Professional Documents

Culture Documents

39359746

Uploaded by

lolorelopezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

39359746

Uploaded by

lolorelopezCopyright:

Available Formats

Petroleum Science and Technology, 27:874881, 2009 Copyright Taylor & Francis Group, LLC ISSN: 1091-6466 print/1532-2459

9 online DOI: 10.1080/10916460802455574

Study of Resin Adsorption onto Asphaltene and Silica-Asphaltene Particles

J. C. Pereira,1;2;4 E. Carrasquero,1;2 L. Becerrit,1;2 L. Puerta,1;2 and J. C. Lpez3;4

de Carabobo, Facultad Experimental de Ciencias y Tecnologa, Departamento de Qumica, Valencia, Venezuela 2 Lab. Petrleo, Hidrocarburos y Derivados 3 Universidad de los Andes, Facultad de Ingeniera, Departamentos de Ciencias Aplicadas y Humansticas, Valencia, Venezuela 4 Laboratorio de Formulacin, Interfases, Reologas y Procesos, FIRP Mrida, Venezuela

1 Universidad

Abstract: We present a methodology to study the adsorption behavior of resins on asphaltenes, which we call silica-asphaltene complex methodology (SACOM), and compare it to a methodology regularly used by many researchers (Acevedo et al., 1995; Gonzlez et al., 2003; Len et al., 2002; Marczewski et al., 2002; Pereira et al., 2007) that we call traditional methodology. Three isotherms of resins adsorbed on the complex substrates (asphaltene and its colloidal fractions A1 and A2 adsorbed on silica) were built, analyzed, and then compared with two isotherms built by applying a traditional methodology where resins were adsorbed on two organic substrates: asphaltene and its fraction A1 . Keywords: adsorption, asphaltene, resins

INTRODUCTION Asphaltenes are complex molecules present in a wide variety of crude oil from many different countries. These molecules are the most polar and molecularly heavy petroleum fraction. This fraction causes very serious problems in the petroleum industry, due to colloidal instability and subsequent precipitation. Resins, another petroleum fraction, whose polarity lies between asphaltene and the rest of a crude oil, are correlated with the crude oil colloidal stability (Carbognani et al., 2003; Islas-Flores et al., 2006; Merino-Garcia et al., 2004; Merino-Garcia et al., 2004; Ortega-Rodriguez et al., 2003). Despite the large amount of studies done on this subject, due to the complexity of

Address correspondence to J. C. Pereira Lab. FIRP, Universidad de los Andes, Mrida 5101, Mrida, Venezuela. E-mail: jcpereir@uc.edu.ve 874

