Professional Documents

Culture Documents

Figure I-1 The Pipeline Risk Management Demonstration Project

Uploaded by

romdhan88Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Figure I-1 The Pipeline Risk Management Demonstration Project

Uploaded by

romdhan88Copyright:

Available Formats

Figure I-1 The Pipeline Risk Management Demonstration Project

Risk Management Program Standard

Risk Management Demonstrations

Program Standard is Used by Industry as Guideline for Development and Submittal of Proposed Risk Management Programs Review Protocols and Criteria based on the Program Standard are Used by OPS to Review, Approve, and Monitor Proposed Industry Programs Performance Measures are Used by both OPS and Industry to Evaluate the Success of the Risk Management Demonstration Project

OPS Review and Approval Process

Demonstration Project Performance Measures

Figure II-1 Risk Management Program Overview

Program Elements

Process Elements

Risk Assessment

Administration

Roles & Responsibilities

What is the Scope of the Risk Assessment? What Adverse Events Can Happen? How Likely are These Events to Occur? How Severe Would the Consequences Be if the Events Did Occur?

Personnel Qualifications

Management of Change

What Could Be Done to Control Risks? What Are the Relative Merits of the Risk Control Options? What Set of Activities Best Achieves Risk Management Goals?

Communications

Documentation Program Evaluation and Improvement

Performance Monitoring & Feedback

What Improvements are Expected to Result from the Risk Control Decisions? What Measures Best Capture These Expected Outcomes? Are the Selected Risk Control Activities Having the Intended Effect? How Can the Overall Risk Management Process be Improved?

Feedback Loops

Risk Control & Decision Support

Figure IV-2 Progression of a Pipeline Incident

Hazard

Cause

Accidental Event

Impact

Hazardous liquid or gas contained and delivered during normal operation

Precursor, initiating or contributing events of a pipeline incident; start of the accident event sequence (e.g., coating disbond, mechanical damage)

Loss of containment of hazardous liquid or gas; product migrates along available pathways to people, environmental resources, etc.

Adverse consequences to people, the environment, etc.

Figure IV-4 Risk Control Activities During Progression of a Pipeline Incident

Hazard

Cause

Accidental Event

Impact

Prevention

Example Types of Risk Control Activities

Mitigation

- Isolation Valves - Dike / trench - Sprinkler / deluge

Response

-Evacuation - Spill response - Flowpath diversion

- Corrosion Control - Maintenance Programs - Impact Barriers

Figure IV-6 Performance Measures Associated with Stages of a Pipeline Incident

Hazard

Cause

Accidental Event

Impact

Prevention

Example Performance Measures

Mitigation

Reliability of Isolation Valves

Response

Effectiveness of Emergency Drills

Hydrotest Results

Figure IV-1

The Risk Assessment Process Element

Risk Assessment

Estimate the frequency and consequences of potential incidents (Section IV.1)

Scoping and Screening Analysis

Define the physical and analytical boundaries of the assessment (Section IV.1.1)

Event Identification

Identify the events that could cause pipeline failures and lead to adverse consequences (Section IV.1.2)

Frequency Analysis

Estimate how often the events might occur (Section IV.1.3)

Consequence Analysis

Estimate the severity of the adverse impacts should the events occur (Section IV.1.4)

Risk Estimation

Combine frequency and consequence estimates into relative risk values (Section IV.1.5)

Risk Control & Decision Support

Select activities to reduce risk or produce equal or greater levels of safety more efficiently (Section IV.2)

Performance Monitoring & Feedback

Determine if the risk control decisions produce the anticipated outcomes

Figure IV-3

The Risk Control & Decision-Support Process Element

Risk Assessment

Estimate the frequency and consequences of potential incidents (Section IV.1)

Risk Control & Decision Support

Select activities to reduce risk or produce equal or greater levels of safety more efficiently (Section IV.2)

Identification of Risk Control Issues

Define the major contributors to risk and opportunities for more efficient control of risks (Section IV.2.1)

Identification of Risk Control Options

Define specific alternatives to current design and operation that reduce risk or increase efficiency (Section IV.2.2)

Evaluation & Comparison of Options

Select the best set of design and operational practices that produce equal or greater safety (Section IV.2.3)

Performance Monitoring & Feedback

Determine if the risk control decisions produce the anticipated outcomes

Figure IV-5

The Performance Monitoring & Feedback Process Element

Risk Assessment

Estimate the frequency and consequences of potential incidents (Section IV.1)

Risk Control & Decision Support

Select activities to reduce risk or produce equal or greater levels of safety more efficiently (Section IV.2)

Performance Monitoring & Feedback

Determine if the risk control decisions produce the anticipated outcomes (Section IV.3)

Selection of Performance Measures

Identify expected outcomes of risk control decisions and associated metrics (Section IV.3.1)

Monitoring & Evaluation of Performance

Track actual performance and compare with expectations (Section IV.3.2)

Modifications to the Program

Analyze implications of observed performance to the models, data, assumptions, and conclusions of the risk management program (Section IV.3.3)

You might also like

- HIRA Traiing MaterialDocument64 pagesHIRA Traiing Materialdhir.ankurNo ratings yet

- Irina Maleeva - Ariel Snowflake x6 - ENG - FreeDocument4 pagesIrina Maleeva - Ariel Snowflake x6 - ENG - FreeMarinaKorzinaNo ratings yet

- Plans PDFDocument49 pagesPlans PDFEstevam Gomes de Azevedo85% (34)

- HIRADocument76 pagesHIRAdhir.ankurNo ratings yet

- PHA ProcedureDocument15 pagesPHA ProcedureMohammed Zubair100% (1)

- Guide To Risk AssessmentDocument16 pagesGuide To Risk AssessmentArun IyerNo ratings yet

- Guidance of Risk AssessmentDocument31 pagesGuidance of Risk AssessmentBagus Chandra KurniawanNo ratings yet

- Audit Engagement Strategy (Driving Audit Value, Vol. III): The Best Practice Strategy Guide for Maximising the Added Value of the Internal Audit EngagementsFrom EverandAudit Engagement Strategy (Driving Audit Value, Vol. III): The Best Practice Strategy Guide for Maximising the Added Value of the Internal Audit EngagementsNo ratings yet

- FAA System Safety Handbook, Chapter 8 - Safety Analysis - Hazard Analysis TasksDocument36 pagesFAA System Safety Handbook, Chapter 8 - Safety Analysis - Hazard Analysis TasksPina Korbacs100% (1)

- ISO 9001:2015 Overview. Presentation For Training (Preview)Document7 pagesISO 9001:2015 Overview. Presentation For Training (Preview)Centauri Business Group Inc.No ratings yet

- Guidelines for Hazard Evaluation ProceduresFrom EverandGuidelines for Hazard Evaluation ProceduresRating: 5 out of 5 stars5/5 (4)

- Ohsas 18001Document77 pagesOhsas 18001shaikhbwcNo ratings yet

- Risk MatrixDocument3 pagesRisk MatrixGhanta Ranjith KumarNo ratings yet

- Effectively Control Column PressureDocument12 pagesEffectively Control Column Pressureromdhan88No ratings yet

- Operational Key Risk IndicatorsDocument24 pagesOperational Key Risk IndicatorssjvrNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Troubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingFrom EverandTroubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingRating: 4.5 out of 5 stars4.5/5 (3)

- Risk and OpportunityDocument5 pagesRisk and OpportunityQualityproNo ratings yet

- L27/38S Project Guide - Power Plant: Four-Stroke GensetDocument392 pagesL27/38S Project Guide - Power Plant: Four-Stroke GensetAaron Chan100% (1)

- P&ID AbbreviationDocument4 pagesP&ID AbbreviationDjil Rezoug100% (5)

- Sample ALARP WorksheetDocument7 pagesSample ALARP WorksheetP100% (1)

- 3200AMMe - Part 4Document207 pages3200AMMe - Part 4Tanja Kesic100% (1)

- Guidelines for Integrating Management Systems and Metrics to Improve Process Safety PerformanceFrom EverandGuidelines for Integrating Management Systems and Metrics to Improve Process Safety PerformanceNo ratings yet

- QuestionDocument6 pagesQuestionAnosha AslamNo ratings yet

- Risk ManagementDocument17 pagesRisk ManagementMatthew SibandaNo ratings yet

- Kern Method Heat ExchangerDocument30 pagesKern Method Heat ExchangerCS100% (3)

- BowTieXP Risk Management ProcessDocument1 pageBowTieXP Risk Management Processhazopman100% (1)

- CEV654-Lecture 5a Hazard Analyis FMEADocument41 pagesCEV654-Lecture 5a Hazard Analyis FMEACaratsSVTNo ratings yet

- Iso13485 QOP4101 RiskMng PDFDocument4 pagesIso13485 QOP4101 RiskMng PDFQuality and Safety Consultants Co.No ratings yet

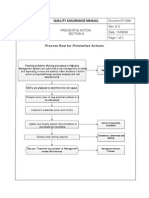

- Quality Assurance Manual: Preventive Action Section 8 Rev: E 0 Date: 15/08/09 Page 1 of 2Document2 pagesQuality Assurance Manual: Preventive Action Section 8 Rev: E 0 Date: 15/08/09 Page 1 of 2Ngonidzashe ZvarevasheNo ratings yet

- 4 2 Hirarc Compatibility ModeDocument56 pages4 2 Hirarc Compatibility ModeImzara AmeaNo ratings yet

- Risk Assesment GuidanceDocument31 pagesRisk Assesment Guidanceajuhaseen100% (2)

- SSPC SP 1Document2 pagesSSPC SP 1romdhan88No ratings yet

- Implicit Explicit SignalsDocument8 pagesImplicit Explicit SignalsVersoza Nel100% (2)

- Deviation HandlingDocument28 pagesDeviation Handlingwindli2014No ratings yet

- Hazard Identification at A Major Hazard Facility: Guidance NoteDocument25 pagesHazard Identification at A Major Hazard Facility: Guidance NotetemterNo ratings yet

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- HIRARCDocument106 pagesHