Professional Documents

Culture Documents

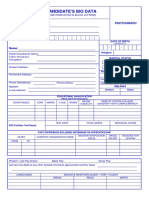

Untitled

Uploaded by

masindesalumCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Untitled

Uploaded by

masindesalumCopyright:

Available Formats

Scribd Upload a Document Search Documents Explore DocumentsBooks - FictionBooks - Non-fictionHealth & MedicineBrochures/CatalogsGo vernment DocsHow-To Guides/ManualsMagazines/NewspapersRecipes/MenusSchool Work+

all categoriesFeaturedRecentPeopleAuthorsStudentsResearchersPublishersGovernment & NonprofitsBusinessesMusiciansArtists & DesignersTeachers+ all categoriesMost FollowedPopular..Sign Up Log In..1First Page Previous Page Next Page / 66Sections Section:2.2A.6.1 TAPES FOR HEIGHT MEASUREMENTSection 1 of 19 .2.2A.6.1 TAPES FOR HEIGHT MEASUREMENTp. 102.2A.6.2 TAPES FOR CIRCUMFERENCE MEASUREMENTp. 112.2A.7 Calibration of Working Tape with the Master Tapep. 122.2A.9 Tank Status Before C alibrationp. 132.2A.12 Shell Plate Thicknessp. 13Top. 162.2A.13 Vertical Tank Me asurementsp. 182.2A.17 Floating Roofsp. 262.2A.17.2 FLOATING ROOF WEIGHTp. 262.2 A.17.4 DEDUCTING FLOATING ROOF DISPLACEMENTp. 262.2A.19 Tank Capacity Table Deve lopment: Calculation Proceduresp. 292.2A.19.8.2 Measurement Procedure for Floati ng Roof Displacementp. 362.2A.19.8.1 Liquid Calibration for Floating Roof Displa cementp. 362.2A.19.8.3 Liquid Level Above Position Bp. 362.2A.19.8.4 Capacity Ta ble with Floating Roof Treated as Deadwoodp. 372.2A.19.8.5 Capacity Table of Gro ss or Open- Tank Capacityp. 372.2A.19.11 CERTIFICATION OF CAPACITY TABLESp. 38Fi gure B-2-Typical NIST Report of Calibrationp. 44.Zoom Out Zoom In Fullscreen Exit FullscreenSelect View Mode View ModeSlideshowScroll ...Readcast Add a Comment Embed & Share Reading should be social! Post a message on your social networks to let others k now what you're reading. Select the sites below and start sharing.Readcast this Document.. Login to Add a Comment.. Share & Embed.Add to Collections Download this Document for FreeAuto-hide: on ManualofPetroleumManagement StandardChapter 2-Tank CalibrationSection 2A-Measure ment and CalibrationofUpright Cylindrical Tanks y theManual Tank Strapping Metho dFIRSTEDITION,FEBRUARY1995American Petroleum Institute1220LStreet, NorthwestWash ington,D.C. 20005rT>COPYRIGHT 2002; American Petroleum InstituteDocument provide d by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Questions or com ments about this message: please call the Document PolicyManagement Group at 1-8 00-451-1584. - - - STEPOne of the most significant long-term trends affecting the future vitalityf the petroleumindustry is the publics concerns about thenvironment. Recognizing th is rend, API mem-ber companies have developed a positive, forward looking strate gy called STEP: trategiesfor Todays Environmental Partnership. This program aims to address public concerns byimproving industrys environmental, health and safety performance; documenting perfor-mance improvements; and communicating them to t he public. The foundation of STEP isthe API Environmental Mission andGuiding Env ironmental Principles. API standards, bypromoting the use of sound engineering a nd operational practices, are an important meansof implementing APIs STEP program .API ENVIRONMENTAL MISSION AND GUIDINGENVIRONMENTAL PRINCIPLESThe members of the American Petroleum Institute are dedicated to continuous efforts toimprove the compatibility ofouroperations with the environment while economically de-velopin g energy resources and supplying high quality products and services to consumers .The members recognize the importance of efficiently meeting societys needs and o ur re-sponsibility to work with the public, the government, and others to develo p and to use nat-ural resourcesinan environmentally sound manner while protectin g the health and safetyof our employees and the public.Tomeet these responsibili ties,APImembers pledge tomanage our businesses according to these principles:To

recognize and to respond to community concerns about our raw materials, products and operations.To operate our plants and facilities, and to handle our raw mater ials and productsinamanner that protectshe environment, and the safety and healt h f our employees and thepublic.To make safety, health and environmental conside rations a priorityinour planning, andour development of new products and process es.To advise promptly appropriate officials, employees, customers and the public of infor-mation on significant industry-related safety, health and environmenta l hazards, and torecommend protective measures.Tocounsel customers, transporters and othersinthe safe use, transportation and disposalof our raw materials, prod ucts and waste materials.To economically develop and produce natural esources an d to conserve those resourcesby using energy efficiently.To extend knowledge by conductingorsupporting research on the safety, ealth and en-vironmental effects of our raw materials, products, processes and waste materials.To commit to reduc e overall emissions and waste generation.To work with others to resolve problems created by handling and disposal of hazardoussubstances from our operations.Top articipate with government and others in creating responsible laws, regulations andstandards to safeguard the community, workplace and nvironment.To promote the se principles and practices by sharing experiences and offering assistanceto oth ers who produce, handle, use, transportordispose of similar raw materials, petro -leum products and wastes.COPYRIGHT 2002; American Petroleum InstituteDocument p rovided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16 MDT Questions or comments about this message: please call the Document PolicyMan agement Group at 1-800-451-1584.--APIMPMSt2-2A95m07322900543363864mManualofPetroleumManagement StandardChapter 2-T ank CalibrationSection 2A-Measurement and CalibrationofUpright Cylindrical Tanks ytheManual Tank Strapping MethodMeasurement CoordinationFIRST EDITION, FEBRUARY1 995AmericanPetroleumInstituteCOPYRIGHT 2002; American Petroleum InstituteDocumen t provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Questio ns or comments about this message: please call the Document PolicyManagement Gro up at 1-800-451-1584.---- APIMPMS*2.2A95m07322900543364'TOmS PECIALNOTES1.API PUBLICATIONS NECESSARILY ADDRESS PROBLEMS OF A GENERALNATURE. W ITH RESPECT TO PARTICULAR CIRCUMSTANCES, LOCAL, STATE,AND FEDERAL LAWS AND REGUL ATIONS SHOULDBE REVIEWED.2. APIISNOT UNDERTAKING TO MEET THE DUTIES OF EMPLOYERS , MANU-FACTURERS, OR SUPPLIERS TO WARN OR PROPERLY TRAIN AND EQUIPTHEIR EMPLOYEE S, AND OTHERS EXPOSED, CONCERNING HEALTH ANDSAFETY RISKSANDPRECAUTIONS, NOR UNDE RTAKING THEIR OBLIGATIONSUNDER LOCAL, STATE, OR FEDERAL LAWS.3.INFORMATION CONCE RNING SAFETY AND HEALTH RISKS AND PROPERPRECAUTIONS WITH RESPECT TO PARTICULAR M ATERIALS AND CONDI-TIONS SHOULD BE OBTAINED FROM THE EMPLOYER, HE MANUFACTUREROR SUPPLIER OF THAT MATERIAL, ORTHE MATERIAL SAFETY DATA SHEET.4.NOTHING CONTAINED IN ANY API PUBLICATION ISO BE CONSTRUED ASFACTURE, SALE, OR USE OF ANYMETHOD, A PPARATUS,OR PRODUCTCOVERED BY LETTERS PATENT. NEITHER SHOULD ANYTHING CONTAINEDI N THE PUBLICATION BE CONSTRUED AS INSURING ANYONE AGAINSTLIABILITY FOR INFRINGEM ENTOF LETTERS PATENT.GRANTING ANY RIGHT, BY IMPLICATION OR OTHERWISE, FORTHE MAN U-5.GENERALLY, API STANDARDS AREREVIEWEDANDREVISED,REAF- FIRMED, OR WITHDRAWN AT LEAST EVERY FIVE YEARS. SOMETIMES AONE-TIME EXTENSION OF UP TO TWO YEARS WILL B E ADDED TO THISREVIEW CYCLE. THIS PUBLICATION WILL NO LONGER BE IN EFFECT FIVEYE ARS AmER ITS PUBLICATION DATE AS AN OPERATIVEPISTANDARD, ORWHERE AN EXTENSION HA S BEEN GRANTED, UPON REPUBLICATION.STATUS OFTHE PUBLICATION CAN BE ASCERTAINED F ROM THE APIPUBLICATIONS AND MATERIALS IS PUBLISHED ANNUALLY AND UPDATEDQUARTERLY BY API, 1220 L STREET,N.W., WASHINGTON, DC 20005.AUTHORING DEPARTMENT [TELEPHON E (202) 682-8000]. A CATALOG OF APICopyrightO1995AmericanPetroleum InstituteCOPY RIGHT 2002; American Petroleum InstituteDocument provided by IHS Licensee=YPF/59 15794100, User=, 09/18/2002 15:43:16 MDT Questions or comments about this messa ge: please call the Document PolicyManagement Group at 1-800-451-1584. - - - APIMPMS+2=2A95m07322900543365637mFOREWORDAPI publications maybeused by anyone desiring todoso.Every effort has been madeby the Institute to assure the accurac

