Professional Documents

Culture Documents

SAFE LIFTING WITH SCISSOR LIFT

Uploaded by

jokerseriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAFE LIFTING WITH SCISSOR LIFT

Uploaded by

jokerseriCopyright:

Available Formats

POWER

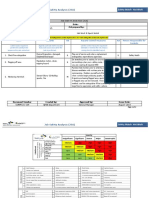

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

ACTIVITY OR TASK: LIFT PERSONNEL IN SCISSOR LIFT

JSA Preparation & task work team:

Competence = Relevant Training/Qualifications + Experience

Location / Project: Job Number: JSA Number: G02 Codes of Practice & Legislation that are applicable: JSA Revision:

Competence/ Qualificn reqd to complete work safely JSA approved by person responsible i.e.

Team Leader / Tradesman

Name:

Position / Competence/ License:

Date:

2. HAZARD IDENTIFICATION

compulsory

Identify hazards that may be present by ticking items on the list below.

3. PRECAUTIONS: hard hat, safety glasses, safety boots

ADDITIONAL PRECAUTIONS

Gloves: type . Goggles Full Face Shield High Visibility Vest Harness Fire Extinguishers Barricades Ventilation Lighting Erect Scaffolding to access Respirator or Dust mask Erect Warning signs Personal Locks or Tag system Group isolation Welding screen Fall Arrest systems Welding Face Shield

WORK LOCATION

Difficult Entry/Exit Oxygen Deficiency Oxygen Excess Engulfment (trench collapse) Poisonous Gas Present Temperature Extremes Defined Confined Space Explosive Gas Present

HAZARDOUS AREA

Hazardous Substances - attach MSDS to JSA Working at Heights Remote Area Motor Room Hazards Toxic Substances Potential for Difficult Rescue

HIGH RISK

Falling Objects Poor Lighting Slippery Surfaces Multiple Electrical Feeds Trip Hazards Electrical Hazards - LV Electrical Hazards - HV Manual Handling Sharp Materials Ladders used in the task Working at Heights Working near Crane & Crane Runways Rail Movement Pressurised Fluids Flamm. Materials Present

HIGH RISK

Suspended loads Poor Visibility Inhalable Dusts/Fibres High Noise Levels Use of Chemicals Elevated Work Platform Difficulty to Communicate amongst workers Moving Machinery Tools & Equipment Heat/ Sunlight/ Radiation Traffic Movement Working near Operation Processing Lines Live Rails Pneumatics

PERMITS

Hot Work Excavation Confined Space Hazardous Work Clearance Access to Area High Voltage Access Scaffolding Other?

HAZARDOUS SUBSTANCES in work area / to be used

-attach MSDS

PERMIT NUMBER

4. ENVIRONMENTAL HAZARDS (IMPACTS) tick those identified

Air Pollution (dust, fumes) Noise (plant & equipment) Spills to drains/waterways Spills to ground Soil Erosion Hazard to Flora /Fauna

Other:

RISK RATING TABLE

This table is used to calculate whether the hazard you have identified is Extreme: 9-10 High: 7-8, Medium: 5-6 or Low: 3-4

The objective of rating the risk is to lower the risk by initiating risk control measures. The score is

Consequences: how severe an Likelihood: How likely is it to injury? 1st Aid be that bad? Death Serious Medical

Injuries Treatment Reqd reqd

Almost Certain Expected to Occur

10 9 8 7 6

9 8 7 6

8 7 6 5

7 6 5 4 3

5. EQUIPMENT REQUIRED: Static Plant & Equipment

Mobile Plant & Equipment

Likely could

happen sometime

Moderate could

happen but not likely

Unlikely could

happen but very rare

Revision Date: March 2005

. of ..

Rare - could happen

but probably never will

OHS-03-F01 5 4

POWER

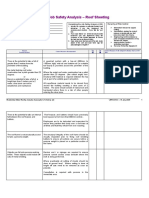

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Safety / Emergency Equipt

noted in the JSA risk score column on the next page both before & after risk control measures have been nominated.

NAME OF TASK: LIFT PERSONNEL IN SCISSOR LIFT

JSA Number: Risk Rating

G02

Rev: Risk Rating

Of the risk following corrective action

Step No.

Logical sequence

Identify the hazards (health and safety or Use table on Break down Job into steps. Each step should accomplish a major task and environmental) associated with each step, the previous page to examine each to find all possible risk factors be logical. score risk Environmental Aspects

Sequence of Basic Job Steps

Potential Safety & Environmental Hazards/Impacts

Recommended Corrective Action or Procedure

Determine what actions are necessary to eliminate or minimise all hazards that could lead to an accident, injury, illness or environmental incident. The risk must be reduced or controlled to a level that is acceptable before work commences. Indicate who is to perform the action where applicable against each action

1 2

Obtain PTW Identify work area

Injury / damage as a result of incorrect information Risk of injury due to low awareness of work environment, Unauthorised operator, Mechanical failure, Falling from heights, Scissors lift topples, Coming into contact with Instruments, Valves or other items.

