Professional Documents

Culture Documents

Excitation CIGREA1 10

Uploaded by

ucb2_ntpcOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Excitation CIGREA1 10

Uploaded by

ucb2_ntpcCopyright:

Available Formats

7.

KONFERENCA SLOVENSKIH ELEKTROENERGETIKOV Velenje 2005 CIGRE K A1 - 10

Excitation systems for high power synchronous generators with redundant configurations

Zvonimir Jurin, Blaenka Brklja, Marin Koli

KONAR Elektronika i informatika Fallerovo etalite 22 , Zagreb, Croatia E-mail: uzbude@koncar-inem.hr tel. 00385 1 365 5768

Mladen Kajari, Vinko esi,

KONAR Institut za elektrotehniku Fallerovo etalite 22, Zagreb, Croatia E-mail: mkajari@koncar-institut.hr tel. 00385 1 365 5301

Abstract In the article the solutions of synchronous generator excitation system with thyristor converter, digital voltage regulator and field discharge equipment are presented with attention paid to achieve increased reliability and availability by applying redundant configurations. The excitation system with thyristor converter in three-phase fully controllable bridge connection and 1+1 configuration, twin channel digital voltage regulator and field discharge equipment for big and important generators in parallel operation are shown. Field results verify the project-foreseen characteristics and qualities of presented solution.

I. INTRODUCTION To achieve high availability of synchronous generators for electric energy production, attention has to be paid to the increase of availability of all generator subsystems and among them of the synchronous generator excitation system during a very long-term service. Requirements on availability of excitation system, beside its technical functions, have been always high and improvements are still being implemented. The excitation system consists of exciter (the excitation power source) and voltage regulator. In the article, the solutions of thyristor rectifier exciter and digital voltage regulator are discussed with the aim of achieving reliable and redundant configurations with increased availability in synchronous generators operation. The actual solution of an excitation system consists of a big number of electrical, electronic and mechanical components and software products, working together under heavy technical conditions. The basic technical environmental requirements are extreme working and storage temperatures, their deviations and rate of change, combined with humidity, dust and oil vapour, vibrations and shock strains and electromagnetic interference. The requirements on excitation power source depend on machine characteristics and its role in power system. There are potential-source and controlled rectifier exciter (static excitation system), alternator supplied rectifier excitation system (brushless excitation system) that use mechanical power on generator shaft and auxiliary constant

voltage shaft generator and static thyristor rectifier. The compound-source controlled-rectifier exciter that utilizes the potential and the current of synchronous generators, as an excitation power source, together with thyristorcontrolled rectifier is also used for special purposes. The actual and world most common solutions of high power synchronous generator excitation system, is potential source thyristor rectifier exciters with digital voltage regulator. The basic approach to achieve high reliability and availability is application the proper ratings for components and usage of high quality components. To avoid production failures comprehensive during and after production tests and commissioning have to be carried out. Beside that it is not possible to guarantee that no failure can occur.

Fig. 1: Block diagram of a static excitation system with thyristor converter in 1+1 configuration, the twin channel digital voltage regulator and discharge equipment

A1 - 55

7. KONFERENCA SLOVENSKIH ELEKTROENERGETIKOV Velenje 2005 CIGRE K A1 - 10

To minimize risks of failure of synchronous generators excitation system and outage of production of the generator the hardware and software redundancy is applied: 1. 2. 3. Thyristor converter configuration n-1 and 1+1, Twin channel digital voltage regulator Field discharge equipment and field overvoltage protection

significant disturbance of generator operation. Converters have redundant cooling fans.

The block diagram of a static excitation system with thyristor converter in 1+1 configuration, the twin channel digital voltage regulator and discharge equipment is in Fig 1.

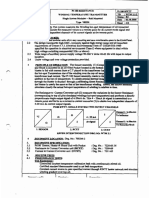

II. THYRISTOR CONVERTER CONFIGURATIONS N-1 AND 1+1 The standard solution of excitation system thyristor converter is a three-phase bridge converter with 1 thyristor in series and n thyristor in parallel per bridge arm. Fast fuse is in series with each thyristor, Fig 2. The number of parallel thyristors per arm is n>3, to maintain selectivity of fuse protection. Current ratings of thyristor are so that n-1 thyristor per arm are capable to withstand all static and transient ratings and one additional thyristor per arm is for security reasons. The converter has redundant fans. Fig. 3. Thyristor converter in 1+1 configuration Behaviour of generator and excitation voltage after simulated failure on one thyristor in the operating thyristor bridge is shown in Fig. 4. Transfer to the second bridge is carried out in app. 50 ms.

Fig. 2. Thyristor converter in n-1 configuration The nowadays-applied configuration of thyristor converter is 1+1 Fig. 3, because high rating thyristors are now available. This configuration consists of two equal three-phase bridge converters with 1 thyristor in series and 1 thyristor in parallel per bridge arm. Fast fuse is in series with each thyristor. Each bridge is rated to withstand all static and transient generator excitation ratings. One bridge converter is in operation while the other is hot stand-by. AC current of bridges are monitored and in case of a thyristor failure the changeover is taking place using free wheeling thyristor without any

Fig. 4. Transfer of excitation Converter Bridge 1 to Bridge 2 in the 1+1 configuration with the generator in parallel operation to the grid

A1 - 56

7. KONFERENCA SLOVENSKIH ELEKTROENERGETIKOV Velenje 2005 CIGRE K A1 - 10

III. TWIN CHANNEL DIGITAL VOLTAGE REGULATOR The single channel digital voltage regulator in comparison to the analogue voltage regulator offers a lot of benefits such as: Performing of sophisticated control, protection, supervision and logical and sequential control functions, Short response time, Long term stability, Self monitoring functions, Reduced diversity of hardware modules, Digital standardized communication to the superimposed control system.

The changeover between channels of two-channel digital voltage regulator after simulated disturbance in operating channel is shown in Figure 5. IV. FIELD DISCHARGE EQUIPMENT AND FIELD OVERVOLTAGE PROTECTION There are two basic solutions of generator field discharge equipment, one, which include DC field circuit breaker with discharge contact, non-linear discharge resistor and separate circuit for overvoltage protection and second which includes AC circuit breaker with common circuit for discharge and overvoltage protection. Besides, there is normal operative procedure for generator deexcitation, the transfer of thyristor exciter to inverter operation mode. In classic solutions of discharge equipment the thyristor converter is connected to synchronous machine field winding via de- excitation D.C. breaker with a discharge contact and a discharge resistor, Fig. 6. When instantaneous electrical fault arises in the synchronous machine or in outside facilities, the short-circuit current will appear and the field should be suppressed as quickly as possible in order to limit fault current damage. It is also necessary to ensure safe de-excitation in event of a fault in the exciter control circuit causing severe over-excitation. The voltage dependent or linear discharge resistor is used to achieve rapid field suppression with regard to the highest permissible voltage across the field winding and the field breaker. The purpose of the rotor overvoltage protection is to prevent the machine field and thyristor converter from being exposed to an excessive overvoltages induced in the machine field with rectifier excitation, which could arise during certain transient condition such as improper synchronizing, loss of synchronism and asynchronous operation. The main overvoltage protection circuit comprises the antiparalell connected thyristor (crow bar) and resistor in series. The thyristors are controlled by the over-voltage sensing triggering unit with BOD elements. When the voltage exceeds the preset protection level the thyristor switch-on and conduct the current caused by over voltage. The series resistor is intended to limit the current in the protection circuits. On the other hand, the resistor must be so designed that the voltage drop caused by the highest induced field current flowing through the resistor does not exceed the protection level. The overcurrent relay supervises of the protection and gives a tripping impulse when the protection operates.

Twin channel digital voltage regulator is a solution with two identical digital voltage regulators working in parallel in hot stand-by configuration. Each of two channels has the same input signals and is executing the same application program. Each channel has a complete structure with automatic and manual voltage control, reactive power regulation, limiters protecting the generator of going-out the generator capability diagram, compound function, V/Hz limiter and power system stabilizer (PSS) functions. Every channel controls both thyristor bridges Comprehensive monitoring program monitors the function of both regulators and in case of detection of an irregularity or exception the changeover is performed to the healthy channel without interfering normal generator operation.

Fig. 5. Changeover of Channel 1 to Channel 2 with generator in parallel operation to the grid

When thyristor converter is applied in configuration 1+1, freewheeling thyristor is used to short-circuit field winding during emergency change over between bridges under high currents.

A1 - 57

7. KONFERENCA SLOVENSKIH ELEKTROENERGETIKOV Velenje 2005 CIGRE K A1 - 10

Fig. 6 Discharge equipment with DC field circuit breaker and separate circuit for rotor over voltage protection In the Fig. 6 the usual and most adequate solution for the field circuit breaker and over voltage protection is shown. The merits of this solution are the completely independent over voltage protection circuit and field circuit breaker that separates generator excitation on both poles from thyristor rectifier. In case of failure on field circuit breaker or non-linear deexcitation resistor, the rotor over voltage protection could act as back-up deexcitation. Usually DC field circuit breaker has two coils for switching-off, which, together with monitoring of switching-off circuits, realize very reliable solution. The alternative solution of discharge equipment is implementation thyristors from thyristors over-voltage protection (crow bar) and AC circuit breaker at primary of thytistor rectifier Fig. 7. Deexcitation is performed by switching-off of the AC circuit breaker what causes the over voltage on the generator excitation winding. This over-voltage will activate over-voltage protection (crow bar), reduce the overvoltage and deexcite the generator. In this case the same resistor is used for the de-excitation and for the field circuit over voltage protection, and in a case of its failure, there is no redundant deexcitation circuit to prevent damage of rotor winding.

Fig. 8 Discharging of generator by DC field circuit breaker and nonlinear discharge resistor Site tests are carried out on excitation system type SEM 11E, delivered and putted into operation for two units on Hydro Power Plant Varadin. Generator and excitation system data are given in Table 1. It is Potential source thyristor rectifier exciter (static excitation system) supplied from the generator terminals. It is controlled by twin (two) channel digital voltage controller with separate hardware for each channel. Each channel of digital voltage regulator comprises Generator voltage regulator (AVR), Excitation current regulator (SR), Trigger pulse system and Follow-up control between main and stand-by controller, and between AVR and SR mode for each channel. Excitation power is derived by: three-phase fully-controlled (6-pulse), air forced cooled, thyristor converter in configuration 1+1, with one thyristor per branch and two converter bridges in parallel. One thyristor bridge is in stand-by and blocked.

TABLE I GENERATOR AND EXCITATION SYSTEM DATA Rated power Nominal voltage Power factor Speed Frequency Nominal current Nominal excitation current Nominal excitation voltage Nominal exciter current Ceiling current Sn Un cosn nn fn In IfN UfN IEN Ip MVA KV min-1 Hz A A V A A Unit A Unit B 53.5 50 10.5 0.85 125 50 2920 890 210 1250 1780 10.5 0.85 125 50 2740 940 220 1250 1880

Fig. 7 Discharge equipment with AC field circuit breaker and common discharge resistor wit rotor over voltage protection

A1 - 58

7. KONFERENCA SLOVENSKIH ELEKTROENERGETIKOV Velenje 2005 CIGRE K A1 - 10

V. CONCLUSION The presented excitation system with redundant configuration with a thyristor converter in consisting 1+1 three phase thyristor bridges, classic discharge equipment with field circuit breaker and separate circuit for over-voltage protection, and microprocessor based twin-channel voltage regulator is suitable for big and important synchronous machines in parallel operation. The excitation system is characterized by increased safety, reliability and availability because of build-in redundancy. Field results have verified characteristics in exploitation and qualities of presented strategy. REFERENCE [1] Z. Jurin, M. Koli, M. Kajari, V. esi: Redundant configuration in synchronous generator excitation system Hydro conference, Dubrovnik 2003. [2] S. Marijan, M. Kajari, N. Peri: Microprocessorbased Control System for Electrical Machines, Proceedings of the 8th International Conference on Electrical Drives and Power Electronics, EDPE94, Pula, Croatia, pp 203 - 209, September 1994. [3] Mladen Kajari, Sinia Marijan, Vinko esi, Nedjeljko Peri: Digital Control of a Synchronous Generator Excitation System, Proceedings of the 8th International Conference on Electrical Drives and Power Electronics, EDPE94, Pula, Croatia, pp 203 - 209, September 1994. [4] N. Peri, S. Marijan, M. Kajari: Microprocessorbased control system for the control of electrical machines and processes. 6th European Conference on Power Electronics and Applications, EPE95, Sevilla, pp (2546-2550) [5] S. Marijan, M. Kajari, N. Peri: Microprocessorbased control system for electrical machines, Automatic 1-2/1995, Zagreb, pp (19-26). [6] V. esi, M. Kajari, S. Marijan, Z. Jurin, M. Koli: Excitation system with microprocessor based twin-channel voltage regulator for synchronous machines, EPE-PEMC 2002. Dubrovnik & Cavtat,

