Professional Documents

Culture Documents

Hvac

Uploaded by

sakshi1405Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hvac

Uploaded by

sakshi1405Copyright:

Available Formats

HVAC

The Basics of Heating, Ventilation

and Air Conditioning

HVAC

Heating, Ventilation and Air

Conditioning

Provides comfort for people

Allows humans to exist under

adverse conditions.

Basic Refrigeration Cycle

Expansion

Valve

Compressor

Evaporator

Condenser

Comfort

Comfort is primary intent of HVAC systems.

Productivity

Building Durability

Health

Load Calculations

Heating and Cooling

Accuracy important!

Design conditions

Building shell load

R, U value

Internal load

Ventilation load

Infiltration

Occupancy schedules

Heat Transfer

Conduction

Convection

Radiation

Resistance (R-Value)

U = 1 / R

Q = U x A x AT

U-Value is the rate of

heat flow in Btu/h

through a one ft

2

area

when one side is 1

o

F

warmer

The amount of solar

heat energy allowed to

pass through a window

Example: SHGC = 0.40

Allows 40% through and

turns 60% away

Solar Heat Gain Coefficient

Psychrometrics

Dry bulb temp.

Wet bulb temp.

Humidity

Dew point

Moisture content

Heating

Cooling

Humidify

De-Humidify

Psychrometric Chart

Basic HVAC Equipment

Fans / Blowers

Furnace / Heating unit

Filters

Compressor

Condensing units

Evaporator (cooling coil)

Control System

Air Distribution System

System Types and Common Terms

Packaged Rooftop

Unit

Split System

Heat Pump

Geothermal

Air to Air

Hydronic (water)

PTAC / PTHP

Constant Volume

Variable Volume

Indoor Air Quality

Direct Expansion

Packaged Rooftop Units

FURNACE

A/C UNIT

Ductwork

Heating

and Cooling

Equipment

Temperature &

Humidity Controls

Split System

Heat Pump

Operate on simple

refrigeration cycle

Reversing the cycle

provides heating

Temperature

limitations

Air to air

Water source

Geothermal

Lake coupled

Geothermal Heat Pump Systems

Variable Air Volume

T

T

Variable Speed

Return Fan

R

e

t

u

r

n

A

i

r

Return Ducts

Zone Thermostat

Reheat Coil

VAV Box

Supply Ducts

Variable Speed

Supply Fan

F

i

l

t

e

r

s

C

o

o

l

C

o

i

l

w

/

T

e

m

p

R

e

s

e

t

H

e

a

t

C

o

i

l

w

/

T

e

m

p

R

e

s

e

t

HVAC-16

Hydronic systems

Pumps

Piping

Valves

Control Devices

Thermostats

Manual

Programmable

Optimum Start

DDC Systems

Variable Speed Drives

Automatic Valves and Dampers

Outdoor Sensors

Major Equipment

Chillers

Boilers

Cooling Towers

Economizers

Air Side

Water Side

Economizers

Free cooling source: When available, use cool outdoor air instead

of mechanically cooled air.

55

o

F

80

o

F

Minimum supply

of outside air

Normal Operation

Outside air dampers are

positioned to provide the

minimum outside air

Economizer Operation

Outside air dampers are fully

open. Maximum outside air is

provided

80

o

F

55

o

F and

up

85%

outside

air

85%

exhaust

HVAC-22

Zoning and Economizers

Economizers provide free cooling

when outdoor conditions are optimal

Proper orientation & zoning yields

comfort & efficiency

N

S

W E Core

HVAC-23

Air Distribution

Ductwork

Metal

Flexible

Ductboard

Grilles, Louvers,

& Registers

Dampers

Shut off

Fire

Smoke

Sealants

Supports

Additional Equipment

Energy Recovery Units

Desiccant Systems

Additional Equipment

Heat Exchangers

Humidifiers

Silencers

Mechanical Dehumidification

Return air is mixed with ventilation air

Cold coil condenses moisture

Heat is added back (electric or gas) so that

room air is not over cooled- Reheat

F

i

l

t

e

r

Historical Minimum Ventilation Rates

(cfm/person)

