Professional Documents

Culture Documents

Glow Wire Test IEC 60696-2-11

Uploaded by

Rana Tahir SultanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glow Wire Test IEC 60696-2-11

Uploaded by

Rana Tahir SultanCopyright:

Available Formats

Fire safety test methods Standards

2. Test methods Standards

The glow wire test to IEC 60695-2, EN 60695-2, VDE 0471-2 The glow wire test to IEC 60695-2-11 is used to test electrical products, assemblies or individual components. The glow wire temperature (Fig. 2) is determined by the Electrical Equipment Committee as a function of the type of risk arising when the product is used. During the test, a note is made of the burning time te (s) after an application time of 30 s, and the dropping of burning or glowing particles of the specimen. The test is considered passed if a) the specimen does not constitute an ignition risk to the environment and b) any flames or glowing on the test specimen extinguish not later than 30 seconds after removal of the ignition source. The glow wire test to IEC 60695-2-12 can also be used to test simple material specimens e.g. discs. The test determines the glow wire flammability index (GWFI), this being the highest temperature at which flaming or glowing of the specimen extinguishes within 30 seconds of the removal of the glow wire coil, without burning or glowing particles dropping onto and igniting the material situated below the specimen. In another version of this test (the glow wire test to IEC 60695-2-13), the ignitability of different materials can be compared. The glow wire ignitability temperature (GWIT) determined here is 25 K higher than the highest temperature (glow wire temperature) that does not lead to ignition (flaming combustion time > 5 s) in three successive tests (Fig. 3).

Glow wire test apparatus

4 mm Test specimen = finished part Temperatures of glow wire: 550, 650, 750, 850, 960 C Maximum penetration depth: 7 mm, pressing force 1 N Application time: 30 s DIN IEC 60695-2-11 Burning or glow time 30 s Paper and wood undamaged

Fig. 2

Fire safety tests using the glow wire test apparatus

IEC 60695-2-11 glow wire test Specimen Electrical product IEC 60695-2-12 GWFI IEC 60695-2-13 GWIT

Sheet Minimum dimensions: 60 mm x 60 mm Preferred thicknesses: 0.75, 1.5, 3.0 mm 48 h at 23 C 2 C 45% RH 75% 550, 600, 650, 700, 750, 800 850, 900, 960 1.0 N 0.2 N 30 s 0.1 s 10 mm/s v 25 mm/s 3 in succession

Conditioning

24 h 15 C T 35 C 45% RH 75% 550, 650, 750, 850, 960 1.0 N 0.2 N 30 s 0.1 s 10 mm/s v 25 mm/s 1

Temperatures of glow wire (C ) Pressing force Application time Rate of approach and withdrawal Number of specimens

Fig. 3 6

Fire safety test methods Standards

Needle flame test to IEC 60695-2-2, EN 60695-2-2, VDE 0471 Part 2-2 The ignition source is a butane gas flame produced by a needle burner. The needle flame is used to simulate ignition sources that can occur on tracking paths as a result of electrical faults in insulating components. The flame is applied to the edge or surface of the specimen for 5, 10, 20, 30, 60 or 120 seconds, after which the burning length and the burning time (which must not exceed 30 seconds) are noted.

Needle flame test apparatus 12 mm

0.5 mm internal 0.9 mm external

Test specimen = Electrical product Flame applied to edge or surface Flame impingement time varies in accordance with VDE/IEC regulations on electrical products (5, 10, 20, 30, 60 or 120 s)

Assessment criteria for the needle flame test DIN IEC 60695-2-2 Burning time < 30 s Paper and wood undamaged Burning length does not exceed the permissible value for the product according to the relevant regulation

Fig. 4 Test using larger flames in accordance with IEC 60695-11-10, Method A; EN 60695-11-10, Method A, VDE 0471 Part 11-10, Method A and UL 94 or CSA 22.2 No. 0.6 Part E Horizontal Burning Test The specimen is placed horizontally and exposed to a Bunsen burner flame (h = 20 mm) for 30 seconds. Any ignition or burning is noted. In accordance with IEC 6069511-10, EN 60695-11-10, and VDE 0471 Part 11-10 (Method A in each case), a classification is awarded on the basis of the burning rate of specimens up to 13 mm thick as follows: HB 40: Burning must cease before the 100 mm mark is reached or v 40 mm/min HB75: v 75 mm/min

UL 94 HB combustibility test 25 mm 75 mm 25 mm Test specimen Wire gauze

6 test specimens (125 x 13 x 13 mm) Flame impingement time 30 s, flame height 20 mm Assessment criteria for UL 94 HB Burning rate of specimens between 3 and 13 mm thick over a distance of 75 mm 40 mm/min or Burning rate of specimens up to 3 mm thick over a distance of 75 mm 75 mm/min or Burning must cease before the 100 mm mark

Fig. 5 7

Fire safety test methods Standards

Test using larger flames in accordance with IEC 60695-11-10, Method B; EN 60695-11-10, Method B;VDE 0471 Part 11-10, Method B and UL 94 or CSA 22.2 Vertical Burning Test In this test the specimen is placed vertically and exposed to a Bunsen burner flame (h = 20 1 mm) for two periods of 10 seconds. The assessment criteria are burning time, total burning time and the dropping of burning particles.

UL 94V flammability test

127 mm

Two groups of 10 test specimens (125 x 13 x 13 mm) Flame impingement time 10 s, flame height 20 mm 300 mm 2nd application of flame for 10 s after extinction

Cotton wad

Assessment criteria for UL 94V-0, 94V-1, 94V-2 94V-0 Burning time after each flame application Total burning time per batch (10 flame applications) Burning up to the clamp Burning and glowing time after second flame application Ignition of cotton wadding 10 s 50 s no 30 s no

94V-1 30 s no 60 s no

94V-2 30 s no 60 s yes

250 s 250 s

Fig. 6

Example: Fire behavior of Makrolon according to UL: Basic grades of Makrolon comply with the requirements of UL (Underwriters Laboratories Inc., USA) Subj. 94V-2 (depending on wall thickness). Certain flame-retarded grades achieve V-0 at 0.8 and 1.6 mm thickness. Glass fiber reinforced products achieve V-1, or V-0 if flame-retarded. Flame-retarded grades of Makrolon present no problems during processing. 8

Fire safety test methods Standards

Test using larger flames in accordance with IEC 60695-11-20; EN 60695-11-20; VDE 0471 Part 11-20, UL 94, Test Method 94-5 V and CSA 22.2 No. 0.6 Test c Vertical Burning Test The specimen is positioned vertically and a Bunsen burner flame (125 mm/40 mm) is applied to its bottom edge five times for 5 seconds with 5 second intervals between each application. In a variant of this method, plaques are tested in a horizontal position, with the flame being applied to the underside of the specimens. A note is made of whether the specimens continue to burn and whether there is any dripping of burning particles. Burning time must not exceed 60 seconds, and there must be no dripping from the specimen after the ignition source is removed for the fifth time. The speciment must not burn away completely.

UL 94-5V flammability test

127 mm

Flame applied to bars at an angle of 20 20 bars (125 x 13 x 13 mm) Flame height 125 mm 300 mm 5 applications of 5 seconds duration with 5-second intervals

Cotton wad

Flame applied to plaques at an angle of 20 12 plaques (150 x 150 x 13 mm) Flame height 125 mm 5 applications of 5 seconds duration with 5-second intervals

Assessment criteria for UL 94-5VA, 94-5VB Burning and glowing time after 5th flame application (bar) Ignition of cotton wadding Specimen (plaque) exhibits burn-through (hole)

94-5VA 60 s no no

94-5VB 60 s no yes

Fig. 7

You might also like

- AISI1045Document2 pagesAISI1045Sandip JawalkarNo ratings yet

- Is 13875 1 1993Document17 pagesIs 13875 1 1993KOSAKA LABNo ratings yet

- Baofeng Uv-5r Ce Certificate 18-211428Document3 pagesBaofeng Uv-5r Ce Certificate 18-211428anshadNo ratings yet

- COUNTER MEASURE of Customer ComplaintDocument2 pagesCOUNTER MEASURE of Customer Complaintpreetam kumarNo ratings yet

- How To Do Millipore TestDocument6 pagesHow To Do Millipore TestVasant bhoknalNo ratings yet

- D 1823 - 95 - Rde4mjmtotuDocument3 pagesD 1823 - 95 - Rde4mjmtotujamaljamal20No ratings yet

- Test Report IEC 62493 Luminaires Assessment of Lighting Equipment Related To Human Exposure To Electromagnetic FieldsDocument6 pagesTest Report IEC 62493 Luminaires Assessment of Lighting Equipment Related To Human Exposure To Electromagnetic FieldsAnouer BelkadiNo ratings yet

- UL94Document7 pagesUL94baga011No ratings yet

- Centaurus Fire Safety ReportDocument24 pagesCentaurus Fire Safety ReportmahnoorimranNo ratings yet

- UCLFire TN 063 PDFDocument1 pageUCLFire TN 063 PDFDnyaneshwarNo ratings yet

- F16 (SOP - hrd.01) Kaizen Implementation SheetDocument1 pageF16 (SOP - hrd.01) Kaizen Implementation SheetRAHUL YADAVNo ratings yet

- Indian Standard: Sampling Inspection ProceduresDocument24 pagesIndian Standard: Sampling Inspection ProceduresarunrathikaNo ratings yet

- In-House Calibration SheetDocument4 pagesIn-House Calibration SheetKannan MurugesanNo ratings yet

- Stiffness Properties of Plastics As A Function of Temperature by Means of A Torsion TestDocument11 pagesStiffness Properties of Plastics As A Function of Temperature by Means of A Torsion TestCristian DíazNo ratings yet

- DTRF 1502Document31 pagesDTRF 1502Omprakash Kumar100% (1)

- Automotive Parts - Unscreened Low-Voltage Cables: Japanese Automobile Standard JASO D611:2009Document25 pagesAutomotive Parts - Unscreened Low-Voltage Cables: Japanese Automobile Standard JASO D611:2009Chung Le100% (1)

- Controlling Heat Treatment Distortion in Gear Rings - MachineMfgDocument37 pagesControlling Heat Treatment Distortion in Gear Rings - MachineMfgxiao mingNo ratings yet

- Melt Flow IndexDocument3 pagesMelt Flow Indexshubhendra mishraaNo ratings yet

- Is.12889.1989 2Document10 pagesIs.12889.1989 2Agniva Dutta100% (1)

- IS 8783 (Part-4-Sec.1) - 1995 - HR PVC Insulated - Winding Wires For Submersible MotorsDocument10 pagesIS 8783 (Part-4-Sec.1) - 1995 - HR PVC Insulated - Winding Wires For Submersible Motorsshivam dwivediNo ratings yet

- BDL Ed QM 1Document162 pagesBDL Ed QM 1Sai DhruvNo ratings yet

- PPAP Part Submission Warrant.Document4 pagesPPAP Part Submission Warrant.aperezpi26606No ratings yet

- A Training Presentation On The N7Document69 pagesA Training Presentation On The N7Nguyen Anh TuanNo ratings yet

- KAIZEN IDEA - TemplateDocument3 pagesKAIZEN IDEA - TemplateKranthi Kumar100% (1)

- Weidmuller Screw Connection Measuring Terminals PDFDocument12 pagesWeidmuller Screw Connection Measuring Terminals PDFMohammad Mahdi BozorgzadehNo ratings yet

- Fmea 39 PDF FreeDocument5 pagesFmea 39 PDF Freeahya azizahNo ratings yet

- Control Plan & FMEADocument13 pagesControl Plan & FMEAAmit LuniaNo ratings yet

- Cab Basic Details: National Accreditation Board For Testing and Calibration LaboratoriesDocument6 pagesCab Basic Details: National Accreditation Board For Testing and Calibration LaboratorieskrlalitNo ratings yet

- PSWDocument1 pagePSWKunal KarmakarNo ratings yet

- Gauging Practice For Plain SurfacesDocument20 pagesGauging Practice For Plain SurfacesAVINASHNo ratings yet

- IPC-TM-650 Test Methods ManualDocument4 pagesIPC-TM-650 Test Methods ManualSSmyLoginNo ratings yet

- Nikhil Quality 6YOEDocument3 pagesNikhil Quality 6YOENikhil DhimanNo ratings yet

- GM Process SheetDocument1 pageGM Process SheetSuraj RawatNo ratings yet

- Is 1363 - 2 2002Document13 pagesIs 1363 - 2 2002Sourav HaitNo ratings yet

- MSA FormatDocument4 pagesMSA FormatSaurabh PhandNo ratings yet

- Method of Shearing Test For Fillet Weld Joint: Nissan Engineering StandardDocument5 pagesMethod of Shearing Test For Fillet Weld Joint: Nissan Engineering StandardRicardo F.A.No ratings yet

- Esd NotionsDocument1 pageEsd NotionsAnonymous FZs3yBHh7No ratings yet

- Break Down SlipDocument7 pagesBreak Down SlipUmangtarangNo ratings yet

- Controls:: Measuring Instruments in ImteDocument5 pagesControls:: Measuring Instruments in ImteDhinakaranNo ratings yet

- 00-Quality Objective Monitoring Chart For Geotechnical DivDocument1 page00-Quality Objective Monitoring Chart For Geotechnical DivAdly Al-SaafinNo ratings yet

- Technical Data Sheet - DST-DEGREEZ-6 - 2020 UKDocument1 pageTechnical Data Sheet - DST-DEGREEZ-6 - 2020 UKBala Sb0% (1)

- 8.fixture Inspection ReportDocument1 page8.fixture Inspection ReportBASAVA ENGINEERINGNo ratings yet

- Rejection Record.Document10 pagesRejection Record.karan shahNo ratings yet

- SOP of MachinesDocument2 pagesSOP of MachinesSangram Kandekar100% (1)

- Bsi BS Iso 11359-1 - 2014Document14 pagesBsi BS Iso 11359-1 - 2014alferedNo ratings yet

- PSWDocument2 pagesPSWLinda G. CordovaNo ratings yet

- As 60068.2.21-2004 Environmental Testing Tests - Test U - Robustness of Terminations and Integral Mounting DevDocument8 pagesAs 60068.2.21-2004 Environmental Testing Tests - Test U - Robustness of Terminations and Integral Mounting DevSAI Global - APACNo ratings yet

- Poster VVVVDocument1 pagePoster VVVVManishi GoelNo ratings yet

- Agilent Calibration FrequencyDocument6 pagesAgilent Calibration Frequencyzilangamba_s4535No ratings yet

- Compressive Strength of Carbon and Graphite: Standard Test Method ForDocument3 pagesCompressive Strength of Carbon and Graphite: Standard Test Method ForJGD123No ratings yet

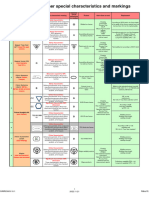

- Customer Special CharacteristicsDocument1 pageCustomer Special Characteristicspundhir12898No ratings yet

- Part Name.:-Distribution Assy 3P386983-1Document50 pagesPart Name.:-Distribution Assy 3P386983-1Sameer SaxenaNo ratings yet

- Indian Standard: Legal Metrology - Material Measures of LengthDocument9 pagesIndian Standard: Legal Metrology - Material Measures of LengthDiptiNo ratings yet

- 18.in House Calibration ProcedureDocument1 page18.in House Calibration ProcedureSAKTHIVEL ANo ratings yet

- Ash Content in Plastics: Standard Test Method ForDocument5 pagesAsh Content in Plastics: Standard Test Method ForSamuel Gaytan RamirezNo ratings yet

- BIS Product Manual 4250Document8 pagesBIS Product Manual 4250selva thanarajNo ratings yet

- Pallava Granite Industries (India) PVT - LTD Manubolu Maintenance Prevetive Maintenance PlanDocument13 pagesPallava Granite Industries (India) PVT - LTD Manubolu Maintenance Prevetive Maintenance Planp kishorNo ratings yet

- IEC 60695-2 Test MethodsDocument4 pagesIEC 60695-2 Test Methodsmpendleton100% (2)

- Fire Resistance Cable TestDocument16 pagesFire Resistance Cable TestsinyitwongNo ratings yet

- En Standards Protective ClothingDocument25 pagesEn Standards Protective Clothinglthyagu100% (1)

- Underwriters LaboratoriesDocument15 pagesUnderwriters LaboratoriesNicko Samar IndicoNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- MediSpa (NO PRICE)Document4 pagesMediSpa (NO PRICE)Rana Tahir SultanNo ratings yet

- ISO 14782-1999 Cor1-2005 Determination of Haze For Transparent MaterialDocument1 pageISO 14782-1999 Cor1-2005 Determination of Haze For Transparent MaterialRana Tahir SultanNo ratings yet

- ClassicSpecs PDFDocument184 pagesClassicSpecs PDFRana Tahir SultanNo ratings yet

- Industrial Computer Chassis - RACK-1150G PDFDocument1 pageIndustrial Computer Chassis - RACK-1150G PDFRana Tahir SultanNo ratings yet

- Def Angulos VisionDocument2 pagesDef Angulos VisionRana Tahir SultanNo ratings yet

- Rizal EarthquakeDocument5 pagesRizal EarthquakeReedzMolzNo ratings yet

- Meet The Demoman ScriptDocument1 pageMeet The Demoman ScriptNopeNo ratings yet

- HAZARDDocument7 pagesHAZARDMark Froilan NamiaNo ratings yet

- Standing Order SampleDocument14 pagesStanding Order SampleJonathan GonzalesNo ratings yet

- Oisd STD 105Document23 pagesOisd STD 105NarendrasinhNo ratings yet

- Sprinkler K 5.6 y K 8Document6 pagesSprinkler K 5.6 y K 8Jimenez FerchoNo ratings yet

- Foam Floating Roof Tank SystemsDocument2 pagesFoam Floating Roof Tank SystemsNeera JainNo ratings yet

- Tailgate Safety Talks Smoking/Fire SafetyDocument4 pagesTailgate Safety Talks Smoking/Fire SafetyAbdulSamadNo ratings yet

- 6.3-5 - Preventive Maintenance Inspection FormDocument3 pages6.3-5 - Preventive Maintenance Inspection FormaleemuddinNo ratings yet

- Dan Winter - Honey of The Queens, The Orion QueensDocument7 pagesDan Winter - Honey of The Queens, The Orion Queensramashakti67% (3)

- Fire Hazard Analysis PDFDocument12 pagesFire Hazard Analysis PDFBobby Vonn100% (1)

- Fire Detection and Alarm System - Lesson PlanDocument5 pagesFire Detection and Alarm System - Lesson PlanBriant King PeñasNo ratings yet

- 613 Model C Mechanical Sprinkler Alarm Operation Care and MaintenanceDocument4 pages613 Model C Mechanical Sprinkler Alarm Operation Care and Maintenancenachalo6No ratings yet

- Fire Shutter MalaysiaDocument4 pagesFire Shutter MalaysiaskshutterNo ratings yet

- Basis ScheepvaartDocument122 pagesBasis Scheepvaartrafael espinosa semperNo ratings yet

- LSMDocument6 pagesLSMscienceteacher2222No ratings yet

- Fire Exting Insp MaintDocument2 pagesFire Exting Insp MaintanoopdrNo ratings yet

- Bus Hi Do 2Document3 pagesBus Hi Do 2Himura SanzouNo ratings yet

- 3/F Assembly Point: Open Area Near Hillside of Cheng Yu Tung Tower 三樓 集合地點:鄭裕彤教學樓對出山邊空地Document8 pages3/F Assembly Point: Open Area Near Hillside of Cheng Yu Tung Tower 三樓 集合地點:鄭裕彤教學樓對出山邊空地Mohammad Haekal NadapdapNo ratings yet

- CWTS Chapter3-5Document2 pagesCWTS Chapter3-5Michael DyNo ratings yet

- Ansul R-102Document4 pagesAnsul R-102Phamngoc SonNo ratings yet

- Repair Procedures HandbookDocument72 pagesRepair Procedures HandbookJoãoFerreiraNo ratings yet

- Fire Risk Assessment For Super High-Rise BuildingsDocument10 pagesFire Risk Assessment For Super High-Rise BuildingsAnjani Kumar SinghNo ratings yet

- 003-MS For Cable Joint and Termination PDFDocument19 pages003-MS For Cable Joint and Termination PDFKöksal Patan100% (1)

- Flood Magazine Special Section CompleteDocument79 pagesFlood Magazine Special Section CompleteMarsha JohnsonNo ratings yet

- Sailmaker Symbolism ThemesDocument14 pagesSailmaker Symbolism Themesapi-235430003No ratings yet

- Cetu Water Mist EN 2010Document31 pagesCetu Water Mist EN 2010kiarashkaveh46No ratings yet

- Fire Safety Guidelines MauritiusDocument19 pagesFire Safety Guidelines MauritiusHans JhubooNo ratings yet