Professional Documents

Culture Documents

) WWW - Easytextileprocess

Uploaded by

ratultex7043Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

) WWW - Easytextileprocess

Uploaded by

ratultex7043Copyright:

Available Formats

ETP-06-Co. Textile Process at 100% Cotton Knitted Fabric ( Dyeing Proc...

http://www.easytextileprocess.com/?p=38

About Writer

Contact Me

Share To The World

Donate

Order Form

Payment Confirmation

Monday, August 15, 2011 Search This Site... GO

www.easytextileprocess.com

About Textile Processing and The Supporting Factors Home Category Process Company Translate

Powered by

Subscribe to RSS

ETP-06-Co. Textile Process at 100% Cotton Knitted Fabric ( Dyeing Process part 2 )

%A %B %e%q, %Y by: admin

Advert

DYEING PROCESS WITH REACTIVE DYES Among some kinds of above dyes , reactive dye is most applied at 100% cotton fabric good in the form of knitted fabric or woven fabric . Reactive dye factors more applied to :

Content

1. Enough simple dyeing proses 2. Choice of more complete available colour 3. Good colour resilience 4. Is available in a few type as according to requirement Some reactive dyes types which many are used by that is: 1. Monoklorotriazin / Diklorotriazin Example : Procion HE type ( ICI ) , Begative HE type ( Colorindo ) 2. Trikloropirimidin Example : Drimarene ( Clariant ) 3. Vinilsulfon Example : Remazol ( Hoechst ) , Begazol ( Colorindo ) 4. Vinilsilfonamida Example : Levafix ( Bayer ) Based on its reactivity , reactive dye divided 2 faction, that is : 1. Hot reactive dyes Reactive dyes which have low reactivity ( monokhlorotriazin faction ) Example of : Procion HE type ( ICI ) , Begative HE type ( Colorindo ) 2. Cool reactive dyes Reactive dyes which have high reactivity ( dikhlorotriazin faction ) Example : Procion MX type ( ICI ) Reactive dye HE type ( Procion HE , Begative HE ) many applied to because of : - Good dye condensation - Good colour resilience - Dyeing at hot temperature so that penetrating of dye into fibre is better Category Auxiliaries Cotton Dyes Nylon General Polyester Fibers Process Common Dyeing Finishing General Process Mercerized-Causticizing Printing Scouring Bleaching Company Mill Management Non Woven Machinery Sewing Threads Suppliers Textile Chemicals alginate for textile general chemicals textile auxiliaries suppliers textile dyes suppliers textile dyes-aux. suppliers Textile Factories Textile Laboratory Textile Machinery Suppliers accessories and spare parts barcode-label-tags complete range machinery data monitoring and processing software dyeing machinery

1 of 5

8/15/2011 10:09 AM

ETP-06-Co. Textile Process at 100% Cotton Knitted Fabric ( Dyeing Proc...

http://www.easytextileprocess.com/?p=38

- Have good levellnes of dyeing result - Have choice of complete colour - Easier process control - Very suited for mercerized cotton cloth - Generally resistant to process post bleach In principle process of dyeing 100% cotton knitted fabric with reactive dye is with circulation material textile with dye solution and some auxiliaries, with certain concentration , certain time and certain temperature applies of dyeing machine. PROCESS OF DYEING WITH HE TYPE REACTIVE DYES WITH EXHAUST DYEING SYSTEM 1. METHOD SALT ADDITION STEP BY STEP

embroidery machinery finishing machinery garment machinery ( zipper-button ) knitting machinery lab equipment looms others ( ac / coolant / chiller / fire / air ) others ( general,sensors,conveyor ) others ( polymerization plant ) printing machinery spinning machinery weaving machinery winding machinery Trade Magazine Yarn Manufacturer/Suppliers