Obtain correct PTW. Training in PTW system. Operators for this task will be trained and competent in the use of SCISSOR LIFTS no other person is to operate the SCISSOR LIFT for this task, First task is to complete your daily checks to assess that the SCISSOR LIFT is in a safe working condition and complete the attached logbook for future reference. Check all oil and fuel levels where applicable or the charge level of the Electric type units. Prior to SCISSOR LIFT set up assess area for obstructions, drains, uneven or unstable ground and any other item that may raise a concern for the work crew. At all times while driving the SCISSOR LIFT along road ways etc the occupants of the work platform of the scissor lift must keep inside the platforms safety rails If the area that requires the use of a scissor lift is congested, then it is advisable to gain the services of an observer to assist the operator to gain access into the area with out the risk of damage to live plant, equipment or personnel

Revision Date: March 2005

. of ..

OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

3

Set up scissor lift

Fire / explosion

Gain a clearance and permit prior to setting scissor lift up on Roadway. The small electric scissor lift is best to be transported to the relevant work sites with the use of a Franna crane to maintain a high battery level. Scissor lift to be directed to set up area by competent person. Scissor lift to operated (driven) and be set up on firm and level foundation as per manufacturers specifications. While setting up scissor lift and equipment if anything is assessed as a physical risk ask for assistance. If the scissor lift is fitted with an attachment point for a safety harness then all occupants of the scissor lift must wear an approved harness. Visually monitor all scissor lift movements and ask for assistance if vision is obscured. Conduct take 5 and Job Start meeting with the entire work crew to discus tasks at hand any potential hazard that may impact on the safety of Personnel. Gain all relevant road closures to eliminate uncontrolled traffic movement in work area. If the scissor lift is working or parked on the Refinery road system then we must protect our work area, personnel and scissor lift by placing high visibility barricading around this area to eliminate any access from unauthorised vehicles, pedestrians or bicycles from entering the danger zone. While working near the edge of Roadways keep Scissor lift a minimum of 1 metre from the edge of the roadway and operate under the guidance of a spotter. If during the scissor lifts operation the supporting surface subsides or shows signs of the scissor lift wheels penetrating and sinking into the ground or if the work area has altered and is deemed to be unsafe, stop work and contact the work group Supervisor. Make the area safe and then once the concerns are discussed if there is an alternative location the scissor lift can be positioned then conduct a new job start meeting and continue on or if the area cannot be deemed safe to continue, stop the work until it is deemed safe to do so.

Prepare to carry out tasks from scissor Scissor lift topples lift platform Fire, explosion Collision with plant, equipment, Vehicles or personnel. FALLING FROM HEIGHTS Edge of road way collapses

Revision Date: March 2005

. of ..

OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

5

Install and remove equipment as required

Falling tools people below Fall from Scissor lift High winds Hand or eye injury

Barricade work area at ground level to prevent people entering in the danger zone for falling objects Position the scissor lift so that personnel working from the work platform do not have to lean out or over reach past the railing to complete the task. If this is a requirement then stop work and conduct another take 5 and job start to discus the risks and an alternate method for completion of the task at hand. Access the risk from high winds and Electrical storms on a regular basis. halt the job if necessary, assess the conditions and if cleared up conduct take 5 and job start. Gloves and safety glasses must be worn When placing scissor lift into lay down or parking area maintain minimum of 1 metre clearance between the scissor lift wheels and the edge of the roadway. As a suggestion with the small electric scissor it is efficient to transport this unit with a franna crane. Please note this is a guide only for firm and stable ground and each area must be assessed on an individual basis prior to this motion-taking place. The electric scissor lift requires that it is placed on charge at the end of each night, gain all relevant permits and clearances and plug in the tested electrical lead to the end of the unit where the battery L.E.D lights a positioned. electric scissor it is efficient to transport this unit with a franna crane. Please note this is a guide only for firm and stable ground and each area must be assessed on an individual basis prior to this motion-taking place. The electric scissor lift requires that it is placed on charge at the end of each night, gain all relevant permits and clearances and plug in the tested electrical lead to the end of the unit where the battery L.E.D lights a positioned.

Placing scissor lift into lay down or parking area

Scissor lift topples Falling from heights

Revision Date: March 2005

. of ..

OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Revision Date: March 2005

. of ..

OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) CONSULTATION & SIGN-OFF RECORD

I confirm by my signature below, that I have attended a briefing on the requirements of the attached Job Safety & Environment Analysis and agree to perform the work in the manner detailed on it. I confirm that copies of the relevant Permits, MSDS's, Isolation Plans etc. have been reviewed.

JSA NAME JSA No:

Rev: DATE

NAME

(Please print)

SIGNATURE

THIS SAFE WORK BRIEFING / TRAINING WAS CARRIED OUT BY (responsible person at that location) : Name: Signature: Date: Client sign off (where applicable) Site / Project Manager sign off (document reviewed)

Revision Date: March 2005

OHS-03-F01

You might also like

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- JSA M36 Hydro Testing Spool Pieces & PipeworkDocument4 pagesJSA M36 Hydro Testing Spool Pieces & PipeworkMianNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Job Safety Analysis Worksheet: Yes NoDocument8 pagesJob Safety Analysis Worksheet: Yes NoBorislav VulićNo ratings yet

- Tower Crane Installation SOP SummaryDocument3 pagesTower Crane Installation SOP SummaryRashidi RahmanNo ratings yet

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- HIRA FOR Equipment Instalation.Document8 pagesHIRA FOR Equipment Instalation.Deepak G100% (1)

- Electrical Works Safety AnalysisDocument6 pagesElectrical Works Safety AnalysisShaikh Abu bakarNo ratings yet

- JSA for Scaffolding Erection, Dismantling and Other Construction WorksDocument9 pagesJSA for Scaffolding Erection, Dismantling and Other Construction Worksuttam mishra100% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Job Safety Analysis: Night Work at SiteDocument2 pagesJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNo ratings yet

- 052 Sand BlastingDocument2 pages052 Sand Blastingwilson mantilla100% (1)

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Jsa For Lifting Crane 016Document6 pagesJsa For Lifting Crane 016kiran kumar100% (1)

- JSA FOR Moving and Handling MaterialsDocument3 pagesJSA FOR Moving and Handling Materialswahyu nugrohoNo ratings yet

- JSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformDocument6 pagesJSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformRaju KhalifaNo ratings yet

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- 3074 - Use of Genie Man LiftDocument1 page3074 - Use of Genie Man Liftcmrig74No ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Jsa Removal Fixing InsulationDocument2 pagesJsa Removal Fixing InsulationAprilia Rizki Ardila63% (8)

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: Facilitywahyu nugrohoNo ratings yet

- Job Safety Analysis Blank FormatDocument2 pagesJob Safety Analysis Blank FormatKumar KushNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- Suroj Buildcon Pvt. LTD.: Job Safety AnalysisDocument6 pagesSuroj Buildcon Pvt. LTD.: Job Safety AnalysisKiran ChenchalaNo ratings yet

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- HIRA - Night Work Hazard ControlDocument3 pagesHIRA - Night Work Hazard ControlHiralal PattanayakNo ratings yet

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Document3 pagesJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21No ratings yet

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- JHA Example Installation of Underfloor Plumbing and DrainsDocument15 pagesJHA Example Installation of Underfloor Plumbing and DrainsShamel Jen FacundoNo ratings yet

- JSA Fire Fighting WorkDocument8 pagesJSA Fire Fighting WorkMehul KolambkarNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Jsa Working at Height (Maintenance & Cleaning)Document2 pagesJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (1)

- Roof Sheeting SafetyDocument6 pagesRoof Sheeting SafetyMomo XxxxNo ratings yet

- Job Safety Analysis (JSA) : Commercial Roofing-Membrane InstallationDocument4 pagesJob Safety Analysis (JSA) : Commercial Roofing-Membrane InstallationRakesh Chauhan100% (1)

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- Jsa Civil Work (00000002)Document6 pagesJsa Civil Work (00000002)Ali AlahmaNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- Jsa For Hvac Equipment InstallDocument4 pagesJsa For Hvac Equipment Installpowergroup engineersNo ratings yet

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 pagesEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- JSA Excavation PDFDocument6 pagesJSA Excavation PDFmohamedamine.zemouriNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Column Erection JSA AnalysisDocument6 pagesColumn Erection JSA AnalysisRaghava Richhu100% (2)

- JSA For Insulation of VesselDocument6 pagesJSA For Insulation of Vesselyc safetyNo ratings yet

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- JSA FORMAT For Materials LoadingDocument2 pagesJSA FORMAT For Materials LoadingVikky KumarNo ratings yet

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- JSA For Flue Gas Duct Height WorkDocument4 pagesJSA For Flue Gas Duct Height Worksubhadipmanna8No ratings yet

- JSA of Pipe Unloading.Document2 pagesJSA of Pipe Unloading.vijay kumar singh100% (1)

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- Crane Mobile SpecificationDocument13 pagesCrane Mobile Specificationsancakemre100% (2)

