating mechanisms. Contracts, which signal the position of an isolator or earthing switch shall operate in accordance with the latest issue IEC 60265 They shall be designed to make, break and carry, without undue heating, the current of their associated circuit or a current of three amperes d. c., whichever is the higher. Not less than four spare auxiliary switches shall be provided with each circuit breaker, isolator and earthing switch. All auxiliary switches shall be wired up via secondary disconnecting devices to a terminal board on the front of the fixed portion, arranged in the same sequence for each individual unit of the same type.

1. 12 ANTI-CONDENSATION

HEATERS:

Anti condensation heaters of an approved type shall be provided inside each compartment of each cubicle. They shall be shrouded and located so as not to cause injury to personnel or damage to equipment. The heaters shall be controlled from a common double -pole miniature circuit -breaker, with a lamp to indicate " cubic heaters on ". The circuit -breaker and indicating lamp shall be mounted externally at one end of the switchboard. The heaters shall operate from a single-phase a. c. supply.

1.13 CURRENT

TRANSFORMERS:

Current transformers shall be suitable for the operation of protective gear instruments and metering equipment and the design characteristics shall be to the PEC approval. Current transformers shall have an output rating adequate to cater c for all burden connected to them. They shall have sufficient rating terminal voltage and accuracy class for the satisfactory operation of their associated equipment. The contractor shall be responsible for taking into account lead and all other burdens. The primary windings shall not, without special approval, have a short -time current rating less than that specified for the associated circuit -breaker. Windings shall be

Rev 2- May. 2011

73

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

capable of carrying the rated primary current for a period of one minute with the secondary winding open circuited. Multi-core current transformers shall be tapped on the secondary side and not on the primary side unless otherwise approved by the Engineer. The current transformer particulars as specified in Latest issue IEC 60044-2 standards shall be given on an accessible plate mounted external to the current transformer.

All connections from secondary windings shall be brought out and taken by means of separate insulated leads to a terminal board mounted in an accessible position. Where multi ratio secondary windings are required a label shall be provided at the secondary terminal board clearly indicating the connections required for each ratio. The connections and ratios in use shall be shown on all diagrams of connections. Current transformer secondary circuits shall be complete in themselves, and shall be earthed at one point only, through links situated in an accessible position. Each separate circuit shall be earthed through a separate link, suitably labelled. The links shall be of the bolted type, Have M6 nuts and provisions for attaching test leads. The earth links for protective and instrument current transformer secondary circuits shall be mounted inside the relay panels. Earth links for metering current transformer secondary circuits shall be mounted at the switch gear. Current transformers shall be air insulated and be installed on the side of the switching device (circuit -breaker etc) electrically remote from the busbar They shall be mounted In the fixed portion of the I switch gear with a method of securing in position such that undue I mechanical pressure cannot be exerted on the transformer windings. Magnetization curves of each type of current transformer shall be submitted for approval. 1.14 VOLTAGE TRANSFORMERS: Voltage transformers shall be suitable for the operation of protective gear, voltage regulating equipment, instruments and or metering, be of the wound type and have outputs adequate to cater for the burdens connected to them. When a polarizing source voltage is required for directional over-current or directional earth fault protection a broken delta connected, residual voltage winding shall be provided. Voltage transformers shall be in accordance with latest issue IEC 60186 standard with rated voltage factor of 1.2 and class 1.0. accuracy. Transformers for ! protective duty shall be accuracy class 3P. Unless specified otherwise, voltage transformer primary windings shall be connected to the circuit side of the current transformers remote from the busbars so as to be included in the protected zone of the associated feeder.

Rev 2- May. 2011

74

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

Voltage transformers shall be capable of being isolated from the equipment and facilities for padlocking in the service position shall be provided (where isolation is carried out by with drawl asset of shatters) capable of being padlocked, shall be provided to cover the stationary isolating contacts. The shutters shall operate automatically by positive drive actuated by movement of the voltage transformer assembly. The primary windings shall be connected via renewable fuses with current limiting features and the secondary windings through fuses and links, labelled to indicate their function and phase colour to the appropriate circuits. For single-phase voltage transformers, both ends of each secondary winding shall be brought out to insulated links. For three -phase voltage transformers each phase end shall be brought out to fuses and the neutral of the secondary winding shall be brought out to insulated links. Where a residual winding is required the open delta shall be brought out to insulated links. The fuses and links shall then be brought out to insulated terminals located in a terminal box. The primary and secondary fuses shall be capable of being removed and replaced '.when the circuit -breaker is closed in the service location. Isolation of the primary fuses for this purpose shall be carried out preferably by withdrawing the entire voltage transformer assembly. Additionally it shall be possible to remove secondary fuses whilst the voltage transformer is padlocked in the service location. For single phase units separate earth links for each secondary winding shall be provided. Each of the neutral leads shall be connected together of a single point and earthed as close as possible to the voltage transformer. Voltage transformer secondary winding shall be earth at the switch gear through a link, which can be removed for insulation testing. Secondary circuits of voltage transformers shall not be paralleled. The secondary voltage connections to metering circuits shall be I broken automatically when the circuit -breaker is opened. Magnetization curves for each type of voltage transformer shall be submitted for approval. 2.0 PROTECTIVE EQUIPMENT: 2.1 GENERAL: Protective equipment shall be designed to disconnect faulty circuits with speed and certainty without interference with healthy circuits. They shall also be so designed that, when properly applied, incorrect operation of the circuit -breakers does not occur as a result of transient phenomena not arising. from a. faulty condition of the section of line or plant associated with each set of relays but which may occur during fault periods due to disturbances on the system.

