Professional Documents

Culture Documents

Gap Supply Chain

Uploaded by

Yingxuan TanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gap Supply Chain

Uploaded by

Yingxuan TanCopyright:

Available Formats

Factsheet 2b Case study: the structure ofG ap suppl chai s y n

www.fashioninganethcialindustry.org

Introduction

The following case-study shows the length and complexity of the supply chains of major brands, in this case Gap. It is taken from Bri ng the G ap:a l at G ap suppl chai from dgi ook s y n 1 the workplace to the store, Women Working Worldwide (2003) . The study represents a typical garment supply chain, and is not intended to single out GAP for criticism. Based in San Francisco, Gap has over 3,000 stores throughout the world, employs 150,000 workers and in 2004 had sales of nearly 16.3 billion US dollars. As a retailer, Gap focuses on design, merchandising and branding. It does not manufacture any of the products it sells. In 2003, it was buying from over 3,000 companies in approximately 50 countries.

1 Although the focus of Women Working Worldwide research was not Gap, the sheer size of the company means

that the researchers often came across suppliers to the company. Gap was therefore taken as an example of how current supply chains are structured.

Factsheet 2b Case study:the structure ofG ap suppl chai s y n brief history of the fashion industry

www.fashioninganethcialindustry.org

The actors

Gap Stores: Sal data are constantl rel es y ayed to G ap Regi s onalheadquarters (see bel )i ow n order to monitor what products are selling and which are not. This information is used to plan and refine sourcing and design strategies. Gap USA: Thi i the com pany overal headquarters.There are al regi ss s l so onalheadquarters i n Europe, Canada and Japan. Departments responsible for design, sourcing and monitoring factories are located in Gap USA as well as in regional headquarters. Gap International Regional Sourcing Office: The regional sourcing office is responsible for sending out contracts to manufacturers and, generally, for choosing the manufacturers to whom the designs are contracted. Gap International - National Sourcing Office: Gap has national sourcing offices in countries where significant production is carried out (e.g. Philippines, Pakistan and Bangladesh). National sourcing offices are generally responsible for quality control and for the monitoring of working conditions in factories. Sometimes they are also responsible for shipping finished garments. Note: we have not used the real names of the following stakeholders. Blue Textile and Garment Manufacturing (Blue T&G): This is the headquarters of a large textile and garment manufacturing company. Blue Textiles and Garment Manufacturing is a transnational company with factories in several different countries. It receives orders from agents and from buying houses as well as through its own, in-house buying office. It receives orders from l arge com pani lke the G ap,through the com pany regi es i s onalsourci offi ng ces. Large transnationals like Blue T&G are responsible for sourcing the raw materials and for the production and distribution of the finished garments. It is easier for Gap to work with companies that also produce textiles: it is cheaper and reduces turnaround time as both sections of the company work together on deadlines. In this example, Blue Textiles and Blue Garments coordinate their schedules so production can be planned more efficiently. Equally, working with large companies makes it easier for Gap to monitor quality and working conditions. Blue Textiles: Blue Textiles is a subsidiary of Blue Textile and Garment Manufacturing. It produces some of the textiles that will be used by Blue Garments but does not have the capaci to suppl al ofG ap needs.G ap therefore al orders texties from l ty y l s so l arge m il that do ls not have manufacturing firms for instance Orange Textiles in the diagram. When the textiles are ready, they are sent to Blue Garments. Blue Garments: Blue Garments is also a subsidiary of Blue Textile and Garment Manufacturing. Garments are cut and sewn here and this where all raw materials are sent. Blue Garments is a first tier manufacturer contracted to produce the Gap order. The number of workers in Blue Garments is stable. Not all production, however, is done in this factory. Blue Garments may sub-contract some or all of the production - to factories it may or may not own (it owns Blue small factory but not Purple small factory). There are several reasons why it may do that:

Factsheet 2b Case study:the structure ofG ap suppl chai s y n brief history of the fashion industry

www.fashioninganethcialindustry.org

it may have accepted orders that are bigger than it can handle; it may be required to deliver more quickly than it can manage; Purple small factory may have agreed to do the work for a cheaper price than Blue Garments or Blue small factory.

Gap does not like production to be sub-contracted to smaller factories, but it does happen. Blue small factory: Big companies like Blue T&G often have smaller factories that take the overflow of work or time-consuming work. They are second tier manufacturers. Conditions are generally worse in these units than in first tier manufacturers as the smaller units employ women on short contracts or without contracts at all and pay piece rate wages. Purple small factory: This is also a second tier manufacturer, a small factory that is not owned by Blue T&G. Small factories like Purple are often funded through local capital rather foreign investment. It sub-contracts orders from Blue Garments. Research found that owners of small units like Purple small factory frequently have a personal connection with the management of the company from whom they sub-contract. They may be former workers, related to a member of management or may be a member of management who has set up his own small factory. Generally, these factories have worse working conditions as workers are temporary and are paid piece rate. This gives the company flexibility to hire and fire workers according to demand. When there is less work, they let workers go, when there is more work, they can hire extra workers on contracts. Agent: Blue Garments may also sub-contract work to an agent. Agents function at all levels of the supply chain. They may work with small or large volumes of production. At the top of the chain there are buying houses employing many agents. At the lower end of the chain, agents tend to operate individually. The agent is sub-contracted by the company either a first tier or second tier company to carry out either part or all of an operation: this is frequently stitching or finishing. Individual agents frequently have personal contacts in the factory: they may be a former employee or be related to someone in management or even be a line manager at the main factory. They are often paid in advance and many earn over 20% in commission. The agent may also sub-contract the work to another, second or third tier manufacturer. Homeworkers: They generally work from home or in small workshops, often based in a nei ghbour house.They get j because they know the agent personaly.They norm aly pay s obs l l their own overheads, from machines and thread to electricity. Work is infrequent: sometimes they go months without work. In peak season, they may have to work 12-14 hours a day, seven days a week. They are paid less than factory workers for the same work.

Moving down the supply chain

O rders for new desi are sent to G ap I gns nternati Regi onals onalSourcing Office, in this case in Asi (there are others i South Am eri and Europe).G ap Asi Regi a n ca s an onalSourci O ffi i ng ce s

Factsheet 2b Case study:the structure ofG ap suppl chai s y n brief history of the fashion industry

www.fashioninganethcialindustry.org

based in Singapore. The Singapore office will give the order directly to a large manufacturer like Blue Textile and Garment Manufacturing which will make up samples of the designs. If the sam pl are accepted by G ap,they w ilnegoti on pri m ateri s and delvery.G ap es l ate ce, al i s preference is for big manufacturers who are able to produce large volumes of high quality garments. In the case of re-ordering popular products, computerised check-out tills send sales information from every store to the Regional Headquarters, telling brand managers and merchandisers which garments are selling well and need re-ordering. These orders are then sent to National Sourcing Offices (there are many in Asia and other regions) which then passes the order on to first tier suppliers, normally a large factory like Blue Textiles and Garment Manufacturing. National Sourcing Offices also monitor quality and scheduling and organise shipping and factory checks.

Further reading

Adapted/extracted from: Bri ng the G ap:a l at G ap suppl chai from the w orkpl to the store, Women dgi ook s y n ace Working Worldwide (2003) <http://www.women-ww.org/!GAP_BOO.PDF> Sub-contracting Chains in the Garment Industry, Women Working Worldwide (June 2003)

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Squirrel Cage Induction Motor Preventive MaintenaceDocument6 pagesSquirrel Cage Induction Motor Preventive MaintenaceNishantPareekNo ratings yet

- Analysis of Material Nonlinear Problems Using Pseudo-Elastic Finite Element MethodDocument5 pagesAnalysis of Material Nonlinear Problems Using Pseudo-Elastic Finite Element MethodleksremeshNo ratings yet

- Saet Work AnsDocument5 pagesSaet Work AnsSeanLejeeBajan89% (27)

- Form16 2018 2019Document10 pagesForm16 2018 2019LogeshwaranNo ratings yet

- Selvan CVDocument4 pagesSelvan CVsuman_civilNo ratings yet

- RENCANA KERJA Serious Inspeksi#3 Maret-April 2019Document2 pagesRENCANA KERJA Serious Inspeksi#3 Maret-April 2019Nur Ali SaidNo ratings yet

- 30 Creative Activities For KidsDocument4 pages30 Creative Activities For KidsLaloGomezNo ratings yet

- Low Cost Building ConstructionDocument15 pagesLow Cost Building ConstructionAtta RehmanNo ratings yet

- A PDFDocument2 pagesA PDFKanimozhi CheranNo ratings yet

- Professional Regula/on Commission: Clarita C. Maaño, M.DDocument31 pagesProfessional Regula/on Commission: Clarita C. Maaño, M.Dmiguel triggartNo ratings yet

- Sustainable Urban Mobility Final ReportDocument141 pagesSustainable Urban Mobility Final ReportMaria ClapaNo ratings yet

- Capital Expenditure DecisionDocument10 pagesCapital Expenditure DecisionRakesh GuptaNo ratings yet

- Course Specifications: Fire Investigation and Failure Analysis (E901313)Document2 pagesCourse Specifications: Fire Investigation and Failure Analysis (E901313)danateoNo ratings yet

- SCDT0315 PDFDocument80 pagesSCDT0315 PDFGCMediaNo ratings yet

- Basics: Define The Task of Having Braking System in A VehicleDocument27 pagesBasics: Define The Task of Having Braking System in A VehiclearupNo ratings yet

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocument7 pagesPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiNo ratings yet

- Doas - MotorcycleDocument2 pagesDoas - MotorcycleNaojNo ratings yet

- 450i User ManualDocument54 pages450i User ManualThượng Lê Văn0% (2)

- BMA Recital Hall Booking FormDocument2 pagesBMA Recital Hall Booking FormPaul Michael BakerNo ratings yet

- Water Hookup Kit User Manual (For L20 Ultra - General (Except EU&US)Document160 pagesWater Hookup Kit User Manual (For L20 Ultra - General (Except EU&US)Aldrian PradanaNo ratings yet

- TLE - IA - Carpentry Grades 7-10 CG 04.06.2014Document14 pagesTLE - IA - Carpentry Grades 7-10 CG 04.06.2014RickyJeciel100% (2)

- Banjara EmbroideryDocument34 pagesBanjara EmbroideryKriti Rama ManiNo ratings yet

- BluetoothDocument28 pagesBluetoothMilind GoratelaNo ratings yet

- Droplet Precautions PatientsDocument1 pageDroplet Precautions PatientsMaga42No ratings yet

- Check Fraud Running Rampant in 2023 Insights ArticleDocument4 pagesCheck Fraud Running Rampant in 2023 Insights ArticleJames Brown bitchNo ratings yet

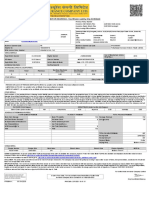

- MOTOR INSURANCE - Two Wheeler Liability Only SCHEDULEDocument1 pageMOTOR INSURANCE - Two Wheeler Liability Only SCHEDULESuhail V VNo ratings yet

- Executive Summary - Pseudomonas AeruginosaDocument6 pagesExecutive Summary - Pseudomonas Aeruginosaapi-537754056No ratings yet

- HandloomDocument4 pagesHandloomRahulNo ratings yet

- 4109 CPC For ExamDocument380 pages4109 CPC For ExamMMM-2012No ratings yet

- Form Three Physics Handbook-1Document94 pagesForm Three Physics Handbook-1Kisaka G100% (1)