Professional Documents

Culture Documents

Welds

Uploaded by

abeyivanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welds

Uploaded by

abeyivanCopyright:

Available Formats

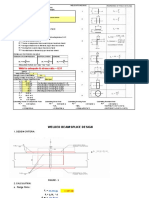

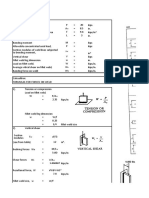

This worksheet is for checking weld sizes References: Pressure Vessel Handbook, 8th ed, Megyesy Mechanical Engineering

Design, 7th ed, Shigley By: DJY Date: 8/4/2008 Job: 6093 Description of weld: Vaporizer skid cross beam to main welds

WELD OUTLINE CASE

DEFINITION OF SYMBOLS A w = Length of weld, in f = Allowable unit force on weld, kip per lin in of weld M = Bending moment, kip-in l = Bending moment arm length, in P = Tension or Compression Load S w = Section Modulus of weld lines subjected to bending moment, in^2 V = Vertical load for bending and/or shear, kip w = Fillet weld leg dimension, in W n = Tensive or compressive force on weld, kip per lineal inch of weld W s = Average vertical shear on fillet weld, kip per lineal inch of weld W b = Bending force on weld, kip per lineal inch of weld W r = Resultant load on fillet weld, kip per lineal inch of weld FORMULAS FOR FORCES ON WELD TENSION OR COMPRESSION VERTICAL SHEAR Wn = P Aw Ws = V Aw

BENDING 5 Wb = M Sw

2 2 2 RESULTANT FORCE: W r = (W n + W s + W b )

Weld is adequate & stress ratio = 0.51

INPUT 6 Weld Outline Case: 5 Strength Level of Weld Metal: 70* Loading condition for bending, ieCantilever or Mid-Span of Simply Supported Beam Mid-Span w = 3/8 in P = 12.50 kip If no tension or compression is present, P = 0 V= 12.50 kip If only tension or compression is present, V = 0 7 b= 4 in Weld dimension; refer to figure on right d= 10 in Weld dimension; refer to figure on right l= 48 in If bending is not to be considered, l = 0 Aw = 18.00 in Sw = 56.67 in^2 8 M= 150 lb-in f = 5.57 kip/lin in Calculating Tensive or Compressive Force Calculating Shear Force Calculating Bending Force Wn = Ws = Wb = 0.69 kip/lin in 0.69 kip/lin in 2.65 kip/lin in =P/Aw =V/Aw =M/Sw =12.5kip/18lin in =12.5kip/18lin in =150kip-in/56.67in^2

Calculating Resultant Force Wr = 2.82 kip/lin in =SQRT(W n^2 + W s^2 + W b^2) =SQRT(0.69^2 + 0.69^2 + 2.65^2)

You might also like

- Calculation Sheet: Padeye Calculations LoadsDocument15 pagesCalculation Sheet: Padeye Calculations Loadsshani5573No ratings yet

- BEAMCOL9Document10 pagesBEAMCOL9Richard FallegaNo ratings yet

- AISC 13th Slip Critical Bolt Capacity ASDDocument1 pageAISC 13th Slip Critical Bolt Capacity ASDdantevariasNo ratings yet

- 6952-4.T&Angle-Brace Connection (Knee Brace) (M Project) - 0618Document81 pages6952-4.T&Angle-Brace Connection (Knee Brace) (M Project) - 0618Omprakash KhodkeNo ratings yet

- "Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionDocument7 pages"Baseplt9" - Steel Column Base Plate Analysis: Program Descriptionsivasan10006098No ratings yet

- EMBEDMENT CALCULATIONDocument5 pagesEMBEDMENT CALCULATIONMWKELIOLANo ratings yet

- Basic Design ValuesDocument4 pagesBasic Design Valuesnenpatel-1No ratings yet

- Capacities of UB SectionsDocument48 pagesCapacities of UB SectionsRohan KarandeNo ratings yet

- Hot-rolled steel beam section properties and classificationDocument19 pagesHot-rolled steel beam section properties and classificationken koemhongNo ratings yet

- LRFD Beam Column DesignDocument242 pagesLRFD Beam Column DesignChristian FTNo ratings yet

- Anchor Bolt and Base PlateDocument4 pagesAnchor Bolt and Base Platevijaystructural100% (1)

- Atasehir Gardens Podium OF: Member: LocationDocument7 pagesAtasehir Gardens Podium OF: Member: LocationAlphyl BalasabasNo ratings yet

- Pad Eye Connected To Bottom PieceDocument7 pagesPad Eye Connected To Bottom PieceAsaru Deen0% (1)

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaNo ratings yet

- Beam Column Web ConnectionsDocument9 pagesBeam Column Web Connectionsmsiddiq1No ratings yet

- Base Plate Design CapacitiesDocument4 pagesBase Plate Design CapacitiesSrishti Project Consultants0% (1)

