Professional Documents

Culture Documents

Design of Free Standing Walls Feb 1984

Uploaded by

Dale StewartOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Free Standing Walls Feb 1984

Uploaded by

Dale StewartCopyright:

Available Formats

J. O. A.

KORFF BSc CEng FIStructE MICE

DESIGNOrrREE

STANDINGWALLS

e l/SfS' (21) ' F '

,

February 1984

THE

BRICK

DEVELOPMENT

ASSOCIATION

Information notes prepared in August 1995 relevant to

DESIGN OF FREESTANDING WALLS

By J. O. A. Korff

BDA Design Guide 12, February 1984

Introduction

The Design of Freestanding Walls DG12 was first

published by BDA in February 1983 and subsequently

revised and reprinted in February 1984. Due to its

popularity with designers and because much of the

guidance is still relevant , DG12 is being retained in the

BDA's Publications List.

Codes, Standards and other reference material have

changed during the intervening 12 years since the guide

was reprinted i n 1984, and the purpose of these

information notes is to highlight those important

reference changes which have a significant influence

on the use of the guide. These updated references will

need to be fully considered by designers in the

interpretation and use of DG12.

It is not possible to issue a teJduralline-by-lineaddendum

sheet to the guide and no attempt is being made to do

this . In due course when all the essential Codes,

Standards and other reference sources which are

currently changing have come into effect, it is the

Association's intention to completely revise DG12.

Design for Exposure/Durabil ity

Pages 4 to 8 inclusive of DG12 provide advice on

exposure, durability and associated detailing

considerations for the design of freestanding walls .

Some of this guidance has been superseded by more

up-to-date information and reference material. The

"special" and "ordinary" qualities classification of clay

bricks is now redundant and has been superseded.

Reference should be made to BS 39211'), BS 187(2),

BS 4729(3) and BS 6649(1 3) and to BS 5628: Use of

Masonry: Part 3: 1985:Mat eri al s and components ,

design and workmanship(14). Those clauses of BS

5628:Part 3:1985 which are of particular relevance to

brickwork masonry are : Clause 21 - Exclusion of

Moistu re (sub-clauses 21.2 and 21.7), Clause 22 -

Durability, Clause 23 - Selection of Mortars, andTable

13 - Durability of Masonry in Fi nished Construction.

A further source of information regarding durability of

brick masonry construct ion is BDA Design Note 7 -

Brickwork Durab ility(15).

Wi nd Loads

DG12 derives wind loadings in accordance with BS

CP3:Chapter V:Part 2:1972:Wind Loads. At the present

time this Code is still relevant to wind loading derivation,

although the current version has been amended from

the 1972 edition. Consequently figure 3 on page 11 of

DG12 - Basic wind speed In mls requi res revising in

accordance with the latest amendment of CP3.

During 1995 it is expected that BS 6399:Loadi ng for

Bulldings:Part 2: 1995:Code of pract ice f or wind

l oads, will be published by the British Standards

Institution. This new wind load code will be a complete

revision of CP3. BS 6399:Part 2 is likely to coexist

alongside CP3:Chapter V:Part 2 for about 12 months,

after which time CP3 will be withdrawn. BS 6399: Part

2 wi ll contain specific information for the derivation of

wind loads on freestanding walls.

DG12 can be used in either the context of CP3:Chapter

V:Part 2 or BS 6399: Part 2. If wind loading derivation is

in accordance with BS 6399:Part 2 then Table 2 (page

12) of DG12 becomes redundant whilst Figure 7 (page

18) of DG12 continues to be relevant if "p. , the design

wind pressure is derived fully in accordance with BS

6399:Part 2 and incorporates the appropriate partial

factor of safety for loading (YI) from BS 5628 (usually YI

= 1.2). This latter requirement also applies to DG12

guidance in respect of the use of "p". the design wind

pressure, referenced on pages 17, 18, 19,20,21 and

23 for unreinforced brickwork design and to similar

design wind pressure references for reinforced

brickwork, (pages 26 to 34 inclusive of DG12).

St ructural Masonry Design Codes

All references in DG12 to BS 5628:Use of Masonry:

Part 1:1978:St ructural use of unrel nf orced masonry,

should be replaced by reference to BS 5628: Use of

Masonry:Part 1:1992:St ruct ural use of unreinforced

masonry. For brickwork freestanding wall design to

DG12 the 1992 version of BS 5628:Part 1 is identical to

the 1978 edition with the exception that the characteristic

shear strength of unreinforced masonry in designati on

iii) mortar is reduced to 0.15 N/mm

2

(from 0.35 N/mm

2

) .

Page 21 of DG12 shows a shear strength calculation

for piers and if the revised characteristic shear strength

of 0.15 N/mm

2

is taken into account the pier design

demonstrated remains adequate.

Pages 26 to 34 inclusive of DG12 demonstrate

reinforced brickwork design using two alternative

methods. Thefirst isa permissiblestressdesignmethod

based on CP 111 :Part 2:1970, while the second is limit

states based to SP91. Reference to SP91 should be

replaced by BS 5628:Use of Masonry:Part

2:1985:Structural use of reinforced and prestressed

masonry. BS5628:Part 2 becameavailableafter DG12

was published. The detailed design approach and

worked examplesfor limit statesdesign shown in DG12

from pages 29 to 34 inclusive need to be modified in

respect of the recommendations of BS 5628: Part

2:1985, although the basic principles of reinforced

masonry design using this Code remain the same as

those given in SP91 . SP91 was a forerunner to BS

5628:Part 2.

An amended version of BS 5628:Part 2 is expected to

be published in the Autumn of 1995. Upon publication

by the British Standards Institutionthis Code should be

substituted for the 1985 edition. Major changes will

include guidance on design for durability of reinforcing

steels (cover and infill concrete quality) and changes to

design methods for laterally loaded masonry panels

incorporating bed-joint reinforcement. References will

also be brought fully up-to-date.

References

The list of references on page 35 of DG12 should be

amended as follows (others not amended remain

current):

(1) BS 3921 :1985. Specification for clay bricks.

British Standards Institution.

Note that in due course CP3:Chapter V:Part 2

is likely to be withdrawn.

(10) BS 5628:Use of Masonry:Part 1:1992:

Structural use of unreinforced masonry.

British Standards Institution.

(12) Replace reference to SP91 :1977 by:BS

5628:Use of Masonry:Part 2:1985:Structural

use of reinforced and prestressed masonry.

British Standards Institution.

Note that in due course BS 5628:Part 2:1995 will

supersede BS 5628:Part 2:1985.

Add new references:

(13) BS 6649:1985. Specification for clay and

calcium silicate modular bricks. British

Standards Institution.

(14) BS 5628:Use of Masonry:Part 3:1985:

Materials and components, design and

workmanship. British Standards Institution.

(15) J R Harding & R A Smith. Design Note 7

Brickwork Durability. 1986. BOA.

(16) MHammell & J Morton. The Design of Curved

Brickwork. 1991 . BOA.

(17) B A Haseltine & J N Tull. Handbook to BS

5628:Part 2:Section 1:Background and

Materials. 1991. BOA.

(18) B A Haseltine & J N Tull . Handbook to BS

5628:Part 2:Section 2:Reinforced Masonry

Design. 1992. BOA.

(3)

(4)

(6)

BS4729:1990. Specification for dimensions

of bricks of special shapes and sizes . British

Standards Institution.

Delete reference to BS 3798:1964 which is a

withdrawn standard and add in its place:

BS 5642:Sills and Copings:Part 2:1983:

Specification for copings of precast

concrete, cast stone, clayware, slate and

natural stone. British Standards Institution.

Add additional reference to BS 6399:Loading

for Buildings:Part 2:1995:Code of practice

for wind loads, whenavailablefromthe British

Standards Institution.

The following two references may be of interest and

are published by BRE. They are compatible with DG12

and its recommendations.

(19) Good Building Guide 14. Building Simple

Plan Brick or Blockwork Freestanding Walls.

Revised May 1994. Building Research

Establishment.

(20) Good BUilding Guide 19. BUilding

Reinforced, Diaphragm and Wide Plan

Freestanding Walls. March 1994. Building

Research Establishment.

August 1995

e Brick Development Association Limited

First p ublished February 1983

Revised and reprinted February 1984

(see Editor's Note opposite)

Edited by J.Morton liSe PhD CEng MICE l\lInstM

Designof

fl'ee slanding

walls

J. o. A. KORFF BSc CEng FIStructE MICE

Deputy Structural Engineer. OLC Department of Ar chi tectur e and Civic Design

The Brick Development Association

1

INTRODUCTION

I

This document. which has been prepared for the guidance of civil and structural engineers. architects and

builder s. deal s with the design and use of plain and reinforced free-sta nding brick walls not forming part

of a building.

Free-standing brick walls are widely used for bou nda ry demarcation. landscaping. screening. secur ity.

and noise barri ers. When properly constr ucted. free-standi ng br ick wall s have proved to be extremely

durabl e a nd pleasing in appearance. There are many examples of brick wall s. hundreds of years old.

which apart from occasiona l point ing and attention to coping require no other maintenance. By

modern sta ndards. most of these old walls. built by rule of thumb. are clearly over-designed.

