Professional Documents

Culture Documents

Elliott Ethylene Bulletin Aug09

Uploaded by

Sachin SingareOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elliott Ethylene Bulletin Aug09

Uploaded by

Sachin SingareCopyright:

Available Formats

Elliott Compressors for World-Scale Ethylene Plants

Proven Turbomachinery Technology

Optimized Profits in Ethylene Production

The winning combination for profitable ethylene production is high volume, low-cost operation and uninterrupted production runs. Compressor performance is critical for achieving these goals. For decades, leading ethylene producers throughout the world have turned to Elliott for efficient, reliable compressors and steam turbines. For over 50 years, Elliott has been the world leader in centrifugal compressors for ethylene production. Elliotts strengths in refrigerant compression technology evolved from expertise developed when Elliot was a division of Carrier Corporation. Elliott equipment is operating today in approximately 50% of the worlds ethylene plants, including most of the largest facilities with capacity of one million tons per annum (MTPA) or greater. With frame sizes designed for volumetric flowrates up to 320,000 icfm (544,000 m3/hr), Elliott compressors deliver efficient, reliable performance processors require for dependable, high-volume ethylene production. Elliotts experience and achievements in the ethylene industry include: Installations in nearly 50% of the worlds nameplate ethylene capacity Installations in over 40% of the ethylene plants that produce > 500 KTA Installations in over 100 ethylene plants in more than 60 countries worldwide Installation of more than 700 compressors worldwide for ethylene service

Shell Chemical, Moerdijk, Netherlands

Reprinted with permission from Shell Chemicals Limited

Engineered for Mega Plants

Cracked gas, propylene and ethylene compressor trains from Elliott are custom engineered to meet the high volume, high efficiency requirements of todays mega ethylene plants. As demands for production capacity grows, processing equipment and drivers must increase in size, throughput and reliability. Along with a history of engineering excellence and product innovation, Elliott stands apart in its ability to design and manufacture the large, reliable compressors and steam turbines required for the uninterrupted operation of these very large plants. Elliotts advanced modeling techniques and proven engineering experience result in machinery for refrigeration service custom designed for challenging applications such as efficient side-load mixing. Our steam turbines deliver the power required to drive the processing strings in high capacity ethylene plants. We offer a broad line of multistage, multivalve turbines with horsepower ratings to 140,000 hp (104,398 kW) and speeds to 16,000 rpm.

88M6-4 refrigeration compressor with two side-loads

Multistage, multivalve steam turbine assembly

Engineered Solutions for Challenging Applications

Refrigeration applications in ethylene production create extreme challenges in compressor design. These applications involve high molecular weights combined with low temperatures and variations in volume flow requirements. Large volume side-streams are common in the refrigeration process. Elliotts skill in designing compressors for these demanding conditions ensures an accurate fluid dynamic design with high efficiency performance, a broad operating range and conservative mechanical characteristics. Computer modeling confirms that the flow streams merge at similar velocities for minimum pressure loss and maximum efficiency. Performance simulations incorporate the resultant data into the compressor selection. Verification of the aerodynamic design is proven during factory performance testing. Cracked gas service requires cooling to reduce the process temperature through the compressor stages. The compressor selection program calculates the amount of knockout and the resultant gas composition at each cooling point; this is especially helpful during feasibility studies for ethylene plants. In addition to knockout calculations, the program can account for water injection into the process gas to help reduce the gas temperature and can calculate the effects water injection has on the compressor performance. Our experience in cracked gas applications allows flexibility in engineering compressor and driver configurations. Compressor strings can include two to four compressor bodies in addition to the specified driver. In typical cracked gas applications, steam from the highest pressure header is used as the inlet for the steam turbine. Controlled extraction from the steam turbine typically feeds a medium or low pressure steam header to supply other steam turbines or plant services. A representative driver for a cracked gas compression string is the Elliott 2SNV9 double-shell, controlled extraction, condensing steam turbine. This turbine is rated for 1500 psig (103 barg) at 900 F (482 C) and over 70,000 HP (52,199 KW).

Cracked gas train - Elliott 2SNV9 steam turbine driver with 88M6I & 60M6I compressors

Superior Protection of Aerodynamic Components

Elliotts proprietary protective coatings provide excellent antifouling and corrosion resistance for the aerodynamic components of a compressor. Polymerization during the compression process can produce build-up that accumulates on aerodynamic surfaces and affect compressor performance. The build-up of these polymers can increase rotor vibration, constrict the gas flow path, decrease efficiency and reduce throughput. Elliott Pos-E-Coat 523 provides excellent releasing properties for polymer build-up, corrosion resistance of the aerodynamic components, and the ability to withstand the harsh liquids or chemical injections typically used for cleaning compressors in cracked gas service. Field experience demonstrates that Pos-E-Coat 523 helps to maintain rotor dynamics and compressor efficiency under severe fouling conditions significantly longer than other industry coatings. Reducing polymer build-up on the aerodynamic components of a compressor also minimizes the downtime and the cost of materials required to clean the equipment.

Compressor rotor with Pos-E-Coat 523

Increased Production Through Design Optimization

Powerful design and modeling tools enable Elliott engineers to develop the highly efficient compressor and steam turbine designs required for high-volume ethylene production. Computational fluid dynamic (CFD) analysis, finite element analysis (FEA) and solids modeling provide full 3-dimensional analyses of the aerodynamic flow path and the structural mechanics of compressor designs. We employ rotor dynamic analysis, compressor selection, and dynamic simulation programs to optimize multistage compressor applications. Compressor configurations we design with these tools include those with side-streams, double flow, back-to-back, and inter-cooling. Typical steam turbine designs include multiple controlled and uncontrolled extractions, inductions, and double flow exhaust.

110M6 compressor impeller

World-Class Manufacturing and Testing Capabilities

Elliotts manufacturing centers in Jeannette, Pennsylvania, USA and in Sodegaura, Chiba, Japan are fully equipped with the latest machine tools and test equipment. Both facilities produce the very large centrifugal compressors required for mega-scale ethylene production. These large compressors are designed for capacities up to 320,000 icfm (544,000 m3/h). One of Elliotts techniques to reduce cycle times for the fabrication of large compressor casings is to employ a weldment positioner. The positioner allows for a continuous welding process by moving the weldment around the welder. All Elliott compressors and turbines are thoroughly tested before shipment. The testing facilities in Jeannette and Sodegaura can accommodate multiple equipment test strings simultaneously. In Jeannette, a modern at-speed rotor balancing facility is one of only a few facilities equipped to handle large rotors up to 284 inches (7,213 mm) in length and 96 inches (2,438 mm) in diameter, with a maximum weight of up to 27,000 lbs (12,246 kg), and speeds up to 30,000 rpm.

Multi-axis CNC casing machining center

Comprehensive Testing Facilities

Elliotts testing capabilities include: Testing to API requirements for: - API 612 (steam turbines) - API 614 (lube, control and seal oil systems) - API 617 (axial and centrifugal compressors) Testing to ASME Power Test Code (PTC-10) requirements for compressors Part load and full load testing depending on application Full variable frequence drive (VFD) motor drive capabilities Customer specific testing requirements for ethylene process applications High speed balancing for Elliott and non-Elliott rotors

CNC machining & turning center

Monitoring & data analysis during testing

Global Service and Support

Service Parts Network

Our ISO 9001 certified Service Parts organization delivers the quality parts and rapid turnaround necessary to maintain the performance and reliability of all Elliott equipment. The Service Parts organization has an extensive finished parts inventory and machining centers allowing for quick manufacture and shipment of parts. Same day shipment is available on most stock items and emergency customer support is available 7 days a week. Elliotts knowledgeable customer service representatives and experienced service engineers are dedicated to address the specific needs of each individual customer. Service Parts programs include parts identification, inventory audits, upgrade assessments and parts kit packages.

Field Support

From installation, commissioning and start-up, through maintenance, overhauls and repair, Elliott offers a complete range of turbomachinery service and support. Elliott maintains a global network of full-service repair facilities. We provide experienced on-site project management and skilled field service crews to job sites worldwide. Elliott Rerate Services enhances the performance and extends the life of critical rotating equipment from any manufacturer. Compressors can be modified and rerated in the field to increase reliability, efficiency and capacity. Customized service programs range from routine preventative maintenance and emergency assistance, to comprehensive long-term service agreements.

Installation, commissioning & start-up services

Elliott Service Facilities

Americas Baton Rouge, Brazil, Chicago, Edmonton, Guatemala, Houston, Jacksonville, New Orleans, Pittsburgh, San Francisco, St. Louis, Toronto, Trinidad Europe, Middle East, Asia Australia, Bahrain, Italy, Japan, Malaysia, Singapore, Taiwan, United Kingdom

Elliott Company reserves the right to modify the design or construction of the equipment described in this bulletin and to furnish it, as altered without further reference to the illustrations or information contained herein.

www.elliott-turbo.com

Elliott Company 2009 8

ETHYLENE

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CFMDocument16 pagesCFMShoaibIqbalNo ratings yet

- Cooling Water System DesignDocument18 pagesCooling Water System DesignSachin SingareNo ratings yet

- Dover Artificial Lift - Hydraulic Lift Jet Pump BrochureDocument8 pagesDover Artificial Lift - Hydraulic Lift Jet Pump BrochurePedro Antonio Mejia Suarez100% (1)

- Petroquimica Enfoque GlobalDocument29 pagesPetroquimica Enfoque Globalejemplo1207No ratings yet

- Concept of Static Pressure: Chapter 5: Applications of Equations of Motion and Mechanical EnergyDocument2 pagesConcept of Static Pressure: Chapter 5: Applications of Equations of Motion and Mechanical EnergySachin SingareNo ratings yet

- CR4 - Thread - P11, P22, P9 and P91 MaterialDocument3 pagesCR4 - Thread - P11, P22, P9 and P91 MaterialSachin SingareNo ratings yet

- Urea Ammonia: Control RoomDocument1 pageUrea Ammonia: Control RoomSachin SingareNo ratings yet

- The Laws of Cricket 2000 Code (5th Edition 2013)Document65 pagesThe Laws of Cricket 2000 Code (5th Edition 2013)net2020No ratings yet

- HP 35s PDFDocument382 pagesHP 35s PDFilm112800No ratings yet

- Happy Maths 4 - EnglishDocument24 pagesHappy Maths 4 - EnglishPratham Books100% (83)

- Chinas Rising Stature in Global Finance PDFDocument0 pagesChinas Rising Stature in Global Finance PDFSachin SingareNo ratings yet

- Hans Foods AdvDocument1 pageHans Foods AdvSachin SingareNo ratings yet

- A New Era For Manufacturing in ChinaDocument18 pagesA New Era For Manufacturing in ChinajoeborderlineNo ratings yet

- Flying High HindiDocument20 pagesFlying High HindiSachin SingareNo ratings yet

- Economical Condensing Turbines?: by J.E.Dean, P.EDocument5 pagesEconomical Condensing Turbines?: by J.E.Dean, P.ESachin SingareNo ratings yet

- ICS PAC Read LaterDocument16 pagesICS PAC Read LaterSachin SingareNo ratings yet

- Serie W11 PDFDocument2 pagesSerie W11 PDFOrlandoNo ratings yet

- MoazzamMaqsood Transcript PDFDocument3 pagesMoazzamMaqsood Transcript PDFmoazzam maqsoodNo ratings yet

- 7625-300 Vitamin B12 AccuBind ELISA Rev 6Document2 pages7625-300 Vitamin B12 AccuBind ELISA Rev 6carlosalfredorivasNo ratings yet

