Professional Documents

Culture Documents

Caracterização Tecnologica Laboratorio MET-SOLVE

Uploaded by

Bruno GoesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caracterização Tecnologica Laboratorio MET-SOLVE

Uploaded by

Bruno GoesCopyright:

Available Formats

July 22, 2009

Edson

sancourier comercial exportadora ltda

cnpj 67.138.388/0001-62

av.ribeiro preto 460

mairipor-sp-brasil

cep 07600-000

011 44851875

011 96249697

tucasansone@gmail.com

Dear Edson,

Please find attached the results of the gravity concentration test for gold recovery on the Serra

Pelada sample.

Please feel free to contact us if you have any questions.

Sincerely,

Alex Lum, P.Eng.

Metallurgical Engineer

8515 Eastlake Drive Burnaby, BC CANADA V5A 4T7

Tel: 604-421-7622 Fax: 604-421-7603 www.met-solvelabs.com

GRAVITY GOLD RECOVERY ON

SERRA PELADA SAMPLE

Prepared for:

Edson

sancourier comercial exportadora ltda

cnpj 67.138.388/0001-62

av.ribeiro preto 460

mairipor-sp-brasil

cep 07600-000

011 44851875

011 96249697

tucasansone@gmail.com

Prepared by:

Met-Solve Laboratories Inc.

8515 Eastlake Drive

Burnaby, BC

V5A 6R9

Canada

Project Number:

MS1184

Alex Lum, P.Eng

Metallurgical Engineer

Ish Grewal, M.A.Sc. P.Eng

President

July 22, 2009

Note: This report refers to the samples as received. The information contained in this report is provided

'as is' without warranty of any kind with respect to the interpretation and use of the data by the client.

8515 Eastlake Drive Burnaby, BC CANADA V5A 4T7

Tel: 604-421-7622 Fax: 604-421-7603 www.met-solvelabs.com

Project MS1184 Serra Pelada

1.0 BACKGROUND

Met-Solve received a bag of mineral sample, weighing approximately 11.9 kg, on June 29, 2009.

The samples were sent by:

Edson Sansone

AV Ribeirao Preto 450

Mairipora, Sao Paulo

Brazil

Ph: 55-11-44851875

Earlier, a 1 kg sample of this material was received by Met-Solve on June 24, 2009. The two

samples were combined to produce a composite material for testing.

Met-Solve was informed via e-mail that these samples are from Serra Pelada. The objective of the

test program was to determine if the material was amenable to gravity concentration of gold.

2.0 METHODOLOGY

The sample was screened at 850 m to remove oversize material, which could interfere with

efficient gravity operation of the lab test unit. A multistage low mass yield test was done on the

undersize material (-850 m) using the Falcon L40 to recover gold. The test procedure used the

following flowsheet.

Pan Tail 1

L40 Tails

Pan Tail 2

Pan Con 1

Pan Tail 3

Pan Con 2

Pan Con 3

Three sequential stages were done and each concentrate was panned to get an idea of achievable

grades. A gold recovery curve, as a function of mass yield, was generated from the results.

Project MS1184 Serra Pelada

In addition, the head (feed material) and the L40 tailings were assayed for gold by fractions to get

an idea of the gold distribution and recovery by particle size.

3. 0 RESULTS

The detailed mass balance and size-by-size assay is shown in the appendix. Also included are the

ICP values for the head (feed), the gravity tails, and the oversize material (+850 m). The particle

size analysis, including head and screened head, are also attached.

The gravity concentration report shows that the material responds well to gravity with 70% of the

gold recovered in just under 6% mass yield.

The good agreement between the calculated head, 0.88 grams/tonne, (calculated by mathematically

combining the gold grade of all the test products) and screen-calculated head, 0.78 grams/tonne,

(from screen analysis IA101 with the +850 m fractions omitted) increases confidence in the results.

The size-by-size analysis and the ICP summary show that the oversized material (+850 m) has

higher gold grade, 1.65 grams/tonne.

Comparing the size-by-size assay of the feed and head material, show that the bulk of the recovered

gold came from the sub 212 m (70 mesh) fractions.