- Service Valve: With ISO-fitting For PE Pipe Both Ends No. 2600Document2 pagesService Valve: With ISO-fitting For PE Pipe Both Ends No. 2600Wonmin JeongNo ratings yet

- Unirub Techno India PVT 7Document7 pagesUnirub Techno India PVT 7BalajiYachawadNo ratings yet

- My first experience student teaching chemistry at Manila Science High SchoolDocument2 pagesMy first experience student teaching chemistry at Manila Science High SchoolIta Adri SupriatiNo ratings yet

- Indirect RestorationsDocument32 pagesIndirect RestorationsNaji Z. Arandi100% (1)

- Brief History of Safety ValvesDocument21 pagesBrief History of Safety ValvesUdhayakumar VenkataramanNo ratings yet

- Material Safety Data Sheet - Surgical NeedlesDocument4 pagesMaterial Safety Data Sheet - Surgical NeedlesAri CleciusNo ratings yet

- OPSS 369 Nov08Document7 pagesOPSS 369 Nov08Muhammad UmarNo ratings yet

- AUGMENTIN Syrup: What Is in This Leaflet?Document5 pagesAUGMENTIN Syrup: What Is in This Leaflet?Rafaela LennyNo ratings yet

- (Unit 1&2) PDFDocument41 pages(Unit 1&2) PDFJaiPrakashNo ratings yet

- Product Information Sheet: Phytotechnology Laboratories®Document1 pageProduct Information Sheet: Phytotechnology Laboratories®Jiovanni AmbNo ratings yet

- Method Statement For Installation of Water Recticulation SystemDocument18 pagesMethod Statement For Installation of Water Recticulation SystemRabi'atul Adawiyah Ismail100% (2)

- Studies On Degradation of Synthetic Polymer Nylon 6 by FungusDocument8 pagesStudies On Degradation of Synthetic Polymer Nylon 6 by FungusTiten PinastiNo ratings yet

- Advantage and Disadvantage of Using Nanoparticles in AgricultureDocument13 pagesAdvantage and Disadvantage of Using Nanoparticles in AgricultureAmjadRashidNo ratings yet

- Int Esws at Y9 Workbook Answers TTPPDocument37 pagesInt Esws at Y9 Workbook Answers TTPPChrystal GraceNo ratings yet

- Crosslinker CX100 MsdsDocument59 pagesCrosslinker CX100 MsdsMimi rastamNo ratings yet

- Material Safety Data Sheet Konkreton XSDocument9 pagesMaterial Safety Data Sheet Konkreton XSDaniel DaiaNo ratings yet

- Cambridge IGCSE Physics Coursebook Second Edition (Cambridge University Press) - Pages-DeletedDocument22 pagesCambridge IGCSE Physics Coursebook Second Edition (Cambridge University Press) - Pages-DeletedMariam ShehabNo ratings yet

- Phase I document covers states of matter basicsDocument41 pagesPhase I document covers states of matter basicsdivakarsNo ratings yet

- Chemistry-College 3Document10 pagesChemistry-College 3Subhabrata MabhaiNo ratings yet

- LubKlear Brochure LubLineDocument2 pagesLubKlear Brochure LubLineMarcela FariasNo ratings yet

- Antimicrobial TherapyDocument18 pagesAntimicrobial TherapyekasukmawatyNo ratings yet

- Screw Gluing Pressure Distribution and Bond StrengthDocument10 pagesScrew Gluing Pressure Distribution and Bond Strengthm2auNo ratings yet

- Membrane Technology: Reverse Osmosis Ultrafiltration MicrofiltrationDocument66 pagesMembrane Technology: Reverse Osmosis Ultrafiltration MicrofiltrationShivani MunishwarNo ratings yet

- Motorized Butterfly Valve With Actuator JJ (WAFN3 - MSEENR)Document10 pagesMotorized Butterfly Valve With Actuator JJ (WAFN3 - MSEENR)hvacvn1984No ratings yet

- Production of Insulating Refractory Bricks From Kankara Kaolin Using AchaDocument150 pagesProduction of Insulating Refractory Bricks From Kankara Kaolin Using AchaSAMUEL PSALMNo ratings yet

- UV Led TransmittanceDocument6 pagesUV Led TransmittanceAmandineNo ratings yet

- Protective Paints For Heat Treatment of SteelsDocument4 pagesProtective Paints For Heat Treatment of SteelsMauricio Cesar DalzochioNo ratings yet

- 13 Fluid and Electrolyte Balance محاضرةDocument69 pages13 Fluid and Electrolyte Balance محاضرةRasheed SadekNo ratings yet

- Microwave, IR, NMR spectroscopy techniquesDocument1 pageMicrowave, IR, NMR spectroscopy techniquesSaikiranNo ratings yet

- NORD-Painting CodeDocument3 pagesNORD-Painting CodeubabNo ratings yet