Professional Documents

Culture Documents

Crosby G2140 Shackle

Uploaded by

pgarrett775814233Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crosby G2140 Shackle

Uploaded by

pgarrett775814233Copyright:

Available Formats

Shackle_Eng.

fm Page 68 Tuesday, November 11, 2008 3:53 PM

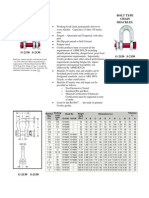

Crosby Alloy Bolt Type Shackles

G-2140 / S-2140

ALLOY

BOLT TYPE

ANCHOR

SHACKLES

Quenched and Tempered.

Alloy bows, Alloy bolts.

Forged Alloy Steel 30 thru 175 metric tons. Cast Alloy Steel

200 thru 400 metric tons.

Working Load Limit is permanently shown on every shackle.

All sizes are individually proof tested to 2.0 times

the Working Load Limit.

Pins are galvanized and painted red.

All sizes are RFID EQUIPPED.

Shackles are Quenched and Tempered and can

meet DNV impact requirements of 42 joules at -20 C.

Crosby products meet or exceed all requirements of ASME B30.26

including identification, ductility, design factor, proof load and

temperature requirements. Importantly, Crosby products meet other

critical performance requirements including fatigue life, impact

G-2140 meets the performance

properties and material traceability, not addressed by ASME B30.26.

requirements of Federal Specification

Shackles

200 metric tons and larger are provided as follows.

RR-C-271D, Type IVA, Grade B, Class 3,

except for those provisions required of

Serialized Pin and Bow

the contractor. For additional infor Material Certification (Chemical)

mation, see page 391.

Magnetic Particle Inspected.

Certification must be requested at time of order.

Type Approval and certification in accordance with ABS 2006 Steel

Vessel Rules 1-1-17.7, and ABS Guide for Certification of Cranes.

s e l k c a h S

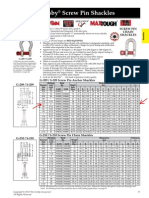

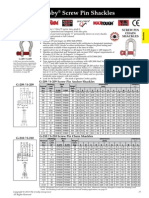

Nominal

Shackle

Size

(in.)

1-1/2

1-3/4

2

2-1/2

3

3-1/2

4

4-3/4**

5 **

6 **

7 **

e p y T

Working

Load

Limit

(t)*

30

40

55

85

120

150

175

200

250

300

400

t l o B

y o l l A

y b s o r C

Stock No.

SN2140Header

G-2140

1021110

1021138

1021156

1021174

1021192

1021218

1021236

1021414

1021432

1021450

1021478

S-2140

1021129

1021147

1021165

1021183

-

Weight

Each

(lbs.)

18.8

33.9

52.0

96.0

178.0

265.0

338.0

450.0

600.0

775.0

1102.0

Dimensions

(in.)

A

2.38

2.88

3.25

4.12

5.00

5.25

5.50

7.25

8.50

8.38

8.25

B

3.62

4.19

4.81

5.81

6.50

8.00

9.00

10.50

12.00

12.00

14.00

C

1.62

2.25

2.40

3.12

3.63

4.38

4.56

6.00

6.50

6.75

7.25

D

1.63

2.00

2.25

2.75

3.25

3.75

4.25

4.75

5.00

6.00

7.00

E

5.75

7.00

7.75

10.50

13.00

14.63

14.50

15.63

20.00

19.50

22.50

F

1.39

1.75

2.00

2.62

3.00

3.75

4.00

3.75

3.88

4.75

6.50

G

6.88

8.81

10.16

12.75

14.62

17.02

18.00

21.00

24.50

25.00

26.00

Tolerance

+/H

7.73

9.33

10.41

13.58

15.13

17.62

20.37

21.21

22.68

25.06

28.68

J

10.00

12.34

13.68

17.90

21.50

24.88

25.68

29.25

35.00

35.25

40.25

K

3.88

5.00

5.75

7.25

7.88

9.00

10.00

11.00

13.00

13.00

13.00

L

1.53

1.84

2.08

2.71

3.12

3.62

4.00

4.50

4.50

5.00

6.00

A

.13

.13

.13

.25

.25

.25

.25

.25

.25

.25

.25

E

.25

.25

.25

.25

.25

.25

.25

.25

.25

.25

.25

* Note: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Load is 4 times the Working Load Limit on 200 thru 400

metric Tons. For sizes 30 thru 175 metric Tons, Minimum Ultimate Load is 5.4 times the Working Load Limit.

** Cast Alloy Steel.

Furnished with Round Head Bolts with welded handle.

For Working Load Limit reduction due to side loading applications, see page 74.

68

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

You might also like

- General ChemistryDocument19 pagesGeneral ChemistryHugoSantaellaSr100% (1)

- Catalogue - Crosby G-2130 Bolt Type Shackle PDFDocument1 pageCatalogue - Crosby G-2130 Bolt Type Shackle PDFAnindya SaputraNo ratings yet

- Guide To Structural Steel Selection - G-SpecificationsDocument56 pagesGuide To Structural Steel Selection - G-SpecificationsFelix RanillaNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Crosby G-2140 Alloy Shackle Product SheetDocument1 pageCrosby G-2140 Alloy Shackle Product Sheetmihai_serban13No ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Crosby ShackleDocument1 pageCrosby Shacklecaner_kurtoglu-1No ratings yet

- Is2062 E350Document12 pagesIs2062 E350Sowmen ChakrobortyNo ratings yet

- Quality Control in FabricationDocument7 pagesQuality Control in FabricationradhakrishnangNo ratings yet

- G S Earth WireDocument10 pagesG S Earth WiresaratNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Structural Steels Equivalent ChartDocument2 pagesStructural Steels Equivalent ChartHamdan PkNo ratings yet

- Asme Sec Ix Guide PDFDocument144 pagesAsme Sec Ix Guide PDFCHARLES Anthonyraj100% (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- CC Transes 1Document6 pagesCC Transes 1Nico LokoNo ratings yet

- Api 1104 VT TestDocument2 pagesApi 1104 VT TestKali AbdennourNo ratings yet

- Regeneration of Waste Lubricant Oil by Extraction-Flocculation PDFDocument8 pagesRegeneration of Waste Lubricant Oil by Extraction-Flocculation PDFsasanNo ratings yet

- 2014 Soil Carbon Book With Cover Page v2Document504 pages2014 Soil Carbon Book With Cover Page v2AmrNo ratings yet

- Determination of Ca and MG ConcentrationDocument3 pagesDetermination of Ca and MG ConcentrationRhea TalibNo ratings yet

- TurnbuckleDocument6 pagesTurnbuckleAbi Latiful HakimNo ratings yet

- Crosby® TurnbucklesDocument11 pagesCrosby® TurnbucklesMidfiild CosminNo ratings yet

- Pharmaceutical Inorganic ChemistryDocument26 pagesPharmaceutical Inorganic Chemistryvivek vermaNo ratings yet

- WPS PresentationDocument27 pagesWPS PresentationSenthil Kumar50% (2)

- Spec EarthingDocument9 pagesSpec EarthingsbpathiNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- CrosbyDocument1 pageCrosbybdispoNo ratings yet

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDocument1 pageScrew Pin Anchor Shackles Screw Pin Chain Shacklesfcesar1986No ratings yet

- Crosby Alloy Screw Pin Shackles: All Rights Reserved 72Document1 pageCrosby Alloy Screw Pin Shackles: All Rights Reserved 72theCrosbyGroupNo ratings yet

- Bolt Type Anchor Shackles Bolt Type Chain ShacklesDocument1 pageBolt Type Anchor Shackles Bolt Type Chain ShacklesMikiNo ratings yet

- Crosby Bolt-Type Shackles: Bolt Type Anchor Shackle G-2130 S-2130 Bolt Type Chain Shackle G-2150 S-2150Document2 pagesCrosby Bolt-Type Shackles: Bolt Type Anchor Shackle G-2130 S-2130 Bolt Type Chain Shackle G-2150 S-2150gdgfdNo ratings yet

