Professional Documents

Culture Documents

Diffusio 1

Uploaded by

Arnab DebOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diffusio 1

Uploaded by

Arnab DebCopyright:

Available Formats

Diffusion in Solids p. 8.

1

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

Diffusion is

The transport of atoms through matter

The mechanism by which many important

processes occur in materials:

Case hardening of steel

Doping of semiconductors

Oxidation of metals

Solid-state formation of compounds from

individual components

Sintering the process by which an object

made from powders becomes dense and

strong

Types of diffusion in solids

Self-diffusion movement of atoms through their

own lattice

Interdiffusion (a.k.a. impurity diffusion) e.g.,

movement of Ni through the lattice of Cu

Mechanisms

Vacancy diffusion

Interstitial diffusion

Typically, interstitial diffusion is much faster than vacancy

diffusion

Diffusion in Solids p. 8.2

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

VACANCY DIFFUSION vs. INTERSTITIAL DIFFUSION

Vacancy diffusion: a host or substitutional

atom exchanges places with a vacancy

Vacancy

Before jump After jump

Callister, Fig. 5.3 schematic illustration of diffusion

Interstitial diffusion: an interstitial atom jumps

into an adjacent unoccupied interstice

After jump Before jump

Diffusion in Solids p. 8.3

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

MACROSCOPIC DESCRIPTION OF DIFFUSION

Ficks first law (in one dimension)

J = D

dC

dx

J: flux,

_ number

area time

or

_ mass

area time

J =

1

A

dM

dt

dC

dx

: concentration gradient,

_ number/volume

distance

or

_ mass/volume

distance

driving force for diffusion

D: diffusion coefficient for diffusing species in

solid,

_ distance

2

time

Minus sign denotes flux is toward lower

concentrations, i.e. down the concentration

gradient

Diffusion in Solids p. 8.4

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

MACROSCOPIC DESCRIPTION OF DIFFUSION (cont.)

Ficks second law (in one dimension)

[rate of accumulation] = [flux gradient]

C

t

=

J

x

J = D

dC

dx

C

t

=

_

D

C

x

C

t

: rate of accumulation,

_ number/volume

time

or

_ mass/volume

time

J

x

: flux gradient;

flux in - flux out

distance

Cases

Steady state

Flux out = flux in

_

J

x

= 0

Zero accumulation

_

C

t

= 0

Unsteady state

Flux in flux out

Accumulation or depletion

D D(x)

C

t

= D

2

C

x

2

Diffusion in Solids p. 8.5

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

STEADY STATE DIFFUSION

Starting from

Fick's 2nd law in 1-D

with D D(x),

and assuming steady state,

D

2

C

x

2

=

C

t

= 0

we find:

2

C

x

2

= 0

i.e., the concentration profile is linear

( only a line has a second derivative equal to zero)

steady state:

C(x)

x

conc'n gradient

= slope

J

in

J

out

=

= C/ x

J

out

J

in

and the flux J can be calculated from Fick's 1st law simply as

J

in

= J

out

= D

C

x

Diffusion in Solids p. 8.6

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

SOLUTIONS TO FICKS SECOND LAW (start)

C

t

= D

2

C

x

2

[for D D(x); 1-D]

General comment:

Many functions

C(x,t)

will satisfy this differential equation.

To correctly describe the concentration profile C(x,t)

that occurs in a particular physical situation,

a function must also satisfy the pertinent

initial condition what prevails at t=0

and boundary conditions that hold at some interface or

boundary in our system.

Diffusion in Solids p. 8.7

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

SOLUTIONS TO FICKS SECOND LAW (cont.)

Example thin film solution (start)

S g/cm

2

of solute between two semi-infinite bars

solute layer, S g/cm

2

two semi-infinite bars

x

0

i.c.: C(x,0) = 0

b.c. #1: C(,t) = C(,t) = 0

(composition at ends of bars x > 10

Dt will

not change)

b.c. #2:

C dx = S holds for all t

(constant total amount of solute)

Solution:

C(x,t) =

S

4Dt

exp

_

x

2

4Dt

Diffusion in Solids p. 8.8

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

SOLUTIONS TO FICKS SECOND LAW (cont.)

Example thin film solution (end)

C(x,t) =

S

4Dt

exp

_

x

2

4Dt

C

x

t

1

t

1

t

2

= 2

t

1

t

3

= 4

Gaussian distribution (bell-shaped curve)

Finite supply of diffusing species

area under curves remains constant for all t

Useful exercise:

Where does

2

C/x

2

= 0? Why is that significant?

Diffusion in Solids p. 8.9

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

SOLUTIONS TO FICKS SECOND LAW (cont.)

Example semi-infinite solid; constant surface

composition C

S

i.c.: C(x,0) = C

O

b.c. #1: C(,t) = C

O

(composition at endof bars x > 10

Dt will not

change)

b.c. #2: C(0,t) = C

S

'

surroundings maintain

constant surface concn

Solution: (see Callister, Eq. 5.5 and Figs. 5.5-5.6)

C(x,t) C

O

C

S

C

O

= 1 erf

_

x

2

Dt

erf(z)

1.0

0.5

0.5

1.0

1 2 3 1 2 3

z

Diffusion in Solids p. 8.10

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

SOLUTIONS TO FICKS SECOND LAW (end)

erf solution also gives C(x,t) for two joined semi-infinite

solids:

Callister Figs. 5.1, 5.2

Diffusion in Solids p. 8.11

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

FACTORS INFLUENCING D

A diffusing atom needs

1) a new site to occupy

Vacancy concentrations and hence

substitutional and self-diffusion depend

strongly on temperature: N

V

= Nexp(G

V

/RT)

In contrast, interstitial sites are ~always

available (but only for dilute solutes) number

of available interstitial sites is ~T-independent

2) energy to leave its current location

a. b. c.

a. b. c.

F

r

e

e

e

n

e

r

g

y

G

Distance, x

high solute concn

higher energy

low solute concn

lower energy

Diffusion requires an activation energy

probability of a successful jump exp(G

/RT)

Diffusion in Solids p. 8.12

EMSE 201 Introduction to Materials Science & Engineering 2003 Mark R. De Guirerev. 2/10/03

FACTORS INFLUENCING D (cont.)

D = D

O

exp

Q

d

RT

Plot of lnD vs.

1

T

will be linear, with slope

Q

d

R

Q

d

, apparent activation energy for diffusion

Increases with size of diffusing atom

Is typically larger (G

V

+ G

terms) for vacancy

diffusion than for interstitial diffusion (G

term only)

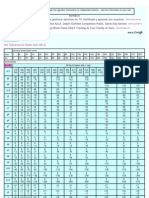

Callister, Figure 5.7 log D vs. 1/T for several metals

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- Aluminum Design Manual-24Document1 pageAluminum Design Manual-24Mohammed AyeshNo ratings yet

- SOURSERVICE Brochure PDFDocument8 pagesSOURSERVICE Brochure PDFshank100No ratings yet

- Beam Design by SP 16Document1 pageBeam Design by SP 16Arnab Deb67% (3)

- MMC All Aluminum Cylinder Block (2ZZ-GE)Document13 pagesMMC All Aluminum Cylinder Block (2ZZ-GE)Jordan DerrickNo ratings yet

- ISO - 286-2 Shaft Limits TolerancesDocument2 pagesISO - 286-2 Shaft Limits TolerancesMixtli Garcia100% (1)

- SC2032 PDFDocument4 pagesSC2032 PDFA MahmoodNo ratings yet

- Grain Dryer DesignDocument41 pagesGrain Dryer DesignAshish Sharma70% (10)

- Crown Cork & SealDocument8 pagesCrown Cork & Sealtconn8276100% (1)

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- Nwankwo Obi ReportDocument23 pagesNwankwo Obi ReportWisdom Alaribe50% (4)

- Pipe Roofing SolutionsDocument12 pagesPipe Roofing SolutionsSubhash KediaNo ratings yet

- Tdg50 Portable Line Boring Machine-DthmachinesDocument16 pagesTdg50 Portable Line Boring Machine-DthmachinesAvaa AmgaaNo ratings yet

- 13 SVC Systems Power Quality D 2008-03-12Document10 pages13 SVC Systems Power Quality D 2008-03-12satelite54100% (1)

- DSFGSDFGDocument1 pageDSFGSDFGArnab DebNo ratings yet

- ScribfsdfdfgfdsgdsfDocument3 pagesScribfsdfdfgfdsgdsfArnab DebNo ratings yet

- UyjghDocument7 pagesUyjghArnab DebNo ratings yet

- MSC Application Form Asstt AnalystDocument4 pagesMSC Application Form Asstt AnalystArnab DebNo ratings yet

- Query PrintDFSFSDocument1 pageQuery PrintDFSFSArnab DebNo ratings yet

- Wind ExampleDocument8 pagesWind ExampleKyle ForemanNo ratings yet

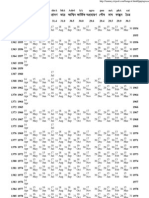

- Roll No. Name Sgpa1 Sgpa2 Ygpa1 Sgpa3 Sgpa4 Ygpa2 Sgpa5 Sgpa6 Ygpa3Document1 pageRoll No. Name Sgpa1 Sgpa2 Ygpa1 Sgpa3 Sgpa4 Ygpa2 Sgpa5 Sgpa6 Ygpa3Arnab DebNo ratings yet

- RISAFloor Demonstration Graphic2Document1 pageRISAFloor Demonstration Graphic2Arnab DebNo ratings yet