y and reliabilityf the data contained n them; however,the Institute makes no rep resentation, warranty,r guarantee in connection with this publi-cation and hereb y expressly disclaimsany liability or responsibility for lossordamageresulting f rom its use r for the violationfany federal, state, or municipal regulation with which this publication may conflict.Suggested revisions are invited and shouldes ubmitted to Measurement Coordination,Exploration and Production Department, Amer ican Petroleum nstitute, 1220LStreet,N.W.,Washington,D.C.20005.iiiCOPYRIGHT 2002 ; American Petroleum InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16 MDT Questions or comments about this message: please call the Document PolicyManagement Group at 1-800-451-1584. - - - CONTENTSSECTION 2AMEASUREMENT AND CALIBRATIONOFUPRIGHTCYLINDRICAL TANKSBYTHE MA NUAL TANKSTRAPPING METHODPage2.2A.1Scope........................................ ........................................................................12.2A.2R eferenced Publications.......................................................... .........................12.2A.4Definitions..................................... ...................................................................22.2A.3Safety ................................................................................ ................................12.2A.5Significance............................. .........................................................................22.2A.6 Equipment....................................................................... ..................................22.2A.6.1Tapes for Height Measurement......... ...........................................................22.2A.6.2Tapes for Ci rcumference Measurement.......................................................32 .2A.6.3Accessory Equipment...................................................... ............................32.2A.7Calibration of Working Tape with the Master T ape..........................................42.2A.8General Practices........... ................................................................................ ...52.2A.9Tank Status Before Calibration........................................ .................................52.2A.10Descriptive Data....................... ........................................................................52.2A.11 Tolerances...................................................................... ...................................52.2A.12Shell Plate Thicknesses.............. .......................................................................52.2A.14C ircumferential Measurements..................................................... ..................122.2A. 14.2Physical Measurements............................. .............................................132.2A.15Deadwood Measurement...... ..........................................................................152.2A .16Tank Bottoms................................................................. .................................182.2A.17Floating Roofs........................ ........................................................................182.2A. 17.1General..................................................................... ................................182.2A. 17.2Floating Roof Weight................ ...............................................................182.2A. 17.4Deduc ting Floating Roof Displacement................................................. ...182.2A.19Tank Capacity Table Development: Calculation Procedures............. .............212.2A.13Vertical Tank Measurements................................ ..........................................102.2A. 14.1Preparation............... ................................................................................ 122.2A. 17.3Deadwood Determination.............................................. ...........................182.2A. 18Insulated Tanks............................ ...................................................................182.2A.19.12. 2A. 19.22.2A.19.32.2A.19.42.2A.19.52.2A.19.62.2A.19.72.2A.19.8Capacity Table Req uirements...................................................................22Ca libration of the Master Tape to60F............................................... .....22Conversion of Outside to Inside Circumferences........................... ..........22Deductions for Circumference Tape Rises............................. ..................22Expansion and Contraction of Steel Tank Shells Due to Temper ature....27Floating Roofs.......................................................

...................................28Expansion and Contraction of Steel Tank She lls Due to Liquid Head.....25Effect of Tilt on Cylindrical Portion of Tank...... .....................................27.2.2A. 19.8.1Liquid Calibration for Float ing Roof Displacement........................282.2A. 19.8.2Measurement Procedure for Floating Roof Displacement...............282.2A.19.8.3Liquid Level Above Po sition B........................................................282.2A. 19.8.4Ca pacity Table With Floating Roof Treated as Deadwood..............292.2A.19.9Summ ary Data on the Capacity Table.................................................. ..302.2A.19.11Certification of Capacity Tables.................................. ...........................302.2A. 19.8.5Capacity Table of GrossorOpen-Tank Capa city.............................292.2A.19.10Recalibration Requirements......... ..........................................................30APPENDIXA-GUIDELINES FOR RECALIBRATION OFSTORAGETANKS............................................... ............................31VCOPYRIGHT 2002; American Petroleum InstituteDocum ent provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Quest ions or comments about this message: please call the Document PolicyManagement G roup at 1-800-451-1584.---PageAPPENDIX B-EXAMPLE CALCULATIONS FORUPRIGHTCYLINDRICAL STEEL TANK-ABOVEGROU ND....................35APPENDIX C- GUIDELINES FOR COMPUTER INPUT............... ........................47APPENDIXD-SHELL TEMPERATURE CORRECTION FACTORS........ ............49APPENDIXE-UNDERGROUND TANKS....................................... .......................53APPENDIX F-TANK CALIBRATION METHOD SELECTION........... ................57Figures1-Height Measuring Tape and Bob........................ ....................................................22-Strapping TapesforCircumf erence Measurements...............................................33-Jointed Typ e Tape Guides................................................................... ...................4Record Form for Deadwood..................................... ..............................................6&Measurement Locations for Rivete d Shingled Arrangement...............................107-Measurement Locations f or Bolted Tanks............................................................118-V ertical Tank Measurements-Welded................................................ ...................129-Vertical Tank Measurements-Bolted........................ ............................................1410-Vertical Tank Measurements-Rive ted................................................................1511-Effectiv e Inside Tank Height-Cone Roof.................................................. .........1612-Effective Inside Tank Height-Floating Roof........................ ..............................1713-Spherical Segment (Dished), Hemispherical and Semi-EllipsoidalBottoms, Convex and Accessible Measurements of Upright Tanks... ................1914-Coned Downward Bottom and Accessible Measurements of Uprigh t Tanks....205-Measurement Locations for Welded Upright Tanks................... ............................915-Diagram of Floating Roof at Rest (A) and Floatin g (B)...................................2116-Typical Steel Pontoon Floating Roof With Single Center Deck........................2517-True Circumference Versus T ape Pathat Axial Lap Joint AwayFrom Circumferential Joint....................... .........................................................26B-2-Typical NIST Repo rt of Calibration............................................................... ..36E- 1-Locations of Measurements on Upright Cylindrical ConcreteUnderground Ta nks............................................................................. .............54E-2-Locations of Measurements on Rectangular Steel or ConcreteUnd erground Tanks.................................................................. ........................55F-1-External Floating-Roof Tank Decision Chart........ ...........................................58F-2-Fixed-Roof Tank Decision Chart. .....................................................................58F-3-Chart for Internal Floating-Roof Tanks............................................... .............58B-1-Upright Cylindrical Tanks Composite Construction............. ...........................35Tables1-Suggested Record FormAfor Measurements of Upr ight2-Suggested RecordFormB for Measurements of UprightCylindrical Tanks.......... ................................................................................ .........83-ElevationsforCircumference Measurements on Various Types ofUpright C