2.2 RELAYS: The relays shall preferably be of the digital static design with individual cases. All relays shall be contained in dustproof cases. All metal bases and frames of Rev 2- May. 2011

75

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

relays shall be earthed except where the latter must be insulated for special requirements. All relays essential for protection shall be mounted on the front only of relay panels. Where relays are accommodated in rear of panels, they shall be so mounted as to be accessible for inspection and wiring. The relays shall be so arranged that replacements can be effected quickly and with the minimum amount of labor. Relay equipment's incorporating electronic devices shall be arranged to jack in and shall have positive means for retaining them in the service position. Equipment incorporating telephone type relays shall preferably have similar facilities. Current transformer operated relay coils shall have continuous thermal ratings of not less than the maximum continuous secondarycurrent of the current transformer at the full rating of the circuit in which the current transformer is connected. The contacts of all relays shall be capable of making the maximum current, which can occur in the circuit, which they have to control. They shall also be capable of breaking such currents unless provision is made for breaking the current on contacts elsewhere in the circuits Relays shall not be affected by mechanical shock or vibration, or by external magnetic fields consistent with the place or method of mounting. The contacts shall be capable of repeated operation without deterioration. All relays, which are connected to complete either the tripping circuit of a circuit -breaker or the coil circuit of an auxiliary tripping relay shall be provided with operation indicators, which, wherever possible, shall be of the mechanical type. Indicators shall also be provided on such additional relay elements as will enable the type or phase of the fault condition to be identified. Each indicator whether of the electrically operated or mechanically operated type shall be capable of being reset by hand without opening the relay case, and it shall not be possible to operate the relay when resetting the operation indicator. Each indicator shall be so designed that it cannot move before the relay has completed its operation except for induction disc relays where the indication may show just before the trip contacts are made. Indicators shall be clearly visible from the front when operated and concealed at all other times. shall not be possible to operate any relay by hand without opening the case. Unless otherwise agreed all protective relay which initiate tripping (excluding tripping relays) shall not have less than two independent pairs of contacts, of which one shall operate the tripping relay or circuit - breaker directly without the interposition of auxiliary contactors and preferably without the use of reinforcing contactors.

Rev 2- May. 2011

76

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

All relays shall be so arranged that, provided that reasonable care be taken, any dust which may have collected on the case shall not fall on the relay mechanism when opening the case. Over current relays shall be of the three pole type and shall be of the digital type with adjustable time and current setting .The time/current characteristics of all relays shall be to BS 142 normal inverse curve. Balanced earth -fault relays shall be instantaneous in action unless otherwise specified The arrangement shall be such that the relay is stable under " transient " conditions. In order to facilitate testing each earth fault relay shall be fitted with a plug bridge. Thermal overload devices for motor protection shall have a characteristic so related to the characteristics of the motor with which they are associated that effective protection is obtained. . Where relays are required to operate with a time delay, the delaying attachment shall not be of the dashpot type. Relay directional elements which are designed to be energized normally by voltage and current when carrying any current between zero and 15 times rated current shall take up such a position that the contacts are open when the voltage coil is not energized. All d.c. relays used for tripping shall operate correctly when a voltage is applied within the range 70% to 110% of rated voltage. All relays shall be capable of withstanding voltages up to 120% of rated voltage. All relays shall be suitably marked with the following information:2.2.1 Functions of relay (e.g. Impedance- phase fault). 2.2.2 Phase identification of the current supply. 2.2.3 Characteristic curve. 2.2.4 Rated current and/or voltage of the relay coils. 2.2.5 Rated making capacity of tripping contacts. items (2.2.1) and (2.2.2) above shall be visible from the front without removing the cover. All relays other than auxiliary relays shall be provided with a card holder and card, the latter having space for the user's reference number and bearing the following information relating to the actual service connection of the relay: i) Current Transformer Ratio including all ratios of multi ratio Transformer. ii) Voltage Transformer Ratio. iii) Ratio in use where multi-ratio current transformers are employed. iv) Value of any external resistance or impedance. Rev 2- May. 2011

77

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

Rectifiers used in or in association with protective relays shall be of the selenium or other approved type. In order to minimize the effects of electrolysis, operation indicator coils and d.c. relay operating coils shall be so placed in the circuit that they are not connected to the positive pole of the battery except through contacts which are normally open. With draw-able pattern relays shall be designed so that when in the withdrawn position associated current transformers shall be automatically short -circuited and associated tripping circuits disconnected. Except where otherwise agreed, relays shall be capable of being tested with the circuit on load, for-which suitable test plugs and testing equipment shall be provided. Any setting knobs and adjusting devices shall be readily accessible.

2.3 FEEDER OVERCURRENT AND EARTH FAULT PROTECTION:

2.3.1 Over-current

And Earth Fault Protection: Unless otherwise specified over current and earth fault relays shall have standard inverse characteristics according to the formula: -

t= [0.14/(I-02-1)]

standard inverse

Where is the operating fault in seconds when the maximum time multiplier setting is applied and is the relay current in multi ples of the current setting. The phase and earth fault relays shall be provided with , adjustable plug settings for both operating current and time the design being such that the adjustment can be carried out on load. , directional earth fault relay incorporating an internal means for polarization to be considered alternatively. Where specified the over-current relays shall have high set instantaneous elements. These elements shall have a setting range of 500 to 2000 per cent of the CT secondary rated current. They shall have a transient over -reach of not more than 10 per cent for system angles up to 80 Where directional over current protection is provided on the low voltage sides of star/delta step -down transformers, in order to provide discriminative protection for high voltage phase faults, the directional elements shall not be of the true wattmeter type but shall be internally compensated so that maximum torque in a direction such as to close the contacts of each element is exerted.