- Room No. 215: 4 Year Odd Semester (7 Sem) Class RoutineDocument1 pageRoom No. 215: 4 Year Odd Semester (7 Sem) Class RoutineArnab DebNo ratings yet

- Construction of P-M Interaction DiagramDocument1 pageConstruction of P-M Interaction DiagramArnab DebNo ratings yet

- Coloumn 2Document1 pageColoumn 2Arnab DebNo ratings yet

- RISAFloor Demonstration Graphic2Document1 pageRISAFloor Demonstration Graphic2Arnab DebNo ratings yet

- RC DesigningDocument1 pageRC DesigningArnab DebNo ratings yet

- RISAFloor Demonstration Graphic 2Document1 pageRISAFloor Demonstration Graphic 2Arnab DebNo ratings yet

- Beam 2Document1 pageBeam 2Arnab DebNo ratings yet

- Steel Section Analysis / Design: Coloumn Design As Per IS - 800:2007 & SP-6 (1) CodeDocument1 pageSteel Section Analysis / Design: Coloumn Design As Per IS - 800:2007 & SP-6 (1) CodeArnab DebNo ratings yet

- Query PrintDocument1 pageQuery PrintArnab DebNo ratings yet

- E-Receipt Government of WESTBENGAL Finance DepartmentDocument1 pageE-Receipt Government of WESTBENGAL Finance DepartmentArnab DebNo ratings yet

- 3757ammnd 2Document1 page3757ammnd 2Arnab DebNo ratings yet

- KBF Map - 2013Document1 pageKBF Map - 2013Arnab DebNo ratings yet

- 1Document3 pages1Arnab DebNo ratings yet

- Bengalee CalendarDocument3 pagesBengalee CalendarArnab Deb100% (4)

- Palash EpaperDocument1 pagePalash EpaperArnab DebNo ratings yet

- RR 411Document6 pagesRR 411Arnab DebNo ratings yet

- IIM Calcutta Final Placements 2010Document5 pagesIIM Calcutta Final Placements 2010rohitshrisNo ratings yet

- Flexible Cables BrochureDocument16 pagesFlexible Cables Brochuresunil_v50% (1)

- Arnco FTTX Fiber SolutionsDocument3 pagesArnco FTTX Fiber SolutionsPeterLOW0218No ratings yet

- Strainoptic Stress ManualDocument9 pagesStrainoptic Stress Manualjsrplc7952No ratings yet

- ADIDASSDocument3 pagesADIDASSkessa thea salvatoreNo ratings yet

- Hix HTM (Heat Transfer Machine) BookletDocument8 pagesHix HTM (Heat Transfer Machine) BookletHIX CorporationNo ratings yet

- NUST Journal of Engineering Science (NJES) PDFDocument97 pagesNUST Journal of Engineering Science (NJES) PDFjasim aliNo ratings yet

- Design of RCC Structural Elements July 2016 (2010 Scheme)Document2 pagesDesign of RCC Structural Elements July 2016 (2010 Scheme)Sandeep DevikereMathNo ratings yet

- Environmental Laws and RegulationsDocument50 pagesEnvironmental Laws and RegulationsPaul Santos NonatNo ratings yet

- Synthesis and Characterization of Erbium Doped Nickel Zinc Ferrites NanoparticlesDocument30 pagesSynthesis and Characterization of Erbium Doped Nickel Zinc Ferrites Nanoparticlessaleem saleemNo ratings yet

- Sika PDS E Plastomix TPIDocument2 pagesSika PDS E Plastomix TPIlwin_oo2435100% (1)

- Dimension of IncubatorsDocument3 pagesDimension of IncubatorsSwarali KamathNo ratings yet

- Pages From ASME B31.3 - 2016Document5 pagesPages From ASME B31.3 - 2016Gulzar AliNo ratings yet

- General Notes and Specifications: Roof Line Roof LineDocument1 pageGeneral Notes and Specifications: Roof Line Roof LineCyril AleaNo ratings yet

- Metals: 3D Printed Acetabular Cups For Total Hip Arthroplasty: A Review ArticleDocument18 pagesMetals: 3D Printed Acetabular Cups For Total Hip Arthroplasty: A Review ArticleUtkarsh AnandNo ratings yet

- SDMyers Test Packages BrochureDocument4 pagesSDMyers Test Packages BrochureYesid FigueroaNo ratings yet

- Reinforcing Steel Bars and TendonsDocument31 pagesReinforcing Steel Bars and TendonsJebone Stein Web JuarbalNo ratings yet

- Steels For Construction Special Steels Structural Steel Construction Steel dd11 PickledDocument2 pagesSteels For Construction Special Steels Structural Steel Construction Steel dd11 PickledhelderfsnNo ratings yet

- Miramer M262 TDSDocument1 pageMiramer M262 TDSAdesh GurjarNo ratings yet

- CAD CAM TemporaryDocument9 pagesCAD CAM TemporarySaleh AlmohammadNo ratings yet