Professional Documents

Culture Documents

Example Vessel Re Rating

Uploaded by

RBKUMAROriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Example Vessel Re Rating

Uploaded by

RBKUMARCopyright:

Available Formats

PRESSURE EQUIPMENT ENGINEERING SERVICES, INC.

402 WILD PEACH PLACE MISSOURI CITY, TX - 77459

TEL. : (281)-261-4628 FAX : (281)-261-4629 E-Mail: Bharat@peesi.com

EVALUATION OF THE VESSEL TO CALCULATE THE MINIMUM RETIREMENT THICKNESS VALUES FOR VARIOUS COMPONENTS OF THE VESSEL AND TO RE-RATE THE VESSEL TO A HIGHER TEMPERATURE

PROBLEM DESCRIPTION:

The current design conditions for the carbon steel vessel were 86 psig @ 400 F. It was requested to rerate the vessel to a possible higher temperature of 820 F. The engineering analysis and fitness-for-service evaluation of the vessel was required to see if the vessel can be qualified for 86 psig @ 820 F operation. Also, it was required to calculate the minimum retirement thickness values based on the re-rated design conditions.

RESULTS:

The vessel was analyzed using the Pressure vessel design and analysis software COMPRESS. It should be noted that the vessel has Class 150 and Class 300 flanges. The Carbon steel Class 150 flanges are not rated for 86 psig @ 820 F. Hence, the temperature rating of 86 psig @ 820 F could not be achieved for this vessel. However, the vessel was found to be suitable for 86 psig @ 720 F and it has been rated for these conditions. The re-rated design temperature was acceptable for the operation of the vessel. The new recommended minimum retirement thickness values were based on the re-rated MAWP condition of 86 psig @ 720 F. It was also determined that with the new retirement thickness values, the vessel had enough safe and useful life for continued operation for next 3 - 4 years.

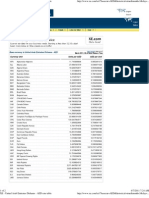

Pressure Summary

Pressure Summary Pressure Summary for Chamber bounded by Bottom Head - Hemispherical and Top Head Ellipsoidal

T MAWP Design ( psi) (F) 720.0 720.0 720.0 720.0 720.0 127.35 126.84 130.59 133.18 104.00 103.89 87.13 103.89 117.54 103.89 120.64 103.89 94.84 99.03 126.24 562.03 311.30 97.24 98.50 MDMT Rating MAP ( psi) MDMT (F) Note 1 Note 2 Note 3 Note 4 Note 5 Note 5 Note 5 Note 5 Nozzle Note 6; Pad note 7 Note 5 Nozzle Note 8; Pad note 9 Note 5 Nozzle Note 5; Pad note 10 Note 5 Nozzle Note 11; Pad note 12 Note 13 Note 14 Note 5 Note 5 Exemption Corrosion Impact Allowance Test (in) 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 No No No No No No No No No No No No No No No No No No No

Identifier

Top Head - Ellipsoidal Straight Flange on Top Head Ellipsoidal Shell - Cylindrical Bottom Head - Hemispherical Nozzle A - 12" Dia. (A)

140.35 1.1 139.78 1.1 151.73 -0.5 156.59 -35.8 N/I N/I N/I N/I N/I N/I N/I N/I N/I N/I N/I -20.0 -20.0 -20.0 -20.0 -5.5 -20.0 -7.9 -20.0 -20.0 -20.0 -7.2

Nozzle AL - 1-1/2" LWN (AL) 720.0 Nozzle B - 3" Dia. (B) 720.0

Nozzle BL - 1-1/2" LWN (BL) 720.0 Nozzle C - 6" Dia. (C) 720.0

Nozzle CL - 1-1/2" LWN (CL) 720.0 Nozzle D - 4" Dia. (D) 720.0

Nozzle DL - 1-1/2" LWN (DL) 720.0 Nozzle E - 6" Dia. (E) Nozzle EL - 2" Dia. (EL) Nozzle F - 10" Dia. (F) Flange for F Bolted Cover for F Nozzle G - 2" LWN (G) Nozzle GL - 2" Dia. (GL) 720.0 720.0 720.0 720.0 720.0 720.0 720.0

