Professional Documents

Culture Documents

The Mechanical Properties of Asbestos: Nationa/ Physical Laboratory, Teddington, UK Received 4 January 1969

Uploaded by

Jacob 'Jeremy' FarrimondOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Mechanical Properties of Asbestos: Nationa/ Physical Laboratory, Teddington, UK Received 4 January 1969

Uploaded by

Jacob 'Jeremy' FarrimondCopyright:

Available Formats

JOURNAL

OF MATERIALS

S C I E N C E 4 (1969) 6 2 5 - 6 3 3

The Mechanical Properties of Asbestos

d. A V E S T O N

Nationa/ Physical Laboratory, Teddington, UK Received 4 January 1969

Stereoscan electron microscope studies and measurements of tensile strength and Young's modulus have been made on chrysotile and five naturally-occurring fibrous amphiboles. The effect of heat on the modulus and fracture mechanism has also been examined. With the exception of tremolite which has a different microstructure from the remaining amphiboles, the moduli and strengths were similar. The loss of strength which occurs when the fibrous amphiboles, and to a lesser extent, chrysotile are heated below their decomposition temperature is shown to be due to an increase in interfibrillar bonding causing the material to become notch-sensitive

1. I n t r o d u c t i o n The commercially important fibrous silicates are chrysotile which accounts for 9 0 ~ of total asbestos production and the amphiboles crocidolite and amosite which make up most of the remainder. Chrysotile, Mg3(Si~O~) (OH)4 has a complex tubular structure which has not been fully resolved whereas the amphiboles, although susceptible to extensive cation substitution, also occur in a non-fibrous form which enabled Warren to determine the structure of tremolite as early as 1930 [1]. It is based on infinite double chains of silicon oxygen tetrahedra, held together by five 6-co-ordinated and two 8-co-ordinated cations per unit cell. Two hydroxyl groups are attached to the central cation of each unit cell and there is a small amount of additional hydrogen, probably as SiOH groups on the peripheral silicate chains. The asbestiform varieties approximate to the following idealised formulae but with extensive interchange of Fe" and Mg":

Crocidolite Amosite Actinolite Tremolite Anthophyllite

Na2Fea" F%'" SisO2z(OH)2 Mg2Fes" SisO22(OH)z Ca2F%" SisO2~(OH)~ Ca2Mg5 SisO~,2(OH)2 Mg7 SisO~2(OH)2

They occur as extremely close packed lath-like crystals, which we shall call fibrils, aligned with

their c-axes parallel. A bundle containing several hundred such fibrils will be called a fibre. The finest fibre which can be used for X-ray diffraction (about 10 Fm thick) gives a photograph with full rotational symmetry so that the fibrils cannot be much more than 0.1 Fm thick, nor can they be much less than this as quite sharp spots are obtained [2]. Electron micrographs of chrysotile fibres show them to average about 0.03 Fm diameter [2] and to be filled and surrounded by amorphous material of the same composition. The common structure and closely similar cell parameters of the amphiboles should give rise to fairly similar mechanical properties, but the published data, although conflicting, suggests otherwise. Thus Hodgson [3] reports tensile strengths of 35000 and 25000 kg/cm 2 for crocidolite and amosite but less than 5000 kg/cm 2 for the remaining amphiboles. Nadgornyi et al [4] however found that the strengths of crocidolite and anthophyllite (and chrysotile) were similar but decreased inversely with fibre diameter, in a hyperbolic manner characteristic of whiskers, from 25 000 kg/cm 2 at a diameter d = 2/xm to 5000 kg/cm 2 at d = 25/zm. On the other hand Zukowski and Gaze [5] found a length/strength relationship but no diameter/ strength effect so that strengths up to 60 000 kg/cm ~ (depending on length) were maintained at least up to d = 30 Fm. Another puzzling feature is the drastic loss of strength which has been found [3] when the amphiboles are heated 625

J. A V E S T O N

to a moderate temperature which is insufficient to cause any change in crystal structure. The object of the present work was to measure the strength and modulus of chrysotile, the naturally occurring amphiboles and synthetic amphiboles of controlled cation substitution, to determine whether there is any correlation between strength and composition, and also to compare the fracture mechanisms of the natural and heat-treated fibres. There is also need for work on modes of failure of bundles of interacting fibrils.

2. Experimental

The asbestos fibres, supplied by Cape Asbestos Fibres Ltd, were as follows: chrysotile, Thetford, Canada; crocidolite, Koegas, Cape Province; amosite, Penge, Transvaal; anthophyllite, Finland; tremolite, Pakistan and actinolite, Koegas. They were as mined, and consisted of blocks of adherent, closely packed fibrils varying in length from 0.6 cm (actinolite) to 12 cm (amosite) Standard Tem-Pres hydrothermal equipment was used to synthesise the sodium magnesium amphibole according to the method of Gier et al [6]. Tensile strengths and Young's moduli were measured with an "Instron" testing machine. The strain rate was kept roughly constant by varying the cross head speed between 0.01 and 0.1cm/ min according to the length of fibre, although preliminary tests with 3 cm long crocidolite at these two speeds showed that the strength was independent of strain rate within this range. Each fibre was first weighed on a "Cahn" electrobalance [7] and its cross-section obtained from the measured density of the material in the case of the Amphiboles, and the literature value of 2.55 [3] for chrysotile. The fibres were then glued with Araldite to the centres of flats cut in the ends of a pair of 3/16 in. diameter brass rods which were aligned in a jig at the required gauge length. When the glue had set, the rods were inserted into special mountings on the "Instron", fixed in place with set screws and the jig finally removed. Specimens for short term shear tests were set in casting Araldite to prevent splitting, cut to length with a diamond saw and then cleaved to remove the Araldite. The heattreated crocidolite did not cleave easily, so further machining with a diamond surface grinder was necessary. Stereoscan samples were coated with 500 A of gold-palladium alloy. 626

3. Results 3.1. Tensile Strength and Modulus The mean tensile strengths (maximum load divided by the original cross-section) and moduli are given in the third and sixth columns of table I. Apart from tremolite the strengths are of the same order, and the moduli the same within the scatter of the results, again with the exception of tremolite. The moduli of actinolite and anthophyllite also appear somewhat lower, although these are less reliable due to the short specimen length and small number (about ten compared with sixty to seventy for the others) of samples tested. Chrysotile loses about one-third of its strength when heated at 500 ~ C (1 h, N~ atmosphere) whereas crocidolite under the same conditions becomes so brittle that samples invariably break at the glue. Even at 380 ~ C they retain only about one-third of their former strength although the modulus is unaffected. Fibre cross-sectional areas were in general varied from 5 to 100 10-6 cm 2 ( d = 25 to 114 /xm), but were extended down to 5 10 .7 cm z (d ~ 7 /zm) for chrysotile and crocidolite, and up to 5 10-~ cmz ( d N 2 5 0 Fm) for chrysotile and tremolite. To test for any dependence of strength or modulus on cross-section the slope of the line which gave the least squares fit to the data, and its standard deviation were computed. Broadly speaking if the results for all lengths of a given fibre are taken together the only cases where there is a significant (by the criterion that the slope should be at least twice its standard deviation) size dependence are the strength of heated crocidolite and the modulus of natural chrysotile. For all fibres the small size dependence coupled with the scatter of the results preclude anything other than a linear fit to the data down to 7/zm. The stress/strain curves for the amphiboles were essentially linear up to fracture, which on some occasions occurred suddenly and on others as a series of steps as in fig. 1. As the reduced slope BC corresponds to the reduced crosssection of the fibre remaining unbroken, the final breaking stress can be obtained from the product of the strain and modulus. Comparison with the strengths as originally defined showed that the scatter was reduced and of course the mean strength increased. The stress/strain curve for chrysotile (fig. 2) is more complex: after an initial linear region (which depends on the ratio of fibre length to diameter) the curve becomes convex, although

MECHANICAL PROPERTIES OF ASBESTOS

TABLE

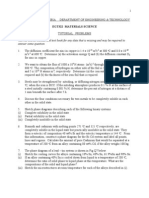

Material

I

Length cm Strength Young's modulus

Mean :t: one Extrapolated Slope of strength standard to zero cross- versus crossdeviation of sectional sectional area points from area ~ e* 4- ~* mean kg/cm~ 10-4kg/cm~ 10-7 kg/cm 2 10-4

Crocidolite 0.3 3.0 5.0 1.0 3.0 5.0 0.3 3.0 5.0 9.0 3.0 0.6 0.6 0.3 3.0 3.0 2.79 4- 0.66 2.04 4- 0.46 1.68 4- 0.37 1.104-0.25 0.83 4- 0.21 0.65 4- 0.28 1.55 4- 0,50 1.63 4- 0.40 1.714-0.42 1.16 4- 0.41 0.31 4- 0.13 1.89 4- 0.47 1.35 ~ 0.50 4.48 :k 1.02 3.06 ~ 0 . 8 3 2.31 :k 0.45 3.03 t 0.14 6.02 4- 3.0 2.10 0.08 - 2.04 2.0 1.67 4- 0.07 0.49 4- 2.1 1.294-0.07 -5.1 1.9 0.94 4- 0.05 - 3.1 i 1.1 0.76 ~ 0.06 - 4.1 4- 1.9 1.59 0.18 - 0.55 4- 3.2 1.74 4- 0.13 , - 2.2 ~ 2.4 1.804-0.11 -2.2 4- 2.3 1.08 4- 0.10 1.9 4- 2.2 0.42 4- 0.04 - 0.36 4- 0.11 1.94 4- 0.31 - 1.58 4- 9.03 1.22 4- 0.46 3.15 ~: 4.55 4.59 4- 0.20 - 31.1 4- 24.7 3.13 4- 0.18 2.86 4- 5.7 2.40 0.09 0.87 5.8

Mean 4- one Extrapolated Slope of standard to zero cross- modulus deviation of sectional area versus crosspoints from s ~* sectional area mean kg/cm 2x 10-~ 4- ~* kg/cm~ 10 6 kg/cm ~ 10-8

