Professional Documents

Culture Documents

Revised Boq1

Uploaded by

RamojeevaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Revised Boq1

Uploaded by

RamojeevaCopyright:

Available Formats

Page 1

INSTITUTE OF ANIMAL HEALTH AND VETERINARY BIOLOGICALS Sl no WORK Supply,erection,testing and comissioning of air-cooled condensing unit with compressor and other accessories like HP/LP cutout,OLP,neceessary tubes,etc.The whole unit is to be mounted in weathr proof,corrosion resistance heavy guage casing. Capacity 11 TR M/s Carrier, Voltas or atleast equlivalent make Supply of Double skin Air handling unit constructed out of 18 G pre coated GI sheet as outer skin and comprising of following sections: Pre filter section with combined 20 & 10 Micron filters, Blower section with DIDW blower,drive set and pulley, fine filter section with 5 micron filters at discharge side. Other accessories like dampers , Common base frame with Vibration isolators pads, Suitable inspection doors for filter, blower sections, are provided.4000 cfm Supply of Single skin Air handling unit constructed out of 18 G pre coated GI sheet as outer skin and comprising of following sections: Pre filter section with combined 20 & 10 Micron filters, Blower section with DIDW blower,drive set and pulley, fine filter section with 5 micron filters at discharge side. Other accessories like dampers , Common base frame with Vibration isolators pads, Suitable inspection doors for filter, blower sections, are provided.2000 cfm Supply,erection,testing and comissioning of return air ducting made up of GI.22 guage sheet with all necessary angle framed supports.All joints to be sealed with rubber(neroperene) gaskets.The duct is to be supported from the celling with anchor bolt fasteners. Supply & Installation XLPE trocellean make insulation with 6mm thick aluminium foil on top for return air duct . Supply,erection,testing and comissioning of supply air ducting made up of GI.22 guage sheet with all necessary angle framed supports.All joints to be sealed with rubber(neroperene) gaskets..The duct is to be supported from the celling with anchor bolt fasteners. Supply & Installation XLPE trocellean make insulation with 10mm thick aluminium foil on top for supply air duct. Supply,insulation and testing of supply and return air perforated grill for proper dustribution of air in the conditioned space to achieve required indoor conditions. Supply,erection,testing and commissioning terminal HEPA filter of 99.97% efficiency upto 0.3micron fitted in M.S powder coated Plenum box. The unit to be fixed at collar.HEPA filter make m/s EMW or equivalent. Size:610x610x105mm

Supply & Installation of FFU units 2' X 4' with air flow 650 cfm ,UL listed CE marked having final HEPA filter rated 99.999% efficienty down to 0.3 micron particles and larger. Sound level is less than 55 db and airflow velocity 90 fpm at filter face.

Units

Qty

Rate

Total

Nos

150000

150000

Nos

200000

200000

Nos

90000

90000

Sqmtr Sqmtr

900 1350

450 450

405000 607500

Sqmtr

900

450

405000

Sqmtr

1350

600

810000

Sqmtr

30

1500

45000

Nos

50000

400000

10

Nos

19

40000

760000

Page 1 of 5

Page 2

Sl no

WORK

Supply and installation of clean room panels of 100mm thick made of 0.8 mm G.I.Sheets and powder coated (with Polyurethane paint)to atleast 60 micron thickness and sandwiched with EPS,TF grade of density 16-18Kg/m3.The moundings has to be done with heavy duty "T" grid,minimum 8mm thick dia G.I rods and with provison for height adjustment.All joints to be sealed with good gradeRTV sealent,necessary cutout for plenum box,lighting fitting to be provided.

Units

Qty

Rate

Total

11

Sqmtr

160

2500

400000

Supply & instalation of View

12

panels of 5mm thick double glazed panels of size 700 mm X 700 mm, fixed in the wall panel as required.

Supply of Diffrential pressure indicating system with the Magnehaulic guages with suitable SS boxes and necessary wiring along with housing. Supply and installation of 2 X 36 watt CLF light fitting with necssary accessories.Flush mounting type suitable for clean room specification size 1'x1'. Supply and installation of 3 X 36 watt CLF light fitting with necssary accessories.Flush mounting type suitable for clean room specification size

Nos Nos Nos Nos

5 17 11 19

4000 7500 3000 6000

20000 127500 33000 114000

13 14

15

2'x2'.

16

Supply of Doors, Modular sandwitched doors with both side Powder Coated GI sheet construction of 0.64mm thickness, with 45mm thick EPS insulation sandwitched between sheets, including, hinges, view panels, SS 304 C type handle, Push plate, Door closure,and suitable gasket. Size: 1250mm x 2100mm ht Size: 1050mm x 2100mm ht Size: 980mm x 2100mm ht Size: 2580mm x 2100mm ht(Double door) Supply of Modular non walkable ceiling Panels 50 mm thick one side Powder Coated, other side plain GI Sheet, GI construction of 0.64 mm thickand the EPS including fastners, hanging rods connectors Etc . GI profile Providing epoxy paiting on the wall over one coat of primer and epoxy patti. The thickness of paint to be 0.15mm.M necessary coat as to be provided to achive this thickness and neat finish. Supply & Installation of GI powder coated Volume

Nos Nos Nos Nos

10 13 2 1

16500 15000 13000 35000

165000 195000 26000 35000

17

Sqmtr

230

2150

494500

18

Sqmtr

350

600

210000

19

control dampers for supply air & return air, & branch ducts.