Resin Adsorption

875

both fractions (resins and asphaltenes), the progress on understanding the asphaltene precipitation phenomenon at the molecular level has been slow. In this sense, researchers from all over the world have been studying the role of resins on the asphaltene-precipitation phenomenon (Branco et al., 2001; Gonzlez et al., 2003; Oh et al., 2002; Marczewski et al., 2002; Pereira et al., 2007; Spiecker et al., 2003; Xie et al., 2005) through different methodologies and techniques. The traditional methodology, one of the most commonly used ones, consists on building adsorption isotherms of resins on asphaltenes, analyzing them, and correlating them with different aspects of the asphaltene stability phenomenon. This methodology, however, presents serious drawbacks, such as: part of the asphaltenes gets dissolved into the solvent (Gonzlez et al., 2003; Len et al., 2002), asphaltene pore penetration (Len et al., 2002), steric hindrance, and solvent swelling (Carbognani et al., 2002), among others. For instance, Acevedo and others (1995) built adsorption isotherms of asphaltenes and resins on inorganic fraction (97% SiO2 , from the deposit that plugged the tubing of a production well) and on organic adsorbents (asphaltenes and the product of heating them at 350C) in n-heptane, toluene and n-heptane-toluene at 26C. Based on their results, they suggest that the following phenomena occur: saturation, multilayer formation and pore penetration. Len and others (2002) built adsorption isotherms of two native resins on two different asphaltene surfaces by using the UV-vis spectrophotometric technique. They found their results support the asphaltene-stabilization model, where resins rst incorporate into the bulk asphaltenes and then help them to diffuse into the solvent. They also observed that the native resins exhibit a higher asphaltene-dissolution power than amphiphiles and a more comparable stabilization power as asphaltene stabilizers. Gonzlez and others (2003) introduced an enhancement to the traditional methodology in order to attenuate the drawbacks present when applying the traditional methodology. Thus, they report that the resin adsorption on non-consolidated asphaltene particles saturate at 600 mg/g at an equilibrium concentration of about 600 mg/L, which might be considered too high (large surface area). It is also worth mentioning that they found that on average, each asphaltene molecule has around three independent sites for the resins to bind to. It is important to highlight that although there has been some progress on characterization, on analysis techniques, and on developing new methodologies to assess asphaltene-resin interactions, the full understanding of this complex subject is still far ahead. New research in the area is, therefore, very welcome. In this article, we propose an adsorption methodology, which we term silica-asphaltene-complex methodology (SACOM). SACOM allows one to better analyze different aspects of the adsorption of resins on asphaltenes and on asphaltene fractions A1 and A2 . To do that, one must rst build adsorption isotherms of resins on complex substrates (i.e. asphaltenes and their fractions A1 and A2 each one adsorbed on silica particles), then, one analyzes them, and, nally, one correlates the resin adsorption-pattern characteristics to different asphaltene properties, such as asphaltene molecular structures.

876

J. C. Pereira et al.

METHOD Materials and Instruments Resins, asphaltene and its fractions A1 and A2 are extracted from Hamaca, an extra heavy crude oil (8API) from the Orinoco Belt, Venezuela. All the analytic-grade reagents (cumene, toluene, heptane, methanol, chloroform) were purchased from J. T. Baker. Silica 70230 mesh (60 pore size) for column chromatography was purchased from Merck. Apart from this, the UV-vis spectra were taken by a diode array HP spectrophotometer, model #8452 A, with a 1cm width quartz cell. For temperature control, a continuously agitated thermostatic bath was kept at 25C. Methodology Fractioning Resins, Asphaltene and its Fractions A1 and A2 Asphaltenes are extracted from crude oil through precipitation according to the following procedure: the crude oil is diluted with the same volume of toluene, then a large excess (60 volumes) of n-heptane is added to the mixture while keeping it stirred. The stirring is maintained for six more hours and the mixture is left to stand overnight. Finally, the precipitated solid, comprised of asphaltene and resins which have co-precipitated, is ltered afterward and placed within a Soxhlet extractor, under continuous operation for about 24 hours, with boiling n-heptane in order to remove most of the resins. The asphaltene obtained is then dried, weighed and stored in an inert atmosphere of nitrogen. By applying this methodology, the yield of asphaltenes is around 11 wt%. On the other hand, the resins are substances coming from the maltene fraction (a mixture containing parafns, aromatics, and resins) that remain soluble in n-heptane, together with those obtained from the Soxhlet extraction. The mixture is then fractionated by liquid chromatography on a silica column. The rst two fractions of this mixture (i.e., saturated and aromatic compounds) are sequentially eluted and collected by using the following solvents: n-heptane and toluene. Finally, resins are obtained by eluting the still retained mixture with a toluene-methanol blend at a 7:3 volume ratio. In order to obtain asphaltene fractions A1 and A2 , the following experimental procedure is carried out: solutions of asphaltene in cumene and p-nitroaniline (PNA) saturated in cumene are separately prepared and then mixed together in 100 mL volumetric asks so that the nal concentration of asphaltene is 5 g/L 1 . The solution, thus obtained, is then allowed to stand for ve days at room temperature. Afterward, the solvent (cumene) is evaporated until the volume reaches 50 mL. Next, an equal volume of n-heptane is added under stirring, precipitating a solid phase, the so-called fraction A1 (Gutirrez et al., 2001). The solution, on the other hand, contains the fraction