- Question IARDocument4 pagesQuestion IARAryan jay vermaNo ratings yet

- Hindu Temples Models of A Fractal Universe by Prof - Kriti TrivediDocument7 pagesHindu Temples Models of A Fractal Universe by Prof - Kriti TrivediAr ReshmaNo ratings yet

- Limitations of Learning by Discovery - Ausubel PDFDocument14 pagesLimitations of Learning by Discovery - Ausubel PDFOpazo SebastianNo ratings yet

- Class VI (Second Term)Document29 pagesClass VI (Second Term)Yogesh BansalNo ratings yet

- Tutorial Week 5 AnswersDocument8 pagesTutorial Week 5 Answerspotato moon berryNo ratings yet

- CSIE Fisa Disciplina - Baze de DateDocument4 pagesCSIE Fisa Disciplina - Baze de DateCostin CheluNo ratings yet

- Edan M3B Vital Signs Monitor User ManualDocument92 pagesEdan M3B Vital Signs Monitor User ManualJosé marino Franco AlzateNo ratings yet

- Appraisal Assistant User ManualDocument55 pagesAppraisal Assistant User ManualDamian Padilla100% (3)

- Chapter 19. TemperatureDocument41 pagesChapter 19. TemperatureNguyên Nguyễn SơnNo ratings yet

- فيزياء لغات ثانوية عامة أنجليزى-webDocument462 pagesفيزياء لغات ثانوية عامة أنجليزى-webMohamed RayanyNo ratings yet

- CHMT 2009 Week 5 Coal PropertiesDocument38 pagesCHMT 2009 Week 5 Coal PropertiesTiisetso MokwaneNo ratings yet

- GMS60CSDocument6 pagesGMS60CSAustinNo ratings yet

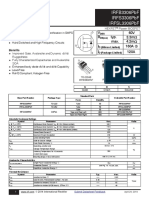

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADocument12 pagesIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligNo ratings yet

- OK Flux 231 (F7AZ-EL12) PDFDocument2 pagesOK Flux 231 (F7AZ-EL12) PDFborovniskiNo ratings yet

- Effect of Petrol Fumes On An Anthropometry and Ventilatory Function Among Petrol Pump Workers of Puducherry, IndiaDocument13 pagesEffect of Petrol Fumes On An Anthropometry and Ventilatory Function Among Petrol Pump Workers of Puducherry, IndiaABHINABA GUPTANo ratings yet

- Urban Road Types 25.01.2022Document5 pagesUrban Road Types 25.01.2022Balogun IbrahimNo ratings yet

- TMT Boron CoatingDocument6 pagesTMT Boron Coatingcvolkan1100% (2)

- Unit-3 BPDocument48 pagesUnit-3 BPShreyas ShreyuNo ratings yet

- A Simulation-Based Process Model For Managing Complex Design ProcessDocument13 pagesA Simulation-Based Process Model For Managing Complex Design ProcessMetehan AgacaNo ratings yet

- Which Is The Best Solid Modelling - Dhyan AcademyDocument3 pagesWhich Is The Best Solid Modelling - Dhyan Academydhyanacademy engineersNo ratings yet

- Servodisc CatalogDocument87 pagesServodisc CatalogEstebanRojasKrustofskyNo ratings yet

- Geomorphic Evidences of Recent Tectonic Activity in The Forearc, Southern PeruDocument11 pagesGeomorphic Evidences of Recent Tectonic Activity in The Forearc, Southern PeruVayolait BardNo ratings yet

- GTG - TFA Belt DrivenDocument2 pagesGTG - TFA Belt Drivensuan170No ratings yet

- JZ990D43501 eDocument6 pagesJZ990D43501 eМаксим ПасичникNo ratings yet

- Sap SCM TrainingDocument5 pagesSap SCM TrainingGLOBAL TEQNo ratings yet