Professional Documents

Culture Documents

Optimized Burner

Uploaded by

prashantOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimized Burner

Uploaded by

prashantCopyright:

Available Formats

Optimized Fired Heater Operation Saves Money

by Ashutosh Garg Furnace Improvements Introduction Fired heaters are an essential component of most process plants. They are primarily used to heat all types of hydrocarbons. They are also used to heat hot oils, steam, or air. Fired heaters are major consumers of energy and even the smallest improvements in efficiency can save thousands of dollars. In the refining industry, typical energy consumption is approximately 0.44 MM Btu/BBL of crude oil processed. This translates into 2667 MM Btu/hr for a 200,000-barrel-per-day (BPD) refinery. Even a 1% improvement in thermal efficiency translates into energy savings of $600,000 per year. Ethylene plants (22 MM Btu/ton of ethylene) and ammonia plants (28.5 MM Btu/ton of ammonia) are equally energy intensive. Typical problems observed in fired heaters include: High excess air operation Fouled convection sections High stack temperature Over-firing Bad flames/flame impingement Examples of some of the problems are: Operating heat duty90 MM Btu/hr (Designed for 50 MM Btu/hr) Excess air140% (Designed for 15%) Stack flue gas temperature900F (Designed for 530F) Radiant tube metal temperature830F (Designed for 450F) Burner flame lengths2025 ft. (Designed for 12 ft.) Fired heaters usually operate above the original design specifications. Often the feed stock in the refinery or plant has changed. In most instances, plant capacity has been increased and the fired heater is working hard to deliver the duty. In a few instances, due to a change in the process the heater may be working in turndown conditions. In most cases, the fired heater operation can be optimized to save money. This paper presents guidelines for optimizing fired heaters. Some case studies are presented to illustrate improvements made to some fired heaters. These improvements can save money by saving energy and by extending the life of the equipment. A fired heater is a very large and complex piece of equipment. A typical new fired-heater installation would be fitted with an air preheating system and a NOx reduction system. Figure 2. Typical Fired Heater Types Figure 3. Typical Staged Fuel Gas Burner Figure 1. Typical Horizontal Tube Heater

A brief description of a fired heater and its operating parameters will help us better understand the cases presented in this paper. Fired Heaters A fired heater consists of three major components: a heating coil, the enclosure, and the combustion equipment. Heat is released from the combustion of fuel. Figure 1 provides a cross-sectional view of a furnace. The heating coil consists of tubes connected together in series that carry the charge being heated. Heat is transferred to the material passing through the tubes. The enclosure consists of a firebox. It is a steel structure lined with refractory material that holds the generated heat. Burners create the heat by the combustion of fuel. The furnace is fired by oil or gas. The heating coil absorbs the heat mostly by radiant heat transfer and convective heat transfer from the flue gases. The flue gases are vented to the atmosphere through the stack. Burners are located on the floor or on the sidewalls. Combustion air is drawn from the atmosphere. For increased heat recovery, an air preheater or waste heat boiler is installed downstream of the convection section. Instruments are generally provided to control the firing rate of the fuel and flow through the coils to maintain the desired operating conditions. Figure 2 shows different types of furnace configurations used in the industry. Figure 4. Typical Draft Profile in a Natural Draft Heater Combustion Combustion or burning is an exothermic reaction resulting from rapid combination of oxygen with fuel. The oxygen is found in the air. Most fuels contain hydrocarbons and some sulfur. Since perfect mixing of fuel and air is not possible, it becomes necessary to supply excess air to complete combustion of the fuel. Excess air is expressed as a percentage of theoretical quantity of air required for perfect combustion. For every one part of oxygen, there are four parts of nitrogen which enter the combustion process and leave without taking part in the reaction. They absorb a portion of the heat generated and carry it to the stack. It is necessary to minimize excess air to avoid excessive heat loss. It is also undesirable to operate with less than stoichiometric combustion air, as it will lead to a smoking stack and incomplete combustion. Incomplete combustion leads to a loss of energy. If a burner is operated with insufficient air, carbon monoxide (CO) and hydrogen will appear in the flue gas. Both carbon monoxide and hydrogen are combustibles. The presence of combustibles is an indicator of combustion inefficiency. Table 1 below gives the net heater thermal efficiency based on the flue gas temperature and flue gas oxygen content (assuming a 2% heat loss and using typical natural gas fuel).