Rev 2- May. 2011

78

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

when the current flowing in the relay current circuit leads the voltage applied to the relay voltage terminals by 45. In addition the external current and voltage transformer connections to the elements shall be arranged so that the phase current in anyone element associates with the line voltage applied from the voltage transformer, which lags behind it by 90C.

2.3.2

Sensitive Earth Fault Protection:

To cater for high resistance feeder earth faults conventional protection sensitive earth fault protection should be provided. The sensitivity shall be adjusted between.) & 5% of rated CT current as the relay has a circuit of any conventional current-protection very low setting as it is to be connected in the residual. It is essential that -the burden in posed by the relay is small in any case the burden should not exceed 0.01VA at setting current. Time delay adjustable from 1 -10 sec, is required. 2.4 TRANSFORMER PROTECTION: 2.4.1 Overall Differential Protection: Transformer overall differential protection shall be of the biased differential type providing protection for phase and earth faults. The relays shall corporate a harmonic restraint, which shall prevent the operation of the protective gear due to the magnetizing current when switching a transformer or changing transformer tapping. Relays that introduce a time delay to prevent operation during transformer energization will not be accepted. The relay operating and bias settings shall be individually adjustable. The minimum operating setting shall not be greater than 10-50% of the current transformer secondary rating. The protection shall remain stable on all transformer tap positions under maximum through fault conditions corresponding to the rated system short circuit level. The trip coils of the circuit -breakers on the primary and secondary sides of the transformer shall be so connected to the relays that the circuit -breakers shall operate together when the protective gear functions. Facilities shall be retained for independent tripping by hand of either circuit -breaker. 2.4.2 Transformer Restricted Earth Fault Protection: Transformer windings shall be provided with restricted earth fault protection. Relays shall be of the high impedance type with necessary protection against over voltages. Suitable current transformers will be provided in the neutral earthing connection of the winding of the power transformer and matching current transformers in the switch gear/transformer bushings are required. Relays shall have maximum sensitivity and minimum operating times consistent with stability for faults outside of the protected zone. Voltage limiting devices shall be included to restrict the current transformer secondary voltage to a safe value. Rev 2- May. 2011

79

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

The setting of the relay shall be such that it will operate reliably with current of the following magnitudes in the primary winding of the neutral current transformer alone:i) Power transformer neutral directly earthed -highest system voltage blow 72.5 kv not more than 50 % of the rated current. ii) Power transformer neutral earthed through resistor or reactor - all voltages not more than 25% of the rated current of the resistor or reactor where this rating does not differ greatly from the primary current rating of the current transformers. Current transformers, which are used for transformer earth fault protection, shall not be used for any other purpose. 2.4.3 Standby Earth Fault Protection The protection shall comprise a two stage definite time earth , fault relay. The current operating range shall be adjustable between 10% and 40% of the current transformer secondary rated current. The two time delay stages shall be adjustable between (1 and 10) seconds. As an alternative to a definite time relay, a long inverse time unrestricted earth fault relay may be offered together with a second stage timer. The current transformer for the SBEF protection shall be mounted in the neutral of the transformer and shall have a primary current rating of the standard value nearest to the rated current of the power transformer winding. Tripping shall be arranged in two stages. The first stage shall initiate the tripping of the L V side circuit -breakers in the section associated with the transformer whose SBEF protection has operated and the bus section circuit -breaker. The second stage shall initiate inter tripping of the associated HV side circuit breaker. 2.5 FR.AME LEAKAGE: Where the busbar frame leakage protection is scheduled the following conditions shall apply.2.5.1 The insulation resistance to earth of all zones (connected in parallel for test purposes) of any individual switchboard shall be less than 5 ohms. 2.5.2 Check relays shall be installed and be energized from the open delta windings of voltage transformers. 2.5.3 Insulation of all cables should be effected by suitable insulated gland plates for HV cables, cable box insulation either in the form of total barrier insulation or substantial insulation inserts in the gland support. The Engineer will reject any design of gland insulation, which is considered inadequate. 2.5 4 The discriminating and check relays shall preferably be of static type with at least two normally open self-reset contacts. Current settings of 20-80% of rated current shall be provided and the operating time shall not be greater than 15 milsecs at five times the current setting. 2.5.5 Associated tripping relays shall also be of the high-speed type. 2.5.6 The following indication facility shall be provided:a) Busbar protection in service with white light. b) Busbar protection out of service with amber light. c) Trip supply healthy, with white light. Rev 2- May. 2011

80

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

d) Trip supplies fail, with amber light. To enable the protective equipment of each zone to be taken out of , service independently during maintenance periods, lockable isolating switches -one switch per zone shall be provided in the trip supply circuits. 2.6 BREAKER FAILURE PROTECTION (For 33 kV Switch gear Only): The breaker failure protection on a circuit -breaker shall be initiated by all the other protection devices which normally initiate tripping of that breaker. In the event of the circuit -breaker failing to open within a pre -selected time, the breaker failure protection shall initiate tripping of all immediate back -up circuit -breakers capability of feeding into the fault. The relay shall be of the 3 -pole version -1 earth fault and 2 overThe position of the circuit-breaker shall be monitored by current relays fed from the back -up over-current CIS The relays shall have an operation time of approximately 10m sec and a consistent reset time of less than l5m sec. The relay shall be more sensitive than all the circuit protection tor phase and earth faults The relays shall be capable of remaining in the operated position continuously and of carrying twice the circuit rated current continuously. The operating time of the breaker failure protection shall be selected by means of a timer with a range of 50 to 500m sec. The timer shall be of static design to minimize over travel. 3.0 CONTROL AND RELAY PANNELS AND AUXCILLARY APPARATUS: 3.1 GENERAL: Control and relay panels shall be of the all mounted type, and shall be constructed of enameled sheet steel not less than 2.5 mm thick unless otherwise approved. Cubicles shall be drip proof, dust proof and vermin-proof. They shall not without special approval be less than 600 mm wide, and in no case shall the depth exceed the width. The width between apparatus mounted on the cubicle side shall not be less than that which will permit full and easy access to all terminals and for apparatus mounted on the panels. Unless otherwise specified, separate cubicles must be provided tor the protection relays associated with each primary circuit. For control purposes one cubicle may accommodate apparatus associated with not more than two circuits in which case a vertical barrier must be provided inside the cubicle to segregate the wiring associated with each primary circuit. Cubicle doors shall be hinged. Hinges shall be of the lift-off type. Doors shall be secured by integral handles, and provision shall be made for padlocking. A lamp shall be fitted inside each cubicle and so arranged that all wiring is illuminated as evenly as possible without dazzle. The lamps shall be controlled from a door switch .

Rev 2- May. 2011

81

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

Circuit labels shall be provided on the front and at the top of the cubicle door. Where panels are supplied to form an extension to an existing installation they shall be designed to match those existing panels in terms of size, color and facilities etc. 3 .2 CONTROL SWITCHES: Control switches for electrically operated circuit-breakers, isolators and integral earth switches shall be of the discrepancy type. Pistol grip type control switches shall be used only for to local control of electrically operated circuit-breakers and shall be arranged to operate clockwise when closing the devices and anti-clockwise when opening the. Shrouded pushbutton controls may be used for local control of 33 kV circuit breakers. 3 .3 INSTRUMENTS: All instruments shall be of the flush mounting type and shall be fitted with non reflecting glass. Measuring instruments used for circuit with a two-way power flow shall have centre zero measuring devices. All instruments and apparatus shall be capable of carrying their full load currents without undue heating. They shall not be damaged by the passage of fault currents within the rating of the associated switch gear through the primaries of their corresponding instrument transformers. All instruments and apparatus shall be back connected, and the cases thereot- shall be earthed. Means shall be provided for zero adjustment of instruments without dismantling. All voltage circuits to instruments shall be protected by a fuse in each unearthed phase of the circuit placed as close as practicable to the instrument transformer terminals, or, where instruments are direct - connected, as close as practicable to the main connection. All power factor indicators shall have the star point of their current coils brought out to a separate terminal, which shall be connected to the star point of the instrument current transformer secondary windings. All indicating instrument scales shall be long, clearly divided and indelibly marked, and the pointers shall be of clean outline. The marking on the dials shall be restricted to the scale marking. Instrument transformer ratios, maker's name, accuracy grades etc., shall not appear on the dials. Busbar voltmeters shall be calibrated will hot. Instrument scales shall be submitted for approval.

3.4 INDICATIONS AND ALARMS: Semaphore indicators shall operate reliably at voltages down to 80 percent of normal. They shall be arranged so that a supply failure does not at any time create an erroneous indication. A trip circuit supervision scheme shall be provided for each circuit 1 a~d shall be arranged to monitor the continuity of the circuit -breaker or I fault throwing Rev 2- May. 2011

82

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

switch trip coil and as much of the associated tripping I wires as possible. The scheme shall be to approval. Annunciated alarms and indications shall be by lamps illuminating a legend, and shall operate from the station battery specified. The " annunciation's shall be grouped, each group containing the alarms and indications associated with the particular switch gear concerned. Each group of alarms shall be provided with pushbuttons for " Accept", "Re- set" and "Lamp Test". The enunciator units shall respond to persistent and transient alarms as prescribed in the following Table.

Initiating Contacts and Repeat Contacts Visual Alarm Persistent Transient Audible Alarm

Alarm/ enunciator Condition

Open

Normal

OFF Flashing Flashing Steady ON

OFF

OFF

Closed Flashing Flashing Steady ON ON ON OFF Open

Alarm initiated Contacts re-set before Accept

After Accept and return to Normal After Accept and return to Normal Re-set before return to Normal re- set after return to Normal Lamp Test

Closed

Open

Slow flash

Steady ON

OFF

Closed

Steady ON

Steady ON

OFF

Open

OFF

OFF

OFF

Open

Steady On

Steady ON

OFF

A return to the alarm state before "Re-Set" shall restore the enunciator to visual alarm flashing audible alarm on the duration of the flash shall be such that the legend may be easily read and the speed of flashing shall not exceed three per second. A distinction shall be made between functions bv the use of the following colors:Red Amber Rev 2- May. 2011 . . . .

83

Trip Alarm SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

White . . Indication The lettering should show white on a dark background or black on an illuminated background. In the former case the amber or red shall show as a bar of approximately 3 mm below the inscription. Where it is desired to include fire alarms in an enunciator group the facia. At each station a lockable switch shall be provided which will enable supplies to audible and visual alarms to be interrupted when the station I unattended. The switch shall not interfere with the storage of alarms. In addition a common audible alarm accept button shall be provided on the common control panel. Facilities shall be available to enable the whole alarm and indication Equipment to work into a Remote Supervisory system, by the provision of potential free repeat alarm contacts on the enunciators units. Where feeder protection requiring a supply from a voltage transformer device is installed, approved means shall be provided to give indication of failure of the voltage from the voltage transformer. Means shall be provided for indicating the failure of normal alarm supplies. The means of indicating such a failure shall be subject to approval. 3.5 INDICATING LAMPS: Indicating lamps and lamp holders shall be arranged so that replacement of lamps and the cleaning of glasses and reflectors employed can be readily effected. To reduce heating and fouling of the panels, lamps, which are continuously alight, shall have the minimum consumption consistent with good visibility of indications in a brightly-lit room. Indicating lamp glasses on control and relay panels, shall conform to the following standard color code:Red Green White Amber . . . . .. .. .. .. Device closed Device open Indications normally alight Alarm indications

