Professional Documents

Culture Documents

Kluber Synthetic Oil

Uploaded by

Rajiv SrivastavaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kluber Synthetic Oil

Uploaded by

Rajiv SrivastavaCopyright:

Available Formats

Healthcare for Your Air Compressors ...

Klber Summit Air Compressor Oils for different industrial Applications

www.klueber.com March 2004 Holger Krber Compressor Training.ppt-Page 1

3 Rotary Screw Compressor

Flow Diagram 1 2 3 4 Rotary Screw Bearings Oil Seperator Oil Filter

Oil is injected in the compression chamber.

The oil-air mixture is discharged (oil vapor and oil aerosols in the compressed air)

March 2004

The oil separator removes only the oil aerosols out of the air stream (not the oil vapor !)

Holger Krber

Compressed air leaves through the oil separator, cooler and filter

Compressor Training.ppt-Page 2

www.klueber.com

4 Klber Product Favorites

For rotary screw compressors

Characteristic: Excellent oxidation stability - for extended oil cange intervals and optimum performance (>8.000 hours)

www.klueber.com March 2004 Holger Krber Compressor Training.ppt-Page 3

4 Klber Product Favorites

For rotary screw compressors

Characteristic: For conversion of Ingersoll-Rand and Sullair compressors with better performance and lifetime

www.klueber.com March 2004 Holger Krber Compressor Training.ppt-Page 4

4 Klber Product Favorites

For rotary screw compressors

Characteristic: For the use in food producing plants to meet the H1 requirements - for lifetimes of about 4.000 hours

www.klueber.com March 2004 Holger Krber Compressor Training.ppt-Page 5

5 Argumentation and benefits 5.1 Oxidation Stability

Klber Summit SH-series achieve oil change intervals up to 8.000 operating hours (based on 90C and 8 bars) Mineral based oils typically achieve only 2.000 hours 15 K-Rule: 15 K increase in temperature cuts the oil change interval by half

Example for deposits in a rotary screw due to strong oxydation

www.klueber.com March 2004 Holger Krber Compressor Training.ppt-Page 6

5 Argumentation and benefits 5.1 Oxidation Stability

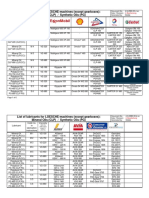

ASTM D-2272 (RBOT): Rotary Bomb Oxidation Test

3000 2500 2000 1500 1000 500 0

KL SUMMIT SB-46 MINUTES 2486 LeROI SSL-46 2155 QUINCY QUINSYN 1997 KL SUMMIT KL SUMMIT MOBIL SUPRA HYSYN FG- RARUS SHC COOLANT 46 1024 1665 1645 1615 Shell CORENA AS 46 1573 BOGE LONGLIFE S46 1198 IR ULTRA COOLANT PLUS 1147 SULLAIR SULLUBE 32 692

ANDEROL 3046 1327

KL SUMMIT SUPRA 32 1180

www.klueber.com

March 2004

Holger Krber

Compressor Training.ppt-Page 7

5 Argumentation and benefits 5.1 Oxidation Stability Whats the benefit for the customer?

www.klueber.com

March 2004

Holger Krber

Compressor Training.ppt-Page 8

5 Argumentation and benefits 5.2 Evaporation Stability

Klber Summit air compressor oils have a lower tendency to evaporate under high temperatures within the compressor Mineral based oils typically evaporate faster Short molecule content

www.klueber.com

March 2004

Holger Krber

Compressor Training.ppt-Page 9

5 Argumentation and benefits 5.2 Evaporation Stability Whats the benefit for the costumer?

Active carbon filter

www.klueber.com

March 2004

Holger Krber

Compressor Training.ppt-Page 10

5 Argumentation and benefits 5.3 Energy Savings

Klber Summit air compressor oils have a lower friction coefficient and a better VT behavior compared to mineral based oils Lower friction coefficient and better VT-behavior generate lower energy consumption Oil injected rotary screws: Energy savings between 2 and 4 % possible

www.klueber.com March 2004 Holger Krber Compressor Training.ppt-Page 11

5 Argumentation and benefits 5.3 Energy Savings Whats the benefit for the costumer?

www.klueber.com

March 2004

Holger Krber

Compressor Training.ppt-Page 12

9 Oil Changeover Procedure

You convinced the customer and he buys our product. How would you carry out the oil change? Have you ever heard of Klber Summit Varnasolv?

