Professional Documents

Culture Documents

Failure

Uploaded by

Stephen MaidzaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Failure

Uploaded by

Stephen MaidzaCopyright:

Available Formats

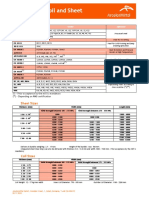

GENERAL TURNING

Practical tips

Problem:

Flank and notch wear a. Rapid flank wear causing poor surface finish or out of tolerance. b/c. Notch wear causing poor surface finish and risk of edge breakage.

Cause:

a. Cutting speed too high or insufficient wear resistance.

Remedy:

Reduce the cutting speed. Select a more wear resistant grade.

b/c. Oxidation

Select an Al2O3 coated grade. For work hardening materials select a smaller entering angle or a more wear resistant grade.

b/c. Attrition

Reduce the cutting speed. (When machining heat resistant material with ceramics increase cutting speed.)

c.

Oxidation

Select a cermet grade

Crater wear

Excessive crater wear causing a weakened edge. Cutting edge breakthrough on the training edge causes poor surface finish.

Diffusion wear due to too high cutting temperatures on the rake face.

Select an Al2O3 coated grade. Select a positive insert geometry. First reduce the speed to obtain a lower temperature, then reduce the feed.

Plastic deformation

Plastic deformation Edge depression or flank impression Leading to poor chip control and poor surface finish. Risk of excesive flank wear leading to insert breakage

Cutting temperature too high combined with a high pressure.

Select a harder grade with better resistance to plasic deformation. Edge depression Reduce speed Flank impression Reduce feed

Built-up edge (B.U.E.)

Built-up edge causing poor surface finish and cutting edge frittering when the B.U.E. is torn away.

Workpiece material is welded to the insert due to: Low cutting speed. Negative cutting geometry. Increase cutting speed. Select a positive geometry.

125

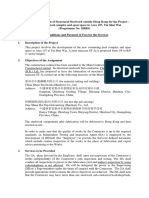

Practical tips

GENERAL TURNING

Problem:

Chip hammering The part of the cutting edge not in cut is damaged through chip hammering. Both the top side and the support for the insert can be damaged.

Cause:

The chips are deflected against the cutting edge.

Remedy:

Change the feed. Select an alternative insert geometry.

Frittering

Small cutting edge fractures (frittering) causing poor surface finish and excessive flank wear.

Grade too brittle. Insert geometry too weak.

Select tougher grade. Select an insert with a stronger geometry (bigger chamfer for ceramic inserts). Increase cutting speed or select a positive geometry. Reduce feed at beginning of cut.

Built-up edge

Thermal cracks

Small cracks perpendicular to the cutting edge causing frittering and poor surface finish.

Thermal cracks due to temperature variations caused by: - Intermittent machining. Select a tougher grade with better resistance to thermal shocks.

- Varying coolant supply.

Coolant should be applied copiously or not at all.

Insert breakage

Insert breakage that damages not only the insert but also the shim and workpiece.

Grade too brittle. Excessive load on the insert.

Select a tougher grade. Reduce the feed and/or the depth of cut. Select a stronger geometry, preferably a single sided insert. Select a thicker/larger insert.

Insert geometry too weak.

Insert size too small.

Slice fracture Ceramics

Too big tool pressure.

Reduce the feed. Select a tougher grade. Select an insert with smaller chamfer.