Links

"Become A Knitting Superstar" Ultimate Video Knitting Course Secrets Of Sewing Machine Repair And Service

mtd tambah grm bertahap-e

This method suited for all dyeing colours and for machine which dyeing solution by died it do not having circulation , the example Winch machine ( Haspel ). 2. METHOD ADDITION SALT IN THE BEGINNING OF PROCESS ( SALT-AT-START )

mtd salt at start-e

This method more compatible applied for dyeing colour from medium to depth colour and for machine with dyeing solution circulation and its the textile material , the example jet dyeing machine , jet flow machine. Example of dyeing recipe for red colour : R/ - Reactive Orange HER - Reactive Red HE-7B - Glauber salt - Soda Ash - Anti crease mark agent - Anti foam agent Liquor Ratio / vlot 1 : 10 Temperature 80 0C The time 60 minute Jet dyeing machine Auxilliaries and its function 1. SALT ( GLAUBER SALT / SULPHATE SODIUM / Na2SO4 ) function to increase absorbtion of reactive dye into fibre 2.0 % 1.5 % 70 g/l 20 g/l 1 2 g/l 1 g/l

- Dispersing-sequestering agent 1 2 g/l

2 of 5

8/15/2011 10:09 AM

ETP-06-Co. Textile Process at 100% Cotton Knitted Fabric ( Dyeing Proc...

http://www.easytextileprocess.com/?p=38

2. ASH SODA ( CARBONATE SODIUM / Na2CO3 ) function to react dye with fibre ( fixation ) 3. DISPERSING-SEQUESTERING functions to tie metal ion ( iron, calcium, copper, magnesium and other ) which is in the dyeing solution be so that got by colour better dyeing result. Besides functioning to increase reactive dye solution in high rate electrolyte. 4. ANTI CREASE MARK AGENT functions to prevent incidence of crease-mark / rope mark ( piebald of fold ) during process of dyeing takes running. 5. ANTIFOAM AGENT functions to eliminate spume arising by during dyeing process because can cause piebald dyeing colour and colour scraggly. Spume arises from water circulation and material which quickly by, also from auxilliaries which can generate spume. Spume which too much by can result machine stucks. Reactive dyeing process of HE type ( monoklorotriazin ) done by at temperature 80 0C while for vinilsulfon type is done by at temperature 60 0C. NB : Liquor Ratio ( LR ) or Vlot 1 : 10 the meaning is amount of comparison of textile material which will be died with amount of water required, that is its example cloth counted 1 kg requires 10 water litre to process . For example will dye cotton knitted fabric 200 kg in one jet dyeing machine requires water for dyeing solution 2000 litre. Clauses requirement of salt and alkali with depth of colour Dyes ( % ) up to 0.5 0.51 1.0 1.01 2.0 2.01 4.0 > 4.0 glauber salt ( g/l ) 30 45 60 70 90 soda ash ( g/l ) 10 15 15 20 20

Illustrating reaction which happened by at dyeing process between reactive dye with cellulose fibre

reaksi pd pencelupan-e

Reactive dye which has been dissolved with water is enterred by into machine dyes containing cotton fabric which

3 of 5

8/15/2011 10:09 AM

ETP-06-Co. Textile Process at 100% Cotton Knitted Fabric ( Dyeing Proc...

http://www.easytextileprocess.com/?p=38

have by is under water , so that happened absorbtion of dye into fibre. Absorbtion dye into fibre is an exothermic process and balanced reaction. Some auxiliiaries , like salt , soda ash / alkali, dispersing sequestering agent, anti crease agent mark , antifoam agent is enterred by into dyeing solution and dyeing process is continued with temperature and when certain up to obtained by colour which is desired climbed. ( ETP-06-Co ) Filed under: Cotton, Dyeing Tags: cool reactive dyes, dyeing process, hot reactive dyes, reactive dyes Comments (111)

Comments

111 Responses to ETP-06-Co. Textile Process at 100% Cotton Knitted Fabric ( Dyeing Process part 2 ) Older Comments Seo Pack says: %A %B %e%q, %Y at %I:%M %p http://www.iworld-media.com/seo/Seo-Pack.htm Thanks for that awesome posting. It saved MUCH time

dell streak 7 says: %A %B %e%q, %Y at %I:%M %p Were a group of volunteers and opening a new scheme in our community. Your website offered us with valuable information to work on. You have done an impressive job and our entire community will be thankful to you.