ylindrical Tanks................................................................ ....................13Hircumferential Tolerances................................ ..................................................135Customary Version Capacity T able......................................................................23&SIV ersion Capacity Table........................................................... .........................24Cylindrical Tanks.................................... ...............................................................7A-1-Tank Bottom Course Inside Diameter Variations.............................................31 A-2-Tank Bottom Course Plate Thickness.......................................... ....................31A-3-Volume Correction for Table Tilt...................... ...............................................31A-Tank Shell Temperature Variati ons..................................................................31A-5-Produ ct Specific Gravity Variations.................................................. ...............32viCOPYRIGHT 2002; American Petroleum InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Questions or comm ents about this message: please call the Document PolicyManagement Group at 1-80 0-451-1584. - - - APIMPMS*Z-ZA95m073229005433b834bmPageB-1-Typical Measurement Recordofan Uprigh t Cylindrical SteelTank for Example Calculations................................ ........................................37B-2-Typical NIST Report of Calibration .................................................................38B-3A-Tank Tab le Run Sheet.................................................................... ...............44B-3B-Run Sheet for Soft ConversiontoMetric..................... .................................45COPYRIGHT 2002; American Petroleum InstituteD ocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16 MDT Questions or comments about this message: please call the Document PolicyManage ment Group at 1-800-451-1584. - - - Chapter 2-Tank CalibrationSECTION 2AMEASUREMENT AND CALIBRATIONOFUPRIGHT CYLIND RICAL TANKS BY THE MANUAL TANK STRAPPING METHOD2.2A.1cope2.2A.1.1This standard d escribes the procedures for cali-brating upright cylindrical tanks used primaril y for thestorage of petroleum liquids. Section 2A first addressesprocedures for making necessary measurements to determinetotal and incremental tank volumes and then presents therecommended procedures for computing volumes.2.2A.1.2Both SI(m etric) and customaryunits represented where appropriaten the chapter.SIand custo maryconversions may not necessarilyeexact. TheSIunits oftenreflect what is avail able in commercial equipment.2.2A.1.3The standard also provides guidelines for r ecal-ibration and for computerization of capacity tables.2.2A.2eferences2.2A.2.1 REFERENCED UBLICATIONSThe following publications are cited in this standard:APIS td650 Welded Steel Tanks for Oil StorageStd 653 Tank Inspection,Repair,Alteratio n,and ReconstructionStd2555Liquid CalibrationofTanksManualoPetroleum Measurement StandardsChapter 2, Tank Calibration, Section 2B,CalibrationofUpright Cylindrical TanksUsing the Optical Reference Line MethodICS/OCIMF2/IAPHInternational SafetyGuid e for Oilankers and Terminals(ISGOTT)4Ip5Petroleum Measurement ManualPart 2, Tank Calibration, Section,VerticalCylindrical Tanks, Measurement MethodsNFPA6306 Contro loGas Hazards on VesselsInternational ChamberfShipping,30/32Mary Axe Street, Lond on EC3A8ET,England.*OilCompanies International Marine Forum, Portland House, 6th Floor,Stag Place, London SWESBH, England.71ntemational AssociationfPorts and Har bors, Kotohira-Kaikan Building,2-8,Toranomon I-Chome Minato-Ku, Tokyo105,Japan.4 1SC07Tis available from Witherby Co., Ltd. Manne Publishing), 32/36Aylesbury Str eet, LondonECIROET,England.51P,61New Cavendish Street, London WIM 8AR, England.6 National Fire Protection Association, Batterymarch Park,P.O. Box 9101,Quincy, Ma ssachusetts 02269-9101.12.2A.2.2NFORMATIVEPUBLICATIONSThe following publications re listed for information only:APIStd 2551 Measurement and CalibrationoHorizont alStd 2552Measurement and CalibrationofSpheres andStd 2554Measurement and Calibr ationofTank CarsManualofPetroleum Measurement StandardsTanksSpheroidsChapter 2, T ank Calibration, Section7,Calibration of Barge Tanks;Section8A,Calibration of Tanks on Ships and Ocean-going Barges1s077507-17507-27507-3Petroleum and Liquid Petrole um Products:Volumetric CalibrationofVerticai Cylin-drical Tanks,Part 1, Strapping

MethodPetroleum and Liquid Petroleum Products:Volumetric CalibrationofVertical C ylin-drical Tanks,Part 2, Optical Reference LineMethodPetroleum and Liquid Petrole um Products:Volumetric CalibrationofVertical Cylin-drical Tanks,Part3,Optical Tri angulationMethod2.2A.3afety2.2A.3.1Before entering any tank, permission must beob tained from the Terminal Supervisor, authorized official,orother responsible per son in charge. This responsibleperson should supply information regarding articu lar mate-rials and conditions or the applicable Material Safety DataSheet (MSDS) .2.2A.3.2Due consideration should be given to applicablesafety procedures. Safet y considerations include, but are notlimited to, potential electrostatic hazards , potential personnelexposure (and associated protective clothing and equipmentr equirements), and potential explosive and toxic hazardsassociated with a storage tanks atmosphere. The physicalcharacteristics of the product and existingperatio nal condi-tions should be evaluated, and applicable international,federal, state , and local regulations should be observed.International OrganizationorStandardiz ation.IS0publications are avail-ablefromANSI.~~~~~COPYRIGHT 2002; American Petro leum InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/200 2 15:43:16MDT Questions or comments about this message: please call the Document PolicyManagement Group at 1-800-451-1584. - - - 2APIPflS*212A9507322900543370TTYCHAPTER,SECTIONA~~~ ~~2.2A.3.3In addition,befo reenteringastorage ank, safety procedures designated by the employer, the termin aloperator, and all other concerned parties should also beobserved. It shall be indicated that the tank is Safe forWorkers and/or Safe for Hot Work, as prescribed i nNFPA 306,U.S.Coast Guard, OSHA, or other international,federal, state, or local regulations that may apply. Suchtesting must be made at least every24hours or m orefrequently when conditions warrant.2.2A.3.4Internationally, theInternationalS afety GuideforOil TankersAndTerminals (ISGOTT) houldbeconsulted.2.2A.3.5Furtherm ore, another person should stand watchat the tank entrance for the duration, and sound an alarm ifan emergency occurs. Appropriate protective clothing andequipm ent shouldbeused. Normal safety precautions withrespect to staging and ladders m ustalso be observed.2.2A.4efinitions2.2A.4.1ACapacityTableor aTank CapacityTable shows the capacities of, or volumes in a tank for variousliquid levels measured from the eference gauge point.2.2A.4.2Deadwoodrefers to any object within the ta nk,including a floating roof, which displaces liquid and reducesthe capacity of the tank;alsoany permanent appurtenanceson the outside of the tank, such as clea nout boxesormanholes, which increase the capacityofthe tank.2.2A.4.3False Bottom is commonly referring to a newbottom installed on top of the previous tank botto m, whichwill reduce the bottom ring height and the effective insidetank height.2 .2A.4.4Master Tapeis a tape that is used for calibratingworking tapes for tank m easurement and s identified with aReport of Calibration at 68 degrees Fahrenheit (68F) [20degrees Celsius (20C)I and at a specific tension designatedby the Nation al Institute of Standards and Technology(NIST)oran equivalent nternational stand ard organization.2.2A.4.5Tank Strappingis the term commonly applied othe procedu re for measuring tankso provide the dimensionsnecessary for computing capacity t ables that will eflect thequantity of product in a tank at any givendeptwevel.2. 2A.4.6Reference Gauge Heightis the vertical distancebetween the reference point on the gauge hatch and thestriking point on the tank loor or on the gauge datum plate.2.2A.4.7Successive Tangent Methodisthe measurementof a circumference on a tank when the tape is not longenough to span the entire circumference of a tank. 2.2A.4.8ContinuousWraparoundProcedureis themeasurement of a tank circumference w itha tape that is longenough to span the entire circumference of a tank.2.2A.5ig nificance2.219.5.1Accurate ank circumference measurements arecritical in determi nations of liquid volume and the develop-ment of capacity table or Custody Trans fer transactions andinventory control. This standard providesmeasurement andcomp utational procedures for the development of such acapacity table.2.2A.5.2All suc h measurements shouldbewitnessed byall parties involved to ensure compliancewith the procedureoutlined in the standard and overall measurement integrity.2.2A.6q uipmentThe equipment used in dimensional Tank Calibration isdescribed in 2.2A.6. 1 through 2.2A.6.3. Allequipment shallbe in good working condition. Ail tapes sh allein one pieceand free of kinks.2.2A.6.1TAPESFORHEIGHTMEASUREMENTFor height me

asurements, a teel tape (see Figure l), ofconvenient length,34or14inches wide an d 0.008 to 0.012inches thick, graduated in feet and inches to eights of aninch, or in feet, tenths, and hundredths of a foot is recom-mended. (For metric tapes, refertoIP Petroleum Measure-mentManual,Part 2, Section1)Graduations shall beu-F igure 1-Height Measuring TapeandBobCOPYRIGHT 2002; American Petroleum InstituteD ocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Q uestions or comments about this message: please call the Document PolicyManageme nt Group at 1-800-451-1584.---MEASUREMENTND CALIBRATIONOF UPRIGHTCYLINDRICALTANKS"_~3accurate withinX6inchor 0.005foot(orto nearestmillimeter) throughout that portion of the tape tobeused.2 .2A.6.2TAPESFORCIRCUMFERENCE MEASUREMENTFor circumference measurements, a mild s teel tape, (seeFigure 2) of convenient length relative to the tankircumfer-ence is recommended. The working tape is usually00,200,300,or500feet long and should notbemore than!4inchwide, and approximately0.01inch thick. The tape maybegraduat ed in feet, withanextra1foot length at the zero endof the tape and raduated in t enths and hundredths of a foot,oritmay be graduated in feet, tenths and hundredt hs of afoot throughout its length (for metric tapes, refer toIPPetroleum Measure ment Manual,Part2,Section1).Allworking tapes should be calibrated with a Master tape (referto 2.2A.7).2.2A.6.3ACCESSORYEQUIPMENTAdditional measuring equipment r ecommended is listedbelow. Other similar equipment may be used, provided itwill give the same results.a. Reels and tapes shall be equipped with appropriate reel sand handles.b. Tape clamps: for assurance of positive grip on tape,clamps shall beused.c. A spring tension scale is needed.d. Rope and ring: two lengths of rope line fitted with snapand ring areobeused in raising and lowering circumferencem easurement tape. Alternatively, jointed-type pole guidesmaybeused (see Figure3). e. Transitorlevel or both are used when required.f.Ladders to facilitate handlin gf tapes and removalfscale,rust, dirt,etc. from the path f measurement are neede d.g. An ultrasonic thickness measurement device is used.h. A plumb line is neede d.i. Depth Gauge: a depth gage of case-hardened steel,6inches in length, graduat ed to%inch (1 millimeter resolu-tion and read o nearest0.5millimeter)isfor deter minationofthicknessofsteel plates is needed.j. Straightedge: a straightedge of a ppropriate length and aprofile board for measuring knuckles are used.k. Calipers and special clamps for spanning obstructions inmaking circumference measurement s, the following arerecommended:Figure 2-Strapping Tapes for Circumference Measu rementsCOPYRIGHT 2002; American Petroleum InstituteDocument provided by IHS Lice nsee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Questions or comments about t his message: please call the Document PolicyManagement Group at 1-800-451-1584.--4CHAPTER,SECTIONAFigure 3-Jointed Type Tape Guides1. Maximumexpansioncalipers o f 6 nches or15centimeters) for spanning the smaller obstructions, such asvertica l flanges, bolt heads, etc.2.Maximum xpansion alipers ofISinches 45centimeters) or24inches (61 centimeters) for spanningthe larger obstructions, such as butt st raps, etc.3.Special clamps may be substituted for calipersinmeasuring projecting flanges.The following may be useful equipment: a six foot rulerfor general meas urements, shovel, spirit level, awl andscriber, marking crayon, record paper, an d cleaning instru-ments, such as putty knife and hard bristle brush or elim-inat ing dirt, grease, paint scale, rust particles, etc. from thepath of circumferenc e measurements.2.2A.7Calibration of Working Tape withthe Master Tape2.2A.7.1The tape used for circumference measurementsshall be calibrated (for required tensio n) by matchingitagainst the master tape in the following manner:a. Choosea conve nient tape path (i.e.0percent of ring height)on the lower ring, and place the ma ster tape around theank.b. Using the successive tangent method, make a scribe ma rkonthe shell, determining the origin of the circumference.Apply the ape, with c onstant application of tension at whichthe master tape was certified to be accur ate, to the tank shellat the proper tape path with the tapes zero mark locatedexa ctlyonthe scribe mark designating the origin point. Thetape is placed in positio n with required tension, and the lastreading on the tape is scribed on the tank shell at each100feet (or 30 meters) or fraction thereof. This measurement iswrit ten on the tank shell and recorded. This procedure isrepeated until the entire c ircumference is measured.c. Total the measurements obtained.d. Place the working

tape around the tank, using the sametape path, by the continuous wraparound proce dure.e. Slide the working tape to break frictional resistance, andapply tension sufficient to equal the measurement obtainedwith the master tape.f.The amount of tension, in pounds, required o be pulled onthe working tape to obtain the same measurement as thatrecorded with the master tape shall be applied to the working tapewhen taking circumferential measurements.f the tensiondetermined tobeproper for the working ape is insufficient tohold the tape in the proper position, addi tional tension shouldbe applied and a correction made to bring the reading intoa greement with that obtained with the master tape.2.2A.7.2The preceding procedure shall be carried outwhen calibrating other tanks whose circumference differs by more than20percent from the calibrated tape section andwhere tank surfaces are d ifferent.2.2A.7.3Two working tape corrections are illustratedinthe following exa mples. Note thatonditions one and two forapplication of working tape orrections apply for either case,that is, where themaster tape and working tapeare of equal or different lengths. The same procedure applies for metricmeasurements.a. Condi tionNo.1: If additional tension is required to beapplied o the working ape to eq ual he measurementobtained by the master tape, thenomathematical correctionis ne eded. The additional tension required to equal themaster tape measurement must b e applied to all subsequentcircumferences obtained with the working tape.b.Condi tionNo.2:If the same or additional tension isapplied to both he master tape and the working tape and themeasurements do not agree, then a mathematical correctio nshall be applied as indicated in the examples below. Thedetermined differences must be applied to all working tapecircumferences before the processingofthe cap acity table.c. ExamplesExample 1:314.515 feet Master tape at10pounds tension per 314.475 feet Working ape at20pounds tension.100 feet or part thereof.0.040feet C orrection orworkingtapetobeaddedto each circumference measured.Example2:314.515 feet Master tape at10pounds tension per3 14.590 feet Working apeat20pounds tensi on.100feet or part thereof.0.075 feet Correction for working tape to besubtracte dfrom each circumferencemeasured.COPYRIGHT 2002; American Petroleum InstituteDoc ument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Que stions or comments about this message: please call the Document PolicyManagement Group at 1-800-451-1584.---API MPMS*I?"2A95m0732290 0543373703MEASUREMENTND CALIBRATIONOFUPRIGHT CYLINDRI CALTANKS~ ~~~~~~~~~ ~ ~~~~~~~~ ~~~ ~~ ~~~~~~I2.2A.8eneralracticesAll measurement s and descriptive data taken at theanksiteshouldbechecked and immediately, legib ly recorded with therecording preferably assigned to single individual,sfollows: a. All measurements should be taken without disruption andpreferably on the same day of calibration with the liquidlevel remaining static.f measurements have to be disrupted,interrupted tank measurement work may be continued at alater date, without repeating thework previously completed,provided all records of the work are complete and legible.Movement of liquid intoorout of the tank may be olerat ed,provided a clearly marked liquid gauge and average temper-atures of both liqu id and utside atmosphere are included sparts of these subsequent strappingoperat ions.b. All data and procedures necessary for the preparation ofcapacity tables should be supported by sound engineeringprinciples.c. Each ank shall be identifi ed clearly and legibly bynumberorby some other suitable marking, but this identi fi-cation should not be painted on tankttachments.2.2A.9TankStatus Before Calibr ation2.2A.9.1Beforecalibration, the tank shall havebeenfilled at least once at i ts present location with liquid t leastas dense as is expected o contain. The hy drostatic test for aperiod of approximately24hours) will usually satisfy thisreq uirement. Any hydrostatic test should be performed inaccordance with applicable construction andperating stan-dards (DIStandard 650 and 653). When possible, the liquidin thetankshould be allowedo stand still for approximately24 hours before calibration s performed.2.2A.9.2Tanks with a nominal capacity of 500 barrels or less may be strapped at any condition of fill, provided thetanks have been illed at least once at their present location.Small movementsof oil intoorout of such tanks are allowedduring strapping.2.2A.9.3Tanks with a nominal capacity of more than500barrels shouldbehandled this way:a. Bolted Tanks (usually in Production Service) must havebeen filled at least oncet their present location and musteat least two-thirds full when strapped. Small movementsofoil into or out of suchtan

ksare allowed during strapping.b. Riveted Tanks and/or Welded Tanks must have be enilledat least once at their present location. They mayestrappedat any conditio n of fill and the full capacity computed asshown in 2.2A.19.5.No movement of oil intoorout of suchtanks is allowed during the strapping operation.2.2A.10Descrip tiveData2.2A.10.1Complete descriptive data should be entered ontheTankMeasuremen ts RecordFormbeing used. Suggestedrecord forms are shown in Figure 4and Tables1a nd 2.52.2A.10.2The API gravity and the temperature of thetank's contents at the timef strapping shallbeobtained andrecorded. The average API gravity, average ov erall ambienttemperature at which the tank shall operate and maximumsafe fill he ight (refero 2.2A.13.5) shall beobtained from thetank owner and recorded.2.2A.10 .3Supplemental ketchesor notations, eachcompletely identified, dated, and signed , should accompanythe strapping report. These should indicate the following:a. T ypical horizontal and verticaloints.b. Number of plates per ring.c. Location of rings at which thickness of plates changearrangement.d. Size of angles at top an d bottom of shell.e. Location and size of pipes and manways.f. Dents and bulges in shell plates.g. Amount of lean from vertical in relation to the referencegaug e point.h. Procedure usednbypassing a large obstruction, such s acleanout box or insulation box locatedinthe path of acircumferential measurement.i. Location of tapepath different from that shown in Figures5 through7.j.Location and elevation of a possible datum plate.k.All other items of nterest and value which wille enc oun-tered.2.2A.10.4Entries of data on a tank measurements recordform or suppleme ntal data sheets should not be erased. Ifalteration is necessary, the entry to b e changed should bemarked out with a single line and the new data recordedadjace nttothe old entry.2.2A.11olerances2.2A.11.1Single circumferential measurements s houldbe read and recorded to the nearest0.005feet (or nearestmillimeter), which is equal to one-half of the distancebetween two adjacent hundredth-foot division marks onhetape. Therefore, all circumferential measurements shoulderecorded thr ough the third decimal place.2.2A.11.2Vertical tank measurements should be read andrecorded to the nearest&inch (or nearest1millimeter).2.2A.11.3Thermometers sh ould be read to the nearest1For 0.5"C).2.2A.11.4Tank plate thicknesses should be determined tothe nearestYMinch (1 millimeter resolution and read tonearest0.5mil limeter).2.2A.11.5Deadwood should be determined and located bymeasurement readin gs to the nearest inch(or3 millimeter).2.2A.12ShellPlateThickness 2.2A.12.1Plate hickness should be measured by Ultra-COPYRIGHT 2002; American Petroleum Institu teDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MD T Questions or comments about this message: please call the Document PolicyManag ement Group at 1-800-451-1584. - - - 6CHAPTER,ECTIONATANKNO.FROMDESCRIPTIONIECESOHlNOZZLE2Figure &-Record Form for DeadwoodCOPYRIGHT 2002; American Petroleum InstituteDocument provided by IHS Lic ensee=YPF/5915794100, User=, 09/18/2002 15:43:16 MDT Questions or comments abou t this message: please call the Document PolicyManagement Group at 1-800-451-158 4.---WASTEMANAGEMENTRACTICESFORPETROLEUMMARKETINGACILITIESTable1Suggested Record Fo rm"A'orMeasurementsofUpright CylindricalTanksReport No.:....................Date :.........................TankNo:............................................... ...................................(OldTankNo.):................................ ..........................................Owner'sName:.......................... ..................................................Plantorproperty Name:......... .............................................................Location:.......... .......................................................................Manufactu red by:......................................................................... ..Erectedby:.................................................................... ............TableFormorSizeDesired:............................................. ...................Height: Shell:................Gauging:....................... ..............................Type ofRoof.................Weight of Floating Roo f........................................Gauge:.................ft.............. .................in.; nnage o: Shell FloororOutageHydrometer Reading:........... .......at.................................."FSample TemperaPrepare:........Copie