0

10

20

30

40

50

60

70

1

8

3

5

1

8

4

2

1

8

4

9

1

8

5

6

1

8

6

3

1

8

7

0

1

8

7

7

1

8

8

4

1

8

9

1

1

8

9

8

1

9

0

5

1

9

1

2

1

9

1

9

1

9

2

6

1

9

3

3

1

9

4

0

1

9

4

7

1

9

5

4

1

9

6

1

1

9

6

8

1

9

7

5

1

9

8

2

1

9

8

9

1

9

9

6

Tredgold

1836

Nightengale

1865

Billings

1895

Flugge

1905

Yaglou

1938

ASHRAE

62-73

ASHRAE 62-81

Smoking 62-81

ASH-

RAE

62-89

Smoking 62-89

Improved Ventilation Effectiveness

Mechanically provide filtered and

dehumidified outdoor air to the

breathing space

Vary ventilation based on the

number of occupants and process

loads - changes in occupancy can

be measured by CO

2

sensors

Consider designs that separate

ventilation and space conditioning

Utilize heat recovery systems to

reduce system size and ventilation

energy costs

Improved Ventilation Effectiveness

Effective mixing of ventilation

air within space

Net positive pressure in the

southeast; exhaust from

appropriate spaces

Provide clean outdoor air,

avoid:

loading docks

exhaust vents

plumbing stacks

waste collection

stagnant water

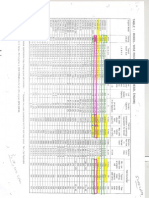

HEAT LOAD CALCULATION

TOPICS COVERED

LOAD CALCULATIONS

FORMS

FORMULAS

TABLES

FACTORS

AIR SIDE

PSYCHROMETRY

HEAT LOAD FORM

HEAT LOAD ESTIMATE

General office

Ceiling 10

Wall 4 brick, plastered both side

Window- ordinary single glass internal

shade

Door- plywood sandwich air space

Occupants - 35 person

Lighting - Fluorescent

DESIGN CONDITIONS

Outdoor design conditions

92F db / 80F wb or 95db/83wb

Overestimating effect

Night time temp. & rh different

76F db/ 75F wb / 95% rh

HEAT LOAD 2 35

DESIGN CONDITIONS

Indoor design conditions

Base on requirement and standards

75F db / 55% rh

72F db / 55% rh

71F db / 50% rh

Peak time at

4.00 pm

HEAT LOAD 2 36

CURRENT AIR-CONDITIONING DESIGN DATA

COMPARISON

ASHRAE 95 CIBSE

INDOOR

TEMP.(

o

C)

23-26 22+/-2

LIGHTING LOAD

(w/ft

2

)

1.85-4.65 1.4

OFFICE EQUIP.

(w/ft

2

)

0.8-2 1.4

OUTLET

VELOCITY

(ft/min.)

40-150 -

FRESH AIR

(cfm/person)

20 20

SOLAR GAIN THROUGH GLASS

Cooling Load = Window Area x Peak solar

heat gain (Table 4) x Storage Factor (Table 5) x

Shade Factor (Table 6)

Refer to Table 4, Table 5 and Table 6

SOLAR AND TRANSMISSION GAIN

Heat Gain Through Walls & Roofs = Area x

Equivalent Temp. Difference (Table 7 for wall &

Table 8 for roof) x Transmission Coefficient (U)

(Table 9)

TRANSMISSION GAIN (EXCEPT

WALLS AND ROOFS)

Heat gain through all glass = Area x

Temp. Difference (OA - RA) x

Transmission coefficient (U) (Table 9)

Heat gain through shade wall,

partition = Area x Temp. Difference

(OA - RA - 5F) x Transmission

coefficient (U) (Table 9)

TRANSMISSION GAIN (EXCEPT

WALLS AND ROOFS) (2)

Heat gain through wall, partition (adjacent to

Kitchen,Boiler Room) = Area x Temp.

Difference (OA - RA + 15F to 25F) x

Transmission coefficient (U) (Table 9)

INFILTRATION

When ventilation exceeds

infiltration (+ve pressure), then

infiltration = 0

When rooms are design at -ve

pressure, have to consider

INTERNAL LOADS

People

No. of people from no. of chairs or base on per

floor area

Table 10 - Heat gain from people

No. of people x Table 10

Activity, Sensible & Latent

INTERNAL LOADS

Power

Table 53 - Heat gain from electric motors

Electric motors contribute only sensible heat to

space

INTERNAL LOADS

Lights - Estimate (w/ft

2

)

Lights - Type

Incandescent

rated lamp watt x 3.413

Fluorescent lamp

rated lamp watt x 1.25 x 3.413

INTERNAL LOADS

Appliances

most appliances contributes both sensible and

latent heat load.