A1 - 59

7. KONFERENCA SLOVENSKIH ELEKTROENERGETIKOV Velenje 2005 CIGRE K A1 - 10

A1 - 60

You might also like

- ISO 9001:2015 Explained, Fourth Edition GuideDocument3 pagesISO 9001:2015 Explained, Fourth Edition GuideiresendizNo ratings yet

- RLC 1st ManualDocument141 pagesRLC 1st Manualjaved shaikh chaandNo ratings yet

- TBEA Modbus Grid-Connected Inverter Communication Protocol20180605Document22 pagesTBEA Modbus Grid-Connected Inverter Communication Protocol20180605ALIM AHMEDNo ratings yet

- Ansaldo Electric Drives 15/30 kW Technical SpecsDocument4 pagesAnsaldo Electric Drives 15/30 kW Technical SpecsMr.K ch50% (2)

- A8000 To SCC 104 ConfigurationDocument6 pagesA8000 To SCC 104 ConfigurationAjith MerinNo ratings yet

- Electricity Act and Regulatory FrameDocument75 pagesElectricity Act and Regulatory Frameucb2_ntpcNo ratings yet

- ASMOPS 2016 - International Invitation PHILIPPINEDocument4 pagesASMOPS 2016 - International Invitation PHILIPPINEMl Phil0% (3)

- Change Management in British AirwaysDocument18 pagesChange Management in British AirwaysFauzan Azhary WachidNo ratings yet

- Gate-drive recommendations for phase control and bi-directionally controlled thyristorsDocument12 pagesGate-drive recommendations for phase control and bi-directionally controlled thyristorsKanhaiya NavaleNo ratings yet

- 0.ACS800 Multidrive Drive Training Agenda PDFDocument2 pages0.ACS800 Multidrive Drive Training Agenda PDFThương NguyễnNo ratings yet

- Commutation Circuits PDFDocument2 pagesCommutation Circuits PDFRalphNo ratings yet

- Zab Abb Unitrol 1010 1020 e RevaDocument12 pagesZab Abb Unitrol 1010 1020 e RevaGavinsiauNo ratings yet

- La-101914 31136 105 PDFDocument4 pagesLa-101914 31136 105 PDFAnonymous TrDuMhMvNo ratings yet

- Hardware Troubleshooting: Course T302Document19 pagesHardware Troubleshooting: Course T302Gajanan Chavhan100% (1)

- ACS 100 ABB DriveDocument54 pagesACS 100 ABB DriveMAHESWARA RAO CHALLANo ratings yet

- IGCT Technology - A Quantum Leap For High-Power ConvertersDocument5 pagesIGCT Technology - A Quantum Leap For High-Power ConvertersSreenivas_Chim_9626No ratings yet

- A New Method For Online Thyristor Conduction Monitoring Based On Thyristor Current Waveform Recording in Static Excitation SystemDocument6 pagesA New Method For Online Thyristor Conduction Monitoring Based On Thyristor Current Waveform Recording in Static Excitation SystemR0B0T2013No ratings yet

- 1SAP130300R0271 Pm573 Ethac500 Prog Logic Contr 512kbDocument3 pages1SAP130300R0271 Pm573 Ethac500 Prog Logic Contr 512kbErick Romucho SánchezNo ratings yet

- INTCN1503-Unitrol 5000 Operation and Maintenance For Generator Excitation Control - Rev-ADocument2 pagesINTCN1503-Unitrol 5000 Operation and Maintenance For Generator Excitation Control - Rev-AjayapalNo ratings yet

- Extension Cord Safety Module 2Document94 pagesExtension Cord Safety Module 2chibssa alemayehuNo ratings yet

- Pulse Analog ConverterDocument4 pagesPulse Analog ConverterAishiteruNo ratings yet

- Avr CubicleDocument28 pagesAvr CubicleJITPLNo ratings yet

- Unitrol 3Document15 pagesUnitrol 3intrudentalertNo ratings yet

- Diagran Masterdrive 500 KWDocument30 pagesDiagran Masterdrive 500 KWemiljanlazeNo ratings yet

- Working Instructions DOC26 ACN634 R9i PP300 RevcDocument38 pagesWorking Instructions DOC26 ACN634 R9i PP300 RevcJezer LugoNo ratings yet