s:..........Increments in.:..........Fractions to:........................Tank C ontentsName:..................Avg. Liquid Temp.,'F:............................. .....tureGauging Reference Point to Top f Top Angle:......t.....in.; Normal Serv ice.....Shell Circumferences:A.......................D...................G...... ................B.......................E...................H................... ...C.......................F...................J.......................Descripti ons of Shell Plates and JointsRingNo.hickness7.........6.........5.........4.... .....3.........2.........(Btm.ing)1.........Shell Connections:h~~~~~~~~~~~~~~~No .Description1..........2..........~~~-Type ofVerticalJoint~~",.34............... ...5..................6..................Amount of Tank Lean from Vertical:c...C ircumferenceaoesed:............................................................. ..............................WidthfhicknessSet, inLaporof Lapor No. of Inside R ingoroutStrap StrapJointsHeightElevation-Top ofFloortoBottom of Connection..--.. .".-............................................................................ ................................................................................ ................................................................................ .....................................................in.....in....t.....n.DateCh k'd....t....TankMeasuredby:............or.............Deadwood and Tank Bottom-U se separate sheets. For each pieceoritem of deadwood record description, size,nu mber of occurrences, and location related to other height measurement data recor ded.Explanatory Notes (such as type f bottom, heightordepth of crown, etc.)..... ......................................................Note: No.=Number; Avg. Liq uid Temp.=Average Liquid Temperature; ft.=foot/feet; in.=inch(es)ashow sketches of vertical and horizontal joints on back of this Table.bShow circumferential lo cation on plan view sketched on back of this Table.Show direction of lean on pla n view sketched on back of this Table.COPYRIGHT 2002; American Petroleum Institu teDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16 MDT Questions or comments about this message: please call the Document PolicyMan agement Group at 1-800-451-1584.--APIMPMS*2-2A950732290O543376 128APIUBLICATION1638~~~~Table 2-Suggested Record Form"B"or MeasurementsofUpright Cylindrical TanksReport No.:...................D ate:........................TankNo:............................................. ....................................Owner'sName:................................ ............................................PlantorPropertyName:................ .....................................................Location:.................. ...............................................................Manufacturedby:.. ........................................................................Erectedb y:.............................................................................. ..Table FormorSize Desired:..................................................... ...........(OldTankNo.):........................................................ .................Prepare:.........Copies:.........Increments in:.........Fractio ns to:Height: Shell:.................Gauging:................................... ................Type of Roof:..................WeightofFloating Roof............ ...............Tank Contents-Name:..................vg. Liquid Temp.,"F......... ............Gauge:.........ft..........in.; Tank Service:...........API Gravity: Hydrometer Reading:...........t.........F Sample TemperatureShell Circumferences :A.......................D..............B.......................E..............C .......................F..............Descriptions of Shell Plates nd Joints:~~~ ______~~____Ringo. Thickness Type of Set, inVertical or outJoint~ ~~~~~76....... ..................5.........................4.........................3......... ................2........................(Btm.ing)1.........................Dead wood and Remarks (use reverse side if necessary):~ ~~ ~~~ ~..................... ......__~Width of ThicknessLaporof LaporStrapStrap~ ~~.......................... ................................................................................ ......................G.......................H.......................J......... ......~No. ofJoints~~~~~Deadwood ElevationDescriptionNo.-~ize From-o............ ................................................................................ ................................................................................ ............................Type of Bottom:.......................HeightofCrown:

............Witness:.............................Measurements by;............... ..............Inside RingHeight................................................. ................................................................................ ..............Note: Avg. Liquid Temp.=Average Liquid Temperature; "F=degrees Fah renheit.; in.=inches; ft=foot; Btm=Bottom~ ~ ~~COPYRIGHT 2002; American Petroleu m InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 1 5:43:16 MDT Questions or comments about this message: please call the Document PolicyManagement Group at 1-800-451-1584.---APIMPMS*Z.ZA95m07322900543377359MEASUREMENTNDCALIBRATIONFUPRIGHTYLINDRICALANKS 9"sonic measurement device as the preferred method.Aminimum of two measurements per ring should bebtained.2.2A.12.2Plate thickness measurements obtained beforeo r during construction and recorded on properly identifiedstrapping record may be accepted. In the absence of anydirectmeasurements of plate hicknessobtained and recorded beforeorduring construction, the least preferredmethod is to use the pl ate thickness shown on the fabricator'sdrawings andsoidentifiedinthe calculation recordsrinfor-mation provided by tank owner.2.2A.12.3The alternate method of me asuring plate thick-ness is by depth gauge. Where the type of constructionleaves the plate dges exposed, a minimumoftwo thicknessmeasurements should be made on each ring. The arith-""""""""i"""-4_"1D4--iButtWeldedLap WeldedFigure 5-Measurem ent Locations for Welded Upright TanksCOPYRIGHT 2002; American Petroleum Institu teDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16 MDT Questions or comments about this message: please call the Document PolicyMan agement Group at 1-800-451-1584.---API MPMS*2*2A95m07322900543378295m10CHAPTER,SECTIONA~~~~~~~~~~~ ~ ~~~metical a verage of the measurements or each ring shoulderecorded; all thickness measureme nts, properly identified,should be notedona supplemental data sheet which should form a part of the measurement record.Care should be takento avoid plate thickne ss measurements at locations whereedges have been distorted by caulking.2.2A.13V erticalTankMeasurements2.2A.13.1Shell height is the vertical distance betweenbot tom of bottom angle (or top offloorplate) and top of topangle, and should be mea sured at a point near the referencegauge hatch (see Figures8,9,and10).2.2A.13.1. 1Additional measurements should be made, asrequired, at other identified points sufficient to investigateand describe known r suspected conditionsinthe tank, su chas tilt or false bottom. Locationsofmeasurements should bemarkedona supplement al sketch.2.2A.13.1.2The amount oftiltin shell height should bemeasured and reco rded. The measurements for possibletiltmay be made in conjunction with measureme nts of shellheights using a theodolite, an optical plummet, orplumb bob.2.2A.13. 2Adescription of the reference gauge pointshouldbeincludedinthe record, or examp le: to op lip of8-inch (or20centimeter) diameter hatch, opposite hinge.2.2A.13.3 A comparison should be made immediatelyf thereference gauge heightith the sum of the shell height plus theheight from the topf the top anglef thetankshell to th e levelof the reference gauge point on the hatch rim,n order to inves-tigate the possible existencef a datum plate or false bottom.2.2A.13.3.1The result of this field investigation shouldberecorded by identifying the reference gauge height as adistance to heflooror to the datum plate.he measufementsand calculations inv olved should be attached to, and becomea part of, the measurement record.2.2A.13 .3.2If a false bottom is known or suspected to bepresent, the record shouldbesom arked.2.2A.13.4Effective nside ankheight s a verticaldistance along the gauging path (see Figures11and12).This is of primary concern to the capacity table calcu lations,establishing the upper and lower limits of variable gauges tobe provided for in the capacity table.2.2A.13.4.1The maximum upper limit of the capacitytab le can be one of the following two items:a. Effective inside tank height.b. Maxi mumfillheight requested by the tank owner,such asat the underside of an overflow .2.2A.13.4.2Ifthe effective inside tank height should beobtained directlyon the tank, this height should be measuredand reportedas such. If effective inside tan k height cannot bemeasured directly, the person responsible for obtaining themea surements should obtain as-built blueprints to enablecalculation of the effectiv e inside tank height.2.2A.13.5Insome installations, an overflow line or otherapp