-1.69 4- 0.19 1.78 4- 0.09 1.65 1.77 1.76 0.13 1.71 4- 0.14 1.72=k0.08 1.72 0.07 1.52 4- 0.15 1.46 4- 0.20 1.54 :k 0.09 1.60 =k 0.13 1.65 4- 0.06 -1.70 :k 0.03 1.81 0.02 1.69:t:0.03 1.77 :k 0.02 1.77 :k 0.03 1.77 ~ 0.04 1.76=k0.02 1.72 :k0.02 1.49 :k 0.10 1.59 :k 0.15 1.53 0.09 1,69 :k 0.04 1.64 4- 0.03 -- 1.0 i - 7 3 ~_ -11.54- 2.3 i - 4.1 - 12.2 -10.1 1.2 1.03 - 36.8 - 0.31 - 20.5 3.1 4444~: 41.5 53 9.7 5.9 9.4 7.8 4.1 4.1 3.8 40.2 10.8

Crocidoliteafter 3 h a t 380 ~ C Amosite

Tremolite Actinolite Anthophyllite Chrysotile Chrysotile after 1 h at 500 ~ C

~: 8.1 7.3

e ' i s the standard deviation of the line or of its intercept o n the strength or modulus axis.

there is no apparent breakage of the fibrils, and on removing the stress it is f o u n d that a permanent strain has developed. On further stressing over the range AB, the outer fibrils were seen to be breaking, and at B the fibre either broke completely or as in the case illustrated in fig. 2, the bulk of the fibre pulled out f r o m a sheath o f b r o k e n fibrils which remained in the glue. As the static friction exceeds the sliding friction a point C (which is at stress zero for some specimens) is reached, where the interfibrillar adhesion is recovered and the curve resumes its original slope f r o m C to D. A t D pull-out occurs and the stress falls to zero as this is completed. Specimens which failed in this way were not included in the data on which table I and fig. l 3 are based but are plotted in fig. 3 as a versus 1/r. With the assumption that the remaining fibre cross-section is circular, that its cross-sectional area is n o t significantly less than the original fibre, and that the length b o n d e d to the outside fibrils at pull-out is equal to the length limmersed in the glue; then a r o u g h estimate o f the interfibrillar shear strength r can be made f r o m the pull-out condition:

or

o- ~

2rl

--

"

The pull-out failures should lie on a line of slope 2It, and the tensile failures in a region b o u n d e d by this line and the m a x i m u m tensile strength. Pull-out failures to the right o f the line will occur when there is a significant reduction in crosssectional area on pull-out. The points in the regions o f interest are rather sparse but it does appear that two lines t h r o u g h the origin with significantly different slopes can be drawn for the heated and unheated fibres. The length of fibre embedded in the glue l, was 0.8 cm in each case. The corresponding values o f r are ca 170 and 100 kg/cm u respectively.

3.2. Short Beam Shear Tests

W h e n an isotropic brittle material in the f o r m o f a beam o f span l, breadth b and depth d is subjected to a centrally applied load F, it will fail when the tensile stress at the lower surface (r, given approximately by

3Fl

627

2~rrlr ~ 7rr2~

J. AVESTON

D A C

8"0

A A

2.0

4"0

/ l ooixo

o~

lx

7o

Ix

Ix o

4 E

o b 1.0

3.0

1 s

x

'E

o "a b 2.0

/.~,~,

9

A

&

1.0

0101

0[03 ~'r,u

0[05

0"07

1.0

2.0

~ strain

Figure 7 Stress/strain curve for crocidolite fibre with

3.0 cm, d = 38 #m. I =

Figure 3 Strength of chrysotile as a function of 1/r. Open

symbols represent unheated and solid points heated fibres. Circles correspond to pull-out and triangles to tensile failure.

B

3-0Re

2.0IE o

1"0

E I

1"O

~ strain

2"0

8.0

Figure 2 Stress/strain curve for chrysotilefibre with

I = 3.0

cm, d = 4 1 Fm.

equals the strength of the material. At that point the shear stress r is approximately 3F de

before e = eF and the material will then fail repeatedly in shear at constant F to give two beams of depth d/2, and so on. In order to establish the effect of heat on the shear strength of crocidolite, a series of short beam shear tests on the heated and natural material was made. The Instron load traces for typical unheated and heated specimens are illustrated in figs. 4 and 5. The unheated material, invariably failed by shear whereas the specimens heat-treated at 380 and 500 ~ C all failed in tension, usually after the shear stress had exceeded that at which the unheated specimens failed. Although in principle each peak in fig. 4 yields a separate value of r F, in practice the computed stress and geometry of the specimens become less well-defined as the deflection and number of cracks increase. A single value of r F was therefore computed from each specimen using the first maximum in F and the original specimen dimension. The results are summarised in table II where the figures in parentheses are the computed stresses for the mode other than that in which the specimen failed. 3.3. Stereoscan Micrographs The Stereoscan electron micrograph of crocidolite (fig. 6) is typical of all the strong amphiboles

r=~-d=~l"

However, if the material is highly anisotropic with r ~ e, r may exceed the shear strength r F 628

MECHANICAL

PROPERTIES

OF ASBESTOS

SO-

2C

o,

10

/

0 I 0"01 I 0"02 ~ 0"03 I 0"04 rnm I 0"015 Flexure

Figure 4 Three point loading test for natural crocidolite

specimen 0.30 cm wide X 0.265 cm deep x 2.25 cm span. Sample failed in shear at T = t55 kg/cm 2.

