Professional Documents

Culture Documents

Aluminium Arc

Uploaded by

Wilson MonteroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminium Arc

Uploaded by

Wilson MonteroCopyright:

Available Formats

Setting the Standard in Mobile Power ABN 40218849719 PROPRIETORS: ROB & ROSE PULZ

PO Box 993 Archerfield Qld 4108 5/806 Beaudesert Road Coopers Plains Qld 4108 Telephone: (07) 32729731 Facsimile (07) 32729831 Email Address: sales@hydrapneu.com.au Web :www.hydrapneu.com.au

HydraPneu P/L as Trustee for the RobRose Trust

Aluminum Arc Welding Rods

Use Your Arc Welder for Welding Aluminium! Now you can weld aluminium anywhere you arc weld, even in poor conditions, without the need for a MIG or TIG torch, special welding wire, hoses, regulators, or expensive and heavy gas bottles. These unique aluminium alloy welding rods let you weld and fill all cast, wrought and extruded aluminium and aluminium alloys, working in all positions, with a high quality high tensile strength (34,000 lb. / 18% elongation) aluminium alloy using only your arc welder! (They can also be used with a conventional oxy-acetylene torch for gas welding aluminium!) Use these special aluminium welding rods for welding repairing cracks and building up missing sections of:

Aluminium sheet metal Truck beds, bodies, and frames, Loading ramps and docks, Engine and motor blocks, Machine bases and supports, Pipe railings, banisters, stairs, diamond plate, Transmission housings and gear boxes, Irrigation piping, Bus bars, electrical switch boxes and mounts.

Aluminium Arc Welding Rod Specifications Description: Highly versatile, smooth running, easy-to-handle, all position Aluminium Alloy arc/torch welding electrode for welding filling low alloy aluminium. Current Type/Polarity: DC reverse polarity

Recommended Amperage: 70-120A Rod Diameter: 1/8" Product Features:

Universal electrode for welding all cast, wrought and extruded aluminium and aluminium alloys in all positions.

Typical Applications:

Truck body/frame repair/fabrication Cafeteria equipment repair/fabrication Loading ramps/dock repair/fabrication Engine and motor blocks/cylinder head repair Repair and fabrication of machine bases and supports Repair and fabrication of pipe railings, banisters, stairs, diamond plate Transmission housings and gear box repair/fabrication Repair and fabrication of irrigation piping, mixers, paddles, vats, Repair and fabrication of electrical bus bars, electrical switch boxes. and mounts

Recommended Welding Techniques: OK for welding in flat, horizontal and vertical applications. Clean weld area by removing oil and grease and by wire brushing and/or sanding/grinding the immediate weld area just prior to welding. Chamfer edges of plated to be joined and open up/chamfer cracks and/or holes to be filled. Preheat heavy sections broadly. In thick to thin joining, preheat heavier member. For multipass work, it might be necessary to reduce amperage setting as base metal increases in temperature. A close to medium arc should be maintained. Feed electrode quickly and move fast. When picking up each bead, weld into the previous crater before continuing. Upon cooling, slag/flux can easily be removed by chipping/brushing/sanding/grinding. Expect best results using motor driven welding equipment with generators with DC rectified DC output. Packaging: 1 lb. box (14 rods)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Inspection Test Plan For Fabrication & Erection 2016Document14 pagesInspection Test Plan For Fabrication & Erection 2016Boj Mingi0% (1)

- Autocad Structural Detailing 2011 BrochureDocument6 pagesAutocad Structural Detailing 2011 BrochureBijoy AVNo ratings yet

- Duct Fabrication ProcedureDocument14 pagesDuct Fabrication Procedureachusanachu80% (5)

- MNT-INTG-2007OP - Maintenance Welding InspectionDocument43 pagesMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNo ratings yet

- BIW - Points Discussed With The CustomerDocument9 pagesBIW - Points Discussed With The CustomerJyoti Kale100% (1)

- Preva: Pressure Vessels and Heat ExchangersDocument6 pagesPreva: Pressure Vessels and Heat ExchangersTrishul Nath PallayNo ratings yet