Excess Air (%) 15 20 25 30 40 50

O2 in Flue Gas% 3.00 3.82 4.56 5.24 6.46 7.49

300 91.76 91.52 91.29 91.05 90.58 90.10

350 90.44 90.15 89.87 89.58 89.01 88.43

400 89.11 88.77 88.44 88.10 87.43 86.76

450 87.77 87.39 87.01 86.61 85.84 85.06

500 86.42 85.98 85.55 85.11 84.24 83.36

550 85.06 84.57 84.09 83.62 82.60 81.64

600 83.6 83.15 82.62 82.07 81.00 79.92

700 80.59 80.28 79.64 78.99 77.71 76.43

800 78.11 77.36 76.61 75.87 74.37 72.28

900 75.25 74.4 73.55 72.69 70.99 69.28

1000 72.35 71.39 70.43 69.47 67.55 65.63

Table 1. Fired Heater Thermal Efficiency % vs. Excess Air and Flue Gas Temperature Burners Burners provide for starting and maintaining combustion in the firebox. They introduce fuel and air in the correct proportions, mix the fuel gas and air, provide a source of ignition, and stabilize the flame. Good combustion requires three steps: Fuel and air in correct quantities; Thorough mixing of fuel and air; and Sustained ignition of the mixture. Burner air register and gas tips control the amount of air and fuel being injected into the burner. Fuel gas pressure and air draft provide the energy for the mixing of fuel and air. Figure 6. Feed Forward Control Scheme Burner tiles provide a hot surface for stabilizing and sustaining ignition of the mixture and provide a flame that is the required shape. There are different types of burners available. They are classified by the type of fuel burned, the supply of air, or the basis of NOx emissions. A typical burner sketch is shown in Figure 3. Draft The hot flue gases inside the firebox and stack are lighter than the cold ambient air outside. This results in the creation of a slightly negative pressure inside the furnace. Combustion air is drawn into the burners and the hot gas flows out of the stack due to this pressure differential. While passing through the convection section and stack, flue gases encounter friction resistance. Sufficient stack height is provided to overcome these losses and to ensure that pressure is always negative inside the firebox. Four types of draft exist: Natural Draft This is the most common type of draft with the air drawn into the furnace by means of the draft created by the stack. The taller the stack, the greater the draft available. Forced Draft In this type of system, the air is supplied by means of a centrifugal fan commonly known as forced draft (FD) fan. It provides for high air velocity, better air fuel mixing, and smaller burners. The stack is still required to create a negative draft inside the furnace. Figure 5. Conventional Heater Control Scheme

Induced Draft When the height of the stack is inadequate to meet the draft requirements, an induced draft (ID) fan is provided to draw the flue gases out of the heater. Negative pressure inside the furnace ensures air supply to the burners from the atmosphere. Balanced Draft When both forced draft and induced draft fans are used with the heater, it is known as a balanced draft system. Most air preheating installation is balance draft. Draft Control The draft in the furnace is controlled by means of a stack damper in natural or forced draft systems. In induced draft heaters, the draft is controlled by means of dampers installed at the suction of the induced draft fan. The arch of the heater or inlet to the convection section is the point having the highest pressure and thus has been used as a point of control. A typical value of 0.1" WC is maintained at the arch. A high draft will lead to more combustion air being drawn in the firebox. Conversely, insufficient draft may lead to positive pressure inside the firebox leading to flue gas leakage from the openings. Figure 4 shows the typical draft profile across the heater.