www.klueber.com

March 2004

Holger Krber

Compressor Training.ppt-Page 13

9 Oil Changeover Procedure

1) Take an oil sample of the previosly used oil to determine the condition of the compressor (wear metals, oil condition) 2) Add 10% Klber Summit Varnasolv for a cleaning during operation for about 40 to 60 hours 3) Drain the old oil (mixture with Varnasolv) and clean all pipes, hoses, filter elements and the oil reservoir 4) Change all filters and oil separators and fill up the new oil 5) Start the compressor and take oil samples on a regular basis to determine the oil change interval 6) When changing to Klber Summit HySyn FG-series: Add a second flushing procedure with Klber Summit HySyn FG-oil after flushing with Klber Summit Varnasolv!

www.klueber.com March 2004 Holger Krber Compressor Training.ppt-Page 14

You might also like

- Advantages of Zinc-Free Hydraulic OilsDocument2 pagesAdvantages of Zinc-Free Hydraulic OilsAnonymous F2TxS3YoaNo ratings yet

- Basf Compounded Lubricants Product CatalogueDocument4 pagesBasf Compounded Lubricants Product Catalogueapi-233668671No ratings yet

- Gear Lubrication 3Document9 pagesGear Lubrication 3rashm006ranjan100% (1)

- F Essenbeck ErDocument22 pagesF Essenbeck Eranhntran4850No ratings yet

- Kluber PresentationDocument79 pagesKluber PresentationZegera MgendiNo ratings yet

- Rust X Brouser PDFDocument4 pagesRust X Brouser PDFPradeep KatiyarNo ratings yet

- FUCHS LUBRITECH Product RangeDocument76 pagesFUCHS LUBRITECH Product RangeBurak GüleşNo ratings yet

- 03 BPA Bakery IndustryDocument12 pages03 BPA Bakery IndustryMAYANK AGARWALNo ratings yet

- Screw TechDocument34 pagesScrew TechJaime Munoz100% (1)

- Foodgrade Lubricants PDFDocument3 pagesFoodgrade Lubricants PDFSridhar ReddyNo ratings yet

- The Basics of Food-Grade LubricantsDocument6 pagesThe Basics of Food-Grade LubricantsOscar CampoNo ratings yet

- List of Products Related To Danieli Standard 0.000.001 - Rev.15Document11 pagesList of Products Related To Danieli Standard 0.000.001 - Rev.15cotteNo ratings yet

- A Comprehensive Solution For Extreme and Specialty ApplicationsDocument7 pagesA Comprehensive Solution For Extreme and Specialty ApplicationsAmjedNo ratings yet

- X - Hydraulic Fluids Electronic HandoutDocument41 pagesX - Hydraulic Fluids Electronic HandoutRay Cepeda Mena100% (1)

- Produktkatalog 2016Document37 pagesProduktkatalog 2016razvanNo ratings yet

- BROCHURE Premium Greases Guide TNRDocument7 pagesBROCHURE Premium Greases Guide TNRRezhaNo ratings yet

- Basic of Lubricant and Lubrication-2Document34 pagesBasic of Lubricant and Lubrication-2Dhanie EndaNo ratings yet

- Technical Focus: UV Curing Short Runs BearingsDocument68 pagesTechnical Focus: UV Curing Short Runs BearingsRicardo Reno RibeiroNo ratings yet

- Industrial - Nye LubricantsDocument3 pagesIndustrial - Nye LubricantsJashim UddinNo ratings yet

- Kluber Lubrication Gear Greases: Portfolio and Grease SelectionDocument31 pagesKluber Lubrication Gear Greases: Portfolio and Grease SelectionErick AvilaNo ratings yet

- Mobil Machine Tool Lubricant PDFDocument66 pagesMobil Machine Tool Lubricant PDFarman chowdhuryNo ratings yet

- Schmiermittelvergleichsliste Öle List of Various Lubricants Oils Lista de Lubricantes Diversos PetróleoDocument3 pagesSchmiermittelvergleichsliste Öle List of Various Lubricants Oils Lista de Lubricantes Diversos PetróleoHaroldoNo ratings yet

- Orelube Food Grade Lubricants - The Orelube Corporation-Pages-1-3Document3 pagesOrelube Food Grade Lubricants - The Orelube Corporation-Pages-1-3Nanthini SevendadasanNo ratings yet

- 01 BPA Food IndustryDocument29 pages01 BPA Food IndustryMAYANK AGARWALNo ratings yet

- High Temperature Grease and Lubricants Market Size, Share and Forecast Upto 2021Document6 pagesHigh Temperature Grease and Lubricants Market Size, Share and Forecast Upto 2021Hari PurwadiNo ratings yet

- Molykote For Sugar Mill Machinery Call +91-98851-49412Document4 pagesMolykote For Sugar Mill Machinery Call +91-98851-49412Project Sales CorpNo ratings yet

- EIC N 1001 0 Hydraulic FluidsDocument13 pagesEIC N 1001 0 Hydraulic FluidsCharitha LiyanagamaNo ratings yet