Resin Adsorption

877

A2 . The liquid phase is ltered and evaporated until solid, which is then dissolved in chloroform and, in order to extract the PNA, is subsequently washed once with aqueous hydrochloric acid (10%). Afterward, the organic phase is washed with water until the pH of the aqueous phase approaches 7. Traces of water are removed by adding anhydrous magnesium sulfate, which is then ltered. Finally, the chloroform is evaporated, and the solid formed, fraction A2 , is dried under vacuum conditions. A similar procedure is applied to the asphaltene fraction A1 . Absorbent Materials Asphaltene particles are used without any treatment as adsorbent materials; complex-adsorbent substrates, on the other hand, are prepared by adsorbing asphaltenes and their fractions A1 and A2 on silica particles. The procedure is as follows: solutions of these petroleum fractions are prepared in chloroform at 200 mg/L 1 . Then, silica particles are added to these solutions under continuous stirring, in order that the [asphaltene or its fraction A1 or A2 ]/ silica ratio is 1/25. Based on studies of kinetics of the asphaltene adsorption on silica (Acevedo et al., 2003), we used an asphaltene concentration/silica weight ratio enough to saturate the silica particles with a monomolecular layer of asphaltenes on the silica particles. The mixture is kept under stirring for eight hours. Next, the solid phase is separated by ltration and washed with chloroform until the ltrate becomes colorless. Finally, the solid phase is dried under vacuum conditions. The solid particles prepared in this way are the adsorbent materials to be used with SACOM. Adsorption Isotherms (Traditional Methodology and SACOM) Both methodologies used in here to study the adsorption phenomenon are similar, except that SACOM used as adsorbent the silica-asphaltenes and silica-asphaltene-fraction complexes (see above section). The different isotherms are plotted as the amount of adsorbed resin versus resin equilibrium concentration in the liquid phase. The data required for the isotherm are obtained by applying the following procedure: rst, different resin solutions are prepared in n-heptane at concentrations between 0 and 400 mg/L 1 . Next, a 10 mL aliquot of the above solution is added to 10 mg of adsorbent previously introduced in a test tube. Then, the tube is closed with a lid and the suspension is gently shaken in a thermostatic bath at 25 C for 18 hours. It is worth remarking that this time span is long enough for the adsorption of resin on asphaltene to reach equilibrium conditions (Carbognani et al., 2002). Next, the samples are centrifuged and the equilibrium concentration in the liquid phase is determined by UV-vis spectrometry at 400 nm wave length. Finally, the adsorbed resin is calculated from the depleted amount in the mass balance. All calibration and actual concentrations are estimated twice and then averaged.

878

J. C. Pereira et al.

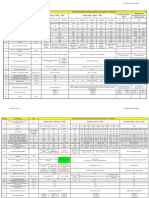

RESULTS AND DISCUSSION The results of applying the traditional methodology are showed in Figure 1, where the resin adsorption-isotherms for the two organic substrates (asphaltene and its fraction A1 ) are depicted. It is worth highlighting, however, that the resin adsorption-isotherm for fraction A2 could not be built because this system totally dissolved in the n-heptane-resin solutions. On the other hand, the results of applying SACOM are showed in Figure 2. Here, three resin-adsorption isotherms, one for each of the three different complexsubstrates, are plotted. The adsorption curves for fractions A1 and A2 follow a Langmuir-like isotherm (Hiemenz, P., 1977), while the adsorption curve for the asphaltene corresponds with a two-step isotherm (Hiemenz, P., 1977). Interestingly, the plateaus reached by each of the former ones are consistent with the two plateaus reached by the latter one. From Figures 1 and 2, one can see that although the resin adsorption-isotherms present similar patterns for both the organic and the complex substrates, the plateaus reached by the organic ones are much lower. Additionally, it seems, no correlation exists between the organic-asphaltene and its fraction A1 isotherms. That is, the plateaus of the asphaltene-substrate isotherm, which correspond to a twostep isotherm, and the one of fraction A1 , a Langmuir-like isotherm, do not coincide, nor do they approach each other. This could make it difcult to cor-

Figure 1. Figure 1 shows three adsorption isotherms of resins on the three different complex adsorbents: Asphaltenes and its fractions A1 and A2 adsorbed each one on silica particles. The resins, asphaltenes and their fractions were extracted from Hamaca crude oil. The adsorption isotherm experiments were carried out at room temperature and n-heptane was used as solvent.