3.6 SYNCHRONIZING APPARATUS: In each circuit equipped with an electrical]y operated circuit-breaker and for which synchronizing apparatus is specified, connections between 1 the specified control point or points and the coil of the circuit-breaker , shall be made through a synchronizing selection arrangement, so that is impossible to close the circuitbreaker until the appropriate synchronizing selection arrangement is made. A switch shall be provided with each synchro-scope to enable it to be disconnected and the voltmeters left in circuit. The connections of regulating voltmeters shall be arranged so that they are connected in circuit by means of the synchronizing selection arrangement of any panel equipped with synchronizing voltage transformer. Rev 2- May. 2011

84

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

Where busbar voltage transformers are not provided, an automatic voltage selection scheme shall be provided to automatically derive a busbar voltage reference from the circuit voltage transformers. The direct paralleling of voltage transformer secondaries is not permitted. Synchronizing check relays shall not operate when one synchronizing voltage or any auxiliary supply is absent or due to transient conditions when being switched in. A voltage check feature shall be incorporated to inhibit synchronizing if either voltage is less than a preset value, which shall be adjustable in steps from 80% to 90% of nominal rated voltage. The synchronizing relay shall prevent closure when the phase difference exceeds 35, but alternative settings of 20 and 45 shall be available also. Closure shall be prevented also if the slip exceeds a setting, which shall be adjustable over the approximate range 0.25% - 0.1%. When specified an automatic override relay shall be provided to permit closing under dead line or dead bus conditions. This relay shall short-circuit the synchronizing check relay contacts when energized by a.c. no-voltage relays novoltage relays having settings cot exceeding 30% of nominal rated voltage. A time delay shall be incorporated into this feature so that the override is not effected in less than 3 seconds from the time of initiation and energization of the synchronizing check relay. When this feature is in operation an audible and visual alarm shall be initiated. The no-voltage relays which shall form the dead line or dead bus checking arrangements shall comprise the following i) A check relay for no running voltage and a check relay for no incoming voltage to be arranged with normally-opened and normally -closed contacts so that the override relay can be energized if one or the other of these two relays is de -energized, but not both or neither, and subject to (b) below. ii) A fused check relay directly connected to the voltage transformer terminals on the line side of the main voltage transformer fuses for the synchronizing phase of every voltage transformer. This relay shall have normally closed contacts which shall be selected by the synchronizing selection relay to the appropriate circuit of the running and incoming check relays referred to under (a) so that the -override relay can be energized only if the voltage transformer no- volt relay is agreement with the incoming or running no-volt relay as may be relevant. Each circuit shall be provided with a synchronizing selection switch to enable MANUAL-OFF-CHECK (or ALTO) positions to be selected. This switch shall be key operated, the key' being released in the OFF position only. All selector switches on both 33 Kv and II kV feeder and incoming circuits shall be operated by one common key. In both the MANUAL and check position the synchronizing instruments shall be connected to the appropriate voltage transformers and the circuit-breaker closing circuit prepared. When supervisory control of a circuit breaker is specified, the closing command from the supervisory system shall automatically initiate selection of synchronizing-check and override relays The selection scheme shall seal-in for a period sufficient for the necessary synchronizing checks to be made and shall re-set after this period has elapsed or when the circuit breaker closes. Rev 2- May. 2011

85

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

Where specified a system synchronizer shall be fitted. This shall be capable of providing a suitable 'close' instruction to the selected circuit breaker when system conditions are correct. It shall be able to operate correctly if the circuitbreaker is to connect two points of the system that are already connected by some other link ( check synchronizing) or if the two points are not yet connected (system synchronizing) and be able to distinguish between the two conditions. When operating as a check synchronizer the device shall only close the circuitbreaker if: i) the phase difference between running and incoming voltage is less ,) than a preset value (adjustable over a range not less that 10-30 in steps not exceeding 100) for a preset time (adjustable over a range not less than 2-10 sec in steps not larger than 2 seconds), and; ii) the voltage difference between running and incoming voltage is below a preset value (adjustable over a range not less than from 10 to 20% of nominal in steps not exceeding 2 %) or the voltage level of both incoming and running voltage is above a preset value ( each individual1y adjustable over a range of not less than 80-90% of nominal). When operating as a system synchronizer the device shall only close the circuitbreaker if:i) The frequency difference between running and incoming voltage is below a preset value (adjustable over a range of values of slip of not less than from 0.05 Hz to 0.2 Hz in steps not exceeding 0.05 Hz). ii) The voltage difference between running and incoming voltage is below a preset value (adjustable over a range of values not less than from 10% to 20% in steps not exceeding 21,2% of nominal). The closing pulse shal1 be generated at a time so that, providing system conditions do not change, the circuit -breaker closes when the two voltages are in phase. This feature shal1 have a setting to allow for circuit- breaker operating times between 50 and l00 ms in steps cot exceeding 10 ms. The synchronizer shall also allow the circuit-breaker to close under dead bar live line conditions or live bar dead line conditions if so preset. In this case equivalent safeguards shall be provided to prevent inadvertent closure should input signals fail on the check-synchronizing scheme as specified elsewhere. The synchronizer shall have voltage free contacts to indicate the relative incoming circuit levies (volts too high, volts too low, frequency too high and frequency too low). It shall also have an adjustable timer to disengage the system synchronizer if system conditions have not been such to permit circuit breaker closure 'Within a preset time. This timer shall be adjustable over a range from 5 min to 30 min in steps not exceeding 5 minutes.