40

Figure 6 Stereoscan micrograph of natural crocidolite.

30

:~ 20

o

1C

0"01

0"02 Flexure

I 0"03 mr&

I 0-04

Figure 5 Three point loading test for crocidolite after

heating for 4.8 h at 500 ~ cm in a N 2 atmosphere. Specimen 0.40 cm wide = 0.35 cm deep X 2.0 cm span failed in tension at cr = 2230 kg/em 2 at which point the shear stress was 195 kg/cm ~. TABLE II

Figure 7 Stereoscan micrograph of tremolite.

Material Natural crocidolite

Mode of failure shear shear shear shear shear tensile tensile tensile tensile tensile

Tensile stress at failure kg/cm 2 (2600) (2860) (2200) (1850) (1280) 2870 2230 1840 1330 1360

Shear stress at failure kg/cm ~ 155 153 176 168 168 (193) (195) (175) (106) (221)

629

Crocidolite after 4 h at 280 ~ C Crocidolite after 2 h at 380 ~ C Crocidolite after 5 h at 500 ~ C

J. A V E S T O N

to the principal tensile stress over large areas of the fracture surface. The surface of chrysotile which had been carefully freed from fine material appeared similar to crocidolite, except that the fibrils were finer. However, some of the fine tangled material which had been peeled from the main block and bent through an acute angle in the process, or any fibre which had been drawn over a sharp edge such as a razor blade, assumed the curious kinked or spiral configuration shown in fig. 10.

Figure 8 Stereoscan micrograph of fractured natural

crocidolite fibre.

Figure 10 Stereoscan micrograph of "kinked" chrysotile

fibre.

Figure 9 Stereoscan micrograph of fractured surface of

crocidolite fibre which had been heated for 1.5 h at 500 ~ in a N 2 atmosphere.

in revealing a close-packed bundle of wellaligned fibrils 0.1 to 0.2 Fm across which appeared to be continuous along the whole length of the specimen. The corresponding micrographs of the heated fibres are identical. In contrast, tremolite (fig. 7) contains short, less well-aligned fibrils. Although the micrographs of the sides of the natural and heat-treated crocidolites are indistinguishable from each other, the fracture surfaces are strikingly different. The natural fibre (fig. 8) is almost completely divided at the extreme ends into the component fibrils, whereas in the heat-treated material (fig. 9) the crack has travelled normal 630

3.4. Synthetic Amphiboles Gier et al [6] have shown that under extreme hydrothermal conditions (3000 arm, 700 ~ C) it is possible to synthesise fibrous amphiboles of controlled cation content. We have been unable to do more than confirm their results: the product always consisted of a wadding-like mass of densely intertangled fibres (fig. 11) which was quite unsuitable for tensile measurements. However, it was clear from the tests on the natural fibres reported above that there was unlikely to be any direct correlation between mechanical properties and chemical composition. 4. Discussions According to Hodgson [3] asbestos fibres are built up from a series of overlapping fibrils of various lengths which are held together in the crystal by hydrogen bonding. He showed that over the temperature range (200 to 500 ~ C) in

MECHANICAL

PROPERTIES

OF ASBESTOS

strength of chrysotile on the other hand was so low that it was not possible to prepare threepoint loading specimens of adequate dimensions and with the ends free from splits. We therefore propose a structure for asbestos which is based on bundles of continuous fibrils in which the interfibrillar adhesion is low for chrysotile, somewhat higher for the amphiboles, and much higher for the heat-treated amphiboles. As the strongest fibres break at a stress of ca E/30 compared to the theoretical value for a perfect brittle material of ca E/10 the component fibrils are assumed to contain stress-concentrating flaws, such as growth steps, distributed randomly throughout the fibrils. It then follows that the strength of the bundle or fibre will be the average of a large number of units arranged in parallel and thus independent of fibre diameter. HowFigure 11 Stereoscan micrograph of sodium magnesium ever, unless the fibre has completely uniform amphibole synthesised at 700 ~ C/3000 atm. properties a length-dependent strength must arise. In practice, fibres of length l/n with strength distribution f(x) were cut from fibres of which virtually all the strength is lost, the length I. The combined probability that any amphibole fibres lose only a small amount of one of the n fibres will have a strength between so-called physically combined water, which is not x and (x ~- dx) and that the remaining (n -- 1) associated with any crystallographic change in the will have a strength greater than x (i.e. that the fibrils, and suggested that the corresponding fibre of length l will fail between x and (x + dx) decrease in hydrogen bonding so weakens the is given by adhesion between the fibrils that they are pulled oo apart on fracture. nf(x)[If(x)dxl(~-l)dx The Stereoscan micrograph of tremolite (fig. 7) is consistent with this model and the low strength x of trernolite could well be due to some of the and hence the strength distribution for fibres of fibrils pulling out on fracture. However, the length I i f they break at the weakest point is micrographs of all the strong amphiboles, of given by which crocidolite (fig. 6) is typical, show that the oo fibrils are essentially continuous. If this were not s o - for example if some fibrils were less than 1 mm - then the chance of seeing the end of a x fibril in fig. 6 would be about 1/20, whereas This function, computed by assuming that the apart from some surface debris all the 200 or so underlying strength distribution of the shortest fibrils appear continuous. Moreover, the shear strengths reported in (0.3 cm) fibres is normal, is drawn on the strength section 3.2 show that far from there being a histograms of crocidolite and chrysotile in figs. decrease in interfibrillar adhesion on heating 12 and 13. If the component fibrils were comthere is actually an increase. Admittedly if the pletely independent over their entire length, then heat-treated (380 and 500 ~ C) specimens had each would break at its weakest point and the failed in shear at the stresses given in parentheses strength of the fibres would be less than that in table II then the increase in shear strength computed on the weakest link basis. Therefore would be insignificant, but it must be emphasised as the strengths of the chrysotile and crocidolite that all of them failed in tension and that fibres fit the computed curves reasonably well it judging from the difficulty experienced in cleav- appears that the fibrils are coupled to the extent ing these specimens the actual shear strengths that the fracture region is restricted to less than were greatly in excess of these values. The shear 0.3 cm, although over shorter distances the fibre 6al