However. since the turn of the cent ury. and part icularly after the Second World War. financial

constr aint s and the phenomenal growth of mass housing estates produced some very unsat isfactor y

examples offree-sta nding walling. Strange as it may seem. walls are not subjected to stat utory cont rol .

except in the Inner London Area where approva l is required when the height exceeds 1.83 m (6 ft )

above ground level. It is. therefore. not surprising that in the major ity of cases walls are put up rather

than designed. and all too frequently prematurely deter iorat e or blowover.

In most cases. a durabl e and stable wall will cost little more than a sub-sta ndard one. All that is

required is the selection of suitable mat er ials combined with an effi cient arrangement of brickwork.

I & 2 Free-standing wall screening a small mews development and reducing noise from a )'ery husy trunk road.

2

3 Staggered boundary wall enhances the roadside.

Desig n (Iffree slanc/in.tt walls

3

FACTORS AFFECTING DESIGN AND

CONSTRUCTION

EXPOSURE

More often than not . free-standing walls are exposed to the full effects of the weather. The action of

wind. as a lateral force. is catered for by the strength design. But. the combined effect of rain and

dr iving wind requ ires the use of suitable materials and correct const ructiona l det ail s.

Figure I shows the driving rai n index map of the United Kingdom which. at present . is the best publi shed

guide to the severity of weather condit ions. In genera l. bricks for free-standing walls in the moderate and

sheltered zones should comply with the frost resistanc e requirement s (but not necessarily the other

requirement s) for special quality bricks. However. wher e the wall is properly weathered (ie provided with

an overhanging coping) ordinary quality bricks may be used if recommended by the manufacturers for the

particular circumsta nces. In areas of severe expos ure. special qualit y bricks to BS3921 ( n . or other bricks

having a high frost resistance, are recommended. Calcium silicate bricks Class 3 or st ronger. in

accordance with BS 187.'" are suita ble for all degrees of expos ure.

These are very general guide lines which may be mod ified in the light oflocal conditions. Users should

contact the manufacturers to confirm tha t thei r bricks are sui ta ble for the intended degree of expos ure.

It is also well worth while to exa mine existing walls in the neighbour hood and note the performance of

particular bri cks after a few winters' service. The exposure of saturated bricks to frost or. even more

importantly. to the freeze/thaw cycle over severa l winters gives a very useful guide to durabil ity.

Some of the mor e economical walls recommended in this guide incorpo rate half-brick pan els. These

wall s are particularl y vulnerable to saturation in the winter months. but should perform sat isfactorily

provided they are constructed in accorda nce with the advice given in thi s guide and under competent

supervision.

COPINGS AND CAPPINGS

The function of copings and cappi ngs is aesthetic as well as pro tective. Th e appearance of a wall may be

dramatically changed by altering the coping or capping.

Th e protective function is against vertical water penetra tion and in sheddi ng rainwater clear of the face

as effectively as possible. The ideal copi ng should be durabl e. waterproof. weather the brickwork. and

constructed prefer abl y with interlocking units. The overhang should include a throating recess or a drip

not less than 13 mm wide. with the outer dri p edge at least 40 mm from the face of the brickwork as

shown in Figure 2e. Different shapes and types of copings and cappings are shown in Figure 2.

For cappings of special brick shapes. refer ence should be mad e to BS4729.,,, and for copings of clayware,

concrete or stone. to BS 3798.... A minimum weight of 1.5 kN/m ' is preferred for copings with concrete

or stone unit s. Some brick manufacturers can supply their own capping system which incorporates a dpc.

In many instances. for aesthetic or functi onal reasons. it is necessary to use a brick-on-edge capping.

Such a capping will perform reasonabl y well. provided that it is const ructed in accordance with the

recommendations of Table I. Suit abl e galvanised steel. stai nless steel or non-ferr ous metal anchors

4

1

Driving rain index

4

3

2

o

L:";;',,,I severe

1>:: ::1 moderate

1 1sheltered

2

NF

NB

3 4

HY

! a

7

TG

5

may be used to prevent movement s of end unit s, Figure 2n. For best result s an overhang such as shown

in Figure 2 (f-i) should be provided.

MORTARS

Free-stand ing walls derive part of their resistance to lat eral forces from their flexural strengt h. Where

adhesion between bricks and mort ar is not achieved, or is lost due to deterioration of the mort ar, the

strength may be reduced by as much as 50%. It is therefore imperative to ensure permanent flexural

tensile adhesion between the bricks and the mortar.

There is some evidence that the presence of entrained air bubbles, due to the use of plasticisers, results

in an inferior adhesion. Experience shows that plasticised or masonry cement mort ars may be perfectl y

workable when the cement content is as low as a half or a third of that specifi ed. Thus, a visual check

on mortar workability cannot indicate whether it has been correctly gauged.

The following recommendations should ensure adeq uate and durable adhesion between bricks and

mortar :

(1) Cement /lime/sand or cement/sand morta rs should be used. Plasticised or masonry cement mort ars

are not recommended, but may be used with the permi ssion of the engineer and under close

supervision ai med at ensuring that:

(a) the mortar is correctl y gauged with adequate water content

(b) mixing is strictly controlled to prevent excessive air entrainment

(c) part ially set mort ar (normally after two hours) is discarded and not reconst itut ed

(d) the suction rate of unit s is adjusted by controlled wett ing.

In general, air-entrained mortars are much more prone to site abuse, and circumstances may ari se

where adequate adhesion is not achieved.

(2) In dry, hot weather, bricks should be wett ed by lightly sprayi ng stacks or docking indi vidual units.

Alternati vely, a wetter mort ar may be used.

(3) Where bricks contain sulphates in excess of 0.5% (ie, where br icks do not conform to the maximum

allowabl e soluble sulphate content for special quality bricks to BS3921) sulphate resisting Portland

2a 2b

castconcretea stone copingS

toas3798. copings witharrinirnm

",..;g,lof 1.5kNJm' are

2 courses of

10 BS 743. 1U1y half-

lapped ard bedded

in 1:14. :3 mortar

. 0

' 0

toundahon

dpc 2 c:o..<sesof

bridIs ., BS3921 &

not exceeding 7%. in

morl ar .....

6

dpc tof orm

drip

----

2c 2d

drip

2e 21 2g

(j .

," .

coping

b -ees 10

854729

dpc tof ormdrip

., ...',"

iiEO

.'; '9'

q, .:..'

n,: ;;. " ..

attemative sector

-cioorsectco petered

2h

brick on edge in

1:l4;3 mortar.

and 2 courses

tilecreasilg

2i 2 cour ses tile

creasingwit h

cross joints ard

ridge tilein

1:14 :3 mortar

7

dPC

2n 215x215x102.5

socerd petered

non-ferrousor galvarised (without c

" ",,: ._ .."..",-,

brick_capping above dpc tobespeciat QUalrty n t : 3 mortar;

or class4 calciLmsilicatebricks in 1 mortar.

see text and lable1 for walland foundations brickwork.and

rroverTB"lt joi nt requirements

2m

p1inthstretdler

2k 21

cut br1ck on end bull-nosed doUJIe

stretcher onflat

dpctofomj

drip

2coorses

rrinrron

aboe dpc

brickonedge

capping

2cocrses

2j

aJtemati've shape

Design offree standing walls

TaM. 1 Brick and mortar requirements and associated materials

Positioninwall Bricks Mortar OPC Remarks

Foundat ions 10 Clay to 1:1:3 SRPC ifsulphates Not esse ntial with No otherformof

150mm above BS3921 in brick or soil, low abso rption dpc should be used.

ground level ( frost ot herwise 1:1:3 PC bricks, but if unless all owed for in

resistant),

Where indoubt desired provide two structural design.

Calcium sulphate resisti ng coursesof bricks

Silicate cement should be having absorption

Class 3 10 used of not more than 7%.

BSI87 or two courses of slates

to BS743 fully half-

lapped and bedded in

mortar

From 150mm Clay to M inimum 1:1:6or I :1:3a nd I :1:41 are

aboveground BS3921 1:1:4ISRPCif more durable

level to u/s sulphates in bricks in

of coping excess ero.s%

otherwise 1:1:6or

1:1:41 PC

Calcium l:l :6PC

Silicate

Class 310

BSI87

Coping or Clay Special 1:1:3 PC

Capping Qualit y to

BS3921 Flexible dpc to BS473 To improve water-

belowcoping or proofingof coping

Calcium 1:1:4IPC

capping. Preferably aluminium stearate

Silicate Permagrip additive may be used

Class 4 10

BSI87

cement (SRPC) sho uld be specifi ed and the mortar strengt h must not be weaker than I : I :6. In cases or

near maximum permitted sulphate content and/o r severe exposure I :! :4!, or even 1: 1:3 SRPC, is

preferable - see Table I.

DAMP PROOF COURSES

The strength of unreinforced free- standing walls described in thi s guide is dependent on their flexural

tensile stress. Consequently, the use or any dpc near gro und level incapable or providing the necessary

adhesion across the joint is not permitted unless the ' No Tension - method or design is used, as explained

in 'Methods or Design' (page 20).

