Professional Documents

Culture Documents

Chipping REV1

Uploaded by

anon_781855461Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chipping REV1

Uploaded by

anon_781855461Copyright:

Available Formats

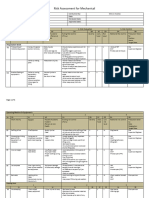

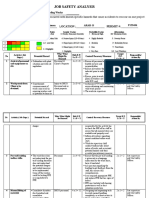

Risk Assessment/Management Form Ref:PCEPL/LIPL-3

AREA-: site

Activity:

Rev-1

Use of Chipping machine

Probability

Risk rating

Basic Job Steps Potential Hazard Consequence Current control measure P E A R

Risk rating

Initial Risk Additional controls P E A R

Probability

Residual risk

Remarks

Obtain PTW

Working without PTW

Electrical Connections

Electricity

Non compliance with lafarge standard perosnnal injury electrocution

all critical activities that require permit accompnied by method statement & Risk assessment.

close supervision by competent supervisor

Machinery is electrically isolated during 2 maintenance. If power is required to enable diagnostics or testing to be performed, a specific risk assessment is carried out to determine control

monthly 2 inspeciton of electrical tools by the electdept

Start Chipping

hand injuries. HAVS, noise pollution. Eye injuries. Inadequate illumination incompetent workers to operate the Chipping Machine

minor injury or damager

measures. use of mandatory PPE. Use 2 of ear plugs. Rotation of employees at regular intervals. Area to be demarked to avoid unauthorised entry. adequate lighting must be ensured Operative must be informed about the safe use of Chipping machine and hazards associated with m/c

monitoring 2 by the competent supervisor

Working at height

1. Fall of material from major injuries height. 2. Fall from height 3. improper access . 4. fire hazard 5.Failure of fall protection equipments 6.lack of supervision 7. lack of emergency response 8.injuries while working at height

1. no loose material to be left on heigts, 2 proper housekkeping to be maintained at all times. 2. All the tools to be tied with the string with the harness. 3. use of drop nets at elevations as per requirement. 4. Life lines to be checked by the competent person and approved prior to use. 5. Use of mandatory PPE & fall protection. 6.Regular inspection of fall protection equipments by the user and

competent 2 supervisor conducting emergency drills at regular intervals.

Working in night

Prepared By

1.Lack of illumination minor 1. adequate illumination is ensured and 2 2.lack of supervision damage or checked by the electrician by lux meter. 3.Sleeping at unauthorized minor injuries 2.Competent supervisor must be areas. available at all times during the night 4.Sleepy and dizziness work. ,fatigue 5.lack of 3.No one is allowed to rest in emergency response. excavation and unauthorized areas, 6.improper access regular monitoring by site supervisor 7.Fall into excavations and hse 8.Stuck by vehicles / Plants 4. no prolonged working for employees, 9.heat stress adequate time is to be given for rest 10.Electrocution after each shift. 11.Power failure 5.Emergency response must be prepared,communicated and implementd. 6.proper access/egressto be maintained at alltimes. 7.all th edeep excavation s must be provided with the warning tapes and signage. 8.All the vehicle and plant must be provided with the banksman. 9. Provision of welfare facilities like adequate water and resting. 10.No one is allowed to do any alteration with the power supply cables and equipments except electricians, 11. Competent electrician must be present in night shift and provided with the emergency torch. Approved By Reviewed By LIPL Date:-

competent 2 supervisor conducting emergency drills at regular intervals.

Date:-

Date:-

Enclosure: 1.Method statement.

You might also like

- J718 SCX1800a RA 220322 Rev02Document13 pagesJ718 SCX1800a RA 220322 Rev02Ion Domnari100% (1)

- JHA for Hill Cutting Activities at Port of SalalahDocument8 pagesJHA for Hill Cutting Activities at Port of SalalahSreekumarNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- AHA-002, Geotechnical WorkDocument5 pagesAHA-002, Geotechnical WorkBuddhikaNo ratings yet

- JSP 42 Use of Power ToolsDocument6 pagesJSP 42 Use of Power ToolsMuhammad AtifNo ratings yet

- Hazard Identification & Risk Assessment FormDocument3 pagesHazard Identification & Risk Assessment FormChandra Shekar EmaniNo ratings yet

- 10 JSA - Cable Drums InstallationsDocument6 pages10 JSA - Cable Drums Installationssyed khaja misbhuddinNo ratings yet

- Risk Assessment / Method Statement Form: (Please)Document5 pagesRisk Assessment / Method Statement Form: (Please)Sham AranNo ratings yet

- Risk Assessment For Mechanical: Preparation WorkDocument3 pagesRisk Assessment For Mechanical: Preparation Workahmedalderbi801No ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- JSEA-ICS-004 Cable Laying and PullingDocument16 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- JHA for Unloading Product from Ship at Port of SalalahDocument4 pagesJHA for Unloading Product from Ship at Port of SalalahSreekumar100% (1)

- Unsafe MEWP Operation ReviewDocument2 pagesUnsafe MEWP Operation ReviewAbdulKatherNo ratings yet

- SAFETY Epoxy Primer SDSDocument9 pagesSAFETY Epoxy Primer SDSJoy Ann MatrianoNo ratings yet

- 04 JSA - Welding WorksDocument6 pages04 JSA - Welding Workssyed khaja misbhuddinNo ratings yet

- Job Safety Analysis (Jsa) N2.Document5 pagesJob Safety Analysis (Jsa) N2.Joseph Paul IlaganNo ratings yet

- GENCHI INDIA PVT.LTD JOB HAZARDS ANALYSISDocument2 pagesGENCHI INDIA PVT.LTD JOB HAZARDS ANALYSISsakthi venkatNo ratings yet

- Job Hazards AnalysisDocument3 pagesJob Hazards AnalysismohamedNo ratings yet

- J S A Electrical Distributaton Board MaintenenceDocument4 pagesJ S A Electrical Distributaton Board MaintenenceASLAM MULANINo ratings yet

- 2.4 Attachments - Risk Assessment and Method StatementDocument10 pages2.4 Attachments - Risk Assessment and Method StatementFahad MaqsoodNo ratings yet

- Risk Assessment On Demolition Work - CompressDocument8 pagesRisk Assessment On Demolition Work - CompressAbegail Manuel GatusNo ratings yet

- Hazard Identification Risk Assessment Risk Control (HIRARC) - Submain Cable Ladder/tray InstallationDocument2 pagesHazard Identification Risk Assessment Risk Control (HIRARC) - Submain Cable Ladder/tray InstallationYasHie PwincsZaNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 pagesRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaNo ratings yet

- CONTRACTOR SAFETY MEASURES FOR STONE WORKSDocument5 pagesCONTRACTOR SAFETY MEASURES FOR STONE WORKSyahiya0% (1)

- Larsen & Toubro Limited Buildings and Factories Independent CompanyDocument5 pagesLarsen & Toubro Limited Buildings and Factories Independent CompanyabbasNo ratings yet

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTDocument6 pagesJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekarNo ratings yet

- Excavation Risk Assessment SheetDocument3 pagesExcavation Risk Assessment SheetYounis KhanNo ratings yet

- 38 Through Installation Job Safe Practice Ladder and Rack InstallationDocument1 page38 Through Installation Job Safe Practice Ladder and Rack InstallationsalmanNo ratings yet

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- SS JSP - 009 Ground Preparation For Lean Concrete (Foundation Works)Document5 pagesSS JSP - 009 Ground Preparation For Lean Concrete (Foundation Works)Farhat SetharNo ratings yet

- RISK ASSESSMENT ACTIVITYDocument2 pagesRISK ASSESSMENT ACTIVITYdak comeiNo ratings yet

- JHA For BreakingDocument18 pagesJHA For BreakingRaheenNo ratings yet

- Motor Maintenance PDFDocument1 pageMotor Maintenance PDFAbdul HadiNo ratings yet

- Risk assessment form for painting workDocument1 pageRisk assessment form for painting workNarender BhardwajNo ratings yet

- Risk Assessment for Office AreasDocument9 pagesRisk Assessment for Office AreaszulmaulNo ratings yet

- Safe Work Method StatementDocument4 pagesSafe Work Method StatementsimoneNo ratings yet

- Ohs PR 09 19 f10 (A) Chain Block InspectionDocument2 pagesOhs PR 09 19 f10 (A) Chain Block InspectionShafie ZubierNo ratings yet

- DSTI Supervisors Daily Safet Task Instruction PDFDocument1 pageDSTI Supervisors Daily Safet Task Instruction PDFRicoNo ratings yet

- 1 Excavations and TrenchesDocument2 pages1 Excavations and TrenchesAruNo ratings yet

- Job Hazard Analysis (Jha) WorksheetDocument4 pagesJob Hazard Analysis (Jha) WorksheetSamer AlsumaryNo ratings yet

- 13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLDocument17 pages13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLkeertiraj09100% (1)

- Rmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)Document1 pageRmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)myn maliQueNo ratings yet

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- RA - 8 - For WaterproofingDocument13 pagesRA - 8 - For WaterproofingIbrahim EsmatNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- Demoltion Work Risk AssesmentDocument2 pagesDemoltion Work Risk AssesmentBijin BalakrishnanNo ratings yet

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- SS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksDocument6 pagesSS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksFarhat SetharNo ratings yet

- HSE Hazards and Effects Management for Wood Cutting MachinesDocument7 pagesHSE Hazards and Effects Management for Wood Cutting Machinessaravana.bNo ratings yet

- 37 Material StorageDocument5 pages37 Material StorageCaron KarlosNo ratings yet

- SWP Excavation Near Overhead Electrical Live LinesDocument2 pagesSWP Excavation Near Overhead Electrical Live LinesSn AhsanNo ratings yet