562.03 -55.0 343.05 -155.0 N/I N/I -20.0 -20.0

file:///C|/Compress-Temp/PresSum6E790E74.html (1 of 2) [8/20/2003 1:53:56 PM]

Pressure Summary

Nozzle H - 2" LWN (H) Nozzle HL - 2" LWN (HL) Nozzle J - 4" Dia. (J) Manway MH1 - 24" Dia. (MH1) Flange for MH1 Bolted Cover for MH1 Manway MH2 - 72" Dia. (MH2) Flange for MH2

720.0 720.0 720.0

104.00 97.42 103.89

N/I N/I N/I

-20.0 -20.0 -7.9

Note 5 Note 5 Nozzle Note 8; Pad note 15 Nozzle Note 16; Pad note 12 Note 17 Note 18 Nozzle Note 19; Pad note 20 Note 21

0.000 0.000 0.000

No No No

720.0 720.0 720.0 720.0 720.0

126.24 458.89 149.67 145.45 160.56

N/I

-7.2

0.000 0.000 0.000 0.000 0.000

No No No No No

458.89 -55.0 164.94 -52.2 N/I 0.0

169.47 -55.0

Chamber design MDMT is 20.00F Chamber rated MDMT is 1.08F Chamber MAWP hot & corroded is 87.13 psi @ 720.0F Chamber MAP cold & new is 87.13 psi @ 70.0F This pressure chamber is not designed for external pressure. Design notes are available on the Settings Summary page.

file:///C|/Compress-Temp/PresSum6E790E74.html (2 of 2) [8/20/2003 1:53:56 PM]

Thickness Summary

Thickness Summary

Component Identifier Top Head - Ellipsoidal Straight Flange on Top Head Ellipsoidal Shell - Cylindrical Bottom Head - Hemispherical Support Skirt #1 Support Skirt #2 Diameter (in) Length Nominal t Design t Joint (in) (in) (in) E 36.71 2.00 299.00 72.50 6.00 0.5800* 0.5800 0.7400 0.3800* 0.3000 0.3000 0.3926 0.3937 0.5010 0.2542 0.0495 0.0662

Material

Load

SA-515 70 145.69 OD SA-515 70 145.69 OD SA-515 70 145.69 OD SA-515 70 145.00 OD SA-515 70 146.29 OD

1.0000 Internal 1.0000 Internal 0.8500 Internal 0.8500 Internal 0.5500 Wind 0.5500 Wind

SA-515 70 146.29/192.00 OD 125.00

Nominal t: Vessel wall nominal thickness Design t: Joint E: * Load internal: external: Wind: Seismic: Circumferential stress due to internal pressure governs External pressure governs Combined longitudinal stress of pressure + weight + wind governs Combined longitudinal stress of pressure + weight + seismic governs Required vessel thickness due to governing loading + corrosion Longitudinal seam joint efficiency Head minimum thickness after forming

file:///C|/Compress-Temp/ThkHist1F1CE2C9.html [8/20/2003 1:53:56 PM]

Nozzle Summary

Nozzle Summary

Reinforcement Pad Design t User t Width (in) (in) (in) N/A N/A N/A N/A 3.0000 N/A 3.0000 N/A 3.0000 N/A 3.2500 N/A N/A N/A N/A 3.0000 9.2500 tpad (in) N/A N/A N/A N/A

Nozzle OD mark (in)

tn (in)

Req tn (in)

Shell A1? A2? Nom t (in)

Corr (in)

Aa/Ar (%)