The ICP show that the material has a significant copper content, 1.5%. The copper content of the

+850 m, at 3.1%, is particularly rich.

Project MS1184 Serra Pelada

3. 0 RECOMMENDATION

Since the gold grade is higher in the coarse fractions, particularly in the +1,700 m, the oversize

material should be ground and processed with the remaining material. Additional gravity tests

should be done to investigate gold recovery with grinding. Removing the oversize material, with a

gold grade of 1.65 grams/tonne, reduces the overall gold grade from 0.93 grams/tonne to 0.78

grams/tonne.

Due to the significant content of copper in the material, copper extraction, such as by sulfuric acid

leach, should be investigated.

Project MS1184 Serra Pelada

APPENDICES

GRAVITY CONCENTRATION TEST REPORT

Client: Serra Pelada - Edson

Test: IA102

Sample: Samples received June 29/09 & June 24/09

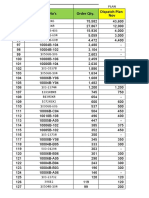

Products

Date: 06-Jul-09

Project: MS1184

Weight

(g)

(%)

9.21

0.12

148.19

1.86

157.40

1.98

7.96

0.10

147.60

1.85

155.56

1.95

12.38

0.16

150.33

1.89

162.71

2.04

475.67

5.97

7,485.47

94.03

7,961.14

100.00

8,001.00

Pan Concentrate 1

Pan Tail 1

L40 Concentrate 1

Pan Concentrate 2

Pan Tail 2

L40 Concentrate 2

Pan Concentrate 3

Pan Tail 3

L40 Concentrate 3

Total L40 Concentrate

L40 Tails

Calculated Head

Screen Calculate Head

Assay (g/t)

Au

198.6

11.5

22.5

23.6

3.0

4.0

37.7

1.8

4.5

10.3

0.3

0.9

0.8

Distribution (%)

Au

26.1

24.4

50.6

2.7

6.3

9.0

6.7

3.8

10.5

70.0

30.0

100.0

Feed

Pan Tail 1

L40 Tails

Pan Tail 2

Pan Con 1

Pan Tail 3

Pan Con 2

Pan Con 3

Precious Metal Recovery (%)

80

70

Test Conditions

Pulp Density: 25%

Bowl: 1/32 holes

Fluid'n Pressure: 3 psi

G-Force: 150 g

Speed: 55.3 Hz

60

50

40

30

20

10

0

0

Mass to Concentrate (%)

SIZE BY SIZE ASSAY

Client: Serra Pelada - Edson

Test: IA101 - Screen Head Material

Sample: Received June 29/09 & June 24/09

Precious Metals

Tyler Mesh Microns

Weight

(g)

2,360

250.0

1,700

60.7

1,180

65.7

850

61.3

600

83.5

425

105.0

300

118.5

212

80.5

150

75.5

106

78.3

75

67.2

53

76.3

37

41.7

-37

502.5

NET: 1,666.7

Assayed Head:

8

12

16

20

30

40

50

70

100

140

200

270

400

-400

Date: 6-Jul-09

Project: MS1184

(%)

15.0

3.6

3.9

3.7

5.0

6.3

7.1

4.8

4.5

4.7

4.0

4.6

2.5

30.1

100.0

(g/t)

1.42

2.19

0.89

0.70

0.49

0.36

0.49

1.12

0.21

1.02

1.40

0.94

0.94

0.85

0.93

0.72

Au

Dist'n (%)

22.9

8.6

3.8

2.8

2.7

2.5

3.8

5.8

1.0

5.2

6.1

4.6

2.5

27.7

100.0

SIZE BY SIZE ASSAY

Client: Serra Pelada - Edson

Test: IA103 - Screen Tails

Sample: Gravity Tails from IA102

Precious Metals

Tyler Mesh Microns

2360

1,700

1,180

850

600

425

300

212

150

106

75

53

37

-37

NET:

Assayed Head:

8

12

16

20

30

40

50

70

100

140

200

270

400

-400

Date: 9-Jul-09

Project: MS1184

Weight

(g)

(%)

0.0

0.0

0.0

0.0

0.0

110.5

52.5

42.4

37.5

45.4

37.1

39.4

29.5

270.3

664.5

0.0

0.0

0.0

0.0

0.0

16.6

7.9

6.4

5.6

6.8

5.6

5.9

4.4

40.7

100.0

(g/t)

0

0

0

0

0.51

0.48

1.31

0.18

0.28

0.17

0.19

0.28

0.25

0.37

0.28

Au

Dist'n (%)

0.0

0.0

0.0

0.0

0.0

22.9

10.2

22.6

2.7

5.2

2.6

3.0

3.4

27.4

100.0

SIZE BY SIZE ASSAY

Client: Serra Pelada - Edson

Date: 6-Jul-09

Test: IA101 - Screen Head Material

Project: MS1184

Sample: Received June 29/09 oversized screened out to get Gravity Feed grade

Precious Metals

Tyler Mesh Microns

8

12

16

20

30

40

50

70

100

140

200

270

400

-400

Weight

(g)

2,360

1,700

1,180

850

600

83.5

425

105.0

300

118.5

212

80.5

150

75.5

106

78.3

75

67.2

53

76.3

37

41.7

-37

502.5

NET: 1,229.0

(%)

0.0

0.0

0.0

0.0

6.8

8.5

9.6

6.6

6.1

6.4

5.5

6.2

3.4

40.9

100.0

(g/t)

1.42

2.19

0.89

0.70

0.49

0.36

0.49

1.12

0.21

1.02

1.40

0.94

0.94

0.85

0.78

Au

Dist'n (%)

0.0

0.0

0.0

0.0

4.3

4.0

6.1

9.4

1.7

8.3

9.9

7.5

4.1

44.8

100.0

MS1184: Serra Pelada ICP Summary

Sample

Sample

Number

Name

78134 Head Material

78135 Gravity Tails

78136 Oversized, +850 m

ICP

Ag

ppm

2.7

2.9

16.5

ICP ICP

Al As

% ppm

0.34 10

0.36 10

0.13 14

Sample

Sample

Name

Description

78134 Head Material

78135 Gravity Tails

78136 Oversized, +850 m

ICP ICP

Mo

Na

ppm

%

3 0.01

4 0.01

13 <0.01

Sample

Sample

Name

Description

78134 Head Material

78135 Gravity Tails

78136 Oversized, +850 m

FA

Au

g/t

0.72

0.28

1.65

ICP

Ni

ppm

191

226

151

ICP

Ba

ppm

739

864

369

ICP

Be

ppm

1.3

1.3

0.5

ICP

Bi

ppm

94

85

157

ICP

Ca

%

0.03

0.03

0.02

ICP

Cd

ppm

2

2

1

ICP

Co

ppm

233

261

209

ICP

ICP

Cr

Cu

ppm

ppm

59 15,000

73 12,800

55 30,700

ICP

P

ppm

297

425

<10

ICP

Pb

ppm

78

69

139

ICP

S

%

0.01

0.01

0.03

ICP

Sb

ppm

9

10

6

ICP

Sc

ppm

6

6

1

ICP

Sr

ppm

16

17

9

ICP

Th

ppm

6

6

<5

ICP

Ti

%

0.03

0.03

0.01

ICP

Fe

%

14

14

8

ICP

Hg

ppm

4

4

2

ICP

K

%

0.01

0.01

0.01

ICP

La

ppm

10

<10

<10

ICP

Mg

%

0

0

0

ICP

Mn

ppm

8,560

9,549

4,601

ICP

Tl

ppm

<10

<10

<10

ICP

U

ppm

34

36

18

ICP

V

ppm

96

100

49

ICP

W

ppm

29

26

146

ICP

Zn

ppm

128

130

124

ICP

Zr

ppm

9

9

4

PARTICLE SIZE ANALYSIS

Client: Serra Pelada - Edson

Test: IA101 - Screen Head Material

Sample: Received June 29/09 & June 24/09

Sieve Size

Tyler Mesh

Microns

2,360

2,000

1,180

850

600

425

300

212

150

106

75

53

37

-53

TOTAL:

250.0

60.7

65.7

61.3

83.5

105.0

118.5

80.5

75.5

78.3

67.2

76.3

41.7

502.5

1666.7

Rosin-Rammler Model

Size

Passing

(um)

P (%)

1491

80

195

50

Cummulative (%)

Retained

Passing

(%)

15.00

3.64

3.94

3.68

5.01

6.30

7.11

4.83

4.53

4.70

4.03

4.58

2.50

30.15

100.0

100

90

80

70

60

50

40

30

20

10

0

15.00

18.64

22.58

26.26

31.27

37.57

44.68

49.51

54.04

58.74

62.77

67.35

69.85

100.00

85.00

81.36

77.42

73.74

68.73

62.43

55.32

50.49

45.96

41.26

37.23

32.65

30.15

Linear Interpolation

Size

Passing

(um)

P (%)

1717

80

205

50

100

Cum. Pass. (%)

Cum. Passing (%)

8

10

16

20

30

40

50

70

100

140

200

270

400

Undersize

Weight

(g)

Date: 6-Jul-09

Project: MS1184

200

400

600

800

Particle Size (um)

1,000

1,200

10

1

1

10

100

0

Particle Size (

m)

1,000

10,000

PARTICLE SIZE ANALYSIS

Client: Serra Pelada - Edson

Test: IA103 - Screen Tails

Sample: Gravity Tails from IA102

Sieve Size

Tyler Mesh

Microns

2360

2000

1180

850

600

425

300

212

150

106

75

53

37

-53

TOTAL:

Weight

(g)

Cummulative (%)

Retained

Passing

(%)

0.0

0.0

0.0

0.0

0.0

110.5

52.5

42.4

37.5

45.4

37.1

39.4

29.5

270.3

664.5

0.00

0.00

0.00

0.00

0.00

16.63

7.90

6.38

5.64

6.83

5.58

5.92

4.43

40.68

100.0

100

90

80

70

60

50

40

30

20

10

0

0.00

0.00

0.00

0.00

0.00

16.63

24.53

30.92

36.55

43.39

48.97

54.89

59.32

100.00

100.00

100.00

100.00

100.00

100.00

83.37

75.47

69.08

63.45

56.61

51.03

45.11

40.68

Rosin-Rammler Model

Size

Passing

(um)

P (%)

300

80

74

50

Linear Interpolation

Size

Passing

(um)

P (%)

372

80

71

50

100

Cum. Pass. (%)

Cum. Passing (%)

8

10

16

20

30

40

50

70

100

140

200

270

400

Undersize

Date: 9-Jul-09

Project: MS1184

200

400

600

800

Particle Size (um)

1000

1200

10

1

1

10

100

0

Particle Size (

m)

1000

10000

PARTICLE SIZE ANALYSIS

Client: Serra Pelada - Edson

Test: IA101 - Screen Head Material

Sample: Received June 29/09; +850 m removed to get P80 for Gravity Feed

Sieve Size

Tyler Mesh

Microns

2,360

2,000

1,180

850

600

425

300

212

150

106

75

53

37

-53

TOTAL:

83.5

105.0

118.5

80.5

75.5

78.3

67.2

76.3

41.7

502.5

1229.0

Rosin-Rammler Model

Size

Passing

(um)

P (%)

319

80

75

50

Cummulative (%)

Retained

Passing

(%)

0.00

0.00

0.00

0.00

6.79

8.54

9.64

6.55

6.14

6.37

5.47

6.21

3.39

40.89

100.0

100

90

80

70

60

50

40

30

20

10

0

0.00

0.00

0.00

0.00

6.79

15.34

24.98

31.53

37.67

44.04

49.51

55.72

59.11

100.00

100.00

100.00

100.00

100.00

93.21

84.66

75.02

68.47

62.33

55.96

50.49

44.28

40.89

Linear Interpolation

Size

Passing

(um)

P (%)

365

80

73

50

100

Cum. Pass. (%)

Cum. Passing (%)

8

10

16

20

30

40

50

70

100

140

200

270

400

Undersize

Weight

(g)

Date: 6-Jul-09

Project: MS1184

200

400

600

800

Particle Size (um)

1,000

1,200

10

1

1

10

100

0

Particle Size (

m)

1,000

10,000

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Softening N Penetration Test BitumenDocument11 pagesSoftening N Penetration Test BitumenEdwin LeonNo ratings yet

- Optimizing Technique-Grenade Explosion MethodDocument18 pagesOptimizing Technique-Grenade Explosion MethodUday Wankar100% (1)

- Le22a1321 AocDocument130 pagesLe22a1321 AocEchefisEchefisNo ratings yet

- Order Qty Vs Dispatch Plan - 04 11 20Document13 pagesOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNo ratings yet

- Comparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelDocument12 pagesComparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelWaqqas ChaudhryNo ratings yet

- EN 1991-1-4 NA enDocument4 pagesEN 1991-1-4 NA enanuj3936100% (1)

- 8th ICCIT - 2005 - 564Document5 pages8th ICCIT - 2005 - 564Amit BiswasNo ratings yet

- SQ Presentation 2021-r2Document43 pagesSQ Presentation 2021-r2nadeem4ahmed-805026No ratings yet

- Web 2.0: Dynamic Web PagesDocument12 pagesWeb 2.0: Dynamic Web PagesAra PantaleonNo ratings yet

- Cbse PMT 2012Document33 pagesCbse PMT 2012Vishal RamakrishnanNo ratings yet

- Whirlpool Duet HTDocument96 pagesWhirlpool Duet HTdanny85901100% (2)

- BPSK SimulinkDocument13 pagesBPSK SimulinkpootommyNo ratings yet

- Eramus Bridge PDFDocument10 pagesEramus Bridge PDFBabaO.Riley100% (1)

- Alloys DensityDocument4 pagesAlloys DensityArnold Melissa CollettNo ratings yet

- FR-8x Editor Eng01 WDocument8 pagesFR-8x Editor Eng01 WRadulian Daniel100% (1)

- Jerry Hill's Letter To Bijan Sartipi, Director, District 4 CaltransDocument1 pageJerry Hill's Letter To Bijan Sartipi, Director, District 4 CaltransSabrina BrennanNo ratings yet

- Mimaki Install Guide (En)Document16 pagesMimaki Install Guide (En)หน่อง นพดลNo ratings yet

- Makita 2708Document29 pagesMakita 2708Reuel JacintoNo ratings yet

- Topic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1Document49 pagesTopic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1BeaglelalahahaNo ratings yet

- RT L2 General Examination PaperDocument4 pagesRT L2 General Examination PaperdaddadNo ratings yet

- Iec60092-350 (Ed2 0) enDocument7 pagesIec60092-350 (Ed2 0) enAzad RahmanNo ratings yet

- Programming Bayes Rule OptionalDocument17 pagesProgramming Bayes Rule OptionalajuhaseenNo ratings yet

- Astm D3359Document9 pagesAstm D3359Angel GuachaminNo ratings yet

- Biomasse-HKW Sandreuth E NQDocument8 pagesBiomasse-HKW Sandreuth E NQValeriu StanNo ratings yet

- Standardization of Naoh 1Document3 pagesStandardization of Naoh 1api-309208977No ratings yet

- The Reef Wayfinding Plan and Signage Design Concept 28 August 2019Document51 pagesThe Reef Wayfinding Plan and Signage Design Concept 28 August 2019Michele MontoloNo ratings yet

- Vibration - Electrical or Mechanical - EASADocument3 pagesVibration - Electrical or Mechanical - EASAGilbNo ratings yet

- S09 Power TrainDocument90 pagesS09 Power TrainPLANEAMIENTO MDRILLNo ratings yet

- CoreJava Ratan CompleteMarerial PDFDocument398 pagesCoreJava Ratan CompleteMarerial PDFSivaShankar100% (7)