Professional Documents

Culture Documents

642

Uploaded by

Sunil SharmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

642

Uploaded by

Sunil SharmaCopyright:

Available Formats

CODE NO: R09220303

R09

SET No - 1

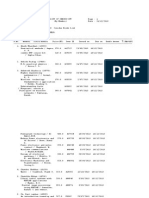

II B.TECH - II SEMESTER EXAMINATIONS, APRIL/MAY, 2011 APPLIED THERMODYNAMICS I (AUTOMOBILE ENGINEERING) Time: 3hours Max. Marks: 75 Answer any FIVE questions All Questions Carry Equal Marks --1.a) Briefly explain the effect of the compression ratio on the thermal efficiency of Otto cycle. b) What are different factors that differentiate the actual Diesel cycle from that of ideal cycle? [7+8] 2.a) b) 3.a) b) What is the function of a Carburetor and what are the engine air-fuel ratio requirements? What are the requirements of fuel injection system for CI engines? What are the differences between air less and air injection of fuel in CI engines? [7+8] Briefly explain different stages of combustion in SI engines with the help of Pressure Vs crank angle diagram. What is the effect of the following parameters on the ignition delay of SI engine combustion? i) Nature of air-fuel ratio ii) Speed iii) Temperature of the gas [7+8] With the help of a simple schematic diagram, explain the working of a turbulence combustion chamber of CI engine. What are its advantages compared to other type of combustion chambers. What are the important qualities of CI engine fuels? [8+7] What is the function of a dynamo meter? Give the classification of dynamo meter. Design bore and stroke of 4s petrol engine for the following data: Brake Power = 73.5 kW Speed = 400 RPM Brake MEP = 8.5 bar Mechanical efficiency = 80% Brake SFC = 0.346 kg/kWh Calorific value = 44100 kJ/kg Compression ratio = 6 Also calculate indicated power, BP air standard and relative efficiency and indicated MEP. Assume that bore is equal to stroke. [7+8] A single acting reciprocating compressor having 8 cm bore and 10 cm stroke compresses air from 1 bar to a delivery pressure of 6 bar. The compressed gas is stored in a receiver having a capacity of 1.2 m3. The speed of the compressor is 500 RPM and consumes 1.175 kW brake power. The indicated mean effective pressure is 2.24 bar. The initial conditions in the reservoir were 1 bar and 150C. After 2 minutes of pumping the pressure rise in the receiver is 6 bar at 520C. Find i) Free air delivered per minute at 150C ii) Volumetric efficiency iii) Mechanical and isothermal efficiencies. [15] Give the classification of compressors based on the principle of operation. Discuss the effect of compressor geometry on the compression efficiency of centrifugal compressor. [7+8] Discuss various losses in an axial flow compressor stage. Give the comparison between reciprocating and axial flow compressors based on various factors. [7+8] ********

4.a)

b) 5.a) b)

6.

7.a) b) 8.a) b)

CODE NO: R09220303

R09

SET No - 2

II B.TECH - II SEMESTER EXAMINATIONS, APRIL/MAY, 2011 APPLIED THERMODYNAMICS I (AUTOMOBILE ENGINEERING) Time: 3hours Max. Marks: 75 Answer any FIVE questions All Questions Carry Equal Marks --1.a) Discuss the deviations of actual Otto cycle from that of ideal. b) In an air standard Diesel cycle, the compression ratio is 15 and the pressure and temperature at the beginning of compression are 1.04 bar and 150C. The maximum temperature of the cycle is 2330 K. Determine the thermal efficiency and the mean effective pressure. [7+8] 2. 3.a) b) 4.a) b) 5.a) b) What are the elements of the complete carburetor system? Explain the function of each in detail. [15] What are the different variables affecting the knock in SI engines ? Briefly explain different methods to reduce detonation in SI engines. [7+8]

Explain the effect of inlet temperature and pressure, engine speed, engine size, injection pressure and chemical composition of fuel on Diesel knock. With the help of simple schematic, explain the working of different types of direct combustion chambers of CI engines [7+8] What is the use of Morse test on multi cylinder engines? Briefly explain. During the testing of a 4s oil engine fitted with a simple rope brake dynamo meter, the following readings were taken. Brake wheel diameter = 60 cm Brake rope diameter = 2.5 cm Dead load on the brake = 200 N Spring balance reading = 50 N Speed = 450 RPM Area of indicator diagram = 4.2 cm2 Length of the indicator diagram = 6 cm Spring constant = 6 bar/ cm Bore = 10 cm Stroke = 15 cm Brake SFC = 0.3 kg/kWh Calorific value = 43960 kJ/kg Determine the brake power, mechanical efficiency and indicated thermal efficiency. [15] The free air delivered by a single stage double acting air compressor measured at 1.013 bar and 150C is 14 m3/min. The pressure and temperature of the cylinder during induction are 0.95 bar and 320C. The delivery pressure is 7 bar and the index of compression and expansion are 1.3. If the clearance volume is 5% of the swept volume, calculate indicated power, delivery temperature and volumetric efficiency. [15] What are the different losses in case of a centrifugal compressor? With the help of neat schematic, explain the working of a roots blower and its mechanical details. [7+8] Derive the expression for work done in a typical axial flow compressor stage with the help of velocity triangles. Briefly explain the phenomenon of surging in axial flow compressors. [8+7] ********

6.