corset and skirt says: %A %B %e%q, %Y at %I:%M %p I wish to show thanks to the writer for rescuing me from this type of circumstance. Just after looking out through the world wide web and finding ideas which are not powerful, I was thinking my life was well over. Existing without the answers to the issues youve fixed as a result of your main blog post is a critical case, as well as ones which might have negatively damaged my career if I hadnt discovered the website. Your own personal training and kindness in dealing with a lot of things was priceless. Im not sure what I wouldve done if I had not come across such a step like this. Im able to at this time relish my future. Thanks a lot very much for your high quality and results-oriented help. I wont think twice to refer the blog to any person who should receive direction on this area.

ksiegowosc szczecin says: %A %B %e%q, %Y at %I:%M %p You got a really useful blog. I have been here reading for about an hour. I am a newbie and your success is very much an inspiration for me.

Connor White says: %A %B %e%q, %Y at %I:%M %p That is good, I never thought about Nostradamus within the OR (Insights from Eugene Litvak at IHI) like that before.

Euro Dolar says: %A %B %e%q, %Y at %I:%M %p Thank you for your site post. Velupe and I are already saving to get a new e book on this topic and your writing has made us to save our money. Your notions really responded to all our questions. In fact, above what we had known just before we discovered your wonderful blog. We no longer nurture doubts as well as a troubled mind because you completely attended to each of our needs in this article. Thanks

Euro Dolar says: %A %B %e%q, %Y at %I:%M %p Thank you so much with regard to giving us an update on this subject matter on your web-site. Please know that if a completely new post becomes available or in the event any alterations occur about the current post, I would be considering reading a lot more and finding out how to make good utilization of those

4 of 5

8/15/2011 10:09 AM

ETP-06-Co. Textile Process at 100% Cotton Knitted Fabric ( Dyeing Proc...

http://www.easytextileprocess.com/?p=38

strategies you share. Thanks for your time and consideration of other folks by making this blog available.

mercado divisas says: %A %B %e%q, %Y at %I:%M %p I like the valuable info you provide in your articles. Ill bookmark your weblog and check again here frequently. Im quite sure I will learn a lot of new stuff right here! Best of luck for the next!

buy atenolol mg says: %A %B %e%q, %Y at %I:%M %p I just added your website on my blogroll. Really enjoyed reading through. Excellent information!

buy keflex online says: %A %B %e%q, %Y at %I:%M %p Great article with very interesting information. You are a very skilled blogger, thats for sure! =)

Makita 9227C says: %A %B %e%q, %Y at %I:%M %p I do not know if its just me or if everybody else experiencing problems with your blog. It seems like some of the written text on your posts are running off the screen. Can somebody else please comment and let me know if this is happening to them too? This could be a issue with my internet browser because Ive had this happen before. Appreciate it

Older CommentsLeave

a Reply

Name (required)

Mail (will not be published) (required)

Website

Submit Comment

Copyright 2011 www.easytextileprocess.com - About Textile Processing and The Supporting Factors Powered by WordPress and DNA Subscribe to our RSS

5 of 5

8/15/2011 10:09 AM

You might also like

- Cotton Fabric Dyeing with Reactive DyesDocument6 pagesCotton Fabric Dyeing with Reactive DyesShaheen Monir HossainNo ratings yet

- Different Dyieng MethodsDocument46 pagesDifferent Dyieng MethodsDeepali Choudhary100% (1)

- Application Methods of Reactive Dyeing - Textile LearnerDocument12 pagesApplication Methods of Reactive Dyeing - Textile LearnerAnas ZidaneNo ratings yet

- Study On Different Types of Dyeing Faults PDFDocument10 pagesStudy On Different Types of Dyeing Faults PDF呂仲書No ratings yet

- Dyeing Process of Cotton Fabric With Reactive DyesDocument6 pagesDyeing Process of Cotton Fabric With Reactive DyesMianAbrarAnjumNo ratings yet

- Batch to Batch Reproducibility and how to avoid creases, spots and stainsDocument32 pagesBatch to Batch Reproducibility and how to avoid creases, spots and stainsJohn VasilonikolosNo ratings yet

- New Development in Winch Dyeing-Dyeing High Efficiency & Low Energy Consumption High Temperature Dyeing MachineDocument4 pagesNew Development in Winch Dyeing-Dyeing High Efficiency & Low Energy Consumption High Temperature Dyeing MachineRezaul Karim Tutul100% (1)

- Dyeing Process Guide: Types, Machines & OptimizationDocument3 pagesDyeing Process Guide: Types, Machines & OptimizationVipin Singh KandholNo ratings yet

- Dyeing of Knitted Fabrics PDFDocument7 pagesDyeing of Knitted Fabrics PDFAhmed AksarNo ratings yet

- Dye House AutomationDocument6 pagesDye House AutomationMd.oaliur RahamanNo ratings yet

- Dyeing DefectsDocument12 pagesDyeing DefectsHARRY1765No ratings yet

- Machine Parameter: RPM (Speed)Document7 pagesMachine Parameter: RPM (Speed)SI ShakilNo ratings yet

- Dyeing Machines and MethodsDocument20 pagesDyeing Machines and MethodsAnonymous UoRu4s100% (3)

- Dyeing-Pad Batch AssignmentDocument22 pagesDyeing-Pad Batch AssignmentTooba Anum100% (1)

- Dyeing of Polyester and Cotton BlendDocument50 pagesDyeing of Polyester and Cotton BlendarafathosainNo ratings yet

- TRI 3004 Garment Dyeing With PigmentsDocument9 pagesTRI 3004 Garment Dyeing With PigmentsAyman sebaeiNo ratings yet

- NEX-GEN DYEING SYSTEM CUTS COSTS AND CONSERVES WATERDocument4 pagesNEX-GEN DYEING SYSTEM CUTS COSTS AND CONSERVES WATERVinod ShelkeNo ratings yet

- Dying of Cotton Fabric With Reactive Dye (Hot Brand) .Document5 pagesDying of Cotton Fabric With Reactive Dye (Hot Brand) .Redwan Ibn MahbubNo ratings yet

- Calculation of Dyestuffs and Auxiliaries For Effective Wet Processing TechnologyDocument3 pagesCalculation of Dyestuffs and Auxiliaries For Effective Wet Processing TechnologyAlexander DeckerNo ratings yet

- Semi Continuous Dyeing ProcessDocument3 pagesSemi Continuous Dyeing ProcessMonjur MorshedNo ratings yet

- Dyeing Faults & RemediesDocument13 pagesDyeing Faults & RemediesSHEIKH SADI100% (1)

- Textile Testing SolutionsDocument10 pagesTextile Testing SolutionsSha Md Ali RanaNo ratings yet

- APO Question With Ans 2Document6 pagesAPO Question With Ans 2nahid hasanNo ratings yet

- 3348Document9 pages3348anowartexNo ratings yet

- Salt Free Reactive Dyeing On Cotton (Cationized) Knit FabricDocument10 pagesSalt Free Reactive Dyeing On Cotton (Cationized) Knit FabricAyman sebaeiNo ratings yet

- Textile AssignmentDocument8 pagesTextile AssignmentMahmudul Hasan Khan40% (5)

- Jet DyeingDocument12 pagesJet DyeingTrinhTruongNo ratings yet

- Lab Experiment 08 BLEACHINGDocument5 pagesLab Experiment 08 BLEACHINGEngr Mujahid Mehdi0% (1)

- Study on dyeing polyester fabric with disperse dyeDocument25 pagesStudy on dyeing polyester fabric with disperse dyeJisun AhmedNo ratings yet

- The preparation, dyeing and finishing of cotton knit goodsDocument67 pagesThe preparation, dyeing and finishing of cotton knit goods郭哲宏100% (1)

- The Preparation, Dyeing and Finishing of Cotton Knit GoodsDocument67 pagesThe Preparation, Dyeing and Finishing of Cotton Knit GoodsSumeet GuptaNo ratings yet

- 6 Sem. B.Tech (Fashion & Apparel Technology) : Pcft4303 Garment Processing & FinishingDocument18 pages6 Sem. B.Tech (Fashion & Apparel Technology) : Pcft4303 Garment Processing & FinishingDarshan HandeNo ratings yet

- Fabric Dyeing MachineDocument8 pagesFabric Dyeing MachineSI ShakilNo ratings yet