Supply & Installation of 630A TP MCCB with Rotary Handle, Voltmeter, Ammeter, Voltmeter Selector Switch, Ammeter Selector Switch,R.Y.B Indication Lamps, ELR, 6A SP MCB, 63A TP MCCB - 5Nos, 16A TP MCB, 32A TPN MCB, 63A TP MCB, 40A Contactor, 32A TP MCB, 32A Contactor,16A DP MCB, OLRs, Push Buttons, Indication Lamps CTs, Star Delta timer, Pla Relay & Auto manual selector Switch. Design, manufacture, Assemble, 20 of sheet steel fabricated panel, made out of 1.6mm thick sheet steel, duly treated by 7 tank process, and powder coated, using only approved components, 50kA Aluminum Bus bars, continuous earth bars, with 2nos.earth terminals necessary lifting hooks, necessary gland plates & panels complete as per specifications & single line diagram. All panels with top entry provision only galvanized, zinc passivated hardware shall be used for assembling.

Sqmtr

15

1500

22500

Nos Sqmtr

1 230

250000 1200

250000 276000

21

Supply of epoxy flooring with self leveleing, and two coats of epoxy paint to achieve final thickness of 2mm.

Page 2 of 5

Page 3

Sl no 23 23 24 27 30 31 32

WORK

Units

RMT RMT Nos Sqmtr LOT LOT LOT

Qty

350 450 1 1 1 1 1

Rate

400 400 25000 25000 20000 15000 10000

Total 140000 180000 25000 25000 20000 15000 10000

Supply & Installation Aluminium extruded coving R 50 duly powder coated. Supply & Installation epoxy extruded coving R 50 duly powder coated.

SS304 CHANGE OVER BENCH

33

Electrial Cabeling For AHU'S &CONDENSING UNIT Removing of exiting false celling Removing of exiting ducting Civil work for wall opening for ducting entry & etc as per site condition Validation , temperature RH, particle counts, Differential pressure & air velocity.The validation includes, As-Built state, At rest state and operation state

TOTAL

25000

25000

6681000

Page 3 of 5

INSTITUTE OF ANIMAL HEALTH AND VETERINARY BIOLOGICALS Sr No Bill Of Quantaties Dismantling and Re-Erection of Exixting AHU and Exhaust Units from Service Floor to terrace Slab cutout to be done for above ducts and necessary civil works for Supply and Exhaust Ducts Ducting of AHU & Exhaust units as per revised layouts Condensing unit erection and commissoning Civil Pedestal for AHU,Exhaust Units and Outdoor units Approx Qty Rate Amount

2 2 3

4 Rerouting of exixting duct works for culture room 5 Removing of old ducts and false cieiling at Corridor Removing of existing tiles in sterile storage and 6 sterile room 7 Pass Box cabling to be concealed 8 Opening for pass box,oven and autoclave 9 Stand for pass box-6 nos Culture room step ceiling as per fermentor 10 dimension 11 Wall panel to be till true ceiling Electrical pionts in fermentor room - industrial 3 nos 12 sockets 16A SS pendents in fermentor-details to be collected 13 from Mr.Ravindra 14 one number autoclave to be cancelled Damper to be installed before entering to false 15 cieiling for easy access/controll Sterile room one slab stone to be removed to 16 accomodate autoclave Additional ducting & grills for change room to be 17 considered Connecting area of 2 wings to be extended to 10 18 feet Light Fitting for above corridor 2 nos Riser panel to be installed away from door for easy 19 removal of wall panel Terminal filter to be considered for both sterile 20 areas Electrical panel location tentaively finalized to be 21 freezed during erection 3 additonal clean room doors for corridor and entry 22 change rooms 23 Ducting for corridor to fabricated false ceiling at corridor and incubator room to be 24 done revised qty to be mentioned

25 AHU corridor supporting to be re-done 26 HEPA plenum box 3 box Corridor return duct to be connected to exhaust 27 unit 28 5 nos light fitting to be considered 29 3 grills at corridor return 30 3 magnehelic gauge to be considered 31 coving to measured as per site condition Provision of cooling coil (3 Nos) to be checked 32 and confirmed

You might also like

- Top 60 Bank Interview QuestionsDocument12 pagesTop 60 Bank Interview QuestionsRamojeevaNo ratings yet

- Interview Capsule Ibps Po IIIDocument10 pagesInterview Capsule Ibps Po IIIganeshsingh1No ratings yet