urtenance is connectedo the tank shell ust below the opangle and provides a pote ntial liquid overflow level atsomepoint below the top of the shell (see Figure12 ).-4-.4-"Ii4-Lteel RivetedFigure 6"eaurement LocationsforRiveted Shingled Arrang ementCOPYRIGHT 2002; American Petroleum InstituteDocument provided by IHS Licens ee=YPF/5915794100, User=, 09/18/2002 15:43:16 MDT Questions or comments about t his message: please call the Document PolicyManagement Group at 1-800-451-1584.--MEASUREMENTNDCALIBRATIONFUPRIGHTYLINDRICALANKS112.2A.13.5.1The measurement rec ord should include acomplete descriptionofsuch a connection, including sizeand l ocation and whetheror not a valve which can be closedand sealed is included in t he line. If such a valve is present,its location shouldbeincluded in the record. 2.2A.13.5.2If the connection cannotbeclosedandsealedagainst overflow, then the e ffective inside tank height is thevertical distance from the striking point on t he tank floor, ordatum plate, upward to the levelt which the tank's contentswill begin to overflow; the tank capacity between the pointofoverflow and the tank r oof should be disregarded in thecapacity table.2.2A.13.5.3Ifthe connection can b e closed and sealedagainst overflow, then the effective inside tank height and t hei""c"c"One Ring TankThree Ring TankTwo Ring TankFigure 7-Measurement Locations forBoltedTanksCOPYRIGHT 2002; American Petroleum InstituteDocument provided by I HS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Questions or comments about this message: please call the Document PolicyManagement Group at 1-800-451 -1584. - - - 12CHAPTER,SECTIONAcapacity table, should extend upward to the topofthe top2.2A .13.5.7Where rings are lapped horizontally, the lapangle. shall be reportedsotha t the inside height of the ringane2.2A.13.5.4Inthis latter case,inwhichhe capaci ty tablebycalculationsais extended upward beyond the connection, the capacitytab le should include a note at the elevationoftheconnection2.2A.14CircumferentialMe asurementsciting its presence and stipulating the condition underwhich 2.2A.14., that portion of the capacity table may be used.2.2A.14.1.1Thecalibration technic ian responsible for2.2A.13.5.5The safe fill height, when required obeindi- measu ring thetankhouldfirstdeteminewherecatedinthebeso'FcifiedytheOwner. tial measure ments are toeaken. Circumferential measure-maximum fill height.measurements are to be taken over nsulation.Asummaryof2.2A.13.5.6Each ringheight hall be measured and elevations for circumference measurements on various typesThesafeheightin'I lstancesbelessthanments are to beaken onthe tank shell.Nocircumferentialrecorded (see Figure5).Height to ReferenceGaugePoint AboveTankShella,-ofupright cylindri cal tanksisshown in Table3.Reference GaugePointJ7-LD'+C+BFigure 8-Vertical Tank Measurements-WeldedCOPYRIGHT 2002; American Petroleum InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Questions or comm ents about this message: please call the Document PolicyManagement Group at 1-80 0-451-1584.---MEASUREMENTNDCALIBRATIONOFUPRIGHTCYLINDRICALTANKS13~~~ ~~~ ~-Table 3-Elevation s for Circumference Measurements on VariousypesofUpright CylindricalTanks~~~ ~Ty pefWelded Steel, OneorMore Rings20percent down from top f each ring whether Butt rLap JointsaRiveted Steel, Shingled ArrangementLowest point on each ring andIfoo t(or300 millimeters) below topof top ringbRiveted Steel, In-and-Out Arrangement Lowest point above horizontal rivet rows n each ring, and1foot (or300millimeters ) below top~ ~~~of top ringbRiveted Steel, Combinationhingled owestointboveorizo ntalivetowsnaching,nd Ifoot(or300 millimeters)elowandn-and-Outrrangementopfoping b Steelank One Ringigh,iveted5 and 75percentboveLap Joints on bottomof shellBolt ed Steel, Lapped Vertical Joints25and75percent above bottom of each ringBolted S teel, Flanged Vertical Joints75percent above bottom of each ringaForone-ring tan ks, two circumferential measurements shall be takent20percent and80percent down from top of the ring. For tanksf more than one ring,if obstructions block the ta pe path at the20percent down plane, the measurement may be taken t a point80perc ent down. If circumference measurementstakenonsuccessive rings indicate unusual variationsordistortions, sufficient additional measurements should be taken to s atisfy the requirements of allconcerned.bWhen bottom angle is welded, take lower

most circumferenceIfoot(or300 millimeters) above bottom of bottom ring. Where ta nk shells are of compositeconstruction. take measurements in accordance with ins tructions aboveforeach type of construction.2.2A.14.1.2Circumferential tape path s located at eleva-tions shown in the appropriate illustrationinFigures5through 10 should be examined for obstructions and type ofupright joints. Dirt, scale, a nd insulation should be removedalong each path.2.2A.14.1.3Occasionally, some fea ture of construction,such as a manwayorinsulation box,may makeitimpracticalto us e a circumference elevation prescribed on the appro-priate illustration. Then a substitute tape path located nearerto the center of the ring, may be chosen. The strappingrecord should include the location of the substitute path andthe reaso n for the departure.2.2A.14.1.4The type and characteristics of upright jointssho uld be determined y close examinationinorder toestab-lish the procedure of measu rement and equipment required.In the case of butt-strap or lap joints at which v oids betweentape and shell occur, the joints will be caused only by butt-strap o r plate thickness, uniform at each joint; then circum-ferences may be measuredna ccordance with the proceduredescribedin2.2A. 14.2.2.2A.14.2PHYSICALMEASUREMENTS2 .2A.14.2.1Fortheeasurementsescribed in2.2A.14.1, a circumference tape of suffici ent length toencircle the tank completely should be used, in which casemeasureme nt of total circumference with one reading shouldbetaken. In the event thathe ta nk circumference is too greatto be completely encircled by the tape, alternate m ethodsmaybeadopted (see AppendixF).2.2A.14.2.2All points at which circumferentia l measure-ments are read should be located at least 2 feet(or600millimeters) fro m an upright joint. After a circumferentialmeasurement has been taken, the tensi on should be reducedsufficiently to permit the ape to be shifted. Before reading ,the tape position should be verified. It should then bereturned to position and requiredension, and two successivereadings should be taken within specified tol erances as perTable4.The average of the two readings should be recordedas the ci rcumferential measurement at that location.Table 4-Circumferential Tolerances-~~ ~ ~ ~~~~~ ~~~~~ ~~~~~ ~CustomarySIUp to150fr.k0.01ft.Upto30m?2mm150to300ft.k0.0 2fr. 30 to50m?4mmOver 00t.f0.03 fr.50to70mk6mm70to 90m?8mmOver90m0mmNote: ft.=fe et; m=meter; mm=millimeter~ ~~~2.2A.14.2.3When butt-strap or lap joints cause un iformvoids between the tape and tank shell t each joint, circum-ference measurem ents should be madeinaccordance with2.2A. 14.2..The proper procedureisto measure and recordthe width and thicknessfbutt straps,and record the numberof butt stra ps in each ring.2.219.14.2.4In the case of lapped joints,oneshouldmeasure and re cord the thickness of exposed lapped plate(see Figure10)in each ring about the c ircumference, andrecord the number f such joints in each ring. The measuredCOPYR IGHT 2002; American Petroleum InstituteDocument provided by IHS Licensee=YPF/591 5794100, User=, 09/18/2002 15:43:16MDT Questions or comments about this message: please call the Document PolicyManagement Group at 1-800-451-1584.---APIMPMS*2-2A95073229005433827Lb14CHAPTER,SECTIONAcircumferences, properly chec ked and recorded, should be2.2A.14.2.6For spanning obstructions in making circum -corrected later for tape rise as described in2.2A.19.4.ference measurements, th e following is recommended.To2.2A.14.2.5When obstructions are encountered in the measure thesPm ofmobstruction, hecdiperinaho*-tape path Over which it is mpracti cable to place the tape (forZonta1 position, as determined by useOfa level, agai nst theexample, features which exert uneven effectsnthe resultantshellOfthetankb eing strapped,earthe centerfa Shell Plate,void between the tape and tank, from j oint to joint) thenand scribe marks on the shell with the two scribing points.al ternate methods may be adopted (see AppendixF).Apply the circumferential working tape under required tensionReference GaugePointHeight to Reference GaugePoint A boveTankShell1.TrFigure 9-Vertical Tank Measurements-BoltedCOPYRIGHT 2002; Ameri can Petroleum InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16 MDT Questions or comments about this message: please call t he Document PolicyManagement Group at 1-800-451-1584. - - APINPNS*Z.ZA95M073229005143383652MEASUREMENTND CALIBRATIONOFUPRIGHTCYLINDRICA LTANKSto the tank shell n such a position that the distance betweeninterior upri

ght cylindrical surface and roof-supportingthe scribed lines along the shell sur face maye estimated tomembers, such as columns and braces in the tank, should be the nearest0.001feet or to the nearest0.5millimeter.clean and ree from any forei gn ubstance including, but notlimited to, residuefcommodities adhering to theide s, rust,dirt, emulsion, and paraffin. Examination and inspectionf a2.2A.15.1The calibration procedures which are outlined ank may ndicate he need for thorough c leaning if accuracyherein are based upon internal cleanliness of the tank. The i n he calibration is to be achieved.2.2A.15DeadwoodMeasurementReference GaugePoin tHeight toReference GaugePoint Above Tank Shelli-LIIIRecord DimensionsofJointsas Indicated Above-F-E-C-B-AFigure1&Vertical Tank Measurements- RivetedCOPYRIGHT 2 002; American Petroleum InstituteDocument provided by IHS Licensee=YPF/591579410 0, User=, 09/18/2002 15:43:16 MDT Questions or comments about this message: ple ase call the Document PolicyManagement Group at 1-800-451-1584.---16CHAPTER, SECTIONA2.2A.15.2Deadwood should be accurately accounted for,b.Adeq uate allocationofthe effects at various elevationsas to size and location, to th e nearestXinch(or3millimeter)within the tank.inorder to permit the following:2.2 A.15.3Deadwood should be measured,ifpossible,a. Adequate allowance or the volume sof liquid displacedorwithin theank.Dimensions shownonthe builders drawingsadmitt ed by the various parts (see AppendixBforexampleordimensions furnished by the ta nk owner may be acceptedcalculations).if actual measurement is impossible.U1dnt1 LuA ShellHeightB Hatch eightCTotalofA+6DReference Gauge HeightE DifferenceBetwee nC&DFEffective nsideTankHeightNew BottomFalseBottomfOldBottomFigure11-Effective Inside Tank Height-ConeRoofCOPYRIGHT 2002; American Petroleum InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16 MDT Questio ns or comments about this message: please call the Document PolicyManagement Gro up at 1-800-451-1584. - - - APIMPMS*2-2A750732i700543385425MEASUREMENTNDCALIBRATIONFUPRIGHTCYLINDRICALANKS 172.2A.15.4Measurementsofdeadwood should show he2.2A.15.5Worksheetsonwhich detai lsofdeadwoodarelowest and highest levels, measured from the tankbottomsketched, dimensioned, and ocated should be clearly identi-adjacent o the shell, atwhichde adwoodaffects the capacity fied and should become a of the strapping record. of the tank (see Figure4).Measurements should be incre-ments which permit allowance or deadwoods varying effecton tank capacity at various elevations.m-aStandpipeIOp en TopAShellHeightB Standpipe HeightCTotalofA+BD ReferenceGaugeHeightE Differenc e BetweenC&DFDistance o BottomofOverflowG Effective InsideTank HeightWIFigure 12 -Effective Inside Tank Height-FloatingRoofICOPYRIGHT 2002; American Petroleum In stituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43 :16MDT Questions or comments about this message: please call the Document Policy Management Group at 1-800-451-1584.---18~~~~~____~~~2.2A.16TankBottoms2.2A.16.1Tank bottoms which are flat, level, a nd stableunder varying liquid loads will havenoeffect on tankcapacity.2.2A.16.2T ank bottoms conforming o geometric shapes(for example, sloping, cone down, crown up, hemispherical,semiellipsoidal, and spherical segment) have volumeswhichmayb eeither computed from linear measurementsr measuredby liquid calibration y incre mental filling,asdesired.2.2A.16.2.1When volumes are to be computed, measure-men ts should be made at the oints shownonthe applicableillustration in Figures 13-1 4.2.2A.16.2.2Any detailed differences in shape affectingthe volume, not shownont he strapping report, such asknuckle radii, should be measured and recordednsuffi cientdetail to permit computation of the true volume.2.2A.16.3Where tank bottom conditions of irregularslope or shape and/or instability existand where correctc apacities cannot be determined accurately from linearmeasurements, liquid calibr ation is preferred.2.2A.16.4If liquid calibration is used, incremental fillingof volumes are introduced into the tank, from the lowestpoint in the bottom to poi nt above which computations canbe made from dimensional measurements. The proced ureshould be continued to a depthinthe tank sufficient to over-come all irregula r shapes or unstable conditions as describedin API Standard2555(ASTM 01406).2.2A .16.5For tanks operated with the bottom completelyand continuously covered with

water, any slopeorirregu-larity, but not nstability, of the bottom may bedisrega rded.2.2A.16.6An alternativemethod of calibrating hebottom zone is by taking lev el elevations at various pointsalong he bottom hrough a bottom survey. A physica lbottom surveyof the tank bottom should be ade, wheneverpossible, after the tank has been hydrotested, in order toestablish the amount of slope from the tank sh ell to the tankcenter. The elevation at the strike point directly under thegaugi ng hatch should also be measured.2.2A.16.7Due to the nature of some bottoms bein g veryirregular, survey readings shouldbetaken at many points tobetter determine the shape. When performing a completebottom survey, elevations shouldesighted a long radii every45 degrees. Along these radii, obtain elevations at equallyspace d intervals not more than 10eet (or3meters) from hetanks center to its shell.2.2A .17FloatingRoofs2.2A.17.1ENERALFloating oofs, llustrated in Figures 15 and 16, a reinstalled in tanks with upright cylindrical shells. FloatingCHAPTER,SECTIONA~~ ~roof displacement, however, gives ise to special deductionsfor floating weight and deadwood, Position A (see Figure15),is the liquid level at which the liquid first touches thecontact deck of the roof. PositionBis the liquid level atwhich the last support of the roofifts free of the tank bottomand the roof is fully bu oyant.2.2A.17.2FLOATINGROOFWEIGHT When a roof is fully buoyant, it displaces an amount ofliquid equal in weight to the floating weight of the roof. Thefloating weight should include the roof plus any appurte-nances thatare canied up and dow n in the tank with the roof,including fifty percent f the weight of the stairway .The roofweight is calculated by the builder and hould be reportedbythe strapper .2.2A.17.3DEADWOODDETERMINATIONWhen all or part of the weight of a roof is resti ngontheroof supports, the roof and all appurtenances should bededucted as deadwo od as they become immersed in liquid.Deadwood includes such parts as the swing j oint, the drain,and other items that are attached to the tank shell or bottom.Si nce a swing pipe is normally full of liquid, only the metalvolumeisdeadwood. On the other hand, a closed drain isnormally empty, and the total pipeorhosevolume s included as deadwood. Deadwood also includes parts thateventually move with th e roof. The roof itself is deadwood,and as the liquid level rises around the roo f, its geometricshape determines how it should be deducted. The geometricshapesh ouldbe taken from he builders drawingsormeasuredinthe field while the roof is res tingn its supports.2.2A.17.4DEDUCTINGFLOATINGROOF DISPLACEMENTTwo methods of ded ucting floating roof displacementfrom capacity tables are as follows:a. Liquid c alibration.b. Mathematicalcalculation of roof displacement (seeAppendixB).2.2A.1 8InsulatedTanksThe following procedures maybeused in determining thedata necessa ry for the preparation of capacity tables. Calibra-tion of outside insulated tan ks may be completed beforetheinsulation is applied by following the procedures f or outsidemeasurements specified in this standard for above groundtanks of the s ametype.If the tank s insulated, the followingprocedures apply. Alternate proced ures, however, may beapplied as here indicated:a. Liquid Calibration: Insulated tanks maybecalibrated bythe introduction of measured quantities of liquid in acc or-dance with API Standard2555(ASTM D 1406).COPYRIGHT 2002; American Petroleum I nstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:4 3:16MDT Questions or comments about this message: please call the Document Polic yManagement Group at 1-800-451-1584. - - - ~~APIMPMS*2.2A950732290543387T8 W~~MEASUREMENTNDCALIBRATIONFUPRIGHTYLINDRICALA NKS19~~~~~~______-~--Tank ShellHead-to-ShellJointISpherical Segment (Dished) Bot tomb-ankShellTank ShellB-angent PointHemispherical Bottom"-4ead-to-Shell JointSe miellipsoidalBottomFigure 13-Spherical Segment (Dished), Hemispherical and emiel lipsoidal Bottoms Convexand Accessible MeasurementsofUpright TanksCOPYRIGHT 2002 ; American Petroleum InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Questions or comments about this message: please c all the Document PolicyManagement Group at 1-800-451-1584.---APIMPMSJ2.2A75m07322700543388 L3420CHAPTER,ECTIONA~ ~~~~"TWith Knuckle RadiusW ithout Knuckle RadiusFigure 14-Coned Downward Bottom and Accessible Measurements ofUpright TanksCOPYRIGHT 2002; American Petroleum InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Questions or comments

about this message: please call the Document PolicyManagement Group at 1-800-45 1-1584.---MEASUREMENTNDCALIBRATIONFUPRIGHTYLINDRICALANKS21b. Calibration Based on Inside Measurements: Calibrationfinsulated tanks may be basedoninside measurements bya pplication of API Chapter 2.2B.c. Calibration BasedonDrawings: Calibration mayeb asedon the data givenn the drawings andnthe specificationsofthe tank builder if none of the preceding methods can beused. This alternativesthe least preferred m ethod and is notrecommended for tanks used for custody transfer.d. Applicationof New Technologies: New technologies suchas optical triangulation method, electro optical distanceranging (EODR method) are described under Appendix.2.2A.19TankCa pacityTableDevelopment: CalculationProceduresSound engineering and mathematical principles shouldeused in all calculations for development of capacity tables.Th ese principles should include those given hereinor appli-cation to this particul ar type of work:nI7I.-"Ua. The capacity tables shouldbeprepared at60F(15C) andshou ld take into account liquid head stress correction, dead-wood,tilt correction, a ndfapplicable floating roof allowance.Note:Even though the base temperatureofthe tanks isWFor15'C).theliquid density used in calculating the liquid headstressco rrection andfloatingroofallowance should be the average observed densityforthatg iven tank.b.Fortemperature allowance, the temperature expansionfactor shouldbe a ppliedasa separate factorseeAppendix D).c. All incrementalortotal volume calcula tions should becarried to seven significant figures. (Refero Appendix C forGuide lines for Computer Input.)d. All deadwood shouldbeaccurately accounted for as to volume and location,inorder to permit adequate allowancefor volumes of liquid di splaced byvariousobjectsorappur-tenances and the llocation of these effects at v arious eleva-tions within the tank.e. The preparation of capacity tables for upr ight tanks isbasedona maximum liquid height not reater than the shelln-u-IIFigur e 15-DiagramofFloatingRoofat Rest(A)and Floating(B)COPYRIGHT 2002; American Petr oleum InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/20 02 15:43:16 MDT Questions or comments about this message: please call the Docum ent PolicyManagement Group at 1-800-451-1584. - - - 22CHAPTER,SECTIONAheight. The volume within the tank which is above that level shall be disregarded in capacity tables. An example of thisdisregarded volume is the space under a cone roof down tothe level of the top dge of the top ring.f.T ank capacities should be expressed in gallons, barrels,cubic meters, litersrothe r (Tables5and 6 and AppendixB).g. Each item on the strapping report is evaluated for accuracybefore processing.h. As a matterof principle,itis recommended that all newlyprepared capacity tables show thereon the date on whichthey are effecti ve. The basis for establishing such a date, inspecific cases, is dependent upon individual circumstancesand the needs of the parties concerned. However, it isin tended that the effective date be established, taking intoconsideration circumst ances including, but not limited to, thefollowing:l. The date a new tank was fir st calibrated.2. The date an old tank was recalibrated.3.The date the tank was r ecomputed.2.2A.19.1CAPACITYTABLEREQUIREMENTS The following parameters must be co nsidered for thedevelopment of capacity tables.a. Expansion and contraction of s teel tank shellue to liquidhead (see 2.2A.19.5).b. Expansion and contraction f s teeltankshell with temper-ature [recommended to be applied independentof capacit ytable computations (see 2.2A.19.6)].c. Tilt from a vertical position (see 2.2A. 19.7).d.Tank bottoms that are irregular in shape (see 2.2A.16).e. Effective ins ide tank height (see Figure 12).2.2A.19.2 CALIBRATION OF THE MASTER TAPETO 60F2.2 A.19.2.1Themasterapeoralibratingank measuring (working) tapes shall be identifie d witha Reportof Calibration at 68F by the National Institute of Standardsand Tec hnology (NIST) ttesting to the masterapeaccuracywithin 0.001 foot (approximately %inch, 1 millimeterreso-lutionandread to the nearest0.5millimeter) per 100 eet o flength. The Report of Calibration shall include the factorsand formulas necessa ry tocorrect tape length or use at 60F(15C) under tension differing from that used during calibra-tion.2.2A.19.2.2The petroleum industry uses 60F(or15C)as a standar d temperature for petroleum products. Themaster tape should be correctedo this t emperature using thefollowing equation:Correction Factor=1+[(TsTc)xC] (1)Correct ion factor=1+[(60-68)x0.00000645]=0.9999484=1+(-8X0.00000645)Where:Tc=Calibratio

n Temperature of master tape(normally 68F).Ts=Standard reference temperature(norm ally 60F).C=Coefficient of expansion for mildsteel0.00000645 FT/FT/Degree Fahrenh eit.2.2A.19.3 CONVERSION OF OUTSIDE TO NSIDECIRCUMFERENCESPlate thicknesses used in calculations should be thosereported on field measurement records. Where pos sible,thicknessshould be measured by ultrasonic hicknessmethod. Values for plate thicknesses taken from drawingsmay be used where necessary.Inside Circumference =Kx(D-2t) (2)Where:t=steel thickness.D=outsidediameter,both n consistent units.2 .2A.19.4DEDUCTIONSFORCIRCUMFERENCE TAPE RISES2.2A.19.4.1In the event that the ta pe is prevented frombeing in contact with the tank shell at all points along its pathby projections from the tank shell, such as butt straps or lapjoints, the a mount of increase in circumference due to aperises at such projections should be determined. Circumfer-ences as measuredona given ring should be corrected byded ucting the sum of the increases in circumference at eachtape-rise location.2.2A. 19.4.2Deductionfortape rise may be computedfrom the tape-rise orrectionEquations 3and5in2.2A.19.4.3 and 2.2A.19.4.4,ormeasured with a caliperwhere practical o do so.Due to the very small correctionortape rise at a ow projection, such as a lap jointorbutt strap,it is impractical to measure accurately the correction with a caliper; herefore, the tape-rise orrectionmethodispreferred for such projections .2.2A.19.4.3The Tape-Rise Correction Equation for ButtStrapsorSimilar Projection s is as follows:2Ntw 8NtDeduction (inches)=7-m3(3)Where:N=number of butt strapsor projections per ring.t=amount of rise (thickness of strapsorprojections),W=width of strapsorprojections, in inches.d=nominal diameter of tank. in inches.in inch es.!COPYRIGHT 2002; American Petroleum InstituteDocument provided by IHS License e=YPF/5915794100, User=, 09/18/2002 15:43:16 MDT Questions or comments about th is message: please call the Document PolicyManagement Group at 1-800-451-1584.---APIflPflS*2.2A95D0732290 0543391 729mMEASUREMENTND CALIBRATIONOFUPRIGHT CYLIND RICALTANKS23COPYRIGHT 2002; American Petroleum InstituteDocument provided by IHS Licensee=YPF/5915794100, User=, 09/18/2002 15:43:16MDT Questions or comments ab out this message: please call the Document PolicyManagement Group at 1-800-451-1 584.---242,SECTIONAA total of 3.016 cubic meters has been deducted fromthistable betwe en3-6nd 3-1O formofdisplacement basedupona floating weight of4.W bs. andobserved A PI gravity of60.0.auged levels above3lOreflect this deduction. For gravities othe r than60.0APl/observed adjust quantities about3-IOasfollows: Add 0.016 cubic meter s per degree below60.0APIIobservod; Subtract 0.016 cubic meten per degree above6 0.0PlIobservedI)A3Prown has been deducted from the first4ofcapacity table.Strappe d by:WS-SL5/19/922)Tank strapped and computed in accordance with API MPMS Chapte r 2.2A. Computed by: MH 5/19/923)Liquid head stress has been appliedtotable at A PI gravity60.0.4)Capacity table reflects expansionoftank shell due to ambient te mperature of 15C. Show sketches of verticalandhorizontalpinsonbackof this Table.5 )For more precise fractional values, interpolate between incremental volumes.Show ircumferentialocat~onnplanvimsketchedonzkofthisTable.6)Capacity table stops at 4 5-51 dueo overtlow. Show direction of leanonplan view sketchedonback of this Table. 7)Nominaltankdiameter=67a. shell heieht=48O.Checked by: MH5/19/92COPYRIGHT 2002; Am erican Petroleum InstituteDocument provided by IHS Licensee=YPF/5915794100, User =, 09/18/2002 15:43:16MDT Questions or comments about this message: please call the Document PolicyManagement Group at 1-800-451-1584. - - MEASUREMENTNDCALIBRATIONOFUPRIGHTCYLINDRICALTANKS~2.2A.19.4.4The Tape-Rise Cor rection Equation for LapJoints is as follows:a. Application of Equation 3 in mod ified form o tape rise atlapjointsisdescribed with reference to Figure 17.InFigu re17, the locations of the plates in the lap joint are shown aspositioned by the plates in he ringsabove and below theapjoint. The position of the plate in the ring ifnojoint existedis shown by the broken lines in relation to the plates in thelap joint.b. The circumference as measured over the lap joint shouldbe correc ted to the true circumferential path the tape wouldtake if no joint existed.Assh own in Figure 17, this requirescorrection for only one-half of theape rise. With