In practice. the only dpcs which meet thi s requiremenl are :

(a) two courses or (engineering) brick s to BS 3921 or BS 743"! For free-standing wall s. special qu al ity

bricks with a water absorption or not more than 7% are considered to be adequate;

(b) two courses or slat es fully half lapped and bedded in mortar to BS 743.

In both cases. 1:1:3 PC or SRPC mortar (as appropriate) sho uld be used. However, in many cases where

walls are constructed of frost-resistant brick s, the need for a dpc near ground level is questionable.

Below the coping or ca ppi ng, a suitable flexible dpc should be provided, fully bedded on the underside

and on top in a suita ble mortar (see Table I) and project ing 10 to 15 mm from the race to form a drip.

Permagrip dpc is part icularl y suitable for t his purpose beca use or its superior adhesion to mortar.

Flexible dpc' s must never be cut back or poi nted over.

MOVEMENTJOINTS

In common with other building materials. bri ckwork is not dimensionally stable, and both reversible

and irreversible changes occur. In the case of free sta nding walls. the following main factors must be

taken into account in deciding the frequency or movement joints :

(1) moist ure expansion or clay brick s

(2) thermal expansion or contraction

t3) drying shrinkage, applicable in practice to calcium silicate br icks only.

Movement joints sho uld be constructed so that , in effect . they int roduce a complete separation over the

8

j

--

._....~ - ~ -

:...:--

4.5& 6 Correctly d<'siglU'c/II/(H', 'I1 1('1I1 joints.

9

7 & 8 Cappings carried across movement joints , Though a

newly constructed .... 011. the b('gi" "ill KS of potential problems

{IN! already apparent,

full height of the wall , including the dpc and coping or ca pping but not the foundations. Detailed

recommendati ons for the design of movement joints a re given in Sect ion 3.

FOUNDATIONS

The foundat ion requirements for free- standing walls may be less onerous than those for buildings.

It is suggested that , for free-standing wall s not forming part of a building a nd not exceeding 2 . ~ m in

height, a foundati on depth 01'0.5 rn, on a suffi ciently firm bottom in any type of soil, provides a

reasonable co mpromise between cost conside rations an d stability. For higher wall s in cohesive soils, a

minimum 01'0.75 m is recommended. Wh ere mixed mad e-up ground is present, it would be reasonable

to assume an allowable net bearing pressure of 50 kN/m ' , provided no organic soil is present and a

reasonable degree of con solidation has been attained over the yea rs.

Fresh fill is not suitable for an y foundation s unle ss mech anically compacted in thin layers. I n such

conditions, the all owable net bearing pre ssure should, however, be limited to 25 kN/m ' and the footings

should be rein forced.

For reasons explained on page 17, the dept h of brickwork below ground ought not to exceed 200 mm.

Detailed reco mmenda tions in respect of founda tions for various walls, a nd worked examples, a re

provided in Sect ion 3.

WIND LOADS

The design wind speed V. is calcul at ed on the basis ofCP 3, Cha pter V, Part 2''':

V, =VS,S,S3

where

V = ba sic wind speed in m/sec (see Fi gure 3)

S, = topographic fact or. normally taken as I

S, = ground roughness. size of st ructure and hei ght fact or. 0.6 value a pplies to wall s of any length not

exceeding 3 m height a bove ground level, located in the co unt ry with many wind breaks, small

towns or outskirts of large citi es.

S3 = statistical fact or ta ken as I in all circumstances.

Therefore,

V. = 0.6V m/ sec.

Since the limit state approa ch is adopted. the design wind speed is redesignated V" the cha racte ristic

wind speed, but not e tha t V. = V, =0.6V. The design wind press ure ca n now be ca lculat ed :

p =KV. 'C,y, N/m '

where

p = design wind pressure, N/ m'

K = 0.613 universal coefficient from the wind code

C, =force coefficient, assumed 1.2

Yr = partial safety fact or for laterall y loaded free-standing wall s = 1.2.

Therefore,

p = 0.613 x (0.6V) , x 1.2 x 1.2

= 0.318V' N/m '

For other S, and S, fact ors, the formula may be wri tten in a more genera l form:

p = 0.88 (S, x S, x V)' .

No guidance is given in CP 3, Ch apter V, Part 2 co ncerni ng the appropriate force coefficient for

free-standing wall s but, in the Wind loading handbook'" the authors suggest that such wa lls should be

treated as members of a n unclad st ructure. A table is provided in the handbook , covering different

ca ses and showing the force coefficient varying between 1.2 a nd 2.

However, if the cases shown a re related to the act ua l configuratio n of bounda ry walls, it becomes clear

that a coefficient ofless than 2 ha rdl y eve r a pplies. Th e contention that a force coefficient of 2 is

exceptionally high, a nd does not accord with the history of service behaviour of garden wall s, may be

best illustrated by the fact that. until 1973, such walls in the a rea covered by the a l C By-laws were

designed to 6Ib/ft ' (290 N/m ' ). Th e current practice in the Gl.C is to use C

r

= 1.2 which produces

8Ib/ft' (380 N/m '), a 33% increase. But , if C

r

= 2, as suggested by the handbook. is assumed, the walls

will have to be designed to with stand 13 Ib/ft ' (636 N/m ') - und oubtedl y a very unreasonable proposition.

The formul a derived above, p = 0.318V' , a pplies to ground roughn ess Ca tego ry 3 which is defined as:

'Country with many windbreaks (hedges, copses, orchards, rows of trees, o r similar), small towns or

outskirts of large cities' . This formula is likely to be appropr iate in the majority of cases but, in the

10

3

Basicwindspeedsinm/s

HY/ J

NF I f <j;; NJ

() J"48

,..'0 0 r.,....

Kilometres

o 20 60 100 140

I I I ! ! , , ! !

I iii i

o 20 40 60 80 100

St atute miles

II

open country with only scattered wind breaks (Categor y 2), equati on p = 0.396V' should be used. Where

there are no windbreaks at all in open country (Categor y I), p = 0.537V' applies.

The relevant value s of design wind pres sure are given in Table 2. It should be noted that the correct

assessment of gro und roughness category is important because it makes an appreciable difference to the

design pres sure. When in doubt, a higher category should be used. In unusual circ umstances, when walls

are constructed on very exposed hill slopes and crests where aocelerat ion of wind is known to occur, or in

valleys shaped to produce funnelling effects, the values of pressure given in Table 2, should be increased

by 20%. The existence of these unusual local effects should be checked with the nearest meteorological

office.

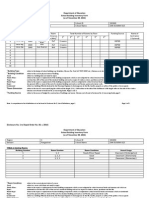

TaM, 2 Design wind pressure for walls ofany Im/(th not ex ceeding J m in height" (abov ground 1..,0

Basic Ground roughness Categor) 3 Category 2 Open country Category 1 Open country

Wind Country with many windbreaks, wit h scattered windbreaks with no obstructions

speed small towns, outskirts of large cities p N/m' p N/m

'

V mrsec p N/m'

38 459 572 775

40 509 634 859

42 561 699 947

44 61 6 767 1040

46 673 838 1136

48 733 912 1237

50 795 990 1343

52 860 1071 1452

54 927 1155 1566

56 997 1242 1684

For walls between 3 & 4 m in height the values of the design wind pressure given in Table I should be increased by 5)0/0

and for walls between 4 & .'5 m the values in Table 2 should be increased by 20%

9

---

......- . ~ -Jr._

:::-- - :

- - ~ ~ ... -

. -

-

-

12

10

9, 10 & 11 Satisfactorily designed wall , with adequate movement joints, suitable overhang and drip 01/ tile-creased capping

(/ 0 ), and t wo-layer slate dpc (II) .

TYPE OF WALL

The ideal characteristics of free-standing walls are :

(1) Strength and durability

(2) Economy

(3) Pleasing appea rance

(4) Simplicity

The wall configurations shown in Tables 3 and 4 conform to these criteria. Tradit ionall y, the type of

wall frequently used by builders and ar chitects comprises a 103* mm leaf with 215 mm square piers

at 2 m spacing. Such a wall is at risk, even in a sheltered environment, and its strength is virtually the

same as that of a 103 mm wall without piers when the direction of the wind is on the face conta ining the

piers. Piers ar c effective when the wind blows on the plain face but , clearl y, there is no way of ensuring

thi s permanently.

In general, 103 mm cant ilever walls - plain or with small piers - should never be more than 0.9 m high,

and should be restricted to parts of the country where the design wind pressure does not exceed

appro ximately 500 Nfm' .

An improved type of 103 mm wall with a sma ll stagge r is shown in Figure 4. This may be used where the

design wind pressure does not exceed approximat ely 500 Nfm ' , provided the wall is not higher than

1.2m.

13

I

l 0 3 m ~ ,._

, collar joint .qalvanised

double triangle ties

tam

4

Simpl e 103mm walls are frequ ently used as boundar y, separation or decorative landscaping features.

However, it is impor tant to remember that timber, or even wire mesh fencing, must not be used to

extend their effective height.

Where screening to ensure privacy and security is required, or where walls are used to provide a noise

barrier, the useful range of height s is 1.8 m to 5 m, although the vast maj ority of walls will be below 3 m.

* For simplicity, halfbrick walls are assumed to be 103 mm.

Design offr ee standing walls

For walls higher than 5 m, diaphragm wall construction may be more economical. Thi s is dealt with in

other BDA pub lication s'" 9} .

Table 3 shows walls of the same order of strength as a 215 mm solid wall. The efficiency number is

. b 100 x section modulus m' d i d d . di h i ' I h

given y . an IS mten e to in reate t e re anon between f1 exura st rengt

cross-sectional area m2

and the volume of materials used. The higher the number, the more efficient the configuration.

Table 4 shows walls of the same order of strength as a 328 mm solid wall which can be used for a height

of about 3 m. Above this height consideration should be given to the use of reinforced masonry, which is

likely to be more economical.

However, if an unreinforced wall is preferred, the configuration shown in Figure 5, which has an average

Z value of 3.0 x IO-'m' per m run, is suitable for height s 3.5 to 4.5 m.

It is not recommended that walls above 3 m high should be constructed without advice from an

engineer or other appropriately qualified person. Many factors vitally affecting the strength may be quite

inadvertently overlooked by the architect or the contractor, and the consequences of a failure of a high

wall could be very serious to life and property. When dealing with high ,expensive walls, the selection of

a suitable configuration should be the subject of a close consultation between t he architect, the quantity

surveyor, and the engineer to arrive at an optimum solution. In the area covered by the GLC By-Laws,

any free-standing walls in excess of 1.83 m in height (from ground level) must be approved by the Distr ict

Surveyor.

Table 3 Walls which can be used f or a height of up to 1.15 m ( depending on location and subject to

design procedure)

Type of wall

Solid 215 mm, either bonded or

collar jointed.

Avera ge cross-sectional

area in m permrun

0.215

Average section property

per mrun of wall

Z m

S

I m'

0.77 x 10- ' 0.83 x 10- '

Efficiency rating

[the higher the better)

3.6

oFor wall type 2. the values for Z & I are calculated

on the basis of a restricted flange width in

accordance with BS 5628: Part 1

110

) : clause 36.4.3.

2 St aggered - GLC pallern

18m

3 With piers

Piers need not besymmetrically

disposed in relation to wall.

Z and I values are based on

piers alone.

18m

14

0.129

0.184

0.79 x 10- ' 1.3 x 10- '

0.92 x 10- ' 2.53 x 10-'

6. 1

4.9

Table 4 Walls which can be used for height of up to 3.25 m ( depending on location and subject to

design procedure)

Type of wall

4 Soli d 328 mm

Average cross-sectlona t

area in mI permrun

0.328

Average section propert y

per m run of wall "

1.79 x 10- ' 2.94 x 10- '

Efficiency rating

the higher the better

5.5

5 Staggered - GLC pattern

6 Staggered - G LC patt ern

0.143

0.156

1.33 x 10- ' 2.93 x 10-'

' See wall type 6 below.

1.93 x 10- ' 5_33 x 10- '

9.3

12.3

215mrn

r--

~

* For walls type 5 & 6, the values for Z & I are

calculated on the basis of a restricted Fl ange width in

accordance with as 5628 : Part 1( 101: cl ause 36.4.3.

18m

7 With piers

Piers need not besymmetrically

disposed in relation to wall.

Zand I valuesare based on

piers alone.

328mm

~ r-

~ ss \\ ~ ~ 5 ~ 3 m m

f l. 147m

I 1 8m

anycnrreosonbetween 0 and562mm

0.206 1.34 x 10- ' 4.47 x 10-' 6.5

12 A very old and tall wall at BSI Conference Centre.

Design of'free S!a1lCUIlX walls IS

DESIGN OF UNREINFORCED BRICK WALLS

Empirical selection procedur e

Whilst this guide deal s in full with the theoreti cal aspect s of the subj ect, and th us will allow professional

engineers to use its recommendations for other wall configurations, it is recognised that architects,

surveyors and builders may wish to use it without havin g to produce lengthy calc ulations. To t his end,

the guide provides tables and di agrams which will allow a suitable wall to be selected by adopting the

procedure illustrated in the following exa mple.

METHODS OF DESIGN

When considering the sta bility offree-standing walls, the designer has three possible methods of approach :

16

Note thefo llowing:

(a) The effe cti ve height of wall is measured/ rom the top ofthe fo undations, thus the 'buried' part o[the wall should be kep t

to a minimum and. in general, shouldnot exceed 200 mm.

(b) The width and thickn ess 0/ thefoundations are the same [or 01/heights ofwall 0[ 0 given type in nnreinf orced brickwork.

(e) I" cohesi ve soils (clays), trees or very large shrubs should 110t be close to the wall. If this is impossible, a depth of

embedment o[fo undations ofat/east / .5 m is recommended.

(d) In made-up soils (see Table 9). the use 0/ reinforced foundations strips is recommended. These will haw' to be designed by

a competent person.

From Ta ble 2. outskirts of cities . ground roughness

Ca tegory 3.

Design wind pressure, p = 561 N/m ' .

Fro m Ta ble 10. releva nt foundat ion dimension s for wall

type 7, an d net bearing press ure of 100 kN jm ' are :

a - 0.5 m, b ~ 0.5 m, C - 0.8 m.

2.2 m wall is required. Therefore, with 0.2 m of wall below

ground (see note (a) below) . t he effecti ve height is 2.4 m.

Loca te point on Figure 7 corresponding to wind pressure

560 n 'rn' and effective height. 2.4 01 curves to the right of

this point ind ica te satisfacto ry wall types. Or. from Table 6.

select nea rest grea ter height (2.5 01) . All wall types ca pa ble

of resisti ng pressures greater than 560 N/m ' are suitable.

Therefore, wallstype 4, 5, 6 & 7 (see Ta ble 4) a re a ll

sat isfactory.

\Vall type 7 is selected. ot e that. in this example. only

wa lls shown in Table 4 are su itable.

Trial holes indicate loose sand. therefore net bearing

pressure 100 kN 'm' .

EXAMPLE

Design a brick wall in the suburbs of Northampton, 2.2 111 high above ground level,

Procedur e Exa mple

I. Locat e t he site of the proposed wall on the map , No rtha mpto n. fro m Figure 3. V = 42 m/sec.

Figu re 3, an d obtai n t he appropriate bas ic wind speed.

V (wind cont our) .

2. From Table 2. select the ground roughness catego ry

which best fits t heenvironment of the wall , and determine

t he design wind pressure from the appropriate basic wind

speed (wind co ntour)

3. Determine the effective heigh t of wall requi red (sec

Figure 6).

4. From the graph s in Figure 7, or Table 6. select type of

wall for the design wind pressure and the effective height.

S. From Tab les 3 & 4, select t he type of wall you prefer.

bearing in mind the efficiency rat ing.

6. From trial holes on t he si te, determine the type of so il

a nd. from Table 9, obta in the va lue of the allowable net

bearing pressure.

7. From Tabl e 10. o btai n det ails of foundat ion

co rresponding to a wall type 7 bea ring o n loose sand .

(a) Flexural st rengt h

(b) Notional rotation about one of the faces at the base, section virt ually full y cracked

(c) Sect ion und er compression throughout

These met hods are illustrated in relati on to a solid wall, but are equally applicable to staggered walls

and walls with piers.

6

I I O-2m

recoi i let ided

max.

00

Hm

17

(a) Design based on flexural strengtb (see Figure 6)

The flexural strengths of a wall is assessed in accordance with the masonry code, BS5628"

0

, (see Tabl e

15). In the guide, for simplicity, the cha racteri stic flexural st rength of masonry is taken as

f = 0.3 Njmrn' . This represents the minimum value which applies to all clay and calcium silicate bricks

laid in a I : I :6 mortar, or stronger, see Table 15 (page 33).

In order to derive a simple relation between H (effective height) and p (design pressure), it is assumed that

the critical section occurs at foundation level. Whilst, in some instances, the wall may have significant

lat eral support from any well-compacted soil over the base, such resistance is not always present , and

qui te diffi cult to quan tify. For economical design, it is best to keep the depth of wall in the grou nd to a

minimum. Plant ing of grass or flowers will require a dept h of soil over t he foundations of some 150mm

but, in any case, the soil cover should not exceed 200 mm.

Design parameters and procedure

The self weight ofa masonry wall assists in its stability.

Weight of masonry, W

m

= 21000 N/m' is assumed.

Where low density bricks are used, the weight of masonry may be as lowas 18000 N/m' . However , thi s

will have insignificant effect on the relation between p and H. It can be shown that for each 1000 N/m'

reduction in the weight of masonry, the height of the wall, as obtained from Table 5, will be reduced

by 1%.

w

m

, weight of masonry, = 21 kN/m'

y, for dead load = 0.9

r. , = 0.3 N/mm' = 300000 N/m'

Ym = 3. 1(it is assumed that bricks used in construction are usually subject to special

manu facturing cont rol)

Whilst the fact or of 3. 1 is considered appropriate to the design of free-standi ng walls, it is recognised that

some designers or regulat ory authorities may prefer to use Ym = 3.5. Accordingly, values and formulae

are given in respect of bot h coefficients.

Z = 0.77 x 10- 'm ' per metr e run (for wall type I in Table 3).

Moment at base, M, = P~ , per m run, where p is the design wind pressure in N/m' , from Table 2, and

H is the height of the wall above the base in m.