Fired Heater Controls Process Side Fluid being heated inside the tubes needs to be controlled for efficient heat transfer and to minimize fouling and coking of the tubes. Flow distribution at inlet is very important. All fluid passes should have an equal amount of fluid passing through the tubes. In most of the liquid or fouling services, it is important to have an individual pass flow controller to avoid unbalancing of the flow due to coking or localized overheating. A simple control scheme is shown in Figure 5. Another variation is the use of the feed forward control and any load changes in the feed minimizes the outlet feed temperature variation. A number of modifications have been made to this scheme. A common variation is the control scheme where the individual pass outlet temperatures are controlled to ensure the uniform outlet temperature as shown in Figure 6. This scheme works fine as long as the service is not fouling. In case of coking or fouling services, it does not work satisfactorily as it tries to cut down on the flow in the pass that is coked up and the situation becomes even worse. The pass tends to coke even more at the reduced flow. Fluid flowing in the tubes should have an adequate pressure drop in the fired heater to ensure good distribution of the fluid in a multiple-pass heater. If the pressure drop across the heater is low, then there is a chance for flow imbalance and the pass may run dry. Flow regime and coil velocities at the outlet in vaporizing services needs to be watched. If the tube experiences slug flow or very high velocities, then there could be a problem and the tubes will start to vibrate or they can have erosion failure. Case Studies 1. One refinery heater was designed as a four-pass heater in the convection section and a two-pass heater in the radiant section. The client did not have an individual flow controller on each pass (one flow controller for each radiant pass was installed) and had no way of knowing the fluid distribution in the convection section. The fluid pressure drop in the convection section was very low. The problem was corrected by installing restriction orifices in each convection pass inlet to increase the pressure drop and equalize the flow.

2. One of the vertical cylindrical crude heaters had an outlet elbow failure due to high velocities in the tube. The solution was to replace the last 6-inch tube and elbow with an 8-inch tube in both passes. 3. Another heater had a severe vibration problem at the convection-to-radiant crossover. High vaporization and high velocities were found to be the cause. The higher vaporization was caused by the injection of steam in the fluid at the convection inlet. The convection tubes were 4-inch size and the radiant tubes were 6-inch size. The recommendation was to change the steam injection point from the convection inlet to the radiant inlet. 4. One refinery heater was experiencing severe tube vibrations in the arch section of the heater. The analysis of the heater revealed the presence of slug flow in two tubes located at the arch. Replacing the two 8-inch tubes with 6-inch size tubes solved the problem. Figure 7. Excess Air vs. Oxygen Content in Flue Gas Firing Controls Three major parameters that need to be controlled and monitored are: 1. Fuel gas/Fuel oil pressure; 2. Excess air; and 3. Draft in the furnace. Fuel Pressure One of the simplest schemes for the control of fuel pressure is shown in Figure 5. The feed output temperature controller provides the set point for the burner fuel pressure controller. Sometimes the feed outlet temperature is directly connected to the fuel control valve. If the heater is fired with more than one fuel, then one of the fuels is base loaded and set at a constant firing rate while the second fuel under control takes load fluctuations. Figure 8. Balanced Draft Control Scheme Excess Air Control Excess air control essentially involves answering three basic questions: 1. How much excess air is provided? 2. How much excess air should be provided? 3. How efficient is the burning equipment? Flue gas analysis provides the answer to the first question. The oxygen concentration in the flue gas provides an indication of the excess air supplied to the combustion process. Figure 7 shows the relationship between oxygen content and the excess air for a typical fuel gas. We should know what the optimum excess air for a particular type of burner is. It varies from one burner type to another and also depends on the type of fuel. Optimum excess air is the minimum excess air because it minimizes the heat loss to the flue gases, minimizes the cooling effect on the flame, and improves the heat transfer. With less than the minimum excess air, the unburned fuel will start appearing in the flue gas due to insufficient air. Minimum excess air should be specified by the burner vendor and should be verified during burner testing. Typical recommended values are given below in Table 2. Fuel/Draft Natural Draft Forced Draft