A AL B BL C CL D DL E EL F G GL H HL J MH1 MH2

12.75 0.4000 0.3281 Yes Yes 2.3125* N/A 2.62 3.50 2.62 6.63 2.62 4.50 2.62 6.63 2.38 0.2500 0.0625 Yes Yes 0.7400 0.1500 0.0714 Yes Yes 0.7400 0.2500 0.0625 Yes Yes 0.7400 0.2500 0.0714 Yes Yes 0.7400 0.2500 0.0625 Yes Yes 0.7400 0.2000 0.0714 Yes Yes 0.7400 0.2500 0.0625 Yes Yes 0.7400 N/A 0.3988 N/A 0.5530 N/A 0.5528 N/A

0.0000 Exempt 0.0000 Exempt 0.0000 100.1 0.0000 Exempt

0.7500 0.0000 175.6 N/A 0.0000 Exempt

0.7500 0.0000 176.6 N/A 0.0000 Exempt

0.2500 0.0714 Yes Yes 0.3800* 0.2368 0.1200 0.0714 Yes Yes 0.7400 N/A

0.7500 0.0000 375.2 N/A 0.0000 Exempt

10.75 0.4000 0.0625 Yes Yes 0.5800* 0.5195 3.06 2.38 3.06 3.06 4.50 0.3500 0.0625 Yes Yes 0.7400 0.1200 0.0714 Yes Yes 0.7400 N/A N/A

0.7500 0.0000 131.0 N/A N/A N/A N/A 0.0000 Exempt 0.0000 Exempt 0.0000 Exempt 0.0000 Exempt

0.3500 0.1890 Yes Yes 1.1900* N/A 0.3500 0.0625 Yes Yes 0.7400 0.2000 0.0714 Yes Yes 0.7400 N/A 0.4760

0.7500 0.0000 221.0 0.7500 0.0000 133.0

25.00 0.4000 0.0967 Yes Yes 0.5800* 0.5195 72.00 0.4000 0.3495 Yes Yes 0.3800* 0.3524

12.0000 1.0000 0.0000 100.1

tn: Req tn:

Nozzle thickness Nozzle thickness required per UG-45/UG-16

Nom t: Vessel wall thickness Design t: Required vessel wall thickness due to pressure + corrosion allowance per UG-37 User t: Local vessel wall thickness (near opening)

file:///C|/Compress-Temp/NozSum3425DBAD.html (1 of 2) [8/20/2003 1:53:55 PM]

Nozzle Summary

Aa: Ar: Corr: *

Area available per UG-37, governing condition Area required per UG-37, governing condition Corrosion allowance on nozzle wall Head minimum thickness after forming

file:///C|/Compress-Temp/NozSum3425DBAD.html (2 of 2) [8/20/2003 1:53:55 PM]

Nozzle Schedule

Nozzle Schedule

Materials Nozzle Service mark Size Nozzle Impact Norm Fine Grain Pad Impact Norm Fine Grain Flange

Nozzle A - 11.95 12" Dia. IDx0.40 Nozzle AL - 11/2" LWN

SANo 515 70

No

No

N/A

N/A

N/A

N/A

WN A105 150# LWN A105 150# WN A105 300# LWN A105 150# WN A105 300# LWN A105 150# WN A105 300# LWN A105 150#

AL

2.12 IDx0.25

SA105 SA106 B Smls pipe SA105 SA106 B Smls pipe SA105 SA106 B Smls pipe SA105

No

No

No

N/A

N/A

N/A

N/A

Nozzle B - 3.20 3" Dia. IDx0.15 Nozzle BL - 11/2" LWN

No

No

No

N/A

N/A

N/A

N/A

BL

2.12 IDx0.25

No

No

No

N/A

N/A

N/A

N/A

Nozzle C - 6.13 6" Dia. IDx0.25 Nozzle CL - 11/2" LWN

No

No

No

SA515 70

No

No

No

CL

2.12 IDx0.25

No

No

No

N/A

N/A

N/A

N/A

Nozzle D - 4.10 4" Dia. IDx0.20 Nozzle DL - 11/2" LWN

No

No

No

SA515 70

No

No

No

DL

2.12 IDx0.25

No

No

No

N/A

N/A

N/A

N/A

file:///C|/Compress-Temp/NozSch0F3A2451.html (1 of 2) [8/20/2003 1:53:55 PM]