- DESIGN OF AXIAL & BENT COLUMN SECTIONDocument4 pagesDESIGN OF AXIAL & BENT COLUMN SECTIONdsanandaNo ratings yet

- RHS & SHS Welding DesignDocument1 pageRHS & SHS Welding DesignMyat Thu Zar KhineNo ratings yet

- Baseplate MonorailDocument31 pagesBaseplate Monorailmohamad chandraNo ratings yet

- Four Bolt Moment Connection DesignDocument12 pagesFour Bolt Moment Connection DesignDarshan Panchal0% (1)

- DG Consulting EngineersDocument8 pagesDG Consulting EngineersThakshayani SellavelNo ratings yet

- Pin Design AISCDocument3 pagesPin Design AISCFernando SimaNo ratings yet

- Specification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsDocument9 pagesSpecification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsMr Incognito100% (1)

- Anchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDDocument11 pagesAnchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDTimothy PinchinNo ratings yet

- Universal Beam and Column Properties SheetDocument11 pagesUniversal Beam and Column Properties SheetkalpanaadhiNo ratings yet

- AISC Tension MemberDocument3 pagesAISC Tension Membermodulor3dNo ratings yet

- Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionDocument1 pageCapacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionThiha KyawNo ratings yet

- BOLTGRP13Document33 pagesBOLTGRP13NEONo ratings yet

- Pad Eye DesignFDocument8 pagesPad Eye DesignFRajasekar MeghanadhNo ratings yet

- "Shear-End-Pl-13" - Beam End Connection Using Shear End PlatesDocument16 pages"Shear-End-Pl-13" - Beam End Connection Using Shear End PlatesArdXkillerNo ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- Embedded PlateDocument2 pagesEmbedded PlateAlma M. LaraNo ratings yet

- Fin Plate-Beam To Beam Inside (AISC-LRFD)Document184 pagesFin Plate-Beam To Beam Inside (AISC-LRFD)AshishNo ratings yet

- "Bracket13" - Bracket Plate Stress Analysis ProgramDocument7 pages"Bracket13" - Bracket Plate Stress Analysis ProgramFarid TataNo ratings yet

- Moment To Column WebDocument905 pagesMoment To Column WebAmanpreet SinghNo ratings yet

- Padeye - 01Document9 pagesPadeye - 01ramNo ratings yet

- Fillet Weld Connection DesignDocument1 pageFillet Weld Connection Designbalaji gmscNo ratings yet

- Corbel and NibDocument17 pagesCorbel and NibCatherine Mohanji GeraNo ratings yet

- GratingDocument4 pagesGratingrammohan100% (1)

- (Joint 1760) : PT - Technip IndonesiaDocument12 pages(Joint 1760) : PT - Technip IndonesiariandiNo ratings yet

- Analysis of Self-Supported Steel Chimney With The Effects of Geometrical ParametersDocument6 pagesAnalysis of Self-Supported Steel Chimney With The Effects of Geometrical Parametersvikram413No ratings yet

- BMREINF13Document50 pagesBMREINF13NEO100% (1)

- Double Angle ConnectionDocument8 pagesDouble Angle ConnectionrunkirNo ratings yet

- Clipconn All Bolt 13Document22 pagesClipconn All Bolt 13NEONo ratings yet

- Project Job Ref.: V B T, y T, R CDocument3 pagesProject Job Ref.: V B T, y T, R CM IQbalNo ratings yet

- Design of Bolt Connections - GussetDocument5 pagesDesign of Bolt Connections - GussetKINGSUK PALNo ratings yet

- Design of Stel Compression Members BS F950Document12 pagesDesign of Stel Compression Members BS F950Rotich VincentNo ratings yet

- Anchor Bolt CheckDocument335 pagesAnchor Bolt CheckariyaNo ratings yet

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNo ratings yet

- Splice 03Document15 pagesSplice 03LexNo ratings yet

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- Annex A:Lifting Lug CalculationDocument3 pagesAnnex A:Lifting Lug CalculationVilas AndhaleNo ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- 15 Ton Tank Concrete PlatformDocument1 page15 Ton Tank Concrete PlatformerickquintoNo ratings yet

- Calculating Gpl under ecc loadingDocument60 pagesCalculating Gpl under ecc loadingandyhrNo ratings yet

- Insert Plate DesignDocument24 pagesInsert Plate Designabhi arote100% (1)

- Beam - Deflection CheckDocument8 pagesBeam - Deflection ChecksharanekkmNo ratings yet

- Welding Splice DesignDocument4 pagesWelding Splice DesignSana Ullah50% (2)

- Design of welded joints formulasDocument4 pagesDesign of welded joints formulasmiteshpatel191No ratings yet

- Calculation of left and right saddle supports for offshore tankerDocument12 pagesCalculation of left and right saddle supports for offshore tankerrustamriyadiNo ratings yet

- BR128 LtGaugeInstallDocument50 pagesBR128 LtGaugeInstallssss2345No ratings yet

- Bending Moment, Shear Force and Deflection FormulasDocument71 pagesBending Moment, Shear Force and Deflection FormulaskumarsathishsNo ratings yet