I M

- f = Z - wmHy,

Ym

O".l ign offree j'1uJI(/ing walls

19000H

pH'

- 1:-.5

74

7-

x

-

I

:c:

O

:- _-=-

= 0, for Ym = 3.1

96800

pH' - 293H - 1490

Similarly,

pH' - 293H - 1320 = 0, for Ym = 3.5

These expressions may al so be assumed to apply to wall s types 2 and 3 which have a higher Z value.

The quadratic equation can be solved with respect to H for different values of the design wind pressure,

p, obtained from Table 2. Similar quadratic equation s can be derived for the wall s shown in Table 4

from the general expression , substituting appropriat e values of Z.

Table 5 Formulae for different types of wall

Type of wall Quadratic equation applicable

(seetables3&4) Ym = 3.t

Quadraticequationapplicable

Ym = 3.5

1, 2. 3

5.7

4. 6

pH ' - 293H - 1490 0

pH ' - 503H - 2580 0

pH' - 677H - 3470 0

pH' - 293H - 1320 0

pH' - 50m - 2280 = 0

pH' - 677H - 307P = 0

The solutions to these equations are pl otted in Figure 7 for valu es of the design wind pressure between

400 and 1500 N/m . Example: a wall is required near Lincoln - basi c wind speed 44 ra]- in the open

count ry with scatt ered windbreaks. From Tabl e 2. the design wind pressure is 767 N/m ' , and from the

graph in Figure 7 we read off the limit ing height s of di fferent types of wall for Ym = 3. 1:

1.6 m for types 1,2 & 3

2.2 m for types 5 & 7

2.6 m for types 4 & 6

(b) Design based on notional rotation about one of the faces at base level

Design parameters andprocedure:

Design wind pre ssure p N/m ' (values from Tabl e 2)

Weight of masonry, W

m

= 21 kN/ m'

Y, for dead load = 0.9

Assume width of stress block at po int X = see Figure 8.

(This assumpt ion is valid for all strengt hs of brickwork)

t = thic kness of wall in m

Moment at base, M

pH '

= - - Nm

2

7

E

\ 1\ I I I

J:

W325 \

,

I I

"3

\ \'\

4 -

1"

..

\

,\\

-

...- ID

s:

3

4 - !> -

\ \

-,

1"-

\\

Hm -

c '

-, -,

... - OlE -

275

..

'\ "-

<,

<,

"' - '0 0.

-

-l

'\." ""'.. "

::

-

2 5

-.

<,

;;j' ",

-

1"-""-

<,

........ walllY!' d&6

2 25 r-, <, <, ! m3 5

......

<,

Xmo31

I\. '\.

""......,

wall type 5

7 ""'-.. <,

2

"\."

<,

' 3 1

<,

I"-

!m

3 5'-......

<, <;

""-"

waillype 1, 2&3 r-,

;---......

--

1-75

<,

1

,........,.

--

---

--

!m.

5............. r-, ...............

----

-

15

............... .......

c-......

----

-

r-

doo 500 600 700 800 900 1000 1100 1200 1300 iaoo 1500

design 'Hindpressure p N111

2

18

8

-

-

Hm

.-

.-

-

-

.-

x

0

.0.

0

0

0

0

.

0

.

0

D 0

The wall is assumed to be rotating about the centre of a very narrow stress block at X, wit h a tensile

crack extending over almost the full width of the wall. In this condition the use of Ymis inappropriate

and a gene ral fact or of safety YG = 1.2 is introduced which, together with partial fact ors for live and

dead loads, give a global factor of safety YGl related to the stability limit state:

YGl = x y,(wind)

I

= 1.2 x 0.9 x 1.2 = 1.6

Consider rot at ion of the wall about the mid-point of the stress block at X, then,

overturning moment x general factor = righti ng moment :

pH '

- 2- x YG = 0.45t x H x t x W

m

x Y,

where the distance between the centre of the st ress block and the centre of the wall is:

t t

2 20

0.6pH

= 0.45t

= 0.45t ' x 21000 x 0.9

Therefore,

H = where H and t are in metres and p in Nlm' .

p

EXAMPLE

Consider 328 mm 11'011 (type 4),fronl the expression above:

H = 14200 X 0.328' = 1530

P P

pin Nlm'

H inm

600

2.55

700

2.19

800

1.91

900

1.70

These result s are more conservative than those obtainable by the applicati on of method (a) based on the

flexural strength. However, in some cases where the flexural tension cannot be relied upon, this approach

will have to be adopted.

Th e method of notional rota tion can also be applied to staggered walls types 2, 5 & 6, but these

configura tions are very much less efficient (being considerably lighter) under no-flexural -tension

conditions. This is particularl y true in the case of wall type 2, but when the stagge r is greater a quit e

reaso na ble moment of resistance is available. It can be shown that , in the case of wall type 6, the

relati on between wind pressure and height is H = 1275 giving result s some 45% lower than those based

p

on met hod (a) - flexura l st rength. In cases where flexural tension cannot be relied upon, this approach

will be useful. It is also reassuring to know that , if a wall loses its flexural strength due to deterioration

or impact, it will still retain over 50% of its original moment of resistance.

Design0/free standi"? walls 19

(c) Design based on section under compression tbrougbout (no tension method)

In thi s approach, it is assumed that flexural tension is not allowed. Thus, the compression due to self

weight, reduced by Yr, must equal the flexur al tension due to the design wind load. Consider a I m run

of wall H m high :

pH' 6

H X Wm X Yr = -2 x -

t'

t '

H = 6300 -

p

By comparing thi s with desi gn method (a) or even (b), it is clear that extremely conservati ve results would

be obtai ned. For example, if the wall is 215 mm and the design wind pressure 420 N/m', then

H = 0.7m.

Thi s design approach should never be used because it lead s to over-conservative results. It is mentioned

here because some designers have been known, qui te wrongly, to attempt to apply it to masonry walls,

and because it may be legitimately used in the design of dry masonry walls.

RECOMMENDED DESIGN

Comparison of the three methods of design, clearl y indicate that an economical solution should be

based on method (a) - flexural strength. Walls must, therefor e, be built to ensure tensile resistance, see

Table I and section on mortars.

The three sets of quadratic equations given in Table 5 can be solved for a given magnit ude ofp (from

Table 2) thus obtai ning the appropriate value of height ; but a simpler way is to substitute values ofH at

0.25 m interval s and obtain the corresponding values of p. In general, p = bH

H

; c where band care

the coefficients of the appropriate quadratic equation from Table 5.

For example, if a wall type 4 or 6 is chosen and a height , H, of 3 m is required, the allowable design

wind pressure is given by:

_ 677 X 3 +3473 _ 612 N/ 'h - 3 I

p - 9 - m, w en Ym - .

Table 6 shows the compilation of these result s for different types of walls. The requi red values can be

obtained by interpolation, or from the graphs in Figure 7 .

Table 6

Maximum allowable design wind pressure, p, in N/m

'

Hm Walls type 1,2,3 Wallstype 5, 7 Wallstype 4, 6

Ym = 3.t Ym = 3.5 Y m ~ 3.t Y m ~ 3.5 Ym = 3.1 Ym = 3.5

3.25 399 371

537 499

3.00 454 421 612 567

2.75 524 484 705 652

2.50 614 566 826 762

2.25 425 733 674 987 907

2.00 519 476 896 822 1207 1106

1.75 654 597 1130 1032 1521 1389

1.50 858 781 1482 1349 2000 1815

1.25 1188 1078 2050 1864

EXAMPLE: THE USEOF TABLE6

A 2.4 m wall is required near Newcast le, in the open country with scallered wind breaks. Wha t type of wall

would be selected?

Basic wind speed is 46 m/ sec and Category 2 appli es.

From Table 2, the design wind pressure is 838 N/m ' . Clearly, wall types 4 or 6 are suitable. Interpolation

of figures from Table 6 shows that a 2.4 m wall type 4 or 6 will have a limit ing design wind pressure of

890N/m'ifYm = 3.1 is chosen.

Flexural strength of 103 mm wall between piers

In the case of walls type 2, 3, 5, 6, & 7, the st rength ofa 103 mm wall spanning continuously between

piers must be checked. The flexural stress is parallel to the bed joint (bending about the vertical axis),

therefore from Table 15 (page 33) f has a minimum value of 0.9 Njmrn "(900 kN/m ' ) for clay and

calcium silicate bricks laid in a I: I :6 mortar.

20

= 0.324p

Assume maximum spanmoment, M = where from Tables 3 & 4 span Lis 1.8 m.

p x 1.8'

10

M

z

0.103' x I

6

= 1.77 x 10- ' m' per metre

I

- x f.,

'Ym

M

= z

I

x 0.9 x 10'

3.1

0.324p

1.77 x 10- '

p = 1.77 x 0.9 x 10' = 1586 N/m' , say 1600 N/m'

3. 1 x 0.324

Thus the wall is safe in all cases when p " 1600 N/m' .

Shear strength of piers

Consider wall type 6, which gives the lowest shear resistance (see Table 4).

When p = 2000 N/m'

Shear force on pier = 1.8 x 2000 x (1.5 - 0.2) = 4680N (see Table 6)

where 1.5 - 0.2 is the height of wall above ground.