Nozzle Schedule

Nozzle E - 6.13 6" Dia. IDx0.25

SA106 B Smls pipe SA106 B Smls pipe

No

No

No

SA515 70

No

No

No

WN A105 150# WN A105 150#

EL

Nozzle EL - 2" Dia.

2.13 IDx0.12

No

No

No

N/A

N/A

N/A

N/A

Nozzle F - 9.95 10" Dia. IDx0.40 Nozzle G - 2.36 2" LWN IDx0.35 Nozzle GL - 2" Dia.

SANo 515 70 SA105 SA106 B Smls pipe SA105 SA105 SA106 B Smls pipe

No

No

SA515 70 N/A

No

No

No

App 2 LWN A105 150# WN A105 150# LWN A105 150# LWN A105 150# WN A105 150#

No

No

No

N/A

N/A

N/A

GL

2.13 IDx0.12

No

No

No

N/A

N/A

N/A

N/A

Nozzle H - 2.36 2" LWN IDx0.35 Nozzle HL - 2" LWN 2.36 IDx0.35

No

No

No

N/A

N/A

N/A

N/A

HL

No

No

No

N/A

N/A

N/A

N/A

Nozzle J - 4.10 4" Dia. IDx0.20 Manway MH1 24" Dia. Manway MH2 72" Dia.

No

No

No

SA515 70 SA515 70 SA515 70

No

No

No

MH1

24.20 IDx0.40 71.20 IDx0.40

SANo 515 70 SANo 515 70

No

No

No

No

No

App 2

MH2

No

No

No

No

No

App 2

file:///C|/Compress-Temp/NozSch0F3A2451.html (2 of 2) [8/20/2003 1:53:55 PM]

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- PVEclc-6847-0.1 Generic Vessel PDFDocument61 pagesPVEclc-6847-0.1 Generic Vessel PDFKarthik AnandanNo ratings yet

- Duct Static Loss CalculationDocument8 pagesDuct Static Loss CalculationYe Thiha Min100% (2)

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Technical Specifications of Aluminium Rivets or Steel MandrelDocument3 pagesTechnical Specifications of Aluminium Rivets or Steel MandrelmutualscrewNo ratings yet

- Hydraulic Hose SelectionDocument16 pagesHydraulic Hose Selectiondavo87No ratings yet

- Condensadora Westinghouse 5TR Mod DS3BA - DS5BADocument4 pagesCondensadora Westinghouse 5TR Mod DS3BA - DS5BAOscar Sanchez Velasquez0% (1)

- Especificacion API 5lDocument44 pagesEspecificacion API 5ljpcc1986100% (1)

- V SeguridadDocument8 pagesV SeguridadARJONA_JGNo ratings yet

- TFP950 10 2010Document6 pagesTFP950 10 2010elpelaracingNo ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- Parafusos PT SemblexDocument10 pagesParafusos PT SemblexSBonderNo ratings yet

- EN6114Document14 pagesEN6114akayirNo ratings yet

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 pagesElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkNo ratings yet

- 1 ATI Stellram U INCIMA DimenzijeDocument8 pages1 ATI Stellram U INCIMA DimenzijeBosko LukavicNo ratings yet

- Antamount: Vishay SpragueDocument22 pagesAntamount: Vishay SpraguemohamedNo ratings yet

- Full Lift Spring Loaded Open PDFDocument4 pagesFull Lift Spring Loaded Open PDFVenkatespatange RaoNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Series 77F-DI-250 Specification SheetDocument2 pagesSeries 77F-DI-250 Specification SheetWattsNo ratings yet