7.a) b) 8.a) b)

CODE NO: R09220303

R09

SET No - 3

II B.TECH - II SEMESTER EXAMINATIONS, APRIL/MAY, 2011 APPLIED THERMODYNAMICS I (AUTOMOBILE ENGINEERING) Time: 3hours Max. Marks: 75 Answer any FIVE questions All Questions Carry Equal Marks --1.a) b) Briefly explain the effect of dissociation of gas on the performance of the Otto cycle with the help of p-V diagram. An engine operates on ideal Diesel cycle with a compression ratio of 12 and the fuel is injected for 10% of the stroke. The pressure of the air entering the cylinder is 0.98 bar and the temperature is 150C. Calculate the cut off ratio, temperature at the end of the compression process and the heat input. [7+8] With the help of a simple schematic diagram, explain the working of a magneto ignition system. What are the requirements of an ignition system in SI engines? [8+7] What are the effects of knock on the performance of SI engines ? Differentiate between normal and abnormal combustion with the help of flame propagation diagram and Pressure Vs crank angle diagram in SI engines. [7+8] Explain why and how knock occurs in CI engines. Compare the phenomena of knock in SI and CI engines with the help of pressure Vs crank angle diagram. Explain the effect of following parameters on the delay period in Diesel knock: i) Compression ratio ii) injection timing iii) fuel volatility. [7+8] What are the factors that affect the volumetric efficiency of an IC engine? A four cylinder, 4s petrol engine has 7.5 cm bore and 10.5 cm stroke. The clearance volume in each cylinder is 1/7th of the swept volume. The speed of the engine measured by a Tachometer is 2000 RPM and the torque at this speed is 70 N. The fuel consumption is 4.5 kg/h. Assuming brake efficiency ratio based on air standard cycle is 60, calculate brake mep and calorific value of the fuel. If the engine has a mechanical efficiency of 80%, calculate the indicated thermal and relative efficiency. [7+8] A 23 kW electric motor drives a single cylinder, single acting air compressor running at 300 RPM. The mechanical efficiency is 87%. The air inlet conditions are 1.013 bar and 150C and the delivery pressure is 8 bar. Assuming that the index of compression and expansion is n = 1, clearance volume is 7% of the swept volume and L = D, calculate the free air delivery in m3/min, volumetric efficiency and the dimensions of the compressor. [15]

2.a) b) 3.a) b)

4.a) b)

5.a) b)

6.

7.a) b)

How the rotary compressors are different from reciprocating compressors? Compare. Derive the expression for work supplied to the gas in a stage of a centrifugal compressor with the help of velocity triangles. [8+7] Explain the phenomenon of surging in stage of an axial flow compressor. Discuss various losses in an axial flow compressor stage in detail. ********

8.a) b)

[8+7]

CODE NO: R09220303

R09

SET No - 4

II B.TECH - II SEMESTER EXAMINATIONS, APRIL/MAY, 2011 APPLIED THERMODYNAMICS I (AUTOMOBILE ENGINEERING) Time: 3hours Max. Marks: 75 Answer any FIVE questions All Questions Carry Equal Marks --1.a) The swept volume of four cylinder petrol engine is 2000 cm3. The clearance volume of each cylinder is 60 cm3. Determine the air standard thermal efficiency. If the inlet conditions are 1 bar and 240C, and the maximum cycle temperature is 14000C, determine the mean effective pressure. Briefly explain the effect of heat losses, blow down losses and pumping losses on the performance of the Otto cycle. [8+7] In case of SI engine or CI engine, give the reason for the size of suction valve being greater than that of delivery. Describe the principle of working of a simple carburetor and mention its defects.[8+7] What is the effect of engine variables on the flame speed? What are the requirements of combustion chambers for the better performance of SI engines? Explain briefly. [7+8] What are the different stages of combustion in CI engines? Explain in detail with the help of pressure Vs crank angle diagram. [15] What are the different methods employed to find the indicated power of IC engines without using indicator? During the testing of a single cylinder 4s oil engine fitted with a simple rope brake dynamo meter, the following readings were taken. Brake wheel diameter = 65 cm Brake rope diameter = 3 cm Dead load on the brake = 270 N Spring balance reading = 40 N Speed = 450 RPM Area of indicator diagram = 4.2 cm2 Length of the indicator diagram = 6.5 cm Spring constant = 12 bar/ cm Bore = 11 cm Stroke = 16 cm Brake SFC = 0.3129 kg/kWh Calorific value = 41868 kJ/kg Determine the brake power, indicated power, mechanical efficiency and indicated and brake thermal efficiency [7+8] A single acting reciprocating compressor having 8 cm bore and 10 cm stroke compresses air from 1 bar to a delivery pressure of 6 bar. The compressed gas is stored in a receiver having a capacity of 1.2 m3. The speed of the compressor is 500 RPM and consumes 1.175 kW brake power. The indicated mean effective pressure is 2.24 bar. The initial conditions in the reservoir were 1 bar and 150C. After 2 minutes of pumping the pressure rise in the receiver is 6 bar at 520C. Find i) Free air delivered per minute at 150C ii) Volumetric efficiency iii) Mechanical and isothermal efficiencies. [15]