4680

Average shear stress = 552 x 215 = 0.039 N/mm'

which is well below the minimum allowable value of = 0. 14 N/ mm2

where 0.35 N/mm' is the characterist ic shear strength of masonry laid in I : I :6 mortar and 2.5 is 'Y mvthe

partial safety factor in shear.

End Condition

Walls type I and 4 can be stopped at any point, and walls type 3 and 7 will clearl y terminate at a pier.

But, in the case of walls type 2, 5 & 6 which deri ve their st rength from the Z configuration, the end pier

has to be considerably enlarged. In some instance s, a gate one metre wide may be attached to the pier

and thus the total length of the wind face supported by the pier is + 0.5 = 1.4 m.

The requi red section modulus of the end pier, Z. = : :: x section modulus of 1.8m run of staggered wall.

In the case of wall type 2, for exampl e, where the section modulus of 1.8 m run = 0.79 x 10- ' x 1.8

= 1.42 x IO- 'm' :

Z. = : :: x 1.42 x 10-' = 1.1 x IO- 'm'

For a pier 328 mm deep,

x B __ 1.1 10 ' F' 9

x - , see igure

9

B

I.I x 6

= ':": 3"" .2"' 8""""

= 0.61 m.

= 0.34 m (0.328 will do), see Table 7. B

Or, if the pier is made 440 mm deep :

I.I x 6

4.4 '

Design (Iffur .stiJJuliug walls

21

End conditions for other staggered walls are shown in Table 7. In all cases a metre wide gate was

ass umed attached to t he end pier.

Table 7

Wall type

2

5

6

Sect ion modulus

of end pier

requiredin m

a

J.1 x 10- '

1.87 x 10- '

2.1 x 10-'

or

End condition

Design of movement joints

As has already been said, masonry materials are subject to dimensional changes for a varie ty of causes,

t he most important of which relate to variations in moi sture content and temperature.

The effect of mois ture expansion of clay bricks will be reduced by using mature bricks. Clay brick

masonry is hardly affected by drying shrinkage. It also has a low coefficient of t hermal expa nsion.

To accommodate movement in free-standing walls of clay brick s, it is recommended that , in the case of

staggered brick walls types 2,5 & 6,10 mm open joints should be provided in the middle of every sixth

bay (see Figure 10), and for straight wall s type s I & 4, such joints should occur at about 10 m centres.

10

joints at 104mcentres

lOnm

movement r

joint \ I

&:::S0l , ~ \;

~ \\ \\ ItS \\ ~

14m 18m

length of bay containing

movementjoint

Where staggered walls are used, the bay containing the expan sion joint should be reduced to 1.4 m. Thi s

is because the section modulus is 12% less due to the reduction in the length of the effective flange, one

end of which is now free.

In the case of walls with piers, type s 3 & 7, the bay containing the movement joint may be of standard

length, ie, 1.8 m.

Where calcium silicate bricks are specified, movement joints at closer centres are recommended to avoid

unsightly cracking. A gap of between 5 & 10mm in every fourth bay - ie, at approxi mately 7 m centres -

should be adequate for this purpose.

It may be advisable to increase the frequency of movement joints in cappings and copings.

22

Table 8 gives the order of free movement that might be expected in a 10m length of wall.

Table 8

Cause of movement

Moisture expansion

Thermal expansion

or contraction

Drying shrinkage

Movement (mm)

in a to m length . fwall

+J.5 to 5.5 (clay)

2.5 (clay) } . 50' C ..

4.5 (calcium silicate) assummg a varration

- 2.5 (calcium silicate)

Where the provision of a movement joint cut s the leaf between piers, it s strength when acting as a

cantilever sho uld be checked. Figure I I (a) shows such a movement joint in a wall type 7. Alt ern at ively,

in wall s type 3 & 7 only, a movement joint may be incorporated at a pier as sho wn in Figure II (b).

11a r movement pm

215mm ., O79m

I. 18m ctrs.

11b

,-movement joint l Qmm

&' i

1-.11..-.1

215

rrm rrm

12 bead of

acrylic mastic

neoprene bailie

approximately

2mmthick

1Qmm

To check the strength of cantilever in Fig II (a) : M = O.7;'P = O.3lp N/m. This is, in fact , a smaller

moment than in the case of a continuous span (see page 21) and the cantilever is clearly adequate for the

design wind pre ssure, p, of up to 1600 N/m' .

Movement joints may be left open or, where pri vacy is required, pointed with acrylic mastic of suitable

colour. Another useful detail , shown in Fig 12, incorporates a folded neoprene baffle lightly tacked to the

ma sonry by a suitable ma stic such as acrylic.

For neat appearance, and to facilitate sealing, movement joint s should be formed using a sliding board

of appropriate thickness. For reinforced brickwork, mo vement j oints may be located and constructed as

recommended for unreinforced brickwork.

Design of foundations

Suitable foundati ons for walls up to 3 m high may, in general, be selected on the basis of Tables 9 & 10,

together wit h information from a trial hole inspection carried out by a competent per son . It is strongly

recommended, however, that for higher walls, advice should be obtained from an engineer. In certain

cases, the engineer may recommend a full ground investigation to establish t he soil properties, and to

confirm the absence of faults (eg, layers of organic soil or swallow holes) lower down and the stability of

sloping ground.

At the time of writing thi s guide, the limit state approach to foundation design has not been int roduced.

Thus, calc ulations will be based on the followi ng parameters:

(i) Wind pre ssure related to height and type of wall, from Fig. 8 or Table 6, divided by 1.2

(ii) Actual weight of ma sonry, concrete and soil

(iii) Allowable net bearing pressures from Table 9, increased by 25% for wind and by an appropriate

amount for depth effect (equal to density of soil x depth of embedment).

D t'S;)!1I oJji- c!' s({l/ ul i l1,l,' walls

= 21 kN/m

3

= 23kN/m

3

= 17 kN/m'

EXAMPLE

Design suitable foundations for a wall 2.5 m high, type 4, Figure 13, beari ng in:

(a) soft clay

(b) loose sand

Design data :

Density of masonry

Density of concrete

Density of soil

23

Wind pressure for foundation design = ~ ~ ~ = 690 N/m' (seeTable 6)

Assume that, in this case, the suitable formation level is 0.7 m belowthe surface.

Allowable beari ng pressure (soft clay)

= 50 x 1.25 + 17 x 0.7 = 75 kN/m'

Allowable bearing pressure (loose sand)

= 100 x 1.25 + 17 x 0.7 = l37kN/m'

(a) Consider I m run of wall and assume 0.75 m width of foundations.

Weight of stem = 2.5 x 0.328 x 21 = 17.2kN

Weight of base = 0.75 x 0.5 x 23 = 8.6 kN

Weight ofsoil = 0.75 x 0.2 x 17 = 2.5 kN

Total 28.3 kN

3.02 x 6

0.75'

Wind moment at formation level

= 2.5 x 690 x (1.25 + 0.5)

3020

e = 28300

28.3

Ground pressure = 0.75

= 3020Nm

= 0.107m

= 38 32

= 70or 6 kN/m' (see Figure 13)

Foundation is suitable for soft clay.

Table 9 Allowable net bearing pressure and other recommendations

Group Type Mi nimumall owable NET Remarks

bearingpressure kN/rn

'

Cohesive Stiff clay ISO Bottoms of trenches must be

soils protected.

Fi rm clay 100 Concretingor blindingshould be

carried out within 2 or 3 days after

Soft clay SO excavation

Non Loose gravel or ISOto 200 Waterlevel at least 0.5 m below

cohesive loose sand and bottom of foundation

soils gravel

Loose sand 100

Rocks Soft chalk 100tolSO Bottoms of trenches must be

(putt y chalk) protected by early concreting or

Otherrocks SOO blinding to prevent formati on

of slurry

Made up Mature SO Local soft spots. pocketsof organic

soils (undisturbed soil etc shouldberemovedand back

for several filledin leanconcrete. Strips should

years)mixed preferably be reinforced

fill ofcohesive

and granular

soils

Made up Newly placed 2S Suitable for foundations of walls not

soils mixed fill exceeding2 min height if fill is

mechanicallyconsolidated in layers

of 200 mmthickness. Foundation

strips must be reinforced. Foundations

maynot always beentirelytrouble

free

Organic Peat and Not suitable for foundations but if

soils organicsoils the layerof organicsoil or peat is at

least 2 m below the underside of

foundations, reinforced strip footing

designed to 2SkNlm' may be

installed in the overlaying suitable

soil. However, some risk of

settlement must be accepted

For many soils higher values ofthe allowable net bearing pressure are appropriate. However, practical considerat ions

preclude the reduction offoundation dimensions below values given in Table 10.

24

= 130kN/m' (see Figure 14)

= 0.123 rn, which is out side the middle third of a 0.5 m strip

(b) Now consider foundations in loose sand and assume a widt h of 0.5 m.

Total weight is now 24.6 kN because the strip is narrower.

Wind moment is unchanged at 3020 N/m

3020

e = 24600

G d

24.6

roun pressure = 0.5 x 0.38

Foundation is suitable for loose sand.

I

14 750mrn

13

o

.0

0

14

,3QkN,m

e

0-127 0-123

0-5m

0

o.

o .

o.

