Professional Documents

Culture Documents

Estimating Deadloads On Timber Canopies

Uploaded by

Conrad HarrisonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estimating Deadloads On Timber Canopies

Uploaded by

Conrad HarrisonCopyright:

Available Formats

????

????

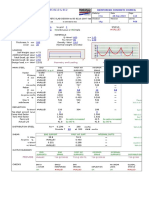

???? ???? Member sizes for Collar-Tied Roof Trusses

1 REF.: Tel : ???? PAGE: Fax :???? DATE: email: ???? DESIGN:

31-Jan-2012

TN/19

SCH

NON-CYCLONIC

Standard Roof Mass suggests to AS1684

Steel sheet roofing 0.5mm thick and battens lower limit upper limit 8 kg/m 12.5 kg/m

10 kg/m suggests to AS1170:2002

LY

lower limit upper limit kPa 0.01 0.01 0.01 0.01 0.01 0.01 ! ! ! ! ! ! ! Only 2.62 kg/m 1.72 2.96 -0.21 5.45 1.684 0.340

Estimate of Deadloads for Standardised Designs DEADLOAD ESTIMATES The Basic foundation of limit state strength design is a 5% probability of failure. With respect to deadload, failure has two modes: 1) Deadload below estimate and resistance required not achieved 2) Deadload in excess of estimate and overload results To account for the variation in dimensions and densities away from the nominal values used in design AS1170:2002 uses partial load factors. 1) 0.9 for reduction of resisting deadload 2) 1.2 for loading or aggrevating dead weight These values have supposedly been determined by statistical analysis of the variations in a variety of construction materials used such that 5% percentile => 5% probability that 0.9G not reached 95% percentile => 5% probability that 1.2G exceeded The timber framing code AS1684:1999 uses standardised roof masses for production of its supplementary framing tables it is using: 1) 0.8 for reduction of resisting deadload 2) 1.25 for loading or aggrevating dead weight from the previous version of AS1170. {The 2006 version of AS1684 may well have adjusted these to the 2002 version of AS1170}

for the current situation roof cladding can change between lightweight polycarbonate sheeting or heavier steel sheeting also batten spacing can change, along with rafter spacing. Also at initial stage of design frame self weight is unknown. Cladding weight Steel Profiles Custom orb Custom Blue Orb Integrity Integrity 890 Klip-Lok 406

kg/m 4.3 4.9 6.1 8 4.7 5.3 4.2 4.8 4.9 5.6 6.9 3 4.7 5.3 4.3 4.9

kPa 0.04 0.05 0.06 0.08 0.05 0.05 0.04 0.05 0.05 0.05 0.07 0.03 0.05 0.05 0.04 0.05 ! !

PL E

mean std. dev variance ! !

Polycarb Profiles Corrugated Greca Half Sheet Greca Wide Cover Wide-Rib Hi-Rib Spantuf

Longline 305 Spandek Hi-Ten Trimdek Hi-ten

SA M

5% percentile 95% percentile

Batten weight density = 45 x 70 Area = 3150 mm spacing = 900 mm Mass = spacing = 1200 mm Mass =

550 kg/m mass = 1.73 kg/m 1.93 kg/m 0.02 mean 1.44 kg/m 0.01 std. dev

O N

kg/m 1.2 1.2 1.2 1.2 1.5 1.5 All 4.077 1.997 3.989 0.79 7.36

9 12

5% percentile 95% percentile

1.12 2.24

spacing of battens varies depending on cladding internal and end spans and the over all span of the canopy Frame weight (Rafters) density = 550 kg/m spacing = 1200 mm Area mass mm kg/m kg/m kPa mean 2.793 kg/m 90 x 35 3150 1.73 1.44 0.01 std. dev 0.925 120x35 4200 2.31 1.93 0.02 5% percentile 1.27 120x45 5400 2.97 2.48 0.02 95% percentile 4.31 140x45 6300 3.47 2.89 0.03 190x35 6650 3.66 3.05 0.03 190x45 8550 4.70 3.92 0.04 240x35 8400 4.62 3.85 0.04 Total Frame Weight Lower Limit 3.19 kg/m Upper Limit 13.92 kg/m adjusted to allow for partial load factors 0.03 kPa 0.11 kPa Therefore standardised roof mass mostly over estimates resistance and slightly under estimates loading. (eg.0.11>0.1kPa) Therefore produce additional design curves for alternative deadloading and assess variation to member sizes. schGableCanopyTimber.xls