They contribute latent heat by virtue of their

function ex. drying, cooking

Hood to remove this is most effective

Table 50 & 51- Heat Gain from Restaurant

SAFETY FACTOR

Safety factor added for possible error in the

survey

Over estimating safety factor will cause

oversized air conditioning equipment - difficult

to maintain space conditions

< 5%

ROOM SENSIBLE HEAT (RSH)

Now all the load components contributing to

sensible load can be added

SUPPLY AIR DUCT LOSSES

In transferring air from system cooling coil to

space, four losses must be considered;

Supply duct heat gain

supply duct leakage loss

fan heat

bypassed outdoor air

SUPPLY DUCT HEAT GAIN

Supply air in the duct at 50F to 60F passes

through surrounding environment above 90F

- potential heat gain to supply air

Insulation reduces this gain

Typical figure < 2% of RSH

SUPPLY DUCT LEAKGE LOSS

Lost capacity in the supply air duct depends

on duct shape, duct pressure and

workmanship.

Low pressure (0 - 2s.p) : <5%

Medium pressure (2 - 6s.p) : 2% - 3%

High pressure (6 & above) : <1%

FAN HEAT

Draw through (draw through the cooling coil)

fan add heat to air supply. Electrical losses for

motor which lies in the air stream also add

heat

< 5%

HEAT LOAD 2 52

BYPASS OUTDOOR AIR

Some of the air passing through the coil

remain untreated.

Load equivalent to infiltration load

Depends on bypass factors use

Load = cfm x (t

oa

-t

rm

) x bf x 1.09

EFFECTIVE ROOM SENSIBLE HEAT

(ERSH)

This load determine the cfm required across

the cooling coil

ERSH = RSH + (SUPPLY DUCT GAIN + SUPPLY

DUCT LEAK LOSS + FAN) + BYPASS OUTDOOR

AIR

LATENT LOAD

The latent counterpart of infiltration, internal

loads, and supply duct load are also calculated

to determine the Room Latent Heat and

Effective Room Latent Heat

Vapor Transmission - only for low or high dew

point application.

ROOM LATENT HEAT (RLH)

SUM OF ALL ROOM LATENT LOAD

INFILTRATION

PEOPLE

STEAM

APPLIANCES

ADDITIONAL HEAT GAINS

VAPOUR TRANSMISSION

EFFECTIVE ROOM LATENT LOAD

(ERLH)

ROOM LATENT HEAT (RLH) + SUPPLY DUCT

LEAKAGE LOSS + BYPASS OUTDOOR AIR

OUTDOOR AIR / VENTILATION

RATES

Outdoor air/ventilation rates from Table 11-Ventilation Std.

Outdoor air quantity can be determined either by

cfm/person or cfm/ft

2

or airchange rate (ach)

Air change is defined as the quantity of changed air every

hour

cfm = vol x ach/ 60

OUTDOOR AIR HEAT

Outdoor air heat comprised of both sensible

and latent load

Except for bypassed air, the load appears on

the upstream of the coil

Requirements of outdoor/fresh air base on air

change rate or cfm/sq.ft or per person

RETURN DUCT LOSSES

Return duct are normally shorter than supply

duct

Temperature of air at about 75F - 80F

Return duct slightly negative

1% for Return duct heat gain &

1% for return duct leakage loss

GRAND TOTAL HEAT

Total heat load the coil must remove from the

air passing over it.

Also known as dehumidifier load

REFRIGERATION LOAD

Introducing two additional loads not

experience by the coil

Piping sensible heat gain

Pumping heat gain

APPARATUS DEW POINT (ADP)

Effective Room Sensible Heat (ERSH) Effective Room

Total Heat (ERTH)

ADP obtained from plot ESHF line or Table 65

Indicated ADP & Selected ADP

ADP must be > 48F

HVAC Systems Duct Design

Fundamentals

Velocity

fpm

Velocity Pressure

in. w.g.

A

Q

V =

2

4005

|

.

|

\

|

=

V

p

v

Fundamentals

Static Pressure

Total Pressure Velocity Pressure

Total Pressure (loss)

Darcy Weisbach Equation

p A

12f L

D

h

--------------

EC +

\ .

|

| |

V

1097

------------

\ .

|

| |

2

=

Pressure Changes

Design Procedures

Arrange outlets/inlets

Adjust calculated air quantities for

Heat gain/loss

Leakage

Duct

Equipment (VAV box)

Accessories (dampers, sensors, access doors,etc.)