Fuel gas Light fuel oil Heavy fuel oil

1520% 1015% 2025% 1520% 2530% 2025% Table 2. Recommended Excess Air Levels

The excess air level in the low NOx burners tend to be higher as the NOx is being reduced by delaying the mixing of air and fuel. In a number of airpreheater installations, where a natural draft burner is used with the airpreheater, optimum excess air tends to fall between the natural and forced draft values. The values recommended are for heaters in good condition and with practically no leakage in the box. Appropriate corrections need to be made for old heaters. Figure 9. Natural Draft Heater Adjustment Flow Chart Furnace Draft Flue gas analysis is the single most powerful tool available to maximize the combustion efficiency. A number of improved control schemes have been proposed. One scheme automatically controlled the oxygen content in the flue gas by varying the draft in the furnace. This approach was not very successful, as the operators didnt want to manipulate the stack damper all the time. The quality of the stack damper operating mechanism was always suspect. In natural draft furnaces, the excess air is controlled by adjusting both stack damper and the burner registers. Control schemes have been installed in the balanced draft systems to control the excess air and draft more accurately. Some of these schemes involve control of the air/fuel ratio. Several problems have been experienced in measuring the fuel and air flowrate accurately. In the case of the fuel, the fuel gas quality (composition) keeps on changing in the refinery. For liquid fuels, the fuel viscosity is so high and temperature dependent that a reliable flow measurement over a period of time is very difficult to obtain. Combustion air flowrate is also difficult to measure reliably, as straight run-lengths for the installation of instruments are not available except when a venturimeter is installed in the suction stack of the FD fan. In view of the above, we recommend simple, reliable control schemes that will save you money and headaches. A typical control scheme is shown in Figure 8. We recommend installation of an oxygen analyzer and a combustible analyzer in the arch. A single analyzer can handle both. The excess air should be adjusted in such a way that the oxygen level in the flue gas is close to the minimum or optimum excess air level. Combustibles should read close to zero during normal operation. The combustible analyzer should not be used to make excess air adjustments, as is the case in some installations. The presence of combustibles is an indication of poor combustion. Combustion air should not be controlled using CO or combustibles as a guide. The presence of CO or combustibles indicates that either the air is deficient or the combustion equipment is not clean, which is generally the case. The dirty burners or poor atomization of oil can easily lead to CO formation. Figure 10. Air Leakage in Fired Heaters

Case Study One of the multi-cell platformer furnace had a common waste heat recovery unit followed by a stack. The fired heater operation was never below a 65% excess air level despite the burner registers being closed. On inspection of the unit it was found that the furnaces had a very large common stack150 ft. high due to environmental reasons. The large stack was generating almost 0.65 inch of draft at arch instead of 0.10 inch of draft required at the arch. There was no stack damper or any damper in the individual ducts. The result was that the client was losing almost $120,000 per year. Modifying the burners cost only $45,000 and the investment was returned in four months. Draft Adjustment The arch draft should be kept at a design value of 0.1" water gauge. This will ensure safe operation and minimum air leakage. Excess air needs to be minimized for efficiency improvement. However, sufficient air must be provided to obtain the correct and desirable flame shape and complete combustion. Closing air registers reduces the airflow but increases the heater draft. Closing the stack damper, reduces the furnace draft In order to adjust excess air, the stack damper must be adjusted in conjunction with the air registers. A step-by-step procedure to adjust the draft and excess air in the natural draft furnaces is shown in Figure 9. Air Leakage In most furnaces, the firebox pressure is kept close to atmospheric pressure. Figure 10 shows the places where air can leak into the heater. As the flue gases progress through the unit, the pressure drops and may go down as low as 10 inches water column at a location close to the induced draft fan suction. The chances of air filtration are highest under those circumstances. The O2 content of the flue gas is best determined as near as possible to the furnace as it will eliminate most of the leakage. It is recommended to locate a zirconium oxide probe in the heater arch where the temperatures are generally high (in the range of 14001800F). In order to minimize the air leakage into the heater, all peepholes must be kept closed. The header box doors must be tightened to eliminate any air leakage. Keep the explosion door closed. Ensure there is minimal air leakage from the tube guide penetrations in the floor. Damper Operation Check the stack damper at every shutdown and make sure it is working properly. Natural draft furnaces should be installed with multiple opposed-blade dampers with a rugged operating mechanism. Damper operation becomes even more critical if the heater has an air preheating system. In this case a tight shutoff quick acting damper is needed. A number of installations have kept the stack damper crack open for the fear of it getting stuck. But what happens is either cold air starts leaking into the system or the hot flue gas leaks into the atmosphere. Both scenarios are not desirable as they cause loss of efficiency. It is recommended to inspect the damper at every shutdown and make necessary modifications as needed. The damper should be kept fully closed and should be tested every two weeks. Case Study In one instance, burners were replaced in a shutdown along with some other maintenance work. The new burners would not light. It was later found that although the stack damper indicator was showing full open, the damper was fully closed. Someone had apparently forgotten to check the stack damper.