Rev 2- May. 2011

86

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

3 .7 RELAYS, FUSES, LINKS AND AUXCILLARY APPARATUS : All relays shall be mounted in such positions that no part requiring inspection or adjustment is less than 450 mm or more than 2 meters above floor level. Where practicable the clearances between relay stems or connecting studs shall not be less than 30 mm and in no case less than 25 mm. Unless otherwise stated all relays for front of panel mounting shall be flush pattern and with draw-able. Relays associated with the three phases shall be marked with the appropriate phase identification and the fuses and links shall also be suitably labelled. Isolating links and fuses as approved shall be provided on e3.ch panel to facilitate the isolation of all sources of electrical potential to permit testing or other work on the panel without danger to personnel or interference with similar circuits on other panels. The use of permanently energized relays shall be kept to a minimum and where approved these shall be of a type having a low burden to prevent drain on the station battery . All fuses and links shall be accommodated within the cubicle. Fuses and links shall be grouped and spaced according to their function in order to facilitate identification. As an alternative to fuses and links miniature circuit breakers will be accepted. Links in current transformer circuits shall be of the bolted type, having size M6 hexagon nuts. All incoming circuits in which the voltage exceeds 125 volts shall be fed through insulated fuses and/or links, the supplies being connected to the bottom terminal, which shall be shrouded. The contacts of the fixed portion of the fuse or link shall be shoaled so that accidental contact with Live metal cannot be made when the unloving portion is withdrawn. Resistance boxes shall be so mounted inside the cubicle that their Adjustment screws are on a vertical and accessible face. Resistance shall be provided with stud terminals. Sets crews shall not be used. 3.8 EARTHING ARRANGEMENTS: All Control and relay panels shall have a continuous earth bar ofa sectional area of not less than 75 mm2 run along the bottom of the panels, each end being connected to the main earthing system. Metal cases of instruments, and metal bases of relays on the panels shall be connected to this bar by conductors of a sectional area of not less than 2.5 mm2. Current transformer and voltage transformer secondary circuits shall be complete in themselves , and shall be earthed at one point only, through links situated in an accessible position. Each separate circuit shall be earthed through a separate link, suitably labelled. The links shall be of the bolted type, having M6 nuts and provision for attaching test leads. The earth link for protective and

Rev 2- May. 2011

87

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

instrument current transformer secondary circuits shall be mounted inside the relay cubicles. Earth links , for metering current transformer secondary circuits shall be mounted at the switch gear . 4.0 SMALL WIRING AND TERMINATIONS: 4,1 GENERAL: All Wiring shall have insulation incapable of supporting combustion. The insulation shall be of a uniform colour. The minimum size of wiring other than for light current (telephone type) apparatus shall be 1.5 mm copper, except for current transformer secondary which shall be not less than 2.5 mm2. All wiring shall be neatly run and securely fixed in suitable cleats in such a manner that, wherever practicable, wiring can be checked against diagrams without removing cleats. Cleats shall be of porcelain, non- reusable metal, or approved mounded insulating material and preferably of The limited compression type. Wiring passing out of the cubicles and wiring between compartments shall be ['In in non-reusable flexible tubes, galvanized steel tubes or robust pressed steel ducting. Wherever practicable, wiring shall be accommodated on the sides of the cubicles, and the wires for each circuit shall be separately grouped. Back of panel wiring shall be so arranged that access to the connecting stems of relays and other apparatus and to contacts of control and other switches is not impeded. Where provision is made for addition of equipment not required initially, means shall be adopted for supporting and terminating wiring during the interim period. All wiring shall be taken to terminal boards and wires shall not be jointed or teed between terminal points. Stranded conductors shall be terminated with tinned (not soldered) claw washers, separate washers, separate. Washers being used for each Conductor or an approved crimped termination may be used. Wiring diagrams shall preferably be drawn as if viewed from the back, and it shall be clearly stated on each diagram which view is employed. They shall show the terminal boards as arranged in service. Bus wires shall be fully insulated, and shall be run separately along the top or bottom of cubicles. Fuses and links shall be provided to enable all circuits in a cubicle, except the lighting circuit, to be isolated from the bus wires. Wherever practicable circuits in which the nominal voltage exceeds 125 volts shall be kept physically separated from the remaining wiring. The nominal voltage of each circuit shall be marked on the associated terminal boards. Except for the lighting circuit the nominal voltage of a.c. circuits brought into relay or control cubicles shall not exceed 125 volts. Lighting circuits in excess of 125 volts shall be fully shrouded throughout. DC supplies and a.c. voltage transformer supplies shall be fed through separate fuses direct from the main supply fuses or the bus wires to each protection or other main group. There shall not be more than one set of supplies to the apparatus comprising each such group. Wiring liable to come in contact with oil shall have suitable oil- resisting insulation. The bared ends of stranded conductors shall be sweated together to prevent creepage of oil along the wire. There shall be no possibility of oil Rev 2- May. 2011