- Textile Processing JuryDocument41 pagesTextile Processing JuryANISHA KUJURNo ratings yet

- Types of Dyeing ProcessesDocument5 pagesTypes of Dyeing ProcessesSyed Inamullah ShahNo ratings yet

- Dyeing MachineDocument17 pagesDyeing MachineRipon SayanNo ratings yet

- Textile DyesDocument5 pagesTextile Dyesapi-27596299No ratings yet

- Printing Chemistry One Phase Vs Two PhasesDocument17 pagesPrinting Chemistry One Phase Vs Two Phasesadali2020No ratings yet

- Dyeing Cotton/Polyester Blend with Reactive & Disperse DyesDocument6 pagesDyeing Cotton/Polyester Blend with Reactive & Disperse DyesSachin PratapNo ratings yet

- Fabric Dyeing ProcessDocument8 pagesFabric Dyeing ProcessNikita JainNo ratings yet

- Dyeing Lab MachineDocument9 pagesDyeing Lab MachineRobotrixNo ratings yet

- Textile Dyeing Waste Water TreatmentDocument27 pagesTextile Dyeing Waste Water Treatmentjakir_env0% (1)

- Cationization OF Cotton Fabrics - Salt Free Dyeing & Pigment Dyeing by Exhaust.Document19 pagesCationization OF Cotton Fabrics - Salt Free Dyeing & Pigment Dyeing by Exhaust.L.N.CHEMICAL INDUSTRYNo ratings yet

- Woven Dyeing MachinesDocument36 pagesWoven Dyeing MachinesProfessorTextech100% (1)

- Enzymatic Desizing and Demineralization for Woven FabricsDocument6 pagesEnzymatic Desizing and Demineralization for Woven FabricsFarhana LaeeqNo ratings yet

- Dyeing & PrintingDocument13 pagesDyeing & PrintingshponNo ratings yet

- Processes Involved in Textile Industry ADocument4 pagesProcesses Involved in Textile Industry APorkkodi SugumaranNo ratings yet

- Comparison of Batch To Batch Shade Variation Considering Parameters in Knit DyeingDocument19 pagesComparison of Batch To Batch Shade Variation Considering Parameters in Knit DyeingMuhammad MustahsinNo ratings yet

- Dyeing and Finishing of Textile Materials - Feasibilities and ProblemsDocument27 pagesDyeing and Finishing of Textile Materials - Feasibilities and ProblemsLieven VerraestNo ratings yet

- Dyeing ProcessDocument2 pagesDyeing ProcessHasibNo ratings yet

- Textile Dyeing Machinery GuideDocument10 pagesTextile Dyeing Machinery GuideSajid arNo ratings yet

- Coloration TechnologyDocument7 pagesColoration Technologywman6914No ratings yet

- NIKHILDocument58 pagesNIKHILNikhil ShaiwaleNo ratings yet

- Dyeing CalculationDocument4 pagesDyeing CalculationIftakharul IslamNo ratings yet

- Scopes of Improvisation in Knit-Dyeing Process of Cotton in Bangladesh To Optimize The Process-TimeDocument8 pagesScopes of Improvisation in Knit-Dyeing Process of Cotton in Bangladesh To Optimize The Process-TimeMuhammad Iqbal ShaikhNo ratings yet

- Soap-Making Manual A Practical Handbook on the Raw Materials, Their Manipulation, Analysis and Control in the Modern Soap Plant.From EverandSoap-Making Manual A Practical Handbook on the Raw Materials, Their Manipulation, Analysis and Control in the Modern Soap Plant.Rating: 4 out of 5 stars4/5 (2)

- Soap Manufacturing TechnologyFrom EverandSoap Manufacturing TechnologyLuis SpitzRating: 4 out of 5 stars4/5 (6)

- The Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentFrom EverandThe Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentNo ratings yet

- Soap-Making Manual. A practical Handbook on the RControl in the modern Soap PlantFrom EverandSoap-Making Manual. A practical Handbook on the RControl in the modern Soap PlantRating: 5 out of 5 stars5/5 (2)

- Knitting BookDocument8 pagesKnitting BookMd. Abrar Ahmed ApuNo ratings yet

- Standard DescriptionDocument3 pagesStandard Descriptionarif_mishaNo ratings yet