Heat Distribution in the Firebox In most heaters, uniform heat distribution in the firebox will improve the heaters performance. This will ensure uniform heating of all the passes. In order to spread the heat as uniformly as possible, the following tips will help: 1. The burners should be spaced as far from the tubes as possible. Use smaller burners if using low NOx burners. 2. Use equal amounts of fuel and air in all the burners. Have equal fuel gas pressure in all the burners. The burner valves should be fully open. 3. For a natural draft heater, the air registers of all burners should be open to the same extent. 4. In the case of forced draft heaters, burner air dampers should be fully open. The fan suction damper controls the air. 5. In the case of low NOx staged air burners, the number of dampers on each burner increases to two or three depending on the design. In this case, all burner dampers should be equally open. 6. Air registers of unused burners should be kept closed 7. Keep all pass-flows equal with a margin of +/-10%. 8. Check all tube skin temperatures frequently.

Figure 11. Air Preheating Scheme

Cause Solution Modify burners Flame impingement Reduce firing Over-firing Equalize flow in all passes Unbalanced pass flow Decoke tubes Coke build up Replace thermocouple Bad thermocouple Open damper Positive pressure at arch Damper not open enough Reduce firing rate Firing rate high Clean convection section Convection section fouled Clean convection section High flue gas temperature Convection Section fouled Replace convection tubes Fins burnt off Modify burners After-burning in convection Reduce firing Over-firing High fuel gas pressure Burners are plugged Clean burners Variation in pass outlet temperatures Unequal pass flow-rates Equalize flow in all passes Uneven firing Equalize firing in all burners High pressure drop through tubes Coke build up Decoke tubes High rate of vaporization Reduce flowrate Reduce furnaces draft High excess air operation High furnace draft Modify burners Poor air fuel mixing Plug air leakage Air leakage in the furnace Table 3. Fired Heater Troubleshooting Guide Burner Operation Indicators of correct combustion in the firebox include:

Problem High or uneven tube skin temperature

1. The firebox is clear; 2. There is no smoky appearance; and 3. The burner flames are steady and well formed.

Check burners regularly for any signs of blockage or unusual flame conditions. If the burner flames are long and lazy, it is a sign of poor mixing. Increasing the airflow to the burner can reduce flame length.

With natural draft burners, increase the primary air and minimize the secondary air to the burners. Primary air mixes with the fuel and creates a short compact flame. Excess of primary air can sometimes lift off the flame and make it unstable. For oil firing, flame lift off can be corrected by increasing the atomizing steam. Figure 12. ID Fan Ducting Modifications Case Studies 1. 1. A client bought a new hot oil heater and quickly found out that the tube metal temperatures were running high. The oil circulation pumps filters clogged very fast. A check indicated that the tube metal temperatures were running high due to flame impingement. The flames were long due to improper air fuel mixing. The burners were modified to reduce the flame lengths. The tube metal temperatures came down after the burners modification.

2. 3. 2. One refiner had three reformer furnaces. The furnaces

had double-fired tubes with flat flame burners on both sides of the tubes. The client was complaining of flame impingement and the tubes were bending all the time. A plant visit indicated that the burners were installed perpendicular to the wall instead of parallel to the wall. This resulted in the flame hitting the tubes all the time. 3. One refinery had a horizontal tube box natural draft heater. It had 32 flat flame burners firing on both sides of the tubes. The burners were mounted in a plenum because of noise considerations. The heater was having high and uneven tube skin temperature problems. The client was not able to achieve uniform firing. They were getting infrared thermograph inspections done every week and were using the results to adjust the firing pattern without much success. The problems were studied in detail and it was found that poor air fuel mixing and non-uniform supply of air were the problems. The burners were modified in association with the burner vendor. An old burner was shipped to the burner vendors testing facility. The burner was tested before and after the modifications. The combustion was much improved and uniform. It even led to fuel savings of 23%. Installing two additional air openings on each plenum chamber solved the non-uniform air distribution problem.

4. One petrochemical plant had a gas cracking furnace with an induced draft located on the top. It was

fired from the floor. The furnace was facing the following problems: 1) Long burner flames 2) Positive pressure at arch The furnace and burner design was studied in detail. The air and fuel mixing was not taking place properly, which resulted in long flames. The burner design was modified and the burner was re-tested at the burner vendors test facility. The modifications to the burner were made during a short shutdown and the problem was solved. The furnace was also facing positive pressure at the arch, although it had an induced draft fan installed. It was found that the ducting sections of the inlet and outlets were causing a substantial pressure drop. The ducting configuration was modified to reduce the pressure losses. Pilot Burners Pilot burners are provided as a continuous source of ignition. In some installations they are continuously monitored using flame failure devices. Self-inspirating pilot burners have been found very reliable. Recently we encountered a hot oil heater that had 12 burners and all of them had the pilots monitored by UV cells. The burners were bottom fired. Any small debris or even an insect would block the signal of the