88

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

entering connection boxes for cables or wring. Where the use of conduits is adopted the runs shall be laid with suitable falls and the lowest parts of the run shall be external to kiosks or boxes. All conduit-runs shall be adequately drained and ventilated. Conduits shall not be run at or below ground level. 4. 2 IDENTIFICATION OF Wiring: Numbered ferrules shall be fitted to all internal wiring and to multi-core cable tails. Ferrules shall be of insulating material of approved colour with a glossy finish to prevent adhesion of dirt. They shall not be affected by damp or oil and shall be clearly and permanently marked and shall not be easily detachable from the wire. Phase terminations shall be colour coded red, yellow and blue unless approved otherwise. Ferrule numbering throughout shall be in accordance with latest issue IEC standards. Marking of Insulated Conductors. The system of marking to be used shall be of the remote-end dependent type. The system of identification marks shall be to the approval of the Engineer. 4.3 TERMINAL BOARDS: All wiring shall be connected to terminal boards; wires shall not be Joined or teed between terminal points. Terminal boards shall have separate terminals for incoming and outgoing wires and shall be to the approval of the Engineer. Not more than two wires shall be connected to any one-stud type terminal. Insulating barriers shall be provided between adjacent pail-s of terminals. The height of the barriers and the spacing of the terminals shall be such as to give adequate protection while allowing easy access to terminals. Sufficient spare terminals equivalent to a minimum of 10% of those used shall be provided in addition to those required for future Remote Supervisory Functions and termination of spare cores of cables. Terminal boards may be of the stud or insertion type by boards incorporating the pinch-screw type of terminal shall not be used. Terminals of a type, which rely on a blade biting through the insulation on wiring to make contact with the conductor, will not be accepted. Insulating barriers shall be provided between adjacent pairs of terminals. The height and spacing of the barriers shall be such as to give adequate protection to the terminal whilst allowing easy access to the same. Terminal boards of the stud type, other than those associated with telephone apparatus shall be provided with brass studs of not less than 6mm in diameter. Stainless steel or phosphor bronze studs of4mm diameter may be utilized. Terminal boards of the insertion type shall be of a type having pressure plates. All connections shall be made to the front of the terminal boards. Current shall not be carried through the boards by the studs, except in the case of oil-tight terminations. No live metal shall be exposed at the back of the terminal boards.

Rev 2- May. 2011

89

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

Covers of insulating material, preferably transparent, shall be provided on terminal boards on which connections for circuits with a nominal voltage greater than 125 volts are terminated. Terminal boards shall be spaced not less than 100mm apart. They shall be mounted vertically at the sides of the cubicle, and set obliquely towards the rear doors to give easy access to terminations and to enable ferrule numbers to be read without difficulty. All terminals on hinged panel doors shall be shrouded. Terminations shall be grouped according to function and labels shall be provided on the terminal board to show the purpose of the group. The working voltages of each circuit shall be marked on the associated terminal board, and where terminals may be live when the Equipment is isolated from the main supply, these shall be clearly identified.

Rev 2- May. 2011

90

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

5 Schedules 5.1 (Sw-01) Technical Particulars 11 Kv Metal clad Switchgear :

Spec NO A 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Description 11 kV SWITCHGEAR SUITE Standard Country of Manufacture Manufactures type number * Highest system voltage * Rated voltage * Rated Continuous current * Rated symmetrical short-circuit current(3sec) *Power. frequency withstand voltage (I min) Impulse withstand voltage (1.2/50 us full wave * Busbar material and cross-section * Busbar permissible temperature rise over 50 ambient * Thickness of steel for the enclose * Details of 630 A circuit-breaker enclose : Length Height. Width. * Details of (1250) A circuit-breaker encloser. Length. Height. Width. Mass. * Details of bus sectionalizes circuit-breaker encloser. Length Height. Width. Mass. KV KV A KA KV KV mm2 C mm mm mm mm mm mm mm kg 12 11 630-1250 25.5 28 75 Copper Unit SPEC Complete by manufacturer

15 -

mm mm mm kg

B

1 2 3

11kV CIRCUIT -BREAKERS

Manufacture Country of manufacture Manufacturers Type number

Rev 2- May. 2011

91

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

Type of arc quenching medium. (vacuum) * Highest system voltage * Rate voltage * Number of phase/class * Rated continuous current * Rated symmetrical short circuit breaking currant 9 kA at highest system voltage * Rated symmetrical short circuit breaking current 10 kA at max rated voltage 11 * Rated peak short circuit current 12 * Rated short circuit making current (peak) 13 *Rated short-time current (3s) 14 * Power frequency withstand voltage (1min.) 15 * impulse withstand voltage (1.2 / 50 us full wave) * Earthing Facility : a) instantaneous peak current rating 16 b) Short-time current rating c) Integral to circuit-breaker 17 Type of insulation medium Ntr Bear of switch operation between two inspection for changing the main contacts: 18 a) with No- Load. b) with rated continuous current c) with rated breaking current Mass of the heaviest pat to be handled during 19 general Inspection

4 5 6 7 8

Kv Kv A KA KA KA KA KA Kv Kv KA KA Yes/No

vacuum 12 11 3

630 1250

31.5 31.5 38 75 630-1250 Vacuum -

Operating mechanism

a) Type - mechanical - hydraulic b) Power consumption for closing per pole c) Power consumption for opening per pole d) Read supply voltage for motor e) Range of voltage for operating the ripping mechanism f) Range of voltage for close breakers g) Number of tripping coils. h) Number of closing coil. Type o auxiliary switches: a. Number of used contacts (normally open, Normally closed) b. Number of spare contacts (normally open, Normally closed Protection Relays: A- E/F and O/C Relays Protection. B- DE/F and DO/C Relays Protection. C- Differential Relays Protection. D- Restricted E/F Relays Protection. E- Sensitive E/F Relays Protection. F- Distance Relays Protection. Measuring instrument: (A,V,PF, F ,Kw ,kvar ,kwh, kvarh) Motor spring Char mechanical 140w 140w 110VDC 85%110%VDC