J. AVESTON

must eventually behave more as a parallel bundle in order to account for the appearance of the fracture surface in fig. 8 and the absence of a strength diameter effect.

2C 16 12

I= 5.0 cm

4I

oi

1 ~ 3 ' 0 cm

il

1=0.3 cm

4;0

(7 kgf cm-2x 10-4

2.0

3"0

Figure 12 Histogram of crocidolite strength. Curve for 3 mm

fibre is normal with the values of the mean and standard deviation given in table I. Other curves are computed from this on a " w e a k e s t link" hypothesis.

16 14 12 10 8 1=3.0cm

4 2 k~ ~6 0

l

i

3 4 "5 46 o'kgf cm-2 x l 0 -

Figure 13 A s

fig. 12 but for ehrysotile.

On heating crocidolite fibres it is suggested that the adhesion between the fibrils reaches the point where the stress concentration at the tip 632

of a surface crack can no longer be relieved by a secondary crack propagating perpendicularly in a plane of weakness according to the mechanism suggested by Cook and Gordon [8]. The onset of a strength/diameter relationship for crocidolite which had been heated at 380 ~ C and the fracture surface of the heat-treated (500 ~ C) crocidolite (fig. 9) are consistent with this increase in notch sensitivity as the interfibrillar adhesion increases. Many of the properties of chrysotile may be similarly interpretedinterms of adhesion between the fibrils. The pull-out data in fig. 3 suggest a moderate increase in interfibrillar adhesion on heating which is consistent with the low (relative to crocidolite) loss of strength and also with the decreased curvature of the stress/strain curves for the heated fibres. The permanent strain developed in the thicker chrysotile fibres (fig. 2) results from the more highly stressed outer fibrils undergoing a permanent displacement relative to those at the centre, so that they remain in tension when the strain is removed. Similarly, when a fibre is bent through an acute angle the outer fibrils are displaced, and if the adhesion can be recovered - and the stress/strain curve (fig. 2) provides some evidence for t h i s then the fibre will assume the spiral configuration shown in fig. 10. The strength of asbestos, which is inferior only to pristine glass fibres and whiskers is not exploited commercially in unreinforced products such as cloth and paper, which fail by the short fibres pulling apart, or in reinforced plastics where the problem is one of alignment and where the above results could be significant. Current alignment methods involve the extrusion of a suspension of the dispersed fibre through a hole or slot. With the amphiboles the process is straightforward, but they have other disadvantages as a reinforcing material. Chrysotile, on the other hand, disperses to a tangled mass of fine fibres and it is necessary to pre-treat the material with hot phosphoric acid [9]. It was found in the present work that the increase in interfibrillar adhesions in the heat-treated material was sufficient to prevent complete dispersion and that a product of fine whiskerlike fibres resulted. In conclusion it must be admitted that no single piece of evidence for the hypothesis that the strength of asbestos is determined largely by the interfibrillar adhesion is sufficient in itself. To prove a direct correlation it would be

MECHANICAL

P R O P E R T I E S OF A S B E S T O S

necessary to m a k e m o r e accurate m e a s u r e m e n t s o f shear strength e n c o m p a s s i n g several varieties o f asbestos b o t h before a n d after heating, b u t the m a t e r i a l is such t h a t it is difficult to devise such experiments to give a n u n a m b i g u o u s answer. The discrepancies b e t w e e n the strengths o f the less c o m m o n a m p h i b o l e s r e p o r t e d here a n d those in the literature, further emphasise the p r o b l e m s a s s o c i a t e d with o b t a i n i n g a representative sample o f a n a t u r a l p r o d u c t . However, when t a k e n together, the evidence f r o m the stereoscan m i c r o graphs the shear tests, the shape o f the stress/ strain curves, the s t r e n g t h / d i a m e t e r relationship for the h e a t e d (but n o t the u n h e a t e d ) crocidolite fibres a n d the p u l l - o u t d a t a for chrysotile, are c o n s i d e r e d r e a s o n a b l y convincing.