- Series 957, 957N, 957ZDocument4 pagesSeries 957, 957N, 957ZWattsNo ratings yet

- Marking of SMD CapacitorDocument3 pagesMarking of SMD CapacitoragunghardonoNo ratings yet

- CTRLDocument57 pagesCTRLpbontyNo ratings yet

- Stiffening Ring Cal For Exteneral Press.Document11 pagesStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)

- Toyo - Heat Exchanger-1Document70 pagesToyo - Heat Exchanger-1alokbdas100% (1)

- Acdx 2Document44 pagesAcdx 2GermánCastiglioniNo ratings yet

- Hammer UnionsDocument16 pagesHammer Unionsram_river808100% (2)

- MDFO UK LowDocument17 pagesMDFO UK Lowmsn86No ratings yet

- Model 200M GVDocument4 pagesModel 200M GVJerrydawangNo ratings yet

- Bom - UPLDocument20 pagesBom - UPLalokbdasNo ratings yet

- ANSI PipeDocument10 pagesANSI PipeEkki Petrus BubunNo ratings yet

- 51371180104Document21 pages51371180104GuillermoadairNo ratings yet

- BSP 05 UK (Nov-11) PDFDocument20 pagesBSP 05 UK (Nov-11) PDFhepcomotionNo ratings yet

- BIG Daishowa Profit Maker ToolsDocument40 pagesBIG Daishowa Profit Maker Toolsgeav25653855No ratings yet

- Pulleys TechDocument8 pagesPulleys TechashkansoheylNo ratings yet

- Flare CalculationDocument22 pagesFlare CalculationHomer SilvaNo ratings yet

- Nozzle Calculation - Auxiliary Boiler Stack-R0Document13 pagesNozzle Calculation - Auxiliary Boiler Stack-R0Aditya JainNo ratings yet

- Vessel Design CalculationDocument54 pagesVessel Design CalculationPohn Myint Han50% (2)

- FR630 662 700NT PDFDocument44 pagesFR630 662 700NT PDFwilmerk_159990No ratings yet

- 65 Twin Reverb ManualDocument9 pages65 Twin Reverb ManualGerardo PaesanoNo ratings yet

- DSM PDFDocument8 pagesDSM PDFSlobodan AnticNo ratings yet

- York Fan Coil UnitDocument16 pagesYork Fan Coil Unitjaja100% (3)

- Memoria de Calculo Recipiente A PresionDocument241 pagesMemoria de Calculo Recipiente A PresionArmando IP100% (1)

- Chiller Koolman CgakDocument8 pagesChiller Koolman Cgakfabieduarte440No ratings yet

- 8-En 5750-C (Dig) - Stack Valves CETOP 05Document13 pages8-En 5750-C (Dig) - Stack Valves CETOP 05abuzer1981No ratings yet

- Rei Vol IDocument297 pagesRei Vol IDineshNo ratings yet

- Inertia Dynamics 2011 CatalogDocument40 pagesInertia Dynamics 2011 CatalogElectromateNo ratings yet

- Steel (TSL) Specification Chemical-Physical270109Document55 pagesSteel (TSL) Specification Chemical-Physical270109dyutimanhazra88% (8)

- Valves Bb-EDocument4 pagesValves Bb-EMindrutauCosminNo ratings yet

- Vertical Compress DrawingDocument1 pageVertical Compress DrawingFaull JackmanNo ratings yet

- Virgo Welded Valve BrochureDocument8 pagesVirgo Welded Valve BrochureHerrera Jorge AgustínNo ratings yet

- Royal Catalog MedDocument32 pagesRoyal Catalog MedGerardo Miranda IIINo ratings yet

- Series LFB6080, LFB6081 Specification SheetDocument2 pagesSeries LFB6080, LFB6081 Specification SheetWattsNo ratings yet