Resin Adsorption

879

Figure 2. Figure 2 shows two adsorption isotherms of resins on the two different organic adsorbents: solid asphaltenes, and their fractions A1 . The resins, asphaltene and its fractions were extracted from Hamaca crude oil. The adsorption isotherm experiments were carried out at room temperature and n-heptane was used as solvent. The adsorption on fraction A2 could not be measured because it dissolves in the resin/n-heptane solution.

relate adsorption properties of these systems with their behavior; for instance, stability. Therefore, for this particular case, SACOM offers more advantages in comparison with the traditional methodology, because it attenuates some of the adsorption phenomenon drawbacks as mentioned before. Speculating, one can say from the results that the number of adsorptionsites on the fraction A1 /silica substrate is much higher than those on the fraction A2 /silica substrate, which can be assessed by the amounts of resin adsorbed at the plateau conditions, around 160 mg/g and 80 mg/g, respectively. The reason for this difference could be that the molecular structure associated with fraction A1 is a at rigid-structure (Acevedo et al., 2004), which can t on the silica particle surfaces, thus providing a large number of active sites for the adsorption of resin.Meanwhile, the molecular structure associated with fraction A2 consists of several at molecular portions connected by single chemical bonds that confer more mobility. This mobility reduces the number of effective activesites for the adsorption on the silica particle surface, due probably to a hindrance steric effect (Kanicky et al., 2002). On the other hand, the two plateaus shown by the isotherm for the asphaltene/silica substrates could suggest two types of sites for the resin to adsorb on, distinguished by the resin equilibrium concentration level: low-concentration (0 to 25 mg/L) sites and high-concentration (100 to 170 mg/L) sites.

880

J. C. Pereira et al.

Although we made some statements about the adsorption phenomenon and its correlation to molecular properties of asphaltene fractions, we mainly wanted to show that SACOM constitutes an alternative methodology to study the adsorption phenomenon of resins on asphaltenes.

CONCLUSIONS SACOM showed, through the particular case studied here, more advantages over the traditional methodology. It is an alternative tool to analyze the adsorption phenomenon of resins on asphaltenes and their fractions. Due to the low solubility of asphaltene fraction A2 adsorbed on silica, it was possible to carry out the adsorption study of resins on fraction A2 through SACOM. The results also suggest that the number of effective active sites for the resins to adsorb on asphaltene fraction A1 are around twice as plenty as those for fraction A2 , which are correlated to the amount of the resins adsorbed (approximately 160 mg/g and 80 mg/g, respectively). This is in agreement with their molecular structures (at and rigid core for fraction A1 , while several smaller rigid and at portions connected by aliphatic chains for fraction A2 ).

ACKNOWLEDGMENTS This work was nancially supported by Universidad de Carabobo and El Consejo de Desarrollo Cientco y Humanstico de la Universidad de Carabobo, Venezuela.

REFERENCES Acevedo, S., Escobar, O., Echevarria, L., Gutirrez, L., and Mndez, B. (2004). Structural Analysis of Soluble and Insoluble Fractions of Asphaltenes Isolated Using the PNP Method. Relation between Asphaltene Structure and Solubility. Energ. Fuel. 18:305311. Acevedo, S., Ranaudo, M., Escobar, G., Gutirrez, L., and Ortega, P. (1995). Adsorption of asphaltenes and resins on organic and inorganic substrates and their correlation with precipitation problems in production well tubing. Fuel. 74:595598. Acevedo, S., Ranaudo, M. A., Garca, C., Castillo, J., and Fernndez, A. (2003). Adsorption of Asphaltenes at the Toluene-Silica Interface: A Kinetic Study. Energ. Fuel. 17:257261. Branco, V., Mansoori, G., De Almeida, X., Park, S., and Mana, H. (2001). Asphaltene occulation and collapse from petroleum uids. J. Petrol. Sci. Engin. 32:217230.

