Professional Documents

Culture Documents

Transmission Line Power Flow

Uploaded by

paramsihra5531Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transmission Line Power Flow

Uploaded by

paramsihra5531Copyright:

Available Formats

What limits power flow through an overhead transmission line?

The answer is it depends. It depends on what is limiting the power flow and how much of an increase is needed to solve the problem. In most circumstances, power flow limits are the result of concerns over electrical phase shift, voltage drop or thermal effects in lines, cables or substation equipment.

Surge Impedance Loading Limits

As power flows along a transmission line, there is an electrical phase shift, which increases with distance and with power flow. As this phase shift increases, the system in which the line is embedded can become increasingly unstable during electrical disturbances. Typically, for very long lines, the power flow must be limited to what is commonly called the Surge Impedance Loading (SIL) of the line. Surge Impedance Loading is equal to the product of the end bus voltages divided by the characteristic impedance of the line. Since the characteristic impedance of various HV and EHV lines is not dissimilar, the SIL depends approximately on the square of system voltage. Typically, stability limits may determine the maximum allowable power flow on lines that are more than 150 miles in length. For very long lines, the power flow limitation may be less than the SIL as shown in Table 0-1. Stability limits on power flow can be a low as 20% of the lines thermal limit. Typical stability limits as a function of system voltage are:

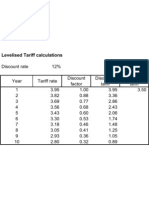

Table 0-1 - Power Flow Limits on Lines and Cables

System kV

XL (/mi)

XC (Mmi)

Surge Impedance ()

SIL(MW)

Thermal Rating (MW)

Transmission Overhead Line Characteristics 230 345 500 765 0.75 0.60 0.58 0.56 0.18 0.15 0.14 0.14 367 300 285 280 145 400 880 2090 440 1500 3000 8000

Transmission Cable Characteristics 345 0.25 0.0060 39 3050 2100

Voltage Drop Limits

In addition to electrical phase shift, voltage magnitude decreases with distance. Generally, for transmission lines, the maximum allowable drop in voltage is limited to between 5% and 10% of the sending end bus voltage. The power flow (in MVA or MW) that corresponds to the maximum allowable decrease in voltage magnitude is called the lines voltage drop limit. As with phase shift, a transmission lines voltage drop limit decreases with transmission distance and is generally higher than the lines thermal limit for short lines but less than the lines stability limit for very long lines. Voltage drop normally limits power flow on HV or EHV lines that are between 50 and 150 miles in length. Voltage drop limits on power flow can be as low as 40% of the lines thermal limit. Voltage drop limits may be increased by the addition of shunt capacitors at the end of the line. Such solutions are typically much cheaper than rebuilding the line.

Thermal Limits

Thermal power flow limits on overhead lines are intended to limit the temperature attained by the energized conductors and the resulting sag and loss of tensile strength. In most cases, the maximum conductor temperature applied to modern transmission lines reflect ground clearance concerns rather than annealing of aluminum. Thermal limits, as typically calculated, are not a function of line length. Thus for a given line design, a line 1 km long and one 500 km long typically have the same thermal limit. Thermal limits usually determine the maximum power flow for lines less than 50 miles in length. There are a number of possible methods by which the MVA thermal capacity of an existing line may be increased. Some of these methods are technically straightforward, such as reinforcing the structures and restringing the line with a larger conductor. These methods come at a price, however. In addition to the dollar cost involved, there is construction out on the line, and either outage time or special construction methods to allow service while the work is in progress. Other methods of thermal uprating, such as the use of weather dependent dynamic thermal ratings or voltage uprating by reduction from normal phase spacing, may require little or no line outage time and less capital investment than reconductoring and reinforcing the structures. The price here lies in the greater degree of technical sophistication required to ensure safe and reliable operation at higher loadings.