b)

2.a) b) 3.a) b)

4.

5.a) b)

6.

7.a) b)

Discuss the influence of impeller blade shape on the performance of a centrifugal compressor. With the help of a neat schematic, explain the working of a vane sealed compressor and give its applications. [7+8] Enumerate the fields of applications of compressors in general and axial flow compressors in particular. Explain the phenomena of stalling and choking in axial flow compressors. [8+7]

8.a) b)

********

You might also like

- Biomimicry: Exploring Research, Challenges, Gaps and Tools (Paper ID 102)Document15 pagesBiomimicry: Exploring Research, Challenges, Gaps and Tools (Paper ID 102)Sunil SharmaNo ratings yet

- Arbitrary Axis RotationDocument6 pagesArbitrary Axis RotationSunil SharmaNo ratings yet

- Training Calendar For The M/o May 2014 Topic/Area Programme Code Trainer/Resource Person Time Date of Training Name Designation Division/School Sr. No Target Audience (As Per List Attached)Document18 pagesTraining Calendar For The M/o May 2014 Topic/Area Programme Code Trainer/Resource Person Time Date of Training Name Designation Division/School Sr. No Target Audience (As Per List Attached)Sunil SharmaNo ratings yet

- Civ339:Hydraulics and Hydraulic Machinery Laboratory: Course OutcomesDocument1 pageCiv339:Hydraulics and Hydraulic Machinery Laboratory: Course OutcomesSunil SharmaNo ratings yet

- Time Table For Registration Number: 11601081 Home SectionDocument2 pagesTime Table For Registration Number: 11601081 Home SectionSunil SharmaNo ratings yet

- MTE ANALYSIS-Student Feedback Form: S.No Student Name Regd - NO MM 40 Reason For Low Performance SignatureDocument1 pageMTE ANALYSIS-Student Feedback Form: S.No Student Name Regd - NO MM 40 Reason For Low Performance SignatureSunil SharmaNo ratings yet

- LS Srinath Four Chapters CompleteDocument137 pagesLS Srinath Four Chapters CompleteSunil SharmaNo ratings yet

- Sop 2Document2 pagesSop 2Sunil SharmaNo ratings yet

- PopularScience of NoblePhysics2016 PDFDocument5 pagesPopularScience of NoblePhysics2016 PDFSunil SharmaNo ratings yet

- Faculty's Time Table: Sunil Sharma 16727Document1 pageFaculty's Time Table: Sunil Sharma 16727Sunil SharmaNo ratings yet

- Friday Name of The School Saturday Name of The School First Friday First SaturdayDocument2 pagesFriday Name of The School Saturday Name of The School First Friday First SaturdaySunil SharmaNo ratings yet

- Effect of Chromium Powder Mixed Dielectric On Performance Characteristic of Aisi D2 Die Steel Using EDMDocument15 pagesEffect of Chromium Powder Mixed Dielectric On Performance Characteristic of Aisi D2 Die Steel Using EDMSunil SharmaNo ratings yet

- Faculty's Time Table: Sumeet Nagar 11588Document1 pageFaculty's Time Table: Sumeet Nagar 11588Sunil SharmaNo ratings yet

- PCC AC NewDocument1 pagePCC AC NewSunil SharmaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- List of Coaches: S No Name Designation Id No Contact No. VenueDocument2 pagesList of Coaches: S No Name Designation Id No Contact No. VenueSunil SharmaNo ratings yet

- R PT Timetable StudentDocument2 pagesR PT Timetable StudentSunil SharmaNo ratings yet

- 22 - Research Projects - Sanctioned TDocument1 page22 - Research Projects - Sanctioned TSunil SharmaNo ratings yet