Space pressurization

Design Procedures

Select outlet sizes based on manufacturer's

data

Sketch the system (connect the dots)

Divide the system into sections

Section is any change in flow, size, shape

Size the system using required/preferred

method

Design Procedures

Calculate the system total pressure loss

Layout the system in detail

Space limitations

Obstructions/coordination concerns

Resize duct sizes to balance

Analyze noise levels

Use sound attenuation where necessary

Design Methods Overview

Equal Friction

Size ductwork based on a constant pressure loss

per unit length (.08-.1 in. w.g. per 100 ft.)

Larger sizes require less energy but have a higher

initial cost

Smaller sizes require more energy but will have a

reduced initial cost.

Practical for simple systems

Duct Calculators

Design Methods Overview

Static Regain

Obtain the same static pressure at diverging flows

Change duct sizes down stream

Iterative process best handled by computers

Start the process by selecting a maximum velocity in the root

section

Higher velocities require more energy but have a lower initial cost

Lower velocities require less energy but have a higher initial cost

Design Methods Overview

T-method

Calculation intensive (use software)

Considers current building costs, energy costs and

future costs.

The calculation process involves:

condensing the system

fan selection (the simulation uses actual fan curves)

expanding the system

Design Methods Overview

Extended Plenum

1-6 in. w.g. systems

Duct velocity up to 3000 fpm

Branch velocity should not exceed trunk velocity

Balancing dampers should be used at each branch

Can result in low velocities

Excessive heat gain/loss

Design Methods Overview

Extended Plenum

Low operating cost

Easier to balance

Less fittings

Easy to modify for (tenant changes)

Design Methods Overview

Constant Velocity

Used primarily for material conveyance

Maintain sufficient velocities to suspend material

Converging flows should offset

Design Methods Overview

Design Considerations

Stack Effect

Height of the building

Elevator shafts, stairwells, other shafts

Wind effect

Prevailing wind direction

Shape of building and nearby objects

Location of intakes and exhausts

Design Considerations

Inlet and outlet conditions

Fan curves are ideal

Inlet conditions to avoid

Pre-rotation

Turbulent flow

Can not be correct by simply adding to the

required pressure

Results in a new curve

Design Considerations

Inlet and outlet conditions

Design Considerations

Fan system effect

Design Considerations

Fan system effect

Difficult to asses

Approximations exist (ASHRAE Duct Fitting

Database)

Experience

Design Considerations

Design Considerations

Flex Duct

Design Considerations

The contractor wants to use a different type of

elbow, is that OK?

It depends on the location in the system

What type of fitting is the proposed replacement?

What are the actual losses in the system?

Velocity pressure

Loss coefficient

Fittings

Comments

Avoid using extractors

Poor airflow

Noise

Use an elbow for the final branch in a duct

run.

Cushion effect

Boot taps

Best performance for cost

Acoustics

If it is good for airflow it is usually good for

acoustics.

Three components:

Source

Path

Receiver

Acoustics

Acoustics

Acoustics

Weighting

Human ear is less sensitive to low and high

frequencies

More sensitive to mid-frequencies

Acoustics

Start with quiet equipment

Locate air-handling equipment in less sensitive

areas

Allow for proper fan outlet conditions

Rectangular length 1.5 x largest dimension

Round length 1.5 x diameter

Acoustics

Use radiused elbows where possible

Larger ductwork reduces velocity and reduces

generated noise

Avoid abrupt changes in layout

Place dampers away from outlets

Flexible connections to equipment

Acoustics

Power splits

Ratio of areas

L1 = 10 log (A1 (A1 + A2))

L2 = 10 log (A2 (A1 + A2))

Units dB, applies across all frequencies, straight

subtraction

Acoustics

Medium-High frequency

Easier to attenuate than low

Lined or double walled duct

Lengthen runs if necessary

Silencers

Acoustics

Silencers

Can be very effective at attenuating sound

Insertion loss

Pressure drops

Generated noise

Elbow

Locate in the wall or as close as possible

Do not locate right off of a fan

Acoustics

Reactive silencers

Low to no pressure drops

Dissipative

No fill use baffles and chambers

You might also like

- Split Type Aircon Installation ManualDocument30 pagesSplit Type Aircon Installation Manualfreddie reyesNo ratings yet