References

I. B. E. WARREN, Z. Krist. 72 (1930) 42. 2. E. S. W. WHITTAKER "Fibre Structure", edited by J. W. S. Hearle and R. H. Poten (Butterworths, London, 1963) p. 594. 3. a. A. HODGSON, Royal Institute of Chemistry Lecture Series (1965) No. 4. 4. E. M. N A D G O R N Y I ~ L. F. G R I G O R E V A ~ and A. P. IVANOR, Izvest Akad. Nauk S S S R Neory. Maths. 1 (1965) 1117. 5. R. ZUKOWSKI and R. GAZE, Nature 183 (1959) 35. 6. T. E. G I E R , N. L. COX, and H. S. YOUNG~ Inorg. Chem. 3 (1964) 100. 7. L. CAHN and H. R. SCHULTZ, Vacuum Microbalance Techniques 3 (1963) 29. 8. J. COOK and s. E. GORDON, Proc. Roy. Soc. A282 (1964) 508. 9. J. GOLDEN, Nature 220 (1968) 64.

633

You might also like

- 100Cr6 Porosity PDFDocument9 pages100Cr6 Porosity PDFMadhusudhan ModemNo ratings yet

- Assignment-3 - CML-231 - Materials Science and EnggDocument1 pageAssignment-3 - CML-231 - Materials Science and EnggGajanan SawantNo ratings yet

- Endurance of Compacted Steel Wire Ropes: ObjectivesDocument7 pagesEndurance of Compacted Steel Wire Ropes: ObjectivesYadi KusmayadiNo ratings yet

- Segregation Stabilizes Nanocrystalline BDocument5 pagesSegregation Stabilizes Nanocrystalline BmehecoNo ratings yet

- Effect of Fibre Orientation and Laminate Geometry On The Dynamic PropertiesDocument27 pagesEffect of Fibre Orientation and Laminate Geometry On The Dynamic PropertiesMd Zillur RahmanNo ratings yet

- Stiffness and Failure Behavior of Model Hybrid Composites: D. Hunston and W. McdonoughDocument9 pagesStiffness and Failure Behavior of Model Hybrid Composites: D. Hunston and W. Mcdonoughrajaraji33No ratings yet

- (2005) Zhou, Allameh, Soboyejo - Microscale Testing of The Strut in Open Cell Aluminum FoamsDocument11 pages(2005) Zhou, Allameh, Soboyejo - Microscale Testing of The Strut in Open Cell Aluminum Foamsandrogyny0wed8No ratings yet

- Material Science Term Paper ON: "Importance of Microstructures and Microstructures of Cast Iron"Document15 pagesMaterial Science Term Paper ON: "Importance of Microstructures and Microstructures of Cast Iron"Abhishek AgarwalNo ratings yet

- Materials Science Manual REVIEW QUESTIONSDocument4 pagesMaterials Science Manual REVIEW QUESTIONSaoguNo ratings yet

- Descripcion Proceso CVDDocument26 pagesDescripcion Proceso CVDEduardo VanegasNo ratings yet

- Hie Tension o F Metallic Films Deposited by ElectrolysisDocument4 pagesHie Tension o F Metallic Films Deposited by Electrolysisn4alpacaNo ratings yet

- Copper Wire Report For SubmissionDocument11 pagesCopper Wire Report For SubmissionAdrien MccandlessNo ratings yet

- Nwssu Final Exam 1Document1 pageNwssu Final Exam 1Axiel John Ray EscalaNo ratings yet

- Materials 13 00369Document11 pagesMaterials 13 00369Siddharth MahalaNo ratings yet

- BPUT Question Bank For Material ScienceDocument4 pagesBPUT Question Bank For Material ScienceMr.S UpenderNo ratings yet

- Effect of Copper Content On The Mechanical and Sliding Wear Properties of Monotectoid-Based Zinc-Aluminium-copper AlloysDocument6 pagesEffect of Copper Content On The Mechanical and Sliding Wear Properties of Monotectoid-Based Zinc-Aluminium-copper AlloysuzairmetallurgistNo ratings yet

- Effect of Volume Fraction of Undissolved Cementite On The High Cycle Fatigue Properties of High Carbon SteelsDocument5 pagesEffect of Volume Fraction of Undissolved Cementite On The High Cycle Fatigue Properties of High Carbon SteelsEngels OchoaNo ratings yet

- Time Temperature Property Curves For Quench Sensitivity of 6063 Aluminum AlloyDocument8 pagesTime Temperature Property Curves For Quench Sensitivity of 6063 Aluminum AlloyAntonio Alonso Diaz ArriagaNo ratings yet

- Microstructural Dependence of Constitutive Properties of EutectiDocument10 pagesMicrostructural Dependence of Constitutive Properties of EutectiAminul HoqueNo ratings yet

- Deep Drawing of AZ31 Alloy SheetsDocument37 pagesDeep Drawing of AZ31 Alloy Sheetsa c s reddyNo ratings yet

- Crystallites - Structure and DefectsDocument8 pagesCrystallites - Structure and Defectschiuchan888No ratings yet

- Modeling of The Yield Strength of A Stainless Maraging SteelDocument4 pagesModeling of The Yield Strength of A Stainless Maraging SteelFernando HenriqueNo ratings yet