Resin Adsorption

881

Carbognani, L., and Espidel, J. (2003). Preparative Subfractionation of Petroleum Resins and Asphaltenes. II. Characterization of Size Exclusion Chromatography Isolated Fractions. Petrol. Sci. Technol. 21:17051720. Carbognani, L., and Rogel, E. (2002). Solvent Swelling of Petroleum Asphaltenes. Energ. Fuel. 16:13481358. Gonzlez, G., Neves, G., Saraiva, S., Lucas, E., and Anjos de Sousa, M. (2003). Electrokinetic Characterization of Asphaltenes and the Asphaltenes-Resins Interaction. Energ. Fuel. 17:879886. Gutirrez, L., Ranaudo, M., Mndez, B., and Acevedo, S. (2001). Fractionation of Asphaltene by Complex Formation with p-Nitrophenol. A Method for Structural Studies and Stability of Asphaltene Colloids. Energ. Fuel. 15:624628. Hiemenz, P. (1977). Principles of Colloids and Surface Chemistry. New York: Marcel Dekker. Islas-Flores, C. A., Buenrostro-Gonzalez, E., and Lira-Galeana, C. (2006). Fractionation of petroleum resins by normal and reverse phase liquid chromatography. Fuel. 85:18421850. Kanicky, J., and Shah, D. (2002). Effect of degree, type and position of unsaturation on the pka of long-chain fatty acids. J. Colloid Interf. Sci. 256:201207. Len, O., Contreras, E., Rogel, E., Dambakli, G., Acevedo, S., Carbornani, L., and Espidel, J. (2002). Adsorption of Native Resins on Asphaltene Particles: A Correlation between Adsorption and Activity. Langmuir. 18:51065112. Marczewski, A., and Szymula, M. (2002). Adsorption of asphaltenes from toluene on mineral surface. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 208:259266. Merino-Garcia, D., and Andersen, S. I. (2004). Interaction of Asphaltenes with Nonylphenol by Microcalorimetry. Langmuir. 20:14731480. Merino-Garcia, D., and Andersen, S. I. (2004). Thermodynamic Characterization of Asphaltene-Resin Interaction by Microcalorimetry. Langmuir. 20:45594565. Oh, K., and Deo, M. (2002). Effect of Organic Additives on the Onset of Asphaltene Precipitation. Energ. Fuel. 16:694699. Ortega-Rodriguez, A., Cruz, S. A., Gil-Villegas, A., Guevara-Rodriguez, F., and Lira-Galeana, C. (2003). Molecular View of the Asphaltene Aggregation Behavior in Asphaltene-Resin Mixtures. Energ. Fuel. 17:11001108. Pereira, J. C., Lpez, I., Salas, R., Silva, F., Fernndez, C., Urbina, C., and Lpez, J. C. (2007). Resins: The Molecules Responsible for the Stability/Instability Phenomena of Asphaltenes. Energ. Fuel. 21:13171321. Spiecker, M., Gawrys, K., and Kilpatrick, P. (2003). Aggregation and solubility behavior of asphaltenes and their subfractions. J. Colloid Interf. Sci. 267:178193. Xie, K., and Karan, K. (2005). Kinetics and Thermodynamics of Asphaltene Adsorption on Metal Surfaces: A Preliminary Study. Energ. Fuel. 19:12521260.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Overall Heat Transfer Coefficient and Pipe Length CalculationDocument2 pagesOverall Heat Transfer Coefficient and Pipe Length CalculationCaleb FalcoteloNo ratings yet

- 12.co Ordination CompoundsExerciseDocument34 pages12.co Ordination CompoundsExerciseMaster Of HakingNo ratings yet

- Chapter 3 2Document41 pagesChapter 3 2jerrica thomasNo ratings yet

- Waste Water Treatment PlantDocument10 pagesWaste Water Treatment PlantBoiler ScrubberNo ratings yet

- Satriana Et Al 2019 - European Journal of Lipid Science and TechnologyDocument1 pageSatriana Et Al 2019 - European Journal of Lipid Science and TechnologyMuhammad Dani SupardanNo ratings yet

- Refineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyDocument3 pagesRefineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyGjorgeluisNo ratings yet

- AIATS Practise Paper-01 AnalysisDocument111 pagesAIATS Practise Paper-01 AnalysisC R Ramsakha100% (1)

- HöglundDocument70 pagesHöglundIndri AuraliaNo ratings yet

- 01-02. The Chemical Context of LifeDocument4 pages01-02. The Chemical Context of LifeDaniel Angelo MiradorNo ratings yet

- Lecturer Chemistry Model QuestionDocument11 pagesLecturer Chemistry Model QuestionPrathana Vidya100% (1)

- SurgeryDocument79 pagesSurgeryIshratNo ratings yet

- Effects of Broken Clay Bricks in Treatment of Grey Water To Be Used For IrrigationDocument33 pagesEffects of Broken Clay Bricks in Treatment of Grey Water To Be Used For IrrigationFred BamwineNo ratings yet

- Technical Data Sheet for Emulsified Bituminous PrimerDocument2 pagesTechnical Data Sheet for Emulsified Bituminous Primerhandhammer qatarNo ratings yet

- Mathematical Heat Transfer Model Research For The Improve-Ment of Continuous Casting Slab TemperatureDocument6 pagesMathematical Heat Transfer Model Research For The Improve-Ment of Continuous Casting Slab TemperatureSanjeev SahuNo ratings yet

- Calculation of Heat and Mass BalanceDocument18 pagesCalculation of Heat and Mass BalanceJitendra Bhatia100% (3)

- Mineral Nutrition MycorrhizaDocument34 pagesMineral Nutrition MycorrhizaZella PurnamaningtyasNo ratings yet

- Principles of HydrotherapyDocument21 pagesPrinciples of Hydrotherapyvaishali jagtap100% (6)

- Emulsiones (Sativay)Document15 pagesEmulsiones (Sativay)Cesar DuqueNo ratings yet

- Aes Secondary Emulsifier: Safety Data SheetDocument8 pagesAes Secondary Emulsifier: Safety Data Sheetgerardo sifuentesNo ratings yet

- Spectrofotometru SpectroDirect (De La Lovibond)Document360 pagesSpectrofotometru SpectroDirect (De La Lovibond)FlaviusNo ratings yet

- On MetalDocument57 pagesOn Metalkatyayani tiwariNo ratings yet

- Newton HydroSeal 107F Elastic 2K TDS 4.0Document8 pagesNewton HydroSeal 107F Elastic 2K TDS 4.0Дмитрий СаламатовNo ratings yet

- Stoichiometry Questions & AnswersDocument2 pagesStoichiometry Questions & Answersnosirat aladeNo ratings yet

- Origins of Rheology: A Brief Look at the Evolution of the Study of Material FlowDocument9 pagesOrigins of Rheology: A Brief Look at the Evolution of the Study of Material FlowAmlan PalNo ratings yet

- PV Module IonDocument4 pagesPV Module IonrmalewarNo ratings yet

- WS3Document2 pagesWS3dextercitomanNo ratings yet

- Cardiac Leads MDT - Cable DéfDocument116 pagesCardiac Leads MDT - Cable DéfRABAH BOUCHELAGHEMNo ratings yet

- Chapter 2 Structure, Properties and Behavior of MatterDocument49 pagesChapter 2 Structure, Properties and Behavior of Matteraxeman1nNo ratings yet

- Chapter 2 BLMs AnswersDocument3 pagesChapter 2 BLMs AnswershelloblargNo ratings yet

- Dehydration of Ethanol To EthyleneDocument10 pagesDehydration of Ethanol To EthylenewiboonwiNo ratings yet