0.14

DeadLoading

You might also like

- Project by Location: Girting Design ADocument10 pagesProject by Location: Girting Design AJurie_sk3608No ratings yet

- Wind Load CalculationDocument17 pagesWind Load CalculationNIHARIKA JAINNo ratings yet

- SAFE VerificationDocument7 pagesSAFE VerificationRahul AggarwalNo ratings yet

- Atari Lynx - Jaguar / CD: Jaguar System & Accessories World Wide WebDocument1 pageAtari Lynx - Jaguar / CD: Jaguar System & Accessories World Wide WebGame DudeNo ratings yet

- Spreadsheets To BS 8110Document11 pagesSpreadsheets To BS 8110NitinShepurNo ratings yet

- Structure Column DesignDocument6 pagesStructure Column DesignGeorge GeorgianNo ratings yet

- Kleinlogel Beam FormulasDocument31 pagesKleinlogel Beam FormulasConrad Harrison50% (2)

- Spreadsheets To Ec2Document25 pagesSpreadsheets To Ec2mustafurade1No ratings yet

- Wind Actions On Enclosed Building With Doubly Pitched RoofDocument8 pagesWind Actions On Enclosed Building With Doubly Pitched RoofConrad Harrison100% (2)

- Combined Footing For 2 Columns-1Document32 pagesCombined Footing For 2 Columns-1Wanda BeasleyNo ratings yet

- Sample Calculations To Australian Standard AS1170 For Design Loads For A Post To A BarrierDocument24 pagesSample Calculations To Australian Standard AS1170 For Design Loads For A Post To A BarrierConrad Harrison100% (12)

- Explanatory Examples On Indian Seismic Code IS 1893 (Part I)Document27 pagesExplanatory Examples On Indian Seismic Code IS 1893 (Part I)hitech ConsultancyNo ratings yet

- Wind Assessment To AS1170.2Document1 pageWind Assessment To AS1170.2Conrad Harrison50% (2)

- RC Design I ColumnsDocument32 pagesRC Design I Columnseph100% (1)

- Overhead Cranes-Safety&InspectorDocument214 pagesOverhead Cranes-Safety&InspectorMohamed Adel100% (6)

- Space 2001Document43 pagesSpace 2001Nguyen Duc CuongNo ratings yet

- Ultimate Strength Design USD of BeamDocument15 pagesUltimate Strength Design USD of BeamJohn Carl Salas100% (1)

- Terminology Introduction 1Document18 pagesTerminology Introduction 1Paula ChenaNo ratings yet

- Slab For Lift ProjectDocument2 pagesSlab For Lift ProjectAnonymous ptLRLiNNNo ratings yet

- Effective Length - Calc PDFDocument1 pageEffective Length - Calc PDFsundar_s_2k100% (1)

- Extracts Kleinlogel Rigid Frame FormulasDocument36 pagesExtracts Kleinlogel Rigid Frame FormulasConrad HarrisonNo ratings yet

- Safe Load Carrying Capacity For RCC Columns (Load in KN) FCK 20N/MM2 Fy 415N/MM2 Size of Columns (CM X CM)Document9 pagesSafe Load Carrying Capacity For RCC Columns (Load in KN) FCK 20N/MM2 Fy 415N/MM2 Size of Columns (CM X CM)rajanciviltnebNo ratings yet

- Load Combinations of Concrete DesignDocument7 pagesLoad Combinations of Concrete Designcarlo cuevasNo ratings yet

- BucklingDocument16 pagesBucklingMikeNo ratings yet

- Staad Result Pass or Fail 1Document136 pagesStaad Result Pass or Fail 1Renzo Ray M. OlivarNo ratings yet

- Beginner Calligraphy Guide PDFDocument5 pagesBeginner Calligraphy Guide PDFannavlastNo ratings yet

- Multistoray Building ProjectDocument16 pagesMultistoray Building Projectanu06bbk100% (1)

- Base Shear ComputationDocument5 pagesBase Shear ComputationAmante MorenoNo ratings yet

- Deflection ChecksDocument8 pagesDeflection Checksabhi aroteNo ratings yet

- Gulariya MC L 5m, B 4mDocument9 pagesGulariya MC L 5m, B 4mrashmi bhailaNo ratings yet