20

W W V.Dc

21

6~0 + 6~C 6~0 + 6~C

22

Yes/No Yes/No Yes/No Yes/No Yes/No Yes/No Yes/No

Yes Yes Yes Yes Yes Yes Yes

23

Rev 2- May. 2011

92

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

C

1 2 3 4 5 6 7 8 9 10

11 kV CURRENTTRANSFORMER

Manufacture Country of manufacture Manufactures Type number Applicable standards *Highest system voltage Rated voltage Rated frequency *Rated primary current Rated secondary current Number of cores Protection core (1). - Ratio - Accuracy class - Rated burden - Saturation factor - Knee point voltage Vk - Magnetizing current - Secondary winding resistance *Protection core2: - Ratio - Accuracy class - Rated burden - Saturation factor - Knee point voltage Vk - Magnetizing current - Secondary winding resistance Protection core (3) : - Ratio - Accuracy class - Rated burden - Saturation factor *Different transformation ratios achieved by reconnection of primary winding tapping on secondary winding. *One minute power frequency with stand voltage (rms) primary winding. Impulse with stand voltage (peak primary winding) * Rated short-time thermal current (3s) *Temperature rise over 50 o C ambient temperature RANGECURRENT TRANSFORMER Manufacture Country of manufacture Manufacture's Type number Applicable standards *Highest system voltage Rated voltage IEC 185, 186 KV KV HZ A A 12 11 50 600-1200 1 3 800-400/1 Class1 15 1.9 0.7 2In 0.05

11

VA % V A

12

% VA V A

-800-400/1 C/15P10 10 1.9 0.7 2In 0.05 800-400/1 Class 15 0.7

13

% VA

14 15 16 17 18

KV KV KA C

38 95 25.5 55

D

1 2 3 4 5 6

KV KV

93

Rev 2- May. 2011

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

7 8 9 10

11

12

13 14 15 16 17 18 19 20 21 22 23 24 25

Rated frequency *Rated primary current Rated secondary current Number of cores Protection core (1). - Ratio - Accuracy class - Rated burden - Saturation factor - Knee point voltage Vk - Magnetising current - Secondary winding resistance *Different transformation ratios achieved by reconnection of primary winding tapping on secondary winding. *One minute power frequency with stand voltage (rms) primary winding. Impulse with stand voltage (peak primary winding) * One minute power frequency withstand voltage (rms) secondary winding. * Rated short-time thermal currant (ls) * Rated dynamic current * Rated continuous thermal current (1s) * Minimum secondary conductor cross section area *Temperature rise over 50 o C ambient temperature * Kind of insulation (molded resin) * insulation class * Material of bushing (porcelain ,_molded rein) * Material of complete current transformer * Over all dimensions -- Length - Width - Height. Description 11/33 kV VOLTAGETRANSFORMER Manufacture Country of manufacture manufacturers type number Applicable standard *Highest system voltage *Rated voltage *Rated frequency * Number of phases * Connection * Rated primary current *Rated secondary current

HZ A A

50 5

% VA V A

KV KV KV KA KA KA mm2 C

Kg mm mm mm Unit

E 1 2 3 4 5 6 7 8 9 10 11

KV KV Hz

KV KV

Rev 2- May. 2011

94

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

12 13 14 15 16 17 18 19 20 21

F 1 2 3 4 5 6

Secondary winding -Accuracy class - Rated output *One minute power frequency with stand voltage (fins) Impulse withstand voltage (peak), primary winding One minute power frequency with stand voltage (fins) secondary winding *Rated voltage factor at rated time& - 30 seconds - continuous *Temperature rise over 500C ambient temperature Kind of insulation Material of bushing (porcelain, molded rein) Mass of complete voltage transformer Overall all dimensions - Length - Width - Height Description IDMT OVER CURRENT AND EARTH FAULT RELAYS Manufacture Country of manufacture Manufacture's Type number Relay Type Current Transformer Secondary Rating(In) Over Current Unit Current Setting -Low Set O/C Stage -High Set O/C Stage Time Setting -Time Multiplier(T.M.S) -Operate Time Earth Fault Unit Current Setting -Low Set E/F Stage -High Set E/F Stage Time Setting -Time Multiplier -Operate Time Burden Operation Indicator Out put Contact -Number -Reset Auxiliary supply Description SENSITIVE EARTH FAULT RELAYS Manufacture Country of manufacture

% VA KV KV

KV

Kv

Unit

SP.

1&5

A A

50-200% --------0.05-1

Sec.

A A

0.1-0.4 ---------0.05-1

10 11 12

sec VA

13 G 1 2

Unit

SP.

Rev 2- May. 2011

95

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

3 4 5 6

8 9 10

11 H 1 2 3 4 5 6

Manufacture's Type number Relay Type Current Transformer Secondary Rating(In) Current Setting -Low Set S.E/F Stage -High Set S.E/F Stage Time Setting -Time Multiplier -Operate Time Burden Operation Indicator Out put Contact -Number -Reset Auxiliary supply Description EARTH FAULT RELAYS 4-

A A A

1&5 0.002-0.5 -------------------0.02-10

sec VA

VDC Unit

110 SP.

8 9 10

11 I 1 2 3 4 5 6

Manufacture Country of manufacture Manufacture's Type number Relay Type Current Transformer Secondary Rating(In) Current Setting -Low Set E/F Stage -High Set E/F Stage Time Setting -Time Multiplier -Operate Time Burden Operation Indicator Out put Contact -Number -Reset Auxiliary supply DIFFERENTIAL PROTECTION RELAYS Manufacture Country of manufacture Manufacture's Type number Relay Type Current Transformer Secondary Rating(In) Current Setting Diff. Operation Current (Id) Bias (In % through circuit) Highest Operation Current Operation Time Burden Operation Indicator Out put Contact -Number -Reset Auxiliary supply

A A A

1&5 0.1-0.4 ---------0.05-1

sec VA

Unit

SP.

A A A ms VA

1&5

---------

7 8 9 10

11

Rev 2- May. 2011

96

SW - 01

11 & 33 kV INDOOR METAL CLAD SWITCH GEAR

J

1 2 3 4 5 6

RESTRECTED EARTH FAULT RELAYS