- Abb Acs800 07 500 2800 PDFDocument193 pagesAbb Acs800 07 500 2800 PDFJesus Oliveros100% (1)

- ACS 1000 Medium Voltage Drives: 315 - 5000 KW 400 - 6200 HPDocument112 pagesACS 1000 Medium Voltage Drives: 315 - 5000 KW 400 - 6200 HPcldanghel4648No ratings yet

- ACS800 Democase Default ParametersDocument14 pagesACS800 Democase Default ParametersRemigio MendozaNo ratings yet

- Service Instruction For Using Thermal CompoundDocument4 pagesService Instruction For Using Thermal CompoundSebastianCicognaNo ratings yet

- ABB ACS880-01-065A-5 PARTS AND QUANTITIESDocument2 pagesABB ACS880-01-065A-5 PARTS AND QUANTITIESThọ NguyễnNo ratings yet

- Siprotec 7ke85 ProfileDocument2 pagesSiprotec 7ke85 ProfileSamatha Vedana100% (1)

- 02 2 s150 System-Ovw CLDocument19 pages02 2 s150 System-Ovw CLANDRES CISTERNASNo ratings yet

- Firmware ManualDocument146 pagesFirmware ManualBhaskar AddepalliNo ratings yet

- COM600 5.0 Product Guide 75764 ENhDocument50 pagesCOM600 5.0 Product Guide 75764 ENhmalebolgia666No ratings yet

- ANSI Device NumbersDocument6 pagesANSI Device Numbersashish sahaNo ratings yet

- 4 3 Moran ApprovedDocument18 pages4 3 Moran ApprovedJonathanNo ratings yet

- ACS1000AD APPL SW Troubleshooting ManualDocument251 pagesACS1000AD APPL SW Troubleshooting ManualLuis Alejandro Prieto MujicaNo ratings yet

- Why We Need Power Supplies and Batteries for Telecom EquipmentDocument18 pagesWhy We Need Power Supplies and Batteries for Telecom Equipmentsamad_omidvar629250% (2)

- Schedule TrainningDocument43 pagesSchedule TrainningdarkbertNo ratings yet

- 7UM62 Catalog SIP E7 PDFDocument36 pages7UM62 Catalog SIP E7 PDFu_ulloaNo ratings yet

- Power Rectifier ASIC ControllerDocument5 pagesPower Rectifier ASIC ControllerQuang TaNo ratings yet

- ADR244ADocument36 pagesADR244AVirender RanaNo ratings yet

- DC1000 8631 To 9925, 10293, 11305, 11330, 11331Document24 pagesDC1000 8631 To 9925, 10293, 11305, 11330, 11331Jaime Arreola100% (1)

- G120 - Parameter List PDFDocument416 pagesG120 - Parameter List PDFNikhil TripathiNo ratings yet

- CYCLODocument5 pagesCYCLOఅనిల్ కుమార్ రాజగిరిNo ratings yet

- ABB Broschure Power Semiconductors 2019 72dpi PDFDocument64 pagesABB Broschure Power Semiconductors 2019 72dpi PDFMarcos FaleiroNo ratings yet

- Power Modules For VFD: Variable Frequency Drives (VFD)Document56 pagesPower Modules For VFD: Variable Frequency Drives (VFD)rajanarsu12No ratings yet

- ABB ACS550 Drives CatalogueDocument16 pagesABB ACS550 Drives CatalogueAnonymous hXUhpe7S100% (1)

- BCC M323 Drag Chain ConnectorDocument2 pagesBCC M323 Drag Chain ConnectorAlberto AvilesNo ratings yet

- (2013 - ) WX-98FT User ManualDocument36 pages(2013 - ) WX-98FT User ManualOscar Omar Quintanilla100% (1)

- Easergy Builder en Rev1.3 104Document114 pagesEasergy Builder en Rev1.3 104alex pardoNo ratings yet

- Tai Lieu TmeicDocument16 pagesTai Lieu TmeicNguyễn Trung HiếuNo ratings yet

- ReportDocument2 pagesReportArka EnergyNo ratings yet

- Class06 Transmission Line BasicsDocument49 pagesClass06 Transmission Line Basicsnavinchopra19860% (1)

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionFrom EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionNo ratings yet

- Excitation SystemDocument38 pagesExcitation SystemRaja Ramachandran100% (1)

- Static Excitation SystemDocument36 pagesStatic Excitation Systemlrpatra100% (1)

- A. Basic Relaying Fundamentals-1.1Document129 pagesA. Basic Relaying Fundamentals-1.1George Asuncion100% (1)

- A Low Cost High Efficiency Inverter For Photovoltaic ApplicationsDocument6 pagesA Low Cost High Efficiency Inverter For Photovoltaic ApplicationsbpchimeraNo ratings yet

- Excitation SystemDocument38 pagesExcitation Systemlrpatra50% (2)

- Static Excitation System Stage-I. 2docDocument28 pagesStatic Excitation System Stage-I. 2docraghavendran raghu100% (1)

- FACTS Technologies SVC PDFDocument9 pagesFACTS Technologies SVC PDFKrishnanNo ratings yet

- Perfect Contrl OTI and WTI Complete Data SheetDocument10 pagesPerfect Contrl OTI and WTI Complete Data Sheetucb2_ntpcNo ratings yet

- Harvard Managementor Course Schedule For One Year 2017-18: Level Level MonthDocument1 pageHarvard Managementor Course Schedule For One Year 2017-18: Level Level Monthucb2_ntpcNo ratings yet

- Honeywell Sensing Position Rangeguide 000709 25 en LowresDocument22 pagesHoneywell Sensing Position Rangeguide 000709 25 en Lowresucb2_ntpcNo ratings yet

- GrammarDocument97 pagesGrammarChavdarska Slavica100% (1)

- SL - No Power Cable Jointing Required/ No As Joints Cable Size 185 SQMM Megger ValveDocument1 pageSL - No Power Cable Jointing Required/ No As Joints Cable Size 185 SQMM Megger Valveucb2_ntpcNo ratings yet

- Phy 2Document8 pagesPhy 2ucb2_ntpcNo ratings yet

- Thyrister DetailsDocument1 pageThyrister Detailsucb2_ntpcNo ratings yet

- GST NTPC 20062017Document59 pagesGST NTPC 20062017ucb2_ntpcNo ratings yet

- Auto SamplerDocument25 pagesAuto Samplerucb2_ntpcNo ratings yet

- Milli Volt DropDocument2 pagesMilli Volt Dropkazishah100% (1)

- Electrical Maintenance Employee ListDocument2 pagesElectrical Maintenance Employee Listucb2_ntpcNo ratings yet

- BITSAT Solved Paper 2013 PDFDocument14 pagesBITSAT Solved Paper 2013 PDFSamip TripathyNo ratings yet

- St-Pro1 2012 PDFDocument379 pagesSt-Pro1 2012 PDFbeihanNo ratings yet

- Kirloskar Spectrum MotorDocument1 pageKirloskar Spectrum Motorucb2_ntpcNo ratings yet

- BITSAT Solved Paper 2012Document14 pagesBITSAT Solved Paper 2012hemanth kumarNo ratings yet

- Simatic Working With STEP 7Document112 pagesSimatic Working With STEP 7Slavisa LejicNo ratings yet

- 2008 BITSAT Solved PaperDocument111 pages2008 BITSAT Solved Paperom123456789No ratings yet

- NonAlignment 2Document7 pagesNonAlignment 2ucb2_ntpcNo ratings yet

- Safety Guidelines For The Application, Installation and Maintenance of Solid State ControlDocument24 pagesSafety Guidelines For The Application, Installation and Maintenance of Solid State ControlLinda SanchezNo ratings yet

- E Governance 2Document7 pagesE Governance 2ucb2_ntpcNo ratings yet

- Safety Guidelines For The Application, Installation and Maintenance of Solid State ControlDocument24 pagesSafety Guidelines For The Application, Installation and Maintenance of Solid State ControlLinda SanchezNo ratings yet

- ARC 10threport Ch5 PDFDocument47 pagesARC 10threport Ch5 PDFucb2_ntpcNo ratings yet

- E-Governance: Initiative in IndiaDocument33 pagesE-Governance: Initiative in Indiajohnny12812No ratings yet

- ARC 11threport Ch1 PDFDocument6 pagesARC 11threport Ch1 PDFshobhaNo ratings yet

- Closed vs Open Impeller Design AdvantagesDocument3 pagesClosed vs Open Impeller Design Advantagesucb2_ntpcNo ratings yet

- E Governance 3Document12 pagesE Governance 3ucb2_ntpcNo ratings yet

- Coal Converyour Fire DetectionDocument4 pagesCoal Converyour Fire DetectionHimat KhimaniNo ratings yet

- AAU Strength of Materials Lecture Notes 09-05-21Document66 pagesAAU Strength of Materials Lecture Notes 09-05-21Tahir Aed100% (7)

- Strength of MaterialsDocument66 pagesStrength of MaterialsSaiKiran Reddy PonnapuReddy100% (3)

- Mercedes BenzDocument56 pagesMercedes BenzRoland Joldis100% (1)

- Logic and Set Theory PropositionDocument3 pagesLogic and Set Theory PropositionVince OjedaNo ratings yet

- DLL - The Firm and Its EnvironmentDocument5 pagesDLL - The Firm and Its Environmentfrances_peña_7100% (2)

- Biagioli Did Galileo Copy The TelescopeDocument28 pagesBiagioli Did Galileo Copy The TelescopeGregory HooNo ratings yet

- Surgery Lecture - 01 Asepsis, Antisepsis & OperationDocument60 pagesSurgery Lecture - 01 Asepsis, Antisepsis & OperationChris QueiklinNo ratings yet

- ITU SURVEY ON RADIO SPECTRUM MANAGEMENT 17 01 07 Final PDFDocument280 pagesITU SURVEY ON RADIO SPECTRUM MANAGEMENT 17 01 07 Final PDFMohamed AliNo ratings yet

- Personalised MedicineDocument25 pagesPersonalised MedicineRevanti MukherjeeNo ratings yet

- M8-2 - Train The Estimation ModelDocument10 pagesM8-2 - Train The Estimation ModelJuan MolinaNo ratings yet

- Unit 1 TQM NotesDocument26 pagesUnit 1 TQM NotesHarishNo ratings yet

- Energy AnalysisDocument30 pagesEnergy Analysisca275000No ratings yet

- Take This LoveDocument2 pagesTake This LoveRicardo Saul LaRosaNo ratings yet

- On The Behavior of Gravitational Force at Small ScalesDocument6 pagesOn The Behavior of Gravitational Force at Small ScalesMassimiliano VellaNo ratings yet

- Katie Tiller ResumeDocument4 pagesKatie Tiller Resumeapi-439032471No ratings yet

- Do You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Document1 pageDo You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Mary Rose BaluranNo ratings yet

- DLP in Health 4Document15 pagesDLP in Health 4Nina Claire Bustamante100% (1)

- The European Journal of Applied Economics - Vol. 16 #2Document180 pagesThe European Journal of Applied Economics - Vol. 16 #2Aleksandar MihajlovićNo ratings yet

- AFNOR IPTDS BrochureDocument1 pageAFNOR IPTDS Brochurebdiaconu20048672No ratings yet

- Neuropsychological Deficits in Disordered Screen Use Behaviours - A Systematic Review and Meta-AnalysisDocument32 pagesNeuropsychological Deficits in Disordered Screen Use Behaviours - A Systematic Review and Meta-AnalysisBang Pedro HattrickmerchNo ratings yet

- Android software download guideDocument60 pagesAndroid software download guideRizky PradaniNo ratings yet

- Ensayo Bim - Jaime Alejandro Martinez Uribe PDFDocument3 pagesEnsayo Bim - Jaime Alejandro Martinez Uribe PDFAlejandro MartinezNo ratings yet

- Budgetary ControlsDocument2 pagesBudgetary Controlssiva_lordNo ratings yet

- Hyper-Threading Technology Architecture and Microarchitecture - SummaryDocument4 pagesHyper-Threading Technology Architecture and Microarchitecture - SummaryMuhammad UsmanNo ratings yet

- Obstetrical Hemorrhage: Reynold John D. ValenciaDocument82 pagesObstetrical Hemorrhage: Reynold John D. ValenciaReynold John ValenciaNo ratings yet

- Mission Ac Saad Test - 01 QP FinalDocument12 pagesMission Ac Saad Test - 01 QP FinalarunNo ratings yet

- ConductorsDocument4 pagesConductorsJohn Carlo BautistaNo ratings yet

- TDS Sibelite M3000 M4000 M6000 PDFDocument2 pagesTDS Sibelite M3000 M4000 M6000 PDFLe PhongNo ratings yet

- Federal Complaint of Molotov Cocktail Construction at Austin ProtestDocument8 pagesFederal Complaint of Molotov Cocktail Construction at Austin ProtestAnonymous Pb39klJNo ratings yet