- Kusa Chemicals Private Limited: Kusapour 340Document1 pageKusa Chemicals Private Limited: Kusapour 340n.hartonoNo ratings yet

- Synthetic Gear Oil SelectionDocument9 pagesSynthetic Gear Oil Selectionsmallik3No ratings yet

- Industrial GreaseDocument6 pagesIndustrial GreaseNurHadi S WibowoNo ratings yet

- Water Soluble Cutting Oil Mobilcut SeriesDocument2 pagesWater Soluble Cutting Oil Mobilcut SeriesAxel Mahya AvichenaNo ratings yet

- Food Grade Lube From Each BrandDocument6 pagesFood Grade Lube From Each BrandCindy OrangeNo ratings yet

- Calcium Sulfonate Complex GreasesDocument9 pagesCalcium Sulfonate Complex GreasesFrancis XavierNo ratings yet

- How To Choose The Right LubricantDocument2 pagesHow To Choose The Right LubricantHesham MahdyNo ratings yet

- 2015 Lubricant FundamentalsDocument47 pages2015 Lubricant FundamentalsRoberto Gómez100% (2)

- Brugarolas Food Industry CatalogueDocument4 pagesBrugarolas Food Industry CataloguenghiaNo ratings yet

- Fundamentals of Lubrication: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDocument38 pagesFundamentals of Lubrication: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia CoralieNo ratings yet

- Loesche List of Lubricants 03 2015 - enDocument6 pagesLoesche List of Lubricants 03 2015 - enphucdc095041No ratings yet

- Viscosity & Viscosity Modifiers: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDocument39 pagesViscosity & Viscosity Modifiers: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia CoralieNo ratings yet

- Lubricant Base Stocks: OutlineDocument23 pagesLubricant Base Stocks: OutlineJahmia Coralie100% (1)

- Fundamentals of Engine Design and Operation: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDocument62 pagesFundamentals of Engine Design and Operation: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia Coralie100% (1)

- High Temperature Grease: DescriptionDocument2 pagesHigh Temperature Grease: Descriptionvicky kNo ratings yet

- Field Testing: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDocument47 pagesField Testing: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia CoralieNo ratings yet

- Mobil Serv Lubricants Analysis Guide 2 PDFDocument20 pagesMobil Serv Lubricants Analysis Guide 2 PDFFajar EkoNo ratings yet

- Kluber-Brochure Lubrication of Various ComponentsDocument17 pagesKluber-Brochure Lubrication of Various ComponentsjalalNo ratings yet

- Product Equivalents OIL PDFDocument5 pagesProduct Equivalents OIL PDFLucasNo ratings yet

- Guidelines & DiagramsDocument20 pagesGuidelines & DiagramsVania BaradiNo ratings yet

- Oil Recommendation For Sauer CompressorsDocument15 pagesOil Recommendation For Sauer CompressorsFILIN VLADIMIR100% (1)

- Construction Lube Apps 18 Jan 16Document46 pagesConstruction Lube Apps 18 Jan 16José Cesário NetoNo ratings yet

- Lubricants For Textile Industry - Spinning / Preparation MachinesDocument6 pagesLubricants For Textile Industry - Spinning / Preparation MachinesAbd Allatife AlshehabiNo ratings yet

- SHELL Product Data Guide Industry 2013Document78 pagesSHELL Product Data Guide Industry 2013Edgar Real ViúlaNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsdnoaisapsNo ratings yet

- Manufacturer Brand Viscosity Base Oil Drop PointDocument8 pagesManufacturer Brand Viscosity Base Oil Drop PointPhillip Feng100% (1)

- Metal Forming Lubricants: Wire Drawing Cold Forming Sheet Metal Forming RollingDocument7 pagesMetal Forming Lubricants: Wire Drawing Cold Forming Sheet Metal Forming RollingNokiabhre WijayaNo ratings yet

- ACEA Engine Oil in ShortDocument2 pagesACEA Engine Oil in ShortRajiv SrivastavaNo ratings yet

- Cortec India NACE - SZ and CII Sept, 2014Document70 pagesCortec India NACE - SZ and CII Sept, 2014harishkumar.ravichandranNo ratings yet

- Shell Risella X 420: Specifications, Approvals & RecommendationsDocument2 pagesShell Risella X 420: Specifications, Approvals & RecommendationsHUM CIREBON DFLTS100% (1)

- Chapter 2 Tensile PropertiesDocument47 pagesChapter 2 Tensile PropertiesMd Nasif MridhaNo ratings yet

- Dieselmax 55kW Engine SpecDocument4 pagesDieselmax 55kW Engine SpecSamir Khan100% (1)

- The Indian Weekender, Friday 15 May 2020 - Volume 12 Issue 09Document20 pagesThe Indian Weekender, Friday 15 May 2020 - Volume 12 Issue 09Indian Weekender ReporterNo ratings yet

- Potato Storage Technology and Store Design Aspects: Eltawil69@yahoo - Co.inDocument18 pagesPotato Storage Technology and Store Design Aspects: Eltawil69@yahoo - Co.inDaniel NedelcuNo ratings yet

- Modelling The Transport of Crude Oil in Sandy Soil: Ejikeme Ugwoha, Victor Emeka Amah, Precious Ehis Agharese-AduDocument12 pagesModelling The Transport of Crude Oil in Sandy Soil: Ejikeme Ugwoha, Victor Emeka Amah, Precious Ehis Agharese-AdusfNo ratings yet

- Electrophile and Nucleophile - Electrophile, Nucleophile, Difference Between Electrophile and NucleophileDocument17 pagesElectrophile and Nucleophile - Electrophile, Nucleophile, Difference Between Electrophile and NucleophileTomiwa AdeshinaNo ratings yet

- Treatment Plan 3Document8 pagesTreatment Plan 3Kathy Lee Hornbeck KendrickNo ratings yet

- Service Bulletin: CautionDocument8 pagesService Bulletin: CautiondfmolinaNo ratings yet

- Xtralift NBS Specification MAY21Document4 pagesXtralift NBS Specification MAY21Ahmed AbdelftahNo ratings yet

- Central Banks Retail Forex DealersDocument7 pagesCentral Banks Retail Forex DealersBCom HonsNo ratings yet

- MotherDocument11 pagesMotherMuhammad Lucky AlfaridzyNo ratings yet

- SafetyMAP Measuring ManagementDocument4 pagesSafetyMAP Measuring Managementindri anggrainiNo ratings yet

- Sina and EelDocument2 pagesSina and Eelapi-290999754No ratings yet

- Total Kjeldahl Nitrogen (TKN) Faqs: Why Is TKN Important?Document4 pagesTotal Kjeldahl Nitrogen (TKN) Faqs: Why Is TKN Important?dsbishtNo ratings yet

- Chapter 52 - Drugs Affecting The Urinary Tract and The BladderDocument12 pagesChapter 52 - Drugs Affecting The Urinary Tract and The BladderJonathonNo ratings yet

- Chapter 3: Curriculum Design: The Teacher and The School Curriculum A Guide To Curriculum DevelopmentDocument14 pagesChapter 3: Curriculum Design: The Teacher and The School Curriculum A Guide To Curriculum Developmenthannah mari100% (1)

- ALP 9th Bio. Ch. 3 MCQs - Nauman SadafDocument2 pagesALP 9th Bio. Ch. 3 MCQs - Nauman SadafSohail AfzalNo ratings yet

- Leeson Plan New NebulizationDocument8 pagesLeeson Plan New NebulizationMakhanVerma100% (6)

- NTCP TCPDocument54 pagesNTCP TCPSAlonii Chawla100% (2)

- Activity Sheet 3 in Science ViDocument4 pagesActivity Sheet 3 in Science ViJohn Cyrel MondejarNo ratings yet

- Lost Youth Assignment-2Document2 pagesLost Youth Assignment-2api-363462333No ratings yet

- Electrolyte & Acid Base Disturbances in Diabetes MellitusDocument12 pagesElectrolyte & Acid Base Disturbances in Diabetes MellitusAla SoroceanuNo ratings yet

- Fuji FCR 5000Document435 pagesFuji FCR 5000Lion Micheal OtitolaiyeNo ratings yet

- Sentinel Node Biopsy For CA BreastDocument7 pagesSentinel Node Biopsy For CA Breastwasima1956No ratings yet

- Mothership Zine Rulebook v5 PDFDocument44 pagesMothership Zine Rulebook v5 PDFAna Luiza FernandesNo ratings yet

- Formatof Indenity BondDocument2 pagesFormatof Indenity BondSudhir SinhaNo ratings yet

- Weld Neck Flange Inches / Pounds: CLASS 900Document1 pageWeld Neck Flange Inches / Pounds: CLASS 900ksathishgreenNo ratings yet

- Young Children's Use of Digital Media and The Corresponding Parental MediationDocument15 pagesYoung Children's Use of Digital Media and The Corresponding Parental MediationFernan EnadNo ratings yet

- Aalco Metals LTD - Stainless Steel 201201L202204 - 97 PDFDocument3 pagesAalco Metals LTD - Stainless Steel 201201L202204 - 97 PDFNaman PrajapatiNo ratings yet

- Initiatives For Field StaffDocument1 pageInitiatives For Field Staffkalpesh thakerNo ratings yet