UV cell leading to nuisance shutdowns. The system was modified to put all the UVs in parallel to avoid nuisance tripping of the heater. It is our recommendation to not provide UV cells in a multi-burner installation. The UV cells are very expensive, especially in hazardous locations, and do not serve any useful purpose. Problem Burners go out Flame flashback Insufficient heat release Pulsating fire Cause a. Gas mixture too lean b. Too much draft a. Low gas pressure b. High hydrogen in fuel a. Low gas flow b. Burner tip plugged Lack of oxygen Lack of draft Lack of combustion air Incorrect burner tip location Damaged burner tile Excessive firing Poor air fuel mixing Table 4. Burner Troubleshooting Solution Reduce air Close stack damper Raise fuel gas pressure Reduce primary air Increase gas pressure Clean burner tips Reduce gas flowrate Open stack damper Open burner air registers Adjust air registers/damper Check burner tip location Replace burner tile Reduce firing rate Improve burner design

Erratic flames

Gas flame too long

Air Preheater Figure 13. Modified NH3 Flow Control Scheme An air preheater improves the efficiency of a furnace sometimes by as much as 7 to 10%. A typical installation is shown in Figure 11. One of the common problems associated with an air preheater is the cold end corrosion. In a number of installations, the air preheater sometimes over performs for a number of reasons. This leads to a drop in the flue gas temperature leaving the air preheater. It also leads to cold end corrosion in the cold section of the air preheater and other downstream equipment due to condensation of sulfur-bearing acids. It is recommended that the outlet flue gas temperature be controlled by adjusting the cold air bypass around the air preheater. High Pressure Drop In some installations limits are reached even below the design capacity on the ID fans. Some of the more common reasons are:

1. High-pressure drop across the air preheater and 2. System losses at ID fan suction and discharge ducts

that are not taken into consideration. Due to tight plot requirements, the ducts are provided with abrupt bends. In one instance (the fan installation) the discharge duct was causing four inches of pressure drop. This was rectified by modifying the fan discharge angle and the connected duct as shown in Figure 12. The fan performance was restored and it even led to power savings worth $25,000 per year. NOx Reduction NOx reduction work requires that correct operating parameters be identified and used as a design basis for implementing NOx reduction work. It is essential that excess air levels be reduced to close to 24% as all

NOx emissions are corrected to 3% O2. SCR installation requires the correct temperature window for successful operation. ULNB Burners One vertical cylindrical heater had eight natural draft gas burners installed. During the NOx reduction, six ultra-low NOx burners replaced the eight burners. The new burners were 33% larger in capacity. Flame lengths of these burners were almost 22.5 ft./MM Btu. The flame lengths increased from 10 ft. to 25 ft. It led to severe flame impingement and coking of the tubes. Higher excess air, dirty fuel gas, and a fouled convection section aggravated the problem. The client was forced to reduce the firing rate in the heater to continue the operation. It is very essential to check the design of the furnace before it is fitted with low NOx burners. SCR Controls Ammonia injection in the flue gas followed by a catalyst bed are used to control NOx emissions from fired heaters. Like most of the reactions, one requires an excess of one of the reactants to complete the reaction. NH3 and NOx are both present in trace quantities. In this case, the amount of ammonia injected can be controlled. In some cases, the control of the ammonia was linked to the outlet NOx concentration. This led the operators to keep increasing the amount of ammonia until the desired NOx reduction was achieved. The result was an excessive byproduct formation of ammonium bisulfate and ammonium sulfate. These salts plugged the SCR catalyst beds and the downstream equipment. What was needed was a control scheme based on inlet NOx concentration. Proper mixing of NH3 and NOx is also required prior to the reactor. Figure 13 shows a typical control scheme recommended for SCR ammonia injection. Conclusions It can be concluded that there is a very good potential for optimizing the performance of fired heaters by making minor modifications and good housekeeping. Below is a summary of fuel-saving tips for your fired heaters. Fuel to the furnaces can be saved in two major ways: Reduce excess air Every 10% reduction in excess air saves about 1% in fuel Reduce flue gas temperatures Every 35F reduction in flue gas temperature saves about 1% in fuel. Check excess air levels and flue gas temperature in the furnaces Recommended excess air level for gas firing is 1015% (23% oxygen), for oil firing it is 2025% (45% oxygen) Recommended flue gas temperature is approximately 100F above the inlet fluid temperature. The following steps will help reduce excess air: 1. Maintain design draft in furnace (typical value is 0.1" WC). 2. Adjust burner registers and stack damper to control the draft. 3. Shut off air registers for the burners not in line. 4. Close all peepholes and doors securely. 5. Close all header boxes in the convection section and radiant boxes. 6. Maintain clean combustion at all times. The following steps will help reduce flue gas temperature: 1. Reduce excess air to burners. 2. Clean convection section tubes. Operate sootblowers or steam lances.