- T AmountDocument5 pagesT AmountSunil SharmaNo ratings yet

- NDT - Non Destructive TestingDocument2 pagesNDT - Non Destructive TestingSunil Sharma100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- A Simple Lamina Flow Engine PDFDocument2 pagesA Simple Lamina Flow Engine PDFSelva KumarNo ratings yet

- Haltech Diagram HT-150400 - QSGDocument16 pagesHaltech Diagram HT-150400 - QSGalistercantNo ratings yet

- Dynamics MachinesDocument40 pagesDynamics MachinessivaprasathNo ratings yet

- Hyundai HD78 Fuel SystemDocument485 pagesHyundai HD78 Fuel SystemBigfair HD7890% (29)

- Robin WR Ey18 3wDocument8 pagesRobin WR Ey18 3wFelix Acebey0% (1)

- Electric Power Technical Standards (2004)Document523 pagesElectric Power Technical Standards (2004)Montree SupaphobNo ratings yet

- Chapter 1Document24 pagesChapter 1ahmed jemalNo ratings yet

- Datos Oreda Modos de Falla Parte MantenibleDocument135 pagesDatos Oreda Modos de Falla Parte MantenibleCarlos Jose Sibaja Cardozo100% (1)

- CATALOGO DE PEÇAS KOMATSU PC 200 - PC 200LC-8 Maquina BaseDocument443 pagesCATALOGO DE PEÇAS KOMATSU PC 200 - PC 200LC-8 Maquina BaseBruno Jonatas Mendes100% (2)

- Business Portal Online Print 27-10-2020Document139 pagesBusiness Portal Online Print 27-10-2020sxturboNo ratings yet

- Diagrama Maxxfoce 11-13 PDFDocument2 pagesDiagrama Maxxfoce 11-13 PDFRuthAnaya100% (1)

- Yba 125Document59 pagesYba 125Luis Emanuel CastroNo ratings yet

- Air Compressor ProblemsDocument10 pagesAir Compressor ProblemslynNo ratings yet

- Yanmar L70N5E PartlistDocument50 pagesYanmar L70N5E PartlistYew LimNo ratings yet

- Detroit Diesel Series 60 IndustrialDocument6 pagesDetroit Diesel Series 60 IndustrialJaimEdu Cortes100% (1)

- Navistar DT466E y 530E ElectronicoDocument226 pagesNavistar DT466E y 530E Electronicocristian picadoNo ratings yet

- BMWDocument5 pagesBMWlorenscribd100% (1)

- PSL 8.8l Propane Service ManualDocument76 pagesPSL 8.8l Propane Service ManualUziel PavónNo ratings yet

- 4runner Wiring DiagramDocument82 pages4runner Wiring Diagramzwesley0% (1)

- A-Team Performance Hei Distributor Installation InstructionsDocument1 pageA-Team Performance Hei Distributor Installation Instructionscolo1evanNo ratings yet

- Internal Combustion Engines: Engine FundamentalsDocument31 pagesInternal Combustion Engines: Engine FundamentalsshubhamNo ratings yet

- (Mechanical Engineering Series) Massoud Kaviany (Auth.) - Principles of Convective Heat Transfer (2001, Springer-Verlag New York) PDFDocument722 pages(Mechanical Engineering Series) Massoud Kaviany (Auth.) - Principles of Convective Heat Transfer (2001, Springer-Verlag New York) PDFAbgail PinheiroNo ratings yet

- Manual DetroitDieselandFreightliner DieselTech PDFDocument38 pagesManual DetroitDieselandFreightliner DieselTech PDFGreg Pulido100% (1)

- Qute - LHD&RHD - Sp.Catalogue - 190816 от 19,08,2016Document85 pagesQute - LHD&RHD - Sp.Catalogue - 190816 от 19,08,2016Indranil BhattacharyyaNo ratings yet

- D25a Parts Catalog #7745010Document177 pagesD25a Parts Catalog #7745010Peskishev Konstantin100% (1)

- Starting From Fg. - NR. MLHJC34A 45 Service Manual: 64 KPP 00Document20 pagesStarting From Fg. - NR. MLHJC34A 45 Service Manual: 64 KPP 00Johann Koch100% (1)

- B&W & 7editionl-Mcmce EnginesDocument398 pagesB&W & 7editionl-Mcmce EnginesArsentiiNo ratings yet

- Tata Hitachi Zaxis 220 LC Construction Machine PDFDocument3 pagesTata Hitachi Zaxis 220 LC Construction Machine PDFYashraj KajaveNo ratings yet

- Diesel Engine For 1990sDocument165 pagesDiesel Engine For 1990schandru_82No ratings yet

- P126Ti G-Drive: Power RatingDocument2 pagesP126Ti G-Drive: Power Ratingsambuka9750% (1)