0

.

o . .

g

0

0

-

-

.0

0

.:>

.

0

. o

o _

. l/V

V i

3xO-'27- 0-38m

Table 10 Recommended f oundations

Type Foundations Max. bt. of Width of hase (m) Allowahle NET Mi nimum l\linimum

of wall measured bearing pressure fromTable 9 thickness depth of

wall from top of (m) embedment (m)

base (m) 50 100 150

I

f

i }

2.25 0.5 0.5 0.5 0.3 0.5

2

t

I I

i

2.25 0.5 0.5 0.5 0.3 0.5

3

: :

a - 0.5

2.25 b =0.5 b -0.5 b =0.5 0.3 0.5

a _ 1

c = 1.0 c =0.75 c =0.75

J.- b-eJ

4

'\

t

3.25 0.8 0.6 0.5 0.3 0.5 0rO.75"

5

f

I I } 3 0.6 0.6 0.6 0.4 0.5 or 0.75"

6

i

H

}

3.25 0.7 0.7 0.7 0.5 0.50rO.75"

7

I':

a =0.5 a =0.5 a =0.5

3 b =0.5 b =0.5 b =0.5 0.3 0.5 0rO.75"

c -0.8

'"bo-l

A minimumdepth of embedment 0[ 0.75 m is recommended/or walls exceeding 2.5 m in height in cohesive soils.

Design of'free standing walls 25

REINFORCED BRICKWORK

4

a - Iever arm coefficient

Pmb-permissible bending stress in masonry

POl - permissible tensile stress in reinforcement:

140N/mm' for mild steel

210 N/mm' for high yield steel

METHODS OF DESIGN

Two methods of design of reinforced brickwork are currently in use:

(I) Permissible stress method, as given in CPI I I, Part 2, 1970(amended June 1971)1111

(2) Limit state method, for which there is as yet no British Standard Code of Practice, but which is

covered by SP 91nil,

PERMISSIBLE STRESS DESIGN METHOD

Figure 15shows a reinforcedbrickwork section in bending,

Where:

d ,,-effective depth

z -lever arm

b -width of section

n -cornpression stress block coefficient

15

Assume the stress ratio POI = r, and the modular ratio EEs = m, then from similar triangles the following

Pmb b

relationships are obtained:

I m n

n = --= --- also a = I - - therefore

I +!.. m +r' 3'

m

2m + 3r

a = ""3-m-+---=3:-r

Moments of resistance of the section can now be derived .

M, = C x z = P ~ t na bd,,' = Qbd,,' is the moment of resistance based on masonry in flexure, and

M, = T x z = A.. p.. x ad" is the moment of resistance based on tension in reinforcement.

In practice, the moment of resistance will be governed by the strength of masonry in bending, and

consequently for a particular masonry the required effective depth is given by d" = ~ where Mis

26

the applied moment and Qis given in Table I I or in Fig 16.

The area of reinforcement is A.. = -;-

Pita er

Design parameters for the working stress method are given inTable 11.

Table /I

Crushing strength or

bricks in:"ljmm

l

io.s 20.5 27.5 .34.5 52 69

CP It I, Table 3.

mort ar 1: 1:3

PmbNjmm

'

1.4 2.2 2.73 3.33 4.67 4.67

limit limit

p" ( H Y) Nlmm' 210.0 210.0 210.0 210.0 210.0 210.0

m (ta ble 6a of (he

E.

33.0 27.0 24.0 21.0 15.0 12.0

amendment) - ~

p"

150.0 95.0 76.9 63. 1 45.0 45.0 r ~ -

Pm.

r

- 4.55 3.52 3.20 3.0 3.0 3.75

m

n 0. 18 0.22 0.24 0.25 0.25 0.21

a, lever arm factor 0.940 0.927 0.920 0.917 0.917 0.930

Q Nlmm' (max .) 0.118 0.224 0. 301 0.382 0.535 0.456

50 60 70

crushingstrengthof bricksN mm"

40 30 20 10

.

E

I

~ ro

HYsteel

~ ~ 1: 1. :3 mortar

"1ll

.k

095

.-

-

->

.....

---..

/'

0 94

<.

-:

./

093

:-...

<,

/'"

I....... >

---

0 92

V

--

---

/

a

1 0 91

o

5

o

05

!\Iortars

Cement mortars should be specified in proportions by the volume of the dry constituent s. as given below :

Grade Cement Hydrated lime Sand

(i) I } 3

(ii) I ~ 4 ~

Grade (i) is preferred.

Grout s

Grouts should be one of the following mixes by volume or dr y materia ls:

Cement Lime (optional) Sand 10 mm aggregat e

(a) 1 ':' -1 3

(b) I ':' -i 3 2

Mix (a) must be liquid and should be used for grout ing internal joi nts and cavities less than 50 mm wide.

Design of{n'(' S[llJldiJl.f! walls 27

r

m

Mi x (b) sho uld have a slump between 75 mm a nd 175 mm a nd sho uld be used to fill grout spaces whi ch

are 50- 100 mm wide.

No addit ives sho uld be used in mort ar, grout or concrete, but carefully controlled amounts of co louring

agents may be used .

Minimum area of reinforcement

Although the Code (CPIII , Part 2) does not specify the minimum percentage of reinforce me nt in

flexura l members, the aut hor consi ders that 0.1%of the gross cross-sectional area of the member

sho uld be provided.

Reinforced Quetta bond, pocket & grouted cavity walls

EXAMPLE, PERMISSIBLE STRESS DESIGN METHOD

Design a free standing wall 3 m high, using three differ ent types of construction: Quetta bond, pocket and

grouted cavity. Basic wind speed is 50 mis, ground roughness Category I. Bricks with a crushing strength of

34.5 N/mm' in l: j:3 mortar are specified in all cases.

Pm. = 3.33 N/mm ' (see Table II ) .

= 21 from Table 6a, CPl lI, Pa rt 2 (Amendment)

P.. = 210 N/mm' for high tensile steel (CPIII, Part 2)

= 210 = 63

3.33

I

n = ~ = 0 . 2 5

1+

21

a = 0.917

Q = 3.; 3 x 0.917 x 0.25 = 0.38 N/mm'

M, = 0.38bd,,'

Alt ernati vely, Q, may be obtained from the graph in Fig. 16, or Table I I.

From Table 2, for basic wind speed 50 mis, ground roughness Catego ry I , we have:

Design wind pressure for limit state de sign

Design pressure for permissible stress design

= 1343 N/m'

= 1343 = 1120 1m'

1.2

D

be di pH '

esign n mg moment, M = 2

M = 1120t 3' = 5040 Nm = 5.04 x 10' mm

The minimum required effect ive depth, d, ca n now be calculated :

d = J5.04 x 10' = 115mm

" 10' x 0.38

Therefore, the wall section in Figure 17 is satisfacto ry a nd, becau se the actual d, is 164 mm, a brick of

lower cr ushing strength would have been adequat e.

packetsat 170mmYo:

A

5.04 x 1

0

' _ 60 e 0 1% r . - 328 '

.. 0.917 x 164 x 2 10 - I mm , or . 0

0

gr oss a rea - mm

Provide 12 mm HY ba rs in alternate pockets, ie, at a pprox imately 340 mm clc.

A.. provided = 332 mm'

28

1m 1m

19

w a l l t i e s ~

Pocket wall ( Figs, 18 & 19)

Use 21 5 mm overall thickness collar j ointed wall with 200 x 110mm staggered pockets at about 2 m elc

on both sides of the wall. Bending moment is as in the previous example.

Q

M 5.04 x 10' 02 h r d h f . I

= bd,,' = 10' x 160' = . , t ere,ore propose strengt 0 masonry IS amp e.

z = 0.917 x I6O = 147 mm

5.04 x 10' x 2 _ 327 ' 2

A.. - 0.917 x 160 x 210 - mm per m run

or,O. I %ofgrossarea = 2000 x 215 x 10- ' = 430mm' .

Provide two 16 mm HY bars in each pocke t, A.. = 402 mm'.

. 402 x 100

percentage of remforcement = 1000 x 215 = 0.18

Shear stress = 11 20 x 3

= 10' x 160 x 0.917

= 0.023 Njrnrn", is satisfactory.

A suitable arrangement of staggered pockets at 2 m spacing, on alternate sides of the wall , is shown

in Fig. 18.

Th e appearance of the wall will be considerabl y improved if the pocke ts are faced with bri ckwork,

attached to the concrete by suitable ties, as shown in Fig. 19.

Grouted cavity wall (Fig. 20)

The wall consists of two half-brick leaves with a 100 mm grouted cavity.

Moment of resistance, M, ~ 0.38 x 1000 x 153' = 8.9 x 10' Nmm. But, since the applied moment is

5.04 x 10' Nmm (see Quetta bond example) the wall is adequate.

5.04 x 10' _ 7 '

A.. 0.917 x 153 x 210 - I I mm

or, 0. 1% of gross area = 306 x 10' x 10- '

Provide 12 mm HY bars at 350 mm clc, A..

= 306 mm' .

= 323mm' .

The seconda ry reinforcemen t should be at least 0.05% of the gross cross-sectional area of the wall.