- HVAC Basics: Hvac - Heating, Ventilation, Air-ConditioningDocument20 pagesHVAC Basics: Hvac - Heating, Ventilation, Air-ConditioningAli GurselNo ratings yet

- 6 Tech Specs Hvac 130116 PDFDocument186 pages6 Tech Specs Hvac 130116 PDFBay MưaNo ratings yet

- The Basics of Heating, Ventilation and Air ConditioningDocument96 pagesThe Basics of Heating, Ventilation and Air Conditioningsakshi1405No ratings yet

- One Btu Equals 1.055 KJ.: Joule (J)Document3 pagesOne Btu Equals 1.055 KJ.: Joule (J)suboo0678No ratings yet

- Compact Ceiling Cassette Chilled-Water Fan Coil Unit (FWF-C SeriesDocument12 pagesCompact Ceiling Cassette Chilled-Water Fan Coil Unit (FWF-C Serieskhadeerabk7925No ratings yet

- HVAC Book TraneDocument11 pagesHVAC Book TraneM M100% (1)

- ACDS-R410A-50-60Hz MS0495C 0315 CsDocument40 pagesACDS-R410A-50-60Hz MS0495C 0315 CsMARCOSNo ratings yet

- 3 Mitsubishi Electric-VRF Technology-PUCT EEIP 1-2012Document35 pages3 Mitsubishi Electric-VRF Technology-PUCT EEIP 1-2012Lee ChorneyNo ratings yet

- Ahu SelectionDocument28 pagesAhu SelectionkaamNo ratings yet

- Marine HVAC SystemsDocument58 pagesMarine HVAC SystemsSiti Aishah Hussien100% (3)

- Psych Rome TricsDocument46 pagesPsych Rome TricsDenitta D'RoseNo ratings yet

- AHU Functions and Components ExplainedDocument7 pagesAHU Functions and Components ExplainedVaishnavi KambleNo ratings yet

- Acoustic Calculation of Ventilation SystemsDocument49 pagesAcoustic Calculation of Ventilation SystemsHari Babu DharmavarapuNo ratings yet

- Duct Design: ME 425 - Air Distribution & ASHRAE Outlet SelectionDocument9 pagesDuct Design: ME 425 - Air Distribution & ASHRAE Outlet SelectionAbul ShaikhNo ratings yet

- HVAC Thermal Load EstimatingDocument28 pagesHVAC Thermal Load EstimatingIntisar Ali SajjadNo ratings yet

- Testing and Commissioning Sheet For HVACDocument10 pagesTesting and Commissioning Sheet For HVACJanitha Lakmina BandaraNo ratings yet

- A - Quotation VRV - r5 Final Discounted PriceDocument5 pagesA - Quotation VRV - r5 Final Discounted PriceMohammed AzharNo ratings yet

- Daikin VRVDocument53 pagesDaikin VRVBazeeth AhamedNo ratings yet

- Central Air Conditioning Systems ReviewDocument23 pagesCentral Air Conditioning Systems ReviewlalaNo ratings yet

- Selecting the Right AHUDocument24 pagesSelecting the Right AHUrahulNo ratings yet

- Air Handling Units (AHU) Pre-Commissioning TestsDocument2 pagesAir Handling Units (AHU) Pre-Commissioning TestsJaya PrathabNo ratings yet

- Mechanical Pressure Test ReportDocument1 pageMechanical Pressure Test ReportAli AimranNo ratings yet

- PCU0610A - Chiller (Small)Document16 pagesPCU0610A - Chiller (Small)jeromeduytscheNo ratings yet

- HVAC 101: The Basics of Heating, Ventilation and Air ConditioningDocument33 pagesHVAC 101: The Basics of Heating, Ventilation and Air ConditioningChan SeanNo ratings yet

- VAV Terminal UnitsDocument15 pagesVAV Terminal Unitsckyee88No ratings yet

- Air Handling Units Air Handling Units: Technical Catalogue Technical CatalogueDocument34 pagesAir Handling Units Air Handling Units: Technical Catalogue Technical CatalogueSMBEAUTYNo ratings yet

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- VRF & DX Split Type ACU Testing MethodologyDocument1 pageVRF & DX Split Type ACU Testing MethodologydamianNo ratings yet