- Little Baby Keith: Yarn - Sock or FingeringDocument3 pagesLittle Baby Keith: Yarn - Sock or FingeringwildflowerNo ratings yet

- Brown Hound: Design by Michelle WilcoxDocument2 pagesBrown Hound: Design by Michelle WilcoxSuchBeea100% (2)

- GiiigDocument3 pagesGiiigẄâQâŗÂlïNo ratings yet

- Bruna Curtosi's Zipper Poncho DesignDocument6 pagesBruna Curtosi's Zipper Poncho Designmaglit777No ratings yet

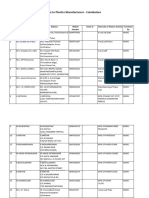

- List of Alternate To Plastics Manufacturers - CoimbatoreDocument3 pagesList of Alternate To Plastics Manufacturers - CoimbatoreRajesh KumarNo ratings yet

- Charkha ManualDocument20 pagesCharkha ManualvivektonapiNo ratings yet

- Celeste FREEInstructions and PatternDocument19 pagesCeleste FREEInstructions and PatternAnonymous ob7SgGfBM100% (4)

- Yarn Manufacturing Tandem CardingDocument5 pagesYarn Manufacturing Tandem CardingIndrajit BoseNo ratings yet

- Gul Ahmed - PresenatationDocument27 pagesGul Ahmed - Presenatationzubair_ahmed_imports0% (1)

- EuroPro 607H Sewing Machine Instruction ManualDocument98 pagesEuroPro 607H Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Conveyor Belts For Aluminum Extrusion: The Megadyne GroupDocument8 pagesConveyor Belts For Aluminum Extrusion: The Megadyne GroupJuan Andrés Díaz RiveroNo ratings yet

- Indonesia Exporters ListDocument33 pagesIndonesia Exporters ListJitender BhadauriaNo ratings yet

- World Turtle Succulent Holder - Knot BadDocument1 pageWorld Turtle Succulent Holder - Knot BadAILEEN JOARY LOZANO SALGADO 17ADG0034FNo ratings yet

- ManipurDocument21 pagesManipurSneha Singh80% (5)

- Horgolás Minta - KesztyűDocument4 pagesHorgolás Minta - KesztyűCagey Ice-RoyNo ratings yet

- Wind Power ApplicationDocument13 pagesWind Power ApplicationSagar PawarNo ratings yet

- Anatomy of A Rag Bag and LiningDocument12 pagesAnatomy of A Rag Bag and LiningBrittany KapjonNo ratings yet

- Sylko Product InformationDocument3 pagesSylko Product Informationjota025No ratings yet

- Lacey Arches Infinity ScarfDocument4 pagesLacey Arches Infinity ScarfJelena951No ratings yet

- Applying Quality Standards (Common-Dressmaking)Document49 pagesApplying Quality Standards (Common-Dressmaking)Angel JandusayNo ratings yet

- Adventure Time Crafts - Finger PuppetsDocument4 pagesAdventure Time Crafts - Finger PuppetsLa Bruja del EsteNo ratings yet

- 2019-08-01 Interweave Knits HolidayDocument94 pages2019-08-01 Interweave Knits HolidayCP35100% (3)

- Cotton Yarn Dyeing: Profile No.: 94 NIC Code:28263Document8 pagesCotton Yarn Dyeing: Profile No.: 94 NIC Code:28263ashwini wadhaveNo ratings yet

- Happy Bears Crochet PatternDocument9 pagesHappy Bears Crochet PatternGemma Bosma-Jansen100% (3)

- Nylon Sling Chart PDFDocument1 pageNylon Sling Chart PDFAnonymous dWa1xtpKmfNo ratings yet

- Snowflake ScarfDocument2 pagesSnowflake ScarfAmalia BratuNo ratings yet

- Bulletin: Toyota Textile MachineryDocument8 pagesBulletin: Toyota Textile MachineryKannan Krishnamurthy100% (2)

- Brother BAS-311A Instruction ManualDocument30 pagesBrother BAS-311A Instruction ManualJeremy IdkNo ratings yet