- CorbelDocument12 pagesCorbelSri Datta Kiran Kuchibhatla67% (3)

- EPA CalculationDocument11 pagesEPA Calculationabeyivan75% (4)

- Lecture 15Document7 pagesLecture 15gendadeyu552625No ratings yet

- TIA 222G wind load parametersDocument29 pagesTIA 222G wind load parametersabeyivan100% (3)

- Overview of Pathophysiology of Hypoxemia and HypoxiaDocument15 pagesOverview of Pathophysiology of Hypoxemia and HypoxiaMARY ANN CAGATANNo ratings yet

- Large and Medium Manufacturing Industry Survey Report 2018Document778 pagesLarge and Medium Manufacturing Industry Survey Report 2018melakuNo ratings yet

- B.pharm Course Handbook 2017 18Document74 pagesB.pharm Course Handbook 2017 18Md RaquibNo ratings yet

- Cardiopulmonary System: Relevant Anatomy & Physiology: HeartDocument12 pagesCardiopulmonary System: Relevant Anatomy & Physiology: HeartJulia SalvioNo ratings yet

- Blues, Rock and Americana MixDocument4 pagesBlues, Rock and Americana MixLuis CrownNo ratings yet

- Home Contents Vehicle Boat Cover Policy Sample Westpac NZDocument27 pagesHome Contents Vehicle Boat Cover Policy Sample Westpac NZRobin Rutter-BaumannNo ratings yet

- 3.1 From Algae To Terrestrial Plants-Student SheetDocument2 pages3.1 From Algae To Terrestrial Plants-Student Sheeteshaaljamal27No ratings yet

- I Wanna Be Yours Arctic Monkeys Love SongDocument3 pagesI Wanna Be Yours Arctic Monkeys Love SongAndréia E NiltonNo ratings yet

- 2 History of OrthodonticsDocument11 pages2 History of OrthodonticsMeiz JaleelNo ratings yet

- Tiger 690 Conversion PDFDocument8 pagesTiger 690 Conversion PDFGerardo Esteban Lagos RojasNo ratings yet

- Dimensions and Relations of The Dentogingival Junction in Humans. Gargiulo 1961Document7 pagesDimensions and Relations of The Dentogingival Junction in Humans. Gargiulo 1961Linda Garcia PNo ratings yet

- Chapter 3 (CHM 127)Document105 pagesChapter 3 (CHM 127)FiqajasmeNo ratings yet

- Protreat Hydro EngrgDocument6 pagesProtreat Hydro EngrgAmitkumar SinghNo ratings yet

- Chapter 1 - Introduction To Machinery PrinciplesDocument27 pagesChapter 1 - Introduction To Machinery PrinciplesYousab CreatorNo ratings yet

- GreyFox Intercom Install GuideDocument12 pagesGreyFox Intercom Install GuideAbdallah HashemNo ratings yet

- Narayana Sukta MeaningDocument4 pagesNarayana Sukta Meaningvinai.20No ratings yet

- Dental Radiographs and Photographs in Human Forensic IdentificationDocument8 pagesDental Radiographs and Photographs in Human Forensic IdentificationBudi PurnomoNo ratings yet

- Why Check Valves SlamDocument2 pagesWhy Check Valves SlamBramJanssen76No ratings yet

- English Test 6Document87 pagesEnglish Test 6Ha PhanNo ratings yet

- 11 F.Y.B.Sc - Chemistry PDFDocument22 pages11 F.Y.B.Sc - Chemistry PDFmalini PatilNo ratings yet

- Eng ThreePDocument192 pagesEng ThreePMr Ahmed AbdallahNo ratings yet

- Lab Journal 4 14032023 104921amDocument8 pagesLab Journal 4 14032023 104921amHammad MashwaniNo ratings yet

- BBO 2011 ROUND 2 QUESTIONSDocument16 pagesBBO 2011 ROUND 2 QUESTIONSMalvina YuanNo ratings yet

- English Qualification TestDocument5 pagesEnglish Qualification TestMoh FaisolNo ratings yet

- Reference Design Hardware Guide for EVM CE-2Document7 pagesReference Design Hardware Guide for EVM CE-2Angie FoleyNo ratings yet

- Turkey ImportDocument14 pagesTurkey ImportMani 1No ratings yet

- MICROPAR PPT Group ADocument43 pagesMICROPAR PPT Group AEben Alameda-PalapuzNo ratings yet

- ABYIPDocument18 pagesABYIP千住 マリエルNo ratings yet

- SI44M 60H 80H-DeN1730-V12web DownloadedDocument4 pagesSI44M 60H 80H-DeN1730-V12web DownloadedtauraimukumbaNo ratings yet

- Assignment #1: 1 HgjyygbykvrfDocument1 pageAssignment #1: 1 HgjyygbykvrfJuan Sebastian ArangoNo ratings yet