- Design of StaircaseDocument4 pagesDesign of StaircaseahmedNo ratings yet

- RCC41 Continuous Beams (A & D)Document17 pagesRCC41 Continuous Beams (A & D)Felicia GhicaNo ratings yet

- Structural Calculations For Timber Canopy With Gable RoofDocument18 pagesStructural Calculations For Timber Canopy With Gable RoofConrad Harrison100% (1)

- Generic Connection Details Cold-Formed Steel StructuresDocument19 pagesGeneric Connection Details Cold-Formed Steel StructuresConrad Harrison100% (1)

- Selender For Regtangular ColDocument3 pagesSelender For Regtangular Colsaddamalsayadi38100% (1)

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionNo ratings yet

- 00 CCSA TestDocument276 pages00 CCSA TestPedro CubillaNo ratings yet

- Cantilever FrameDocument3 pagesCantilever FrameNikki RobertsNo ratings yet

- Splice Connection 200Document19 pagesSplice Connection 200Gheorghe IonicaNo ratings yet

- ( Corbel Thickness) Should Be Less Than 60 D 15 M K (LX + Corbel Depth + Beam Depth) KDocument10 pages( Corbel Thickness) Should Be Less Than 60 D 15 M K (LX + Corbel Depth + Beam Depth) KSambhav PoddarNo ratings yet

- Centre of Stiffness Calculation: Ground FloorDocument91 pagesCentre of Stiffness Calculation: Ground FloorPoshan DhunganaNo ratings yet

- Portal Method: For Transversal/Longitudinal SectionDocument70 pagesPortal Method: For Transversal/Longitudinal SectionJoseph Tan LantoNo ratings yet

- Column-Design by YoyoDocument8 pagesColumn-Design by YoyoyoyoNo ratings yet

- Seismic AnalysisDocument34 pagesSeismic AnalysisCarla OrbetaNo ratings yet

- The Old Axolotl - Hardware Dream - Jacek DukajDocument188 pagesThe Old Axolotl - Hardware Dream - Jacek Dukajferuyo100% (2)

- Tamilnadu Food Ind PDFDocument150 pagesTamilnadu Food Ind PDFdeva nesan100% (4)

- Schools Division of Parañaque City TLE - Electrical Installation & Maintenance 9 Quarter 4 Week 3 & 4 Electrical ToolsDocument4 pagesSchools Division of Parañaque City TLE - Electrical Installation & Maintenance 9 Quarter 4 Week 3 & 4 Electrical ToolsWinsher PitogoNo ratings yet

- Dr. Ali TayehDocument32 pagesDr. Ali TayehvijaykumarzNo ratings yet

- Staad Editor Seismic Analysis of Building As Per Is CodeDocument4 pagesStaad Editor Seismic Analysis of Building As Per Is CodeChetan B ArkasaliNo ratings yet

- Epoxy Connection TimberDocument6 pagesEpoxy Connection TimberJeffery RoweNo ratings yet

- RCC41 Continuous Beams (A & D)Document26 pagesRCC41 Continuous Beams (A & D)Jhondy TibubosNo ratings yet

- Flat Slab Punching Shear Check r1Document5 pagesFlat Slab Punching Shear Check r1Usama ChauguleNo ratings yet

- Load Combination Is 800-2007Document5 pagesLoad Combination Is 800-2007Jitendra PNo ratings yet

- Plane Frame With Steel Design - Staad ProDocument11 pagesPlane Frame With Steel Design - Staad ProScarlet ShweNo ratings yet

- Direct Stiffness MethodDocument14 pagesDirect Stiffness MethodMutiara Puspahati CripstyaniNo ratings yet

- Prob #1: Check For Slenderness of ColumnDocument7 pagesProb #1: Check For Slenderness of ColumnAman Raj VermaNo ratings yet

- CMRL Nehru Park Station column coupler calculationsDocument6 pagesCMRL Nehru Park Station column coupler calculationsvineetukNo ratings yet

- Steel Base Plate DesignDocument5 pagesSteel Base Plate DesignMichael AbandeNo ratings yet

- NODE NO. FOR COMBINED FOOTING CALCULATIONDocument101 pagesNODE NO. FOR COMBINED FOOTING CALCULATIONkumsbamaNo ratings yet