- Design GuideDocument36 pagesDesign GuideDaniel A. NorbergNo ratings yet

- INSTALLATION MANUAL TITLEDocument2 pagesINSTALLATION MANUAL TITLETTaanNo ratings yet

- HVAC SystemsDocument4 pagesHVAC SystemsSyed Shafaat Ali JafferyNo ratings yet

- Heating Ventilation and Air Conditioning (HVAC) : Disusun Oleh: Hendri Amirudin Anwar ST, MKKKDocument54 pagesHeating Ventilation and Air Conditioning (HVAC) : Disusun Oleh: Hendri Amirudin Anwar ST, MKKKACHMAD MAULUDINNo ratings yet

- LG EcoV DX PDFDocument62 pagesLG EcoV DX PDFAnonymous THUA6AsJ100% (1)

- CO2 Sensor RoomDocument8 pagesCO2 Sensor RoomTrần Khắc ĐộNo ratings yet

- 2018 Multi V 5Document72 pages2018 Multi V 5Vo DungNo ratings yet

- AC Systems Lectures ModDocument38 pagesAC Systems Lectures ModAhmed SherifNo ratings yet

- Description of Useful HVAC TermsDocument64 pagesDescription of Useful HVAC TermsShiyamraj Thamodharan100% (1)

- AHU CHW Coil ConnectionDocument1 pageAHU CHW Coil ConnectionMULTIKARTHI07100% (1)

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Document8 pagesADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansNo ratings yet

- Air Handler Check ListDocument3 pagesAir Handler Check Listmnt6176100% (1)

- 04 Multi V ENGDocument44 pages04 Multi V ENGsellabiNo ratings yet

- Hvac Formulas PDFDocument3 pagesHvac Formulas PDFdasmechNo ratings yet

- Technical Overview On AHUDocument12 pagesTechnical Overview On AHUJahidul IslamNo ratings yet

- HVAC at TorqueDocument3 pagesHVAC at TorqueFarzanaShaikNo ratings yet

- HVAC Testing-Adjusting-Balancing For Small SystemsDocument17 pagesHVAC Testing-Adjusting-Balancing For Small SystemsgabrielNo ratings yet

- Aircraft Flying Project (PRINT OUT)Document24 pagesAircraft Flying Project (PRINT OUT)Priyanka KumariNo ratings yet

- York - Water Cooled Floor Standing Package E SeriesDocument3 pagesYork - Water Cooled Floor Standing Package E Seriespalitha19020% (1)

- HVAC ReportDocument5 pagesHVAC ReportrazahNo ratings yet

- Technical Spec for AHUDocument6 pagesTechnical Spec for AHUreddyrioNo ratings yet

- Humidification Load Calculation Armstrong PDFDocument3 pagesHumidification Load Calculation Armstrong PDFsyedNo ratings yet

- BTU MeterDocument13 pagesBTU MeterMahesh Sadasivan NairNo ratings yet

- Guide Spec Summary: Option ListDocument20 pagesGuide Spec Summary: Option ListRamachandra Reddy ChinthamreddyNo ratings yet

- Close Control Twin Circuit Range Engineering Data ManualDocument15 pagesClose Control Twin Circuit Range Engineering Data Manualmuqtar4uNo ratings yet

- MECH3429Air Conditioning and Refrigeration Engineering3Document84 pagesMECH3429Air Conditioning and Refrigeration Engineering3Umair Khan MarwatNo ratings yet

- Metal DuctsDocument14 pagesMetal Ductsanand_nambiar2003No ratings yet

- Carrier Brochure VRF PDFDocument16 pagesCarrier Brochure VRF PDFGiftson ImmanuelNo ratings yet

- Catalogo PQS PDFDocument234 pagesCatalogo PQS PDFpaito2363100% (1)

- York Chiller Log SheetDocument4 pagesYork Chiller Log SheetEngr Fazal AkbarNo ratings yet

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963From EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963No ratings yet

- HVAC Fundamentals: Fresh Air Calculation and ComponentsDocument24 pagesHVAC Fundamentals: Fresh Air Calculation and ComponentsAaron LisboaNo ratings yet

- DG Data-1Document1 pageDG Data-1nim_gourav1997No ratings yet

- Fundamentals of Air DistributionDocument12 pagesFundamentals of Air Distributionsakshi1405No ratings yet

- Fundamentals of Air DistributionDocument12 pagesFundamentals of Air Distributionsakshi1405No ratings yet