- Applied Mechanics (ME 14.101) Tutorial Sheet-6: (Tension, Compression & Shear)Document1 pageApplied Mechanics (ME 14.101) Tutorial Sheet-6: (Tension, Compression & Shear)atulkumargaur26No ratings yet

- Excersises For Essentials and Engineering of MaterialsDocument5 pagesExcersises For Essentials and Engineering of MaterialsBraulio BolañosNo ratings yet

- Ultimate Tensile StrengthDocument7 pagesUltimate Tensile StrengthAgung Pratama JuniantoNo ratings yet

- 7 4Document8 pages7 4Izwan HassanNo ratings yet

- High-Cycle Fatigue Behavior of Type 316L Stainless SteelDocument9 pagesHigh-Cycle Fatigue Behavior of Type 316L Stainless SteelDeva RajNo ratings yet

- Processing of PM PartsDocument7 pagesProcessing of PM Partshayder1920No ratings yet

- TMS2003 CompetitionbetweenDocument19 pagesTMS2003 CompetitionbetweenbuseNo ratings yet

- Accepted ManuscriptDocument15 pagesAccepted ManuscriptpeterNo ratings yet

- Effect of Al2O3 NanoparticlesDocument11 pagesEffect of Al2O3 NanoparticlesmirelamanteamirelaNo ratings yet

- QbankDocument8 pagesQbanknkchandruNo ratings yet

- The Effect of Fibre Fractures in The Bridging Zone of Fatigue Cracked Ti-6Al-4V-SiC Fibre Composites-2004, Acta MaterialiaDocument16 pagesThe Effect of Fibre Fractures in The Bridging Zone of Fatigue Cracked Ti-6Al-4V-SiC Fibre Composites-2004, Acta MaterialiaaeromatNo ratings yet

- Cracking Chatterjee MST 2006Document5 pagesCracking Chatterjee MST 2006puri16No ratings yet

- Numericalsmassignments SolvedDocument5 pagesNumericalsmassignments SolvedghasNo ratings yet

- Hutchinson2006 BuenoDocument4 pagesHutchinson2006 BuenoJhonNo ratings yet

- CeramographyDocument6 pagesCeramographyRomer John DetubioNo ratings yet

- Thermo-Electric Design of A 500 Ka CellDocument6 pagesThermo-Electric Design of A 500 Ka CellreaktorenergiNo ratings yet

- Cyclic Response and Fracture Behaviors Under LCFDocument13 pagesCyclic Response and Fracture Behaviors Under LCFLjubica MilovicNo ratings yet

- IEEEXplore 2Document3 pagesIEEEXplore 2momenziNo ratings yet

- The Influence Drawing, Twisting, Heat Setting, and Untwisting On The Structure and Mechanical Properties of Melt-Spun High-Density Polyethylene FiberDocument25 pagesThe Influence Drawing, Twisting, Heat Setting, and Untwisting On The Structure and Mechanical Properties of Melt-Spun High-Density Polyethylene Fiberapi-3733260No ratings yet

- Shear Behaviour of Steel Fibre Reinforced Self-Compacting ConcreteDocument8 pagesShear Behaviour of Steel Fibre Reinforced Self-Compacting Concretejack21abNo ratings yet

- Attenuation of Gamma Radiation From 60co 137Cs 192ir and 226ra in Various Materials Used in RadiotherapyDocument7 pagesAttenuation of Gamma Radiation From 60co 137Cs 192ir and 226ra in Various Materials Used in RadiotherapySHAMSUL HADI JamianNo ratings yet

- Bulk Amorphous Magnetic MaterialsDocument10 pagesBulk Amorphous Magnetic MaterialsZdenko PopNo ratings yet

- MosDocument3 pagesMosrajapratyNo ratings yet

- Texture Development and Dynamic Recrystallization in AA5083 During Superplastic Forming at Various Strain RatesDocument13 pagesTexture Development and Dynamic Recrystallization in AA5083 During Superplastic Forming at Various Strain RatesezekingsNo ratings yet

- Taller 2 - 2019Document2 pagesTaller 2 - 2019DAHANA CAICEDO PAREDESNo ratings yet

- Contribution To The Understanding of The Relationship Between Mechanical and Dielectric Strengths of AluminaDocument7 pagesContribution To The Understanding of The Relationship Between Mechanical and Dielectric Strengths of AluminaFaridah HassanNo ratings yet

- Interconnect AlDocument25 pagesInterconnect AlEfren De Dios IbañezNo ratings yet

- 10.1016@0379 67798090022 3Document8 pages10.1016@0379 67798090022 3Yeison NúñezNo ratings yet

- Chen 2009 Thep Lam KhuonDocument5 pagesChen 2009 Thep Lam KhuonPhung Tuan AnhNo ratings yet

- Texture in Wire DrawingDocument5 pagesTexture in Wire DrawingPedro OliveiraNo ratings yet

- Ballistic Impact of Fibre Composite Armours by Fragment Simulating ProjectilesDocument7 pagesBallistic Impact of Fibre Composite Armours by Fragment Simulating ProjectilesdjNo ratings yet

- Crack Detection Methods For Lead-Free Solder Joints: Milos Dusek & Christopher HuntDocument26 pagesCrack Detection Methods For Lead-Free Solder Joints: Milos Dusek & Christopher HuntpastelquenteNo ratings yet

- The Structure o F An / Brass: Acta CrystDocument5 pagesThe Structure o F An / Brass: Acta CrystFergiawanNo ratings yet

- CablesDocument20 pagesCablesalejotoroNo ratings yet

- 06435039Document4 pages06435039Yesid MorenoNo ratings yet

- 2012 - Tensile Deformation Characteristics of Bulk Ultrafine-Grained Austenitic Stainless Steel Produced by Thermal CyclingDocument4 pages2012 - Tensile Deformation Characteristics of Bulk Ultrafine-Grained Austenitic Stainless Steel Produced by Thermal CyclingOmar S Al-AbriNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 6, Slice 8 "Conduction, Electric"From EverandEncyclopaedia Britannica, 11th Edition, Volume 6, Slice 8 "Conduction, Electric"No ratings yet

- EmployWise JAVA ASSIGNMENTDocument2 pagesEmployWise JAVA ASSIGNMENTPreet PatelNo ratings yet

- RESEARCH 10 Module 1 Lesson 1 (WEEK 1-2)Document5 pagesRESEARCH 10 Module 1 Lesson 1 (WEEK 1-2)DennisNo ratings yet

- Phy Mock SolDocument17 pagesPhy Mock SolA PersonNo ratings yet

- B0187 B0187M-16Document9 pagesB0187 B0187M-16Bryan Mesala Rhodas GarciaNo ratings yet

- FHHR 013 Red Tag Procedure PDFDocument5 pagesFHHR 013 Red Tag Procedure PDFN3N5YNo ratings yet

- Tourbier Renewal NoticeDocument5 pagesTourbier Renewal NoticeCristina Marie DongalloNo ratings yet

- 7 ElevenDocument80 pages7 ElevenakashNo ratings yet

- Reproduction in PlantsDocument12 pagesReproduction in PlantsAnand Philip PrasadNo ratings yet

- CL200 PLCDocument158 pagesCL200 PLCJavierRuizThorrensNo ratings yet

- Parker HPD Product Bulletin (HY28-2673-01)Document162 pagesParker HPD Product Bulletin (HY28-2673-01)helden50229881No ratings yet

- 3g Node B On Ip MediaDocument79 pages3g Node B On Ip MediaBsskkd KkdNo ratings yet

- BSDDocument26 pagesBSDEunnicePanaliganNo ratings yet

- Dept & Sem: Subject Name: Course Code: Unit: Prepared byDocument75 pagesDept & Sem: Subject Name: Course Code: Unit: Prepared by474 likithkumarreddy1No ratings yet

- ATAL Selected FDPs AY 2023 24Document15 pagesATAL Selected FDPs AY 2023 24parthiban palanisamy100% (2)

- Case No. Class Action Complaint Jury Trial DemandedDocument43 pagesCase No. Class Action Complaint Jury Trial DemandedPolygondotcom50% (2)

- Rin Case StudyDocument4 pagesRin Case StudyReha Nayyar100% (1)

- Electromagnetism WorksheetDocument3 pagesElectromagnetism WorksheetGuan Jie KhooNo ratings yet

- Modified Airdrop System Poster - CompressedDocument1 pageModified Airdrop System Poster - CompressedThiam HokNo ratings yet

- Beautiful SpotsDocument2 pagesBeautiful SpotsLouise Yongco100% (1)

- Allegro Delivery Shipping Company Employment Application FormDocument3 pagesAllegro Delivery Shipping Company Employment Application FormshiveshNo ratings yet

- How To Be A Better StudentDocument2 pagesHow To Be A Better Studentct fatima100% (1)

- ISO-3046-4-2009 (Gobernador de Velocidad)Document8 pagesISO-3046-4-2009 (Gobernador de Velocidad)David GastelumNo ratings yet

- Rs2-Seamanship (Inc Anchoring, Mooring, Berthing, Pilot Ladder)Document19 pagesRs2-Seamanship (Inc Anchoring, Mooring, Berthing, Pilot Ladder)Mdpn. Salvador67% (3)

- Ged 102 Mathematics in The Modern WorldDocument84 pagesGed 102 Mathematics in The Modern WorldKier FormelozaNo ratings yet

- Watch One Piece English SubDub Online Free On Zoro - ToDocument1 pageWatch One Piece English SubDub Online Free On Zoro - ToSadeusuNo ratings yet

- LSL Education Center Final Exam 30 Minutes Full Name - Phone NumberDocument2 pagesLSL Education Center Final Exam 30 Minutes Full Name - Phone NumberDilzoda Boytumanova.No ratings yet

- Inspection Report For Apartment Building at 1080 93rd St. in Bay Harbor IslandsDocument13 pagesInspection Report For Apartment Building at 1080 93rd St. in Bay Harbor IslandsAmanda RojasNo ratings yet

- Route Clearence TeamDocument41 pagesRoute Clearence Teamctenar2No ratings yet

- DLI Watchman®: Vibration Screening Tool BenefitsDocument2 pagesDLI Watchman®: Vibration Screening Tool Benefitssinner86No ratings yet

- ATS2017 ProspectusDocument13 pagesATS2017 ProspectusGiri WakshanNo ratings yet