- Crosby ShacklesDocument18 pagesCrosby ShacklesAnjar DarundriyaNo ratings yet

- G-2140 / S-2140 Crosby Alloy Bolt Type Anchor ShacklesDocument1 pageG-2140 / S-2140 Crosby Alloy Bolt Type Anchor ShacklessaurabhsubhuNo ratings yet

- Grilletes G-2140, S-2140 CrosbyDocument1 pageGrilletes G-2140, S-2140 CrosbyLuis Manuel Montoya RiveraNo ratings yet

- Crosby ShacklesDocument6 pagesCrosby Shacklessabah8800No ratings yet

- Screw Pin Anchor ShacklesDocument1 pageScrew Pin Anchor Shacklesnikka2012No ratings yet

- G-209 / S-209 Screw Pin Anchor ShacklesDocument1 pageG-209 / S-209 Screw Pin Anchor Shacklesaizzi1989No ratings yet

- Crosby ShacklesDocument1 pageCrosby Shacklesroy sihalohoNo ratings yet

- Crosby Wide Body Metric For ReferenceDocument1 pageCrosby Wide Body Metric For ReferenceshazanNo ratings yet

- Crosby 2130 2150Document1 pageCrosby 2130 2150Sumner TingNo ratings yet

- G2130, G2140, G2150 Crosby Bolt Anchor Safety Shackles PDFDocument2 pagesG2130, G2140, G2150 Crosby Bolt Anchor Safety Shackles PDFSonhaji11No ratings yet

- Manilhas Crosby G2130Document1 pageManilhas Crosby G2130Álamo NatividadeNo ratings yet

- Shackel PDF Crosby in MMDocument1 pageShackel PDF Crosby in MMkanchanabalajiNo ratings yet

- 82Document1 page82Drajat DarmawanNo ratings yet

- Crosby Bolt Type Shackles: Testing The LimitsDocument1 pageCrosby Bolt Type Shackles: Testing The LimitsStephen KokoNo ratings yet

- Inspection & Testing of Elastic Rail Clips PDFDocument5 pagesInspection & Testing of Elastic Rail Clips PDFvivek adNo ratings yet

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDocument1 pageScrew Pin Anchor Shackles Screw Pin Chain ShacklesJulius HendraNo ratings yet

- Bayu Undan / Darwin LNG Facilities Technical Delivery TermsDocument6 pagesBayu Undan / Darwin LNG Facilities Technical Delivery TermsWidodo MuisNo ratings yet

- A-344, A-347 Master LinkDocument1 pageA-344, A-347 Master LinkAekJayNo ratings yet

- Jaw & Jaw TurnbucklesDocument1 pageJaw & Jaw TurnbucklesBoby ThomasNo ratings yet

- JB-T 1255-2001Document35 pagesJB-T 1255-2001hand42No ratings yet

- Mar2014/zip/10462990 TD Technical SpecificationDocument6 pagesMar2014/zip/10462990 TD Technical SpecificationNaresh Ch MahapatraNo ratings yet

- Psi SpecDocument645 pagesPsi SpecManickavasagam Sadasivam100% (3)

- Technical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsDocument11 pagesTechnical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsMunish100% (1)

- Steel wire rod for bridge cable wire 桥梁缆索钢丝用盘条: (English Translation)Document9 pagesSteel wire rod for bridge cable wire 桥梁缆索钢丝用盘条: (English Translation)Mada TetoNo ratings yet

- Crosby Eye Hooks: On Pages 122 - 123Document1 pageCrosby Eye Hooks: On Pages 122 - 123Yudha J MalmsteenNo ratings yet

- Spec 6a E21 en Add3Document16 pagesSpec 6a E21 en Add3LiLiNo ratings yet

- MQP 2Document10 pagesMQP 2prithvirajd20No ratings yet

- Caixa Gbox - DocDocument15 pagesCaixa Gbox - Docsimao.bolaNo ratings yet

- Bolt Type Anchor Shackles Bolt Type Chain ShacklesDocument1 pageBolt Type Anchor Shackles Bolt Type Chain ShacklesdanamuanNo ratings yet

- Hot RolledDocument16 pagesHot Rolledlbo33No ratings yet

- Ti SPC Ohe Fasteners 0120Document31 pagesTi SPC Ohe Fasteners 0120guri317No ratings yet