- ResignDocument1 pageResignRamojeevaNo ratings yet

- ResignDocument1 pageResignRamojeevaNo ratings yet

- Pharma GuidelineDocument230 pagesPharma Guidelinesksingh82100% (2)

- Pending Work List - AVSDocument1 pagePending Work List - AVSRamojeevaNo ratings yet

- ResignDocument1 pageResignRamojeevaNo ratings yet

- Fan Performance TableDocument5 pagesFan Performance TableRamojeevaNo ratings yet

- Resignation Letter SampleDocument1 pageResignation Letter SampleRamojeevaNo ratings yet

- Weekly ReportDocument1 pageWeekly ReportRamojeevaNo ratings yet

- BSNL JTO Electrical 2009Document12 pagesBSNL JTO Electrical 2009saurabhdabas7No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Wallbond Crack Stitching PDFDocument2 pagesWallbond Crack Stitching PDFKevin BallNo ratings yet

- Professional General Catalog 4Document10 pagesProfessional General Catalog 4UB HeavypartsNo ratings yet

- ES0153-75440100-DBR-0003 Dust ExtractionDocument19 pagesES0153-75440100-DBR-0003 Dust Extractionraaj bharathNo ratings yet

- PDS - SikaWrap FX-50 C-En PDFDocument3 pagesPDS - SikaWrap FX-50 C-En PDFjohanes b mudaNo ratings yet

- Strength, Durability and Shrinkage Characteristics of Cement Stabilised Soil BlocksDocument10 pagesStrength, Durability and Shrinkage Characteristics of Cement Stabilised Soil BlocksSam ChongNo ratings yet

- Villa Ottolenghi by Carlo ScarpaDocument6 pagesVilla Ottolenghi by Carlo ScarpaOana ZavoianuNo ratings yet

- Steel Doors and Windows For 2013-14Document59 pagesSteel Doors and Windows For 2013-14Senthil KumarNo ratings yet

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaiseNo ratings yet

- Mechanical GA Drawings - Rev.1Document14 pagesMechanical GA Drawings - Rev.1unnicyriacNo ratings yet

- Clean Agent Fire Suppression System SpecificationDocument14 pagesClean Agent Fire Suppression System Specificationhendrik wibowoNo ratings yet

- Accumulators Catalogue EngDocument21 pagesAccumulators Catalogue EngThái Mai ĐìnhNo ratings yet

- Sudhar PipesDocument5 pagesSudhar Pipesyashas sNo ratings yet

- Saudi Arabian Oil Company: SECTION 15060 Chilled Water PipingDocument10 pagesSaudi Arabian Oil Company: SECTION 15060 Chilled Water Pipingthahar ali syedNo ratings yet

- Dr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiDocument3 pagesDr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiRao SahabNo ratings yet

- Teóricas - 11. Co-Cr Alloys PDFDocument14 pagesTeóricas - 11. Co-Cr Alloys PDFrostcarNo ratings yet

- Roads Division KasaragodDocument142 pagesRoads Division KasaragodShameer UppalaNo ratings yet

- CK Jet Diffuser Technical SpecificationDocument4 pagesCK Jet Diffuser Technical SpecificationJf OngNo ratings yet

- Construct 01 Tube Well RabupuraDocument57 pagesConstruct 01 Tube Well Rabupuraankur yadavNo ratings yet

- Total Building Cost CalculationsDocument6 pagesTotal Building Cost CalculationshadeeqaNo ratings yet

- Model of Tender SpecificationDocument15 pagesModel of Tender SpecificationRishi KathirNo ratings yet

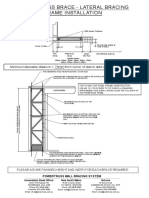

- PT Brace Installation 1Document1 pagePT Brace Installation 1Tony PedaNo ratings yet

- No Fines Conc SpecsDocument3 pagesNo Fines Conc Specsway2saleemNo ratings yet

- 13 PT ProcedureDocument14 pages13 PT ProcedureThân KhaNo ratings yet

- BhandupDocument69 pagesBhandupMrudulaNo ratings yet

- Fly OverDocument29 pagesFly OverUrvisha Butani100% (1)

- Primavera Engineer To Order (ETO)Document9 pagesPrimavera Engineer To Order (ETO)ShriNo ratings yet

- 285 Scale Paper Buildings 3Document7 pages285 Scale Paper Buildings 3Richard K100% (3)

- N-G-HE - 200 - EN Pressure Safety ReliefDocument77 pagesN-G-HE - 200 - EN Pressure Safety ReliefMEGAN ASBROCK100% (1)

- Project References Uola-Volkslift-1Document9 pagesProject References Uola-Volkslift-1DaveNo ratings yet

- " Hysil " Calcium Silicate Insulation Blocks & Pipes-SpecificationsDocument1 page" Hysil " Calcium Silicate Insulation Blocks & Pipes-SpecificationsJCSNo ratings yet