You might also like

- Mvar Cap CurveDocument17 pagesMvar Cap Curvemshireeshareddy100% (1)

- Diulvxwfroemhnv7m9ay9gwlkv9l4rDocument1 pageDiulvxwfroemhnv7m9ay9gwlkv9l4rparamsihra5531No ratings yet

- Modern Power Station PracticeDocument1,052 pagesModern Power Station Practiceparamsihra553195% (20)

- UntitledDocument1 pageUntitledTamas GyörigNo ratings yet

- NPL PDDDocument42 pagesNPL PDDparamsihra5531No ratings yet

- XRRatio ABBDocument2 pagesXRRatio ABBAshish RanjanNo ratings yet

- UntitledDocument1 pageUntitledTamas GyörigNo ratings yet

- FactsDocument9 pagesFactsparamsihra5531No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Modelling Load Flow and Short Circuit ScenariosDocument4 pagesModelling Load Flow and Short Circuit ScenariosCRISTIAN CAMILO MORALES SOLISNo ratings yet

- 14825Document76 pages14825tuncaNo ratings yet

- Proceedings of The Inter-ISC 18 PDFDocument240 pagesProceedings of The Inter-ISC 18 PDFLiviu GruiaNo ratings yet

- Measuring wavelength of light using diffraction gratingDocument5 pagesMeasuring wavelength of light using diffraction gratingSaksham BargujarNo ratings yet

- Shaker Screen Interchange Sell Sheet 1Document2 pagesShaker Screen Interchange Sell Sheet 1NME KaridaNo ratings yet

- Wehrhahn Dry Mortar Web en 5694 PDFDocument8 pagesWehrhahn Dry Mortar Web en 5694 PDFTUSHAR AGGARWALNo ratings yet

- Digital Fiberoptic Sensor: FS-N SeriesDocument28 pagesDigital Fiberoptic Sensor: FS-N SeriesOlger Garcia FalconesNo ratings yet

- Voltage Source Drive Programming Manual SummaryDocument262 pagesVoltage Source Drive Programming Manual SummaryCarolina HuertaNo ratings yet

- Arithmetic and Logic InstructionsDocument83 pagesArithmetic and Logic InstructionsAkash PandaNo ratings yet

- Soil Support Testing With DCP ToolsDocument2 pagesSoil Support Testing With DCP Toolsdana setiawanNo ratings yet

- Brake SystemDocument77 pagesBrake Systemmuchamad luthfi aliNo ratings yet

- Actuation Product Catalogue - OneSteelDocument65 pagesActuation Product Catalogue - OneSteelJOHN100% (1)

- Midterm Exam Physics General 1 Forces MotionDocument3 pagesMidterm Exam Physics General 1 Forces MotionNam Anh Nguyễn HữuNo ratings yet

- 0653 s16 QP 62Document20 pages0653 s16 QP 62yuke kristinaNo ratings yet

- Civil Engineering Laboratory DSTDocument6 pagesCivil Engineering Laboratory DSTJuhil ZalavadiyaNo ratings yet

- Java Developer ResumeDocument3 pagesJava Developer ResumeRavi ManiyarNo ratings yet

- p92-3838 Harness - Front Chassis CumminsDocument11 pagesp92-3838 Harness - Front Chassis CumminsDiego LiraNo ratings yet

- CV - Hamdullah UÇAR-ıngDocument3 pagesCV - Hamdullah UÇAR-ıngHamdullah UcarNo ratings yet

- Fault Current CalculatorDocument6 pagesFault Current CalculatorVũDuyTânNo ratings yet

- Liste de Prix BCM Juin 2010Document4 pagesListe de Prix BCM Juin 2010bakzazamNo ratings yet

- Five Generations of ComputersDocument4 pagesFive Generations of ComputersMohammed Abu ShaibuNo ratings yet

- TSIO-550 Operation ManualDocument8 pagesTSIO-550 Operation ManualoscarNo ratings yet

- Lift Car Hidrolis Dan SelingDocument32 pagesLift Car Hidrolis Dan SelingMuhammad Arief PrasetyaNo ratings yet

- Colour InconstancyDocument20 pagesColour InconstancynausheneNo ratings yet

- Writing A Parser From Wire To WindowDocument43 pagesWriting A Parser From Wire To WindowJonah H. HarrisNo ratings yet

- Hydro PDFDocument139 pagesHydro PDFVan Quynh100% (2)

- Applying Appropriate SealantDocument64 pagesApplying Appropriate SealantShina AbieraNo ratings yet

- Store 150Document12 pagesStore 150shawanqureshi1706160No ratings yet

- 2 Rectilinear Motion (Updated)Document46 pages2 Rectilinear Motion (Updated)sefieilgua100% (1)

- jQuery 3 Day CourseDocument6 pagesjQuery 3 Day CourseAmit SharmaNo ratings yet