- Codes For Vessels/Heat ExchangersDocument23 pagesCodes For Vessels/Heat ExchangersiFROG ChannelNo ratings yet

- Cat Aluminum KTDocument15 pagesCat Aluminum KTaaguilarm73No ratings yet

- LC Ms ThesisDocument4 pagesLC Ms ThesisWriteMyPhilosophyPaperMilwaukee100% (2)

- Proposal Based On EN 14742Document19 pagesProposal Based On EN 14742Popescu IoanaNo ratings yet

- Activity 1: Which Is Matter, Which Is Not?Document1 pageActivity 1: Which Is Matter, Which Is Not?Marites FernandezNo ratings yet

- FixationDocument5 pagesFixationMargalet Aguinaldo100% (1)

- 1.10 Partial Pressures and KP: Mole FractionDocument3 pages1.10 Partial Pressures and KP: Mole Fractionbazel mukuzeNo ratings yet

- 2014 Fundamentals of IRMS - EBD Course - Sevilla (Lecture Seule)Document128 pages2014 Fundamentals of IRMS - EBD Course - Sevilla (Lecture Seule)Hendy Dwi WarmikoNo ratings yet

- Ice CubesDocument8 pagesIce CubesAbeeha SaeedNo ratings yet

- Solution Manual For Chemistry For Today General Organic and Biochemistry 8th EditionDocument37 pagesSolution Manual For Chemistry For Today General Organic and Biochemistry 8th Editionrepastgraffitie17pv100% (14)

- Oiml G 10Document53 pagesOiml G 10Rafael DavidNo ratings yet

- Organic Chemistry Mechanistic Patterns Canadian 1St Edition Ogilvie Solutions Manual Full Chapter PDFDocument67 pagesOrganic Chemistry Mechanistic Patterns Canadian 1St Edition Ogilvie Solutions Manual Full Chapter PDFmisstepmonocarp1b69100% (7)

- What Are Some Things You Know About Acids and Bases?: Think in INK!Document3 pagesWhat Are Some Things You Know About Acids and Bases?: Think in INK!Nay Chi LwinNo ratings yet

- Iso 6320 2000Document9 pagesIso 6320 2000AbdelhamidKaabiaNo ratings yet

- Material Selection Guide FSD (3 1)Document2 pagesMaterial Selection Guide FSD (3 1)Dale XiaoNo ratings yet

- Experience With Calcium Treatment of SteelDocument4 pagesExperience With Calcium Treatment of SteelSarbendu Sanyal100% (1)

- CEN-TC227-WG1 N1449 CEN TC227 WG1 - CEN Enquiry Draft EN-131Document48 pagesCEN-TC227-WG1 N1449 CEN TC227 WG1 - CEN Enquiry Draft EN-131kamagaraNo ratings yet

- Ip 225-76Document3 pagesIp 225-76Nguyen NguyenNo ratings yet

- Anatomy and Physiology 6th Edition Marieb Test BankDocument36 pagesAnatomy and Physiology 6th Edition Marieb Test Bankinnodate.haemapodbtgdt100% (29)

- Arenes and Aromaticity: Example: Alkyl BenzenesDocument24 pagesArenes and Aromaticity: Example: Alkyl BenzenesSteveNo ratings yet

- INA BuchesDocument68 pagesINA BuchesTravis DavisNo ratings yet

- Chem 345 Exam IIIOS KeyDocument9 pagesChem 345 Exam IIIOS KeyQuoc AnhNo ratings yet

- Properties & Manufacturing & Applications & Limitations of PolymethylmethacrylateDocument4 pagesProperties & Manufacturing & Applications & Limitations of PolymethylmethacrylateRohith RaviNo ratings yet

- PAG 10.1 Rates - Iodine ClockDocument4 pagesPAG 10.1 Rates - Iodine ClockRoman AndrewsNo ratings yet

- 2) BC-6000 Air Dynamic and Liquid SystemDocument59 pages2) BC-6000 Air Dynamic and Liquid SystemCristian Ruiz Roman Ing. de ServicioNo ratings yet