References API Standard 560 for Refinery Heaters API publication 535 Burners for Fired Heaters in General Refinery Service Fired Process Heater Control Alternatives Include Microprocessor-Based Distributed Control by R.K. Johnson and Thomas J. Scheib Move Toward Process Control for CEM Natural But Slow by Jason Makansi, Power, August 1989 Further Reading 1. North American Combustion Handbook 2. Good Heater Specifications Pay Off by A. Garg and H. Ghosh 3. Better Burner Specifications by A. Garg 4. How to Boost Performance of Your Fired Heaters by A. Garg Biographic Information Ashutosh Garg is currently working as a Thermal Engineer at Furnace Improvements, Sugar Land, Texas [Tel. (281) 980-0325, Fax (281) 980-4318, email: ashutosh@prodigy.net]. He has more than 22 years of experience in design, engineering, and troubleshooting of furnaces and combustion systems for the refining and petrochemical industries. He graduated from Indian Institute of Technology, Kanpur, India in Chemical Engineering in May 1974. He started as a graduate engineer in an ammonia plant. It was followed by six years in KTI India and eight years at EIL, New Delhi in their heater group. He joined KTI Corporation at their San Dimas in May 1990 and moved to Houston in 1992. He has published several papers on fired heaters and burners in trade magazines. He is a registered Professional Engineer and a member of A.I.Ch.E. He is also a member of API and is on the task force for the new API standard for NOx control for fired heaters. Electronically reproduced by special permission from HYDROCARBON PROCESSING (June 1997) Copyright 1997, Gulf Publishing, Texas

You might also like

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- Chapter 8Document44 pagesChapter 8prashantNo ratings yet

- Goulds-Pumps Fundamentals PDFDocument140 pagesGoulds-Pumps Fundamentals PDFAgustinus Made Theo Dwijaya100% (2)

- Chapter 14Document24 pagesChapter 14prashantNo ratings yet

- Chapter 1Document76 pagesChapter 1prashantNo ratings yet

- Chapter 18Document40 pagesChapter 18prashantNo ratings yet

- Chapter 10Document28 pagesChapter 10prashantNo ratings yet

- Chapter 7Document20 pagesChapter 7prashantNo ratings yet

- Chapter 9Document22 pagesChapter 9prashantNo ratings yet

- Chapter 17Document34 pagesChapter 17prashantNo ratings yet

- Chapter 13Document60 pagesChapter 13prashantNo ratings yet

- Lubrication 141218114335 Conversion Gate01Document17 pagesLubrication 141218114335 Conversion Gate01prashantNo ratings yet

- Chapter 5Document74 pagesChapter 5prashantNo ratings yet

- Chapter 6Document44 pagesChapter 6prashantNo ratings yet

- Chapter 3Document42 pagesChapter 3prashantNo ratings yet

- Chapter 2Document34 pagesChapter 2prashantNo ratings yet

- Improving Pumping System PerformanceDocument122 pagesImproving Pumping System PerformanceFSnyderJr100% (7)

- Chapter 4Document24 pagesChapter 4prashantNo ratings yet

- GE Steam TurbinesDocument28 pagesGE Steam TurbinesKamal Arab100% (12)

- Rotating Stall - An Overview of Dresser-Rand Experience: J. M. Sorokes Dresser-Rand, Olean, NY, USADocument22 pagesRotating Stall - An Overview of Dresser-Rand Experience: J. M. Sorokes Dresser-Rand, Olean, NY, USAprashantNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Structural Design of Timber To BS 5268Document14 pagesStructural Design of Timber To BS 5268Niceman Natiqi80% (10)

- Chap 4 Wastewater Effluent Treatment Plant ETP Operation Manual FactsheetDocument2 pagesChap 4 Wastewater Effluent Treatment Plant ETP Operation Manual FactsheetAhmedNo ratings yet

- Mark 300 ManualDocument8 pagesMark 300 ManualcjfgksNo ratings yet

- MS5002EDocument8 pagesMS5002EMatt AgonyaNo ratings yet

- Deutz 165 MK3 Electrial 1Document100 pagesDeutz 165 MK3 Electrial 1chrideerNo ratings yet

- 11 CR-CB Data SheetDocument2 pages11 CR-CB Data SheetJLZ972No ratings yet

- Global Energy Balance in The Exchanger and Losses StudyDocument4 pagesGlobal Energy Balance in The Exchanger and Losses StudyJames Clerk MaxwellNo ratings yet

- Diagnostic Exam for Aeronautical Engineering StudentsDocument4 pagesDiagnostic Exam for Aeronautical Engineering StudentsBerns DulamNo ratings yet

- John Carlo Dela Cruz - CHEM - Q3 - W4Document12 pagesJohn Carlo Dela Cruz - CHEM - Q3 - W4johncarlodc99No ratings yet

- Essie Waste ManagementDocument2 pagesEssie Waste ManagementrupenderNo ratings yet

- Vacuum Pump Systems BrochureDocument10 pagesVacuum Pump Systems BrochureMelissa WilliamsNo ratings yet

- mc4 DatasheetDocument8 pagesmc4 Datasheetdth dthNo ratings yet

- Cement Kiln ReportDocument22 pagesCement Kiln Reportamir100% (1)

- Các loại đầu nối cho ống- fittings for high pressure PDFDocument45 pagesCác loại đầu nối cho ống- fittings for high pressure PDFKiên MaiNo ratings yet

- Brazing Methods GuideDocument9 pagesBrazing Methods GuideVitorHugoNo ratings yet

- Petroleum and Petroleum Products - Liquefied Petroleum Gas (LPG) - SpecificationDocument8 pagesPetroleum and Petroleum Products - Liquefied Petroleum Gas (LPG) - SpecificationJon GoeltomNo ratings yet

- HTF System Cleaner, Degreaser and Surface ModifierDocument1 pageHTF System Cleaner, Degreaser and Surface Modifierglycol_brine_coolant_pcmNo ratings yet

- 2020 - 1 s2.0 S0020722520301853 MainDocument20 pages2020 - 1 s2.0 S0020722520301853 MainG DNo ratings yet

- Roll Mill 1Document48 pagesRoll Mill 1klasiko bente tresNo ratings yet

- Cold Extrusion For Bearing Pin in Automotive Application by 5-Axis CNCDocument13 pagesCold Extrusion For Bearing Pin in Automotive Application by 5-Axis CNCAhmad SyafiqNo ratings yet

- Chem HezardDocument21 pagesChem HezardUseless MeNo ratings yet

- Hitatchi ProfileDocument15 pagesHitatchi ProfileAbdul AleemNo ratings yet

- 180 M3 SoftenerDocument11 pages180 M3 SoftenerDinesh DhakneNo ratings yet

- Olefins Production PDFDocument64 pagesOlefins Production PDFAnonymous 0zrCNQNo ratings yet

- Pe Plastics The Facts v7 Tue 19-10-1Document81 pagesPe Plastics The Facts v7 Tue 19-10-1Ajeya SaxenaNo ratings yet

- Asme CCase N-432Document4 pagesAsme CCase N-432julianmorantesNo ratings yet

- Tutorial 1Document4 pagesTutorial 1Kevin TanNo ratings yet

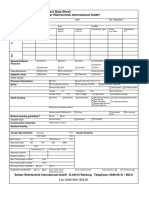

- Agitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDocument1 pageAgitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDeepikaNo ratings yet

- Sigma mixer description and specificationsDocument1 pageSigma mixer description and specificationsBalRam DhimanNo ratings yet

- Screw Conveyor Specification for Industrial UseDocument5 pagesScrew Conveyor Specification for Industrial UseAbinashBeheraNo ratings yet