- General Catalogue VOL1Document330 pagesGeneral Catalogue VOL1lifib23970No ratings yet

- Beam to beam design with landingsDocument10 pagesBeam to beam design with landingsUmesh ChamaraNo ratings yet

- Structural Notes PDFDocument40 pagesStructural Notes PDFEnrico luis EscobarNo ratings yet

- Structural Design and Analysis Proposed Three Storey Commercial ResidenceDocument79 pagesStructural Design and Analysis Proposed Three Storey Commercial ResidenceGEREMY SANTIAGONo ratings yet

- RCC32 Ribbed Slabs (A & D)Document23 pagesRCC32 Ribbed Slabs (A & D)jaffnaNo ratings yet

- DBR How To MakeDocument15 pagesDBR How To Maketanmay271100% (1)

- SP 22 Explanatory Handbook On Codes For Earthquake Engineering - Google SearchDocument2 pagesSP 22 Explanatory Handbook On Codes For Earthquake Engineering - Google Searchvasudeo_eeNo ratings yet

- Software Verification: Example 17Document8 pagesSoftware Verification: Example 17sancloudNo ratings yet

- Zee Purlin Design Sheet AnalysisDocument4 pagesZee Purlin Design Sheet AnalysisShawkat Ali KhanNo ratings yet

- KS1000 KingzipDocument7 pagesKS1000 KingzipmrajansubramanianNo ratings yet

- Reference - Comflor 80 Brochure PDFDocument24 pagesReference - Comflor 80 Brochure PDFgks6043No ratings yet

- Topdek 700 Concealed Clip RoofingDocument16 pagesTopdek 700 Concealed Clip RoofingctaciutNo ratings yet

- KLIP-LOK 700 SpecsDocument8 pagesKLIP-LOK 700 Specsmontree SupaphobNo ratings yet

- KS1000 RW Panel UK Roof Poduct Data SheetDocument6 pagesKS1000 RW Panel UK Roof Poduct Data SheetThe Lone GunmanNo ratings yet

- Roof and Wall LeafletDocument6 pagesRoof and Wall LeafletcosineNo ratings yet

- Product Data Sheet: Product: Ks1000 SF EcosafeDocument4 pagesProduct Data Sheet: Product: Ks1000 SF EcosafeSamuel RICEANNo ratings yet

- Microcomputer Applications in Structural EngineeringDocument42 pagesMicrocomputer Applications in Structural EngineeringConrad HarrisonNo ratings yet

- SCH Planner CalendarDocument2 pagesSCH Planner CalendarConrad HarrisonNo ratings yet

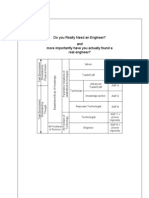

- The Relationship Between Engineering Disciplines, and Related Design and Management Fields.Document1 pageThe Relationship Between Engineering Disciplines, and Related Design and Management Fields.Conrad HarrisonNo ratings yet

- Do You Need An Engineer?Document1 pageDo You Need An Engineer?Conrad HarrisonNo ratings yet

- Qualitative Structural EngineeringDocument165 pagesQualitative Structural EngineeringConrad HarrisonNo ratings yet

- TechNote022pt2 Capacities of Bolts in Cold-Formed Steel ConnectionsDocument1 pageTechNote022pt2 Capacities of Bolts in Cold-Formed Steel ConnectionsConrad HarrisonNo ratings yet

- Wind Loading Compared To Beaufort Wind ChartDocument1 pageWind Loading Compared To Beaufort Wind ChartConrad HarrisonNo ratings yet

- WorkStudy ChartDocument1 pageWorkStudy ChartConrad HarrisonNo ratings yet

- Metamorphs Journal: Patience Deteriorating!Document4 pagesMetamorphs Journal: Patience Deteriorating!Conrad HarrisonNo ratings yet

- Metamorphs Journal: Design: Timing, Costing and Other ResourcesDocument5 pagesMetamorphs Journal: Design: Timing, Costing and Other ResourcesConrad HarrisonNo ratings yet

- Metamorphs Journal: Introduction To Qualitative DesignDocument6 pagesMetamorphs Journal: Introduction To Qualitative DesignConrad HarrisonNo ratings yet

- Metamorphs Journal: Introduction To Engineering DesignDocument10 pagesMetamorphs Journal: Introduction To Engineering DesignConrad HarrisonNo ratings yet

- Metamorphs Journal: Introduction To Qualitative DesignDocument12 pagesMetamorphs Journal: Introduction To Qualitative DesignConrad HarrisonNo ratings yet

- Morf JV01003 OriginDocument4 pagesMorf JV01003 OriginConrad HarrisonNo ratings yet

- Metamorphs Journal: Introduction To Engineering DesignDocument10 pagesMetamorphs Journal: Introduction To Engineering DesignConrad HarrisonNo ratings yet

- Morf JV01001Document58 pagesMorf JV01001Conrad Harrison100% (1)

- Metamorphs Journal: Thoughts On EverythingDocument3 pagesMetamorphs Journal: Thoughts On EverythingConrad HarrisonNo ratings yet

- Metamorphs Journal: Factory Built BuildingsDocument4 pagesMetamorphs Journal: Factory Built BuildingsConrad HarrisonNo ratings yet

- Chart 9 BTC3 y 04 M 06 D 14 R2Document1 pageChart 9 BTC3 y 04 M 06 D 14 R2Conrad HarrisonNo ratings yet

- POLYCAB - MV Power Cable IEC 60502 2Document32 pagesPOLYCAB - MV Power Cable IEC 60502 2AmitabhaNo ratings yet

- R202308263 InvoiceDocument2 pagesR202308263 InvoiceRaghu VeerNo ratings yet

- Reasonable Expectation of PrivacyDocument2 pagesReasonable Expectation of PrivacyAshish UpadhyayaNo ratings yet

- 1SLC009000D0201 CT Combiner LRDocument52 pages1SLC009000D0201 CT Combiner LRJimmy F HernandezNo ratings yet

- Holiday Homework for Class 10 Cbse 2015Document7 pagesHoliday Homework for Class 10 Cbse 2015afmtcbjca100% (1)

- Samsung M31Document1 pageSamsung M31mahmudhassanNo ratings yet

- P+B Hy Wet SDocument34 pagesP+B Hy Wet SatakanNo ratings yet

- Atex Reference Guide PDFDocument2 pagesAtex Reference Guide PDFSrinivas KosuruNo ratings yet

- Xtreme Pivot Table Course SyllabusDocument14 pagesXtreme Pivot Table Course Syllabusgkarunbabu2020No ratings yet

- Law Vidhi MahotsavDocument28 pagesLaw Vidhi Mahotsavsandeepramadugu1No ratings yet

- Mark Java ResumeDocument4 pagesMark Java ResumesravanpaulNo ratings yet

- Digital Communication - Analog To DigitalDocument4 pagesDigital Communication - Analog To DigitalAbbas ismailNo ratings yet

- Deanonymisation of Clients in Bitcoin P2P NetworkDocument15 pagesDeanonymisation of Clients in Bitcoin P2P NetworkGary ShenNo ratings yet

- Basics of Java Programming LanguageDocument5 pagesBasics of Java Programming LanguageNATALIA ALEJANDRA ORTIZ JACOMENo ratings yet

- Talos: Technical SpecificationsDocument2 pagesTalos: Technical SpecificationsAkinbuja 'SolaNo ratings yet

- Fatigue Test of Alsi10mgDocument26 pagesFatigue Test of Alsi10mg180320119134.me.rayush.hariNo ratings yet

- Expert Veri Ed, Online, Free.: Topic 1 - Single TopicDocument507 pagesExpert Veri Ed, Online, Free.: Topic 1 - Single TopicMurat CalhounNo ratings yet

- ANTEZA Accomplishment-Report March 2021Document5 pagesANTEZA Accomplishment-Report March 2021Toni Karla AntezaNo ratings yet

- Rapid Urban Growth TriadDocument18 pagesRapid Urban Growth TriadDiana Sophia KanNo ratings yet

- Section Ii.9 Identifying Training Needs and Planning TrainingDocument9 pagesSection Ii.9 Identifying Training Needs and Planning TrainingRICH FXNo ratings yet

- TAO (Trace Architecture Office) Projects in Beijing, ChinaDocument11 pagesTAO (Trace Architecture Office) Projects in Beijing, ChinaAlina VoNo ratings yet

- 2 Drillstring DesignDocument34 pages2 Drillstring DesignAdel Ahmed AlkhaligyNo ratings yet