126

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CNC ReportDocument39 pagesCNC Reportrasaiya69% (13)

- Modular CleanroomDocument6 pagesModular CleanroomMohamed EidNo ratings yet

- GB50094-98 Code For Construction and Acceptance of Spherical TankDocument55 pagesGB50094-98 Code For Construction and Acceptance of Spherical TankQiuo Shen100% (2)

- Reverse Osmosis and Nanofiltration Operating Data NormalizationDocument74 pagesReverse Osmosis and Nanofiltration Operating Data NormalizationShark1971No ratings yet

- 20MVA TransformerDocument12 pages20MVA TransformerMehul PatelNo ratings yet

- The Hyd Philatelist Sept 2021Document52 pagesThe Hyd Philatelist Sept 2021nsigamanyNo ratings yet

- B Technical Deft: Metallizing Aluminum and Zinc Protection of Iron and SteelDocument3 pagesB Technical Deft: Metallizing Aluminum and Zinc Protection of Iron and SteelRazvan GavrilaNo ratings yet

- Holik Book PagesDocument30 pagesHolik Book PagesKris BillmanNo ratings yet

- Selective Recovery of Lithium From Spent Lithium-Ion Batteries by Coupling Advanced Oxidation Processes (Aops) and Chemical Leaching ProcessesDocument5 pagesSelective Recovery of Lithium From Spent Lithium-Ion Batteries by Coupling Advanced Oxidation Processes (Aops) and Chemical Leaching ProcessesYudha AeroNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Crane SpecififctaionDocument2 pagesCrane SpecififctaionGandhi elumalaiNo ratings yet

- 5 Router PlaneDocument4 pages5 Router PlaneAngel R Rodriguez100% (1)

- 2083 ESR DatasheetDocument1 page2083 ESR Datasheetfuransu777No ratings yet

- AIMOL Cement IndustryDocument57 pagesAIMOL Cement IndustryAdrianNo ratings yet

- Annex 1 - The Conditions and Payment of Fees For The ServicesDocument21 pagesAnnex 1 - The Conditions and Payment of Fees For The ServicesSuntech Testing Limited STLNo ratings yet

- WRD DefectsDocument24 pagesWRD Defectssoumyo broto dasNo ratings yet

- EstimationDocument5 pagesEstimationWOOD UTOPIANo ratings yet

- S-BT Screw-In Stainless Steel and Carbon Steel Threaded StudsDocument10 pagesS-BT Screw-In Stainless Steel and Carbon Steel Threaded StudsJade ClemenoNo ratings yet

- Katalog KarbosanDocument224 pagesKatalog KarbosanTonggo R ManikNo ratings yet

- ALE and ArtDocument8 pagesALE and ArtzwleevivihustNo ratings yet

- Richard M. Beldyk, PE, NSPE AWS Certified Welding Engineer AFE Certified Plant EngineerDocument80 pagesRichard M. Beldyk, PE, NSPE AWS Certified Welding Engineer AFE Certified Plant EngineerScott K.L LeeNo ratings yet

- m2t2-1910 252Document4 pagesm2t2-1910 252Abd El-rahman MohamedNo ratings yet

- Re: AISI 1050 Steel For Injection MoldingDocument2 pagesRe: AISI 1050 Steel For Injection MoldingMaulana PanjiNo ratings yet

- S IKADocument4 pagesS IKAQuevara AntonNo ratings yet

- Micro Machining For Micro Electro Mechanical Systems (Mems) : SciencedirectDocument8 pagesMicro Machining For Micro Electro Mechanical Systems (Mems) : SciencedirectKENN ADAMSNo ratings yet

- Watertite SA 16Document2 pagesWatertite SA 16Alexi ALfred H. TagoNo ratings yet

- Ul94 Versus Ul746c PDFDocument4 pagesUl94 Versus Ul746c PDFCiclair RamosNo ratings yet

- 3.various Units of IOCL Paradip: 3.1. Avu/Srlpg UnitDocument8 pages3.various Units of IOCL Paradip: 3.1. Avu/Srlpg UnitAkankshya MishraNo ratings yet

- MR Suwandi - Malibu F28 - Dapur Kotor - 250121-Model 3Document1 pageMR Suwandi - Malibu F28 - Dapur Kotor - 250121-Model 3Hengky SarjalieNo ratings yet

- Economic and Product Design Considerations in MachiningDocument29 pagesEconomic and Product Design Considerations in Machininghashir siddiquiNo ratings yet