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- Risk Assessment For Use of Power ToolsDocument2 pagesRisk Assessment For Use of Power ToolsRicardo DalisayNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- Safety Training PassportDocument2 pagesSafety Training PassportAbhaySnghNo ratings yet

- Batching Plant Project: Initial Environmental Examination (Iee) ReportDocument16 pagesBatching Plant Project: Initial Environmental Examination (Iee) ReportavieNo ratings yet

- MEE Unit 1Document18 pagesMEE Unit 1dipak1980No ratings yet

- Battery Fluid, AcidDocument2 pagesBattery Fluid, Acidfajry_uhNo ratings yet

- 12Document22 pages12samuel pinedaNo ratings yet

- Msds Barium KloridaDocument5 pagesMsds Barium KloridaLathoifulIsyarohNo ratings yet

- F-251 MSDSDocument4 pagesF-251 MSDSsimran0114125100% (1)

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument10 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingRiyanNo ratings yet

- ARMY TM 9-6115-643-10 (15kW TQG Operators Manual)Document176 pagesARMY TM 9-6115-643-10 (15kW TQG Operators Manual)Damon PipenbergNo ratings yet

- EN-G 11 30 35 11-2017-08-24 2047 Tdo8Document294 pagesEN-G 11 30 35 11-2017-08-24 2047 Tdo8armando rivera100% (1)

- Vehicle Hoist Safe Work ProcedureDocument2 pagesVehicle Hoist Safe Work ProcedureWiwinIndahSariEffendiNo ratings yet

- Aldobash The Osha Ppe StandardsDocument12 pagesAldobash The Osha Ppe StandardsRaad AljuboryNo ratings yet

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company IdentificationThusith WijayawardenaNo ratings yet

- Ear Drops Safety Data SheetDocument5 pagesEar Drops Safety Data SheetShehzadNo ratings yet

- SDS N 7330 NorwayDocument15 pagesSDS N 7330 NorwaytimbulNo ratings yet

- Sodium HypochloriteDocument8 pagesSodium HypochloriteSruthi SomanNo ratings yet

- Job Safety Analysis: Removing Porta Cabin & Loading at Trailor's ActivityDocument7 pagesJob Safety Analysis: Removing Porta Cabin & Loading at Trailor's ActivityMuhammad TariqNo ratings yet

- Zenith Incident InvestigationDocument36 pagesZenith Incident InvestigationAhmed Abd El WahdNo ratings yet

- Dokumen - Pub Advances in Materials and Manufacturing Engineering Select Proceedings of Icmme 2019 1st Ed 9789811562662 9789811562679Document660 pagesDokumen - Pub Advances in Materials and Manufacturing Engineering Select Proceedings of Icmme 2019 1st Ed 9789811562662 9789811562679nestorNo ratings yet

- Classification of Hazardous ChemicalsDocument10 pagesClassification of Hazardous ChemicalsalijadoonNo ratings yet

- Work Instruction Electrical Continuity and Insulation Resistance TestDocument2 pagesWork Instruction Electrical Continuity and Insulation Resistance TestDushanthaNo ratings yet

- TESDA Foundations of Massage Practice CourseDocument48 pagesTESDA Foundations of Massage Practice CourseSusyary S100% (2)

- DORC HSE Department Contractors' Safety MeetingDocument63 pagesDORC HSE Department Contractors' Safety MeetingJosiahNo ratings yet

- COVID-19 Zone Status GuideDocument1 pageCOVID-19 Zone Status GuideAgnesnesssongNo ratings yet

- Abrasive Blasting Check ListDocument3 pagesAbrasive Blasting Check ListSreejith SureshNo ratings yet

- C1 Accident PreventionDocument24 pagesC1 Accident PreventionAyunni LatifNo ratings yet

- Protective Equipment ChecklistDocument2 pagesProtective Equipment ChecklistJack PNo ratings yet

- Brighto Paints: Hamza Fiaz Roll No.198 Bilal Randhawa Roll No.186 Muhammad Tariq Roll No.188 Afnan Masood Roll No.219Document7 pagesBrighto Paints: Hamza Fiaz Roll No.198 Bilal Randhawa Roll No.186 Muhammad Tariq Roll No.188 Afnan Masood Roll No.219Bilal RandhawaNo ratings yet

- Uphec PPT Friska Ayu UnusaDocument10 pagesUphec PPT Friska Ayu UnusaFriska Ayu LigoyNo ratings yet

- Carpentry NC II CGDocument26 pagesCarpentry NC II CGRickyJeciel100% (2)

- OHS Manual for Limketkai Luxe HotelDocument63 pagesOHS Manual for Limketkai Luxe HotelMacario Roy Jr AmoresNo ratings yet

- Instruction Manual Fire Management So3220-9ADocument30 pagesInstruction Manual Fire Management So3220-9ASari Kiswanto100% (1)

- Motorized Cable Reel Owner's Manual: Type Series HFI and HFIIDocument58 pagesMotorized Cable Reel Owner's Manual: Type Series HFI and HFIIMike PoseidonNo ratings yet