- Over View of The Industrial Fabrication YardDocument6 pagesOver View of The Industrial Fabrication Yardzam110100% (1)

- QAP of Steel Bridge Girder PDFDocument6 pagesQAP of Steel Bridge Girder PDFVarun JainNo ratings yet

- Industrial Press 2012 PDFDocument47 pagesIndustrial Press 2012 PDFAli Imamudeen50% (2)

- Quotation For Kirnath FabricatorDocument2 pagesQuotation For Kirnath Fabricatorvinkumar_hbti100% (1)

- Rice Transplanter DesignDocument74 pagesRice Transplanter Designhoney mae100% (1)

- Weld Inspection and RepairDocument10 pagesWeld Inspection and RepairDeepak Kumar Kant KesriNo ratings yet

- Welder Job Description For ResumeDocument5 pagesWelder Job Description For Resumef5dthdcd100% (2)

- E8045-P2 H4RDocument2 pagesE8045-P2 H4RsanrexiNo ratings yet

- Mechanical Project ListDocument7 pagesMechanical Project ListPavan Kumar BalagamNo ratings yet

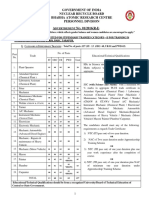

- Government of India Nuclear Recycle Board Bhabha Atomic Research Centre Personnel Division A N - 01/2016 (R-I)Document7 pagesGovernment of India Nuclear Recycle Board Bhabha Atomic Research Centre Personnel Division A N - 01/2016 (R-I)Śáńtőśh MőkáśhíNo ratings yet

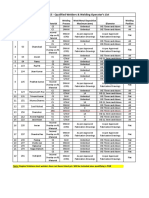

- Modified BOQ - Presidency University 14.01.2015Document34 pagesModified BOQ - Presidency University 14.01.2015yogeshNo ratings yet

- NEXGEN TECHNOLOGY Final Year Tool Die and Jig Fixture Titles 2021-2022Document4 pagesNEXGEN TECHNOLOGY Final Year Tool Die and Jig Fixture Titles 2021-2022Nexgen TechnologyNo ratings yet

- Project: Construction of A Factory Shed For ABC Co. LTD: Planned Start Date: 05 April, 2021Document7 pagesProject: Construction of A Factory Shed For ABC Co. LTD: Planned Start Date: 05 April, 2021Mayank GhaiwatkarNo ratings yet

- Compression Elements for Local BucklingDocument1,205 pagesCompression Elements for Local BucklingMahelyNo ratings yet

- Heavy Wall Equipment TechnologyDocument16 pagesHeavy Wall Equipment Technologyeng_farNo ratings yet

- Sistema de Fabricação de Vigas EstruturaisDocument11 pagesSistema de Fabricação de Vigas EstruturaisdiegosammNo ratings yet

- Welding Chromium-Molybedenum Steel Pipe For Power Plants Induction Heating Becomes An Options For Preheat, Postweld Heat TreatmentDocument6 pagesWelding Chromium-Molybedenum Steel Pipe For Power Plants Induction Heating Becomes An Options For Preheat, Postweld Heat Treatmentروشان فاطمة روشانNo ratings yet

- Boniface EtukDocument2 pagesBoniface EtukAnonymous vmubaau4V7No ratings yet

- Project Qatar 2016Document8 pagesProject Qatar 2016azwrisNo ratings yet

- Road Detailed EstimateDocument8 pagesRoad Detailed Estimatenageshwarraobandi100% (1)

- 1255 - Qualified Welder ListDocument1 page1255 - Qualified Welder ListattaullaNo ratings yet

- Cold Forming ProcedureDocument5 pagesCold Forming ProcedureMassimo FumarolaNo ratings yet

- Screw ConveyorsDocument16 pagesScrew Conveyorsazeez bashaNo ratings yet

- Cataloge of DengFeng Weld PDFDocument143 pagesCataloge of DengFeng Weld PDFLeo SembiringNo ratings yet