Area required = 306 X 10' x 5 x 10-< = 153 mm. Provide 10 mm bar s at 500mm clc.

LIMIT STATE DESIGN METHOD

Principles

This design approach is based on BeRA Special Publication 91"". The design moments of resistance are

given below. The lesser of the two values should be taken as the resistance of the sect ion in bending.

0.3bd, , '1.5f" b d h h f'b ri k k ' b di

Md ase on t e strengt 0 nc wor 10 en 10 9

Ymm

or,

M

d

= A. f,z based on the strength of reinforcement in tension

Ym.

where

d (I 0.53A. f, Ymm) 095 d

z = " - ~ x - x 1 5f " . ,r

er Yms k

The expression in brackets is the lever arm coefficient, a, which has a range of 0.8 " a ,, 0.95.

Design offree standing wafts 29

MYms

As =---zr;-

M = applied design moment

M, = design moment of resistance

b = width of section

d, = effective depth of section

f, = characterist ic tensile st rength of the reinforcement, given in Table 14

f. = characteristic compressive st rengt h of brickwor k, given in Table 12

a = lever arm coefficient (see also page 34 )

z = lever arm

Ymm = partial safety fact or for brickwor k stre ngth, given in Table 13

Yms = parti al safety fact or for reinfor cement strengt h which should be taken as 1.15

Table 11 Characteristic compressive strength of

brickwork.A, normal to bedjoints (Nlmm') for the

design of reinforced masonry to limit state

Mortar

grade and mix

(i) I :1:3

(ii) 1:1:41

Compressive strength of brick (N/ mm

l

)

15 20 35 50 70 100

6.0 7.4 11.4 15.0 19.2 24.0

5.3 6.4 9.4 12.2 15.1 18.2

Table IJ Partial safety factors (y m) * for

strength of brickwork in compression and fl exure

applicable to reinforced and unreirforced masonry

designed to limit state

Ca tegory of

construction control

Catego ry o f Normal

manufacturing control

o f st ructural uni ts Special

Normal

3.5

3. 1

Special

2.8

2.5

For reinforced masonry this fa ctor is designated Ymm

Table 14 Characteri stic strength of reinforcement

for limit state design

Nominal sizes Characteristic

Designation (mm) strengt h f r

(N/mm' )

HOI-rolled mild steel All sizes 250

(BS 4449)

HOI-rolled high yield All sizes 410

(BS 4449)

Cold-worked high yield Up 10 and inc!. 16 460

(BS 4461 )

Over 16 425

Hard-drawn stee l wi re Uploandincl .12 485

(BS 4482)

Th e shea r stress is given by:

V

v

bd"

where

V = shea r force du e to design loads

b = width of section

d, = effecti ve depth

The shear stress, v, should not exceed the characteristic shear stre ngth of brickwork f, o = 0.35 N/mm'

divided by the partial safety fact or Ym v which is taken as 2.5.

Shea r reinforcement is most unli kely to be required, and in any case its use is not recommended in

these simple structures.

30

Slenderness limits for reinforced cantilever wall s

The ratio of spa n to effective depth ofa cantilever wall, with up to 0.5 % reinforcement based on gross

cross-sect ional area, sho uld not normally exceed 18. However, where the load is transient (wind) , and

there is no danger of damage to fini she s, the slenderness ratio limit may be increased by 30% to 23.4.

Reinfor ced Quetta bond wall

EXAMPLE

Design a reinforced free standing wall 3 m high const ruc ted in Quetta bond, using limi t sta te design method.

Basic wind speed is 56 mls, and ground roughness Catego ry 1 are ass umed.

Design moment M = p ~ ' = 1684 x ~ = 7578 Nm. Thickness of wall in th is case is governed by the

slenderness limit. Minimum d" = ~ ~ = 130 mm. Use 328 mm wall as sho wn in Figure 21. The

effective depth of 164 mm is satisfacto ry.

21 J OD ODnC 1- '

It:fJ

0 TI LJEjUl- .t 1

328mm

r\\", d" =1164

~ ,-,

pockets at 17QrrmSt

Assume 20 Nlmm' bricks in l : j :3 mortar. f

o

= 7.4 Nlmm ' = 7.4 x 10' kNlm' (see Table 12) and Ymm

= 3. 1(see Tabl e 13).

The maximum de sign moment of resistance can now be calculated :

= 0. 3 x 10' x 164' x 1.5 x 7.4 = 28900 Nm

M, 3. 1 x 10' .

which is ample in rel ation to the applied moment.

"

Assuming MS reinforcement (f, = 250 N/mm' . see Table 14), a nd z = 0.9 x 164 mm:

_ 7.58 x 10 ' x 1.15 _ 236 s

A, - 250 x 164 x 0.9 - mm

or. 0. 1% of gross cross-sectiona l area = 328 x 10' x 10-'

= 328 mm '

Provide 12 mm MS in a lternate pocket s. Since t hc minimum a rea of reinforcement governs. the

assumpti on of the a pproxi ma te lever arm as 164 x 0.90 has no practical significance.

Shear stress = 1684 x 3 = 0.03 Nlmm' . This is less tha n the design shea r st rength

10' x 164

whi ch is 0.35 = 0. 14 N/mm'.

2.5

'ote : The minimumpercentage ofreinforcement recommended by ref erence CI ZI is 0.2%ofthe gross

cross-sectional area. The authorfeels that this percentage is rather highfor simple boundary walls and,

consequently, 0.1 %has been adopted throughout these examples.

Reinfor ced pocket wall

EXA MPLE

Design a 215 mm pocket wall of maximum height using limit state approach. Basic wind speed of56 mls,

and gro und roughness Category 1 are ass umed as in previous example.

Referring to Figure 22, effective depth, d., = 160 mm. Therefore maximum permitted hei ght =

23.4 x 0. 16 = 3.7 m. Therefore a 3.7 m wall will bc satis facto ry.

pH ' 3.7 '

M = - - = 1684 x- = 11530Nm.

2 2

22 2m%

pockets at 201% onboth

COllar joint facesstaggered

DC!i;I!" offret' standing walls 31

20 N/mm ' bricks in I :1:3 mortar are specified (as in the previous example),

Ymm is taken as 3.1 (see Table 13).

Maximum design moment of resistance

M 0.3 x 10' x 160' x 1.5 x 7.4

d 3.1 x 10'

= 27500 Nm, which is ample.

A. 11 530 x 10' x 1.15assuming HY reinforcement and an approximate lever arm of 160 x 0.90.

460 x 160 x 0.90

A. = 2oomm'

or, 0.1 % of the gross cross-sectional area

= 215 mm ' (all per m run).

Provide staggered pockets of 200 x 110mm approximately, at about 2 m cic on each face as shown in

Figure 18. Area of reinforcement in each pocket = 400 mm', provide one 16 mm and two 12mm HY

bars, A. = 427 mm' . The concrete pockets can be faced with brickwork, as shown in Figure 19.

For 215 mm bonded walls, use I brick wide pockets at 9 br ick cent res.

Half brick wall stiffened with reinforced piers

EXAMPLE

Design a wall 4.25 m high with reinforced piers at about 2.5 m cleo Design wind speed is 46 mls, and gronnd

roughness Category 2.

Design wind pressure from Tabl e 2 is 838 N/m' but. because the wall is j ust 4 m high above ground level.

th is pressur e should be increased by 9% (see footnote to Table 2). Design wind pressures =

838 x 1.09 = 913 N/m' .

Consider 103 mm unreinforced brickwork spanning continuously between piers.

Clear span is 2.035 m, see Figure 23, and the effective span = clear spa n +thickness of wall = 2. 14 m.

23 cover10 main bars 20mm

44Qmm

ef 310mm

'-;1:. ..

Clear span

Take:

M WL 913 x 2. 14 418 Nm

10 10

103' x 1000 .

Z 6 = 1.77 x 10' mm' for I m Wi dt h of wall

Ymm = is taken as 3.1 (see Table 13)

Flexural tension is parall el to the bed joi nt and therefore the two last columns in Table 15apply.

= 418 X IO' x 3. 1 = 0 73 NI '

ft. 1.77 x 10' . mm

From Table 15 (page 33), bricks with an absorption of over 12%in at least grade (iii) mortar ( I : I :6) will

suffi ce. However, for rei nforced piers, gra de (i) mortar ( I :1:3) is prefe rred. Thus, both the wall and the

piers will be const ructed in this mortar using bricks of20 N/mm' stre ngt h.

= 20682Nm

= 4250 = 14

310

= 2290N/m Load on pier = 913 x 2.5

2290 x 4.25'

2

0.3 x 440 x 310' x 1.5 x 7.4 _ 45420 N hi h i I

3. I X 10' - m, w IC IS amp e.

M

Slenderness ratio of pier

32

Assume a lever arm coefficientof 0.9.

A = My m. _ 2.07 X 10' x 1.15 = 185mm'

f, x Z 460 x 0.9 x 310

Provide four 12mm HY bars, percentage of reinforcement = = 0.23.

The lever ann coefficient can nowbe verified using A. = 185mm'

and f, = 460 N/mm' :

a = ( I _ 0.53 x 185 x 460 x 3.1 ) = (I _ 0.08) = 0.92.