- KurtDocument30 pagesKurtmachineCanNo ratings yet

- Heat Shrink Cable Joints & Cable Terminations LV HV, 6.6kV 11kV 33kV SPS CatalogueDocument63 pagesHeat Shrink Cable Joints & Cable Terminations LV HV, 6.6kV 11kV 33kV SPS CatalogueBasman GeorgeNo ratings yet

- Surge Tank Maint Bulletin PDFDocument2 pagesSurge Tank Maint Bulletin PDFihllhmNo ratings yet

- ISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1Document42 pagesISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1markosdistefanoNo ratings yet

- Honda Goldwing GL1100 1980 To 1982 Honda Parts Manual-B760BDocument195 pagesHonda Goldwing GL1100 1980 To 1982 Honda Parts Manual-B760BstormaNo ratings yet

- Hydromation Filter MHydromation FilterDocument26 pagesHydromation Filter MHydromation FilterArt G. EnziNo ratings yet

- Postpaid Tariff As On 01.07.2021: Plan-399 (Ghar Wapsi) Plan-1525 Plan-999 S. No. Particulars Plan-199 Plan-525 Plan-798Document2 pagesPostpaid Tariff As On 01.07.2021: Plan-399 (Ghar Wapsi) Plan-1525 Plan-999 S. No. Particulars Plan-199 Plan-525 Plan-798RBKUMARNo ratings yet

- District Manager DetailsDocument11 pagesDistrict Manager DetailsRBKUMARNo ratings yet

- Shree Balaji EnterprisesDocument4 pagesShree Balaji EnterprisesRBKUMARNo ratings yet

- Shree Balaji EnterprisesDocument4 pagesShree Balaji EnterprisesRBKUMARNo ratings yet

- Brown McFarlane - Boiler and Pressure Vessel - Comparisons and EquivalentsDocument1 pageBrown McFarlane - Boiler and Pressure Vessel - Comparisons and EquivalentsRBKUMARNo ratings yet

- Ie Rules-1956Document191 pagesIe Rules-1956Murali MohanNo ratings yet

- A380 See The Bigger Picture LeafletDocument2 pagesA380 See The Bigger Picture LeafletrvenkatacharyNo ratings yet

- Rapid LeafletDocument2 pagesRapid LeafletRBKUMARNo ratings yet

- Example Vessel Re RatingDocument9 pagesExample Vessel Re RatingRBKUMARNo ratings yet

- Rapid LeafletDocument2 pagesRapid LeafletRBKUMARNo ratings yet

- MF Guide 2010Document62 pagesMF Guide 2010Kumar JayabalanNo ratings yet

- XE - United Arab Emirates Dirhams - AED Rate TableDocument2 pagesXE - United Arab Emirates Dirhams - AED Rate TableRBKUMARNo ratings yet

- Nokia 6300 UG enDocument56 pagesNokia 6300 UG entudy1980No ratings yet

- Nokia 6300 UG enDocument56 pagesNokia 6300 UG entudy1980No ratings yet

- NavagrahasDocument3 pagesNavagrahasRBKUMAR100% (1)

- Resume Views by RecruitersDocument2 pagesResume Views by RecruitersRBKUMAR100% (2)

- Resume BharathDocument8 pagesResume BharathRBKUMAR100% (2)

- Rubber Lined Piping - A Solution To Corrosion ResistanceDocument5 pagesRubber Lined Piping - A Solution To Corrosion ResistanceMohamed AghilaNo ratings yet

- TOP233YDocument24 pagesTOP233YJose BenavidesNo ratings yet

- Calculate Cable Size and Voltage Drop Electrical Notes Articles PDFDocument10 pagesCalculate Cable Size and Voltage Drop Electrical Notes Articles PDFRavi SharmaNo ratings yet

- Refrigeration Engineer Quick ReferenceDocument2 pagesRefrigeration Engineer Quick ReferenceventilationNo ratings yet

- The Influence of School Architecture and Design On The Outdoor Play Experience Within The Primary SchoolDocument20 pagesThe Influence of School Architecture and Design On The Outdoor Play Experience Within The Primary SchoolAnca BalotaNo ratings yet

- CDM816DSpare Parts Manual (Pilot Control) 2Document55 pagesCDM816DSpare Parts Manual (Pilot Control) 2Mohammadazmy Sobursyakur100% (1)

- Infrastructure Definition:: Economic Infrastructure Includes BroadlyDocument3 pagesInfrastructure Definition:: Economic Infrastructure Includes Broadlyabraha gebruNo ratings yet

- Mechanical Advantage HomeworkDocument8 pagesMechanical Advantage Homeworkafeurbmvo100% (1)

- Art1 2Document24 pagesArt1 2Peter Paul Rebucan PerudaNo ratings yet

- Vintage Tavern - PrintInspectionDocument4 pagesVintage Tavern - PrintInspectionBryce AirgoodNo ratings yet

- Penawaran Pekerjaan Fire Fighting (Upah + Material)Document3 pagesPenawaran Pekerjaan Fire Fighting (Upah + Material)vixer ndi100% (6)

- Aplikasi Sistem Penuaian Air Hujan (Spah) Di Kawasan PerumahanDocument18 pagesAplikasi Sistem Penuaian Air Hujan (Spah) Di Kawasan PerumahanFarid Che DeramanNo ratings yet

- General Anaesthesia MCQsDocument5 pagesGeneral Anaesthesia MCQsWasi Khan100% (3)

- Neuromuscular Diseases. ALSDocument7 pagesNeuromuscular Diseases. ALSjalan_zNo ratings yet

- Coca ColaDocument50 pagesCoca Colamariyha PalangganaNo ratings yet

- The Finite Element Method Applied To Agricultural Engineering - A Review - Current Agriculture Research JournalDocument19 pagesThe Finite Element Method Applied To Agricultural Engineering - A Review - Current Agriculture Research Journalsubhamgupta7495No ratings yet

- What's The Use of Neuroticism?: G. Claridge, C. DavisDocument18 pagesWhat's The Use of Neuroticism?: G. Claridge, C. DavisNimic NimicNo ratings yet

- Texas Instruments FootprintsDocument7 pagesTexas Instruments FootprintsSteve SmithNo ratings yet

- Monthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)Document20 pagesMonthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)winda septiaraNo ratings yet

- Scientific Exploration and Expeditions PDFDocument406 pagesScientific Exploration and Expeditions PDFana_petrescu100% (2)

- Assignment 7 - Cocktail RecipiesDocument20 pagesAssignment 7 - Cocktail RecipiesDebjyoti BanerjeeNo ratings yet

- Modern Views Catalogue/Sotheby's BenefitDocument36 pagesModern Views Catalogue/Sotheby's BenefitStudio AdjayeNo ratings yet

- Digital Trail Camera: Instruction ManualDocument20 pagesDigital Trail Camera: Instruction Manualdavid churaNo ratings yet

- FREEWAT Vol0 v.1.1.2Document159 pagesFREEWAT Vol0 v.1.1.2Jonathan QuirozNo ratings yet

- Chapter 2Document82 pagesChapter 2Kavitha Selvaraj50% (2)

- Cateora2ce IM Ch012Document9 pagesCateora2ce IM Ch012Priya ShiniNo ratings yet

- IsdettaDocument2 pagesIsdettaHa Phuoc HoaNo ratings yet

- 2606 PDFDocument6 pages2606 PDFzainab jehangirNo ratings yet

- Popular CultureDocument6 pagesPopular CultureAmritaNo ratings yet

- 1.1 - Selectividad Acti9Document34 pages1.1 - Selectividad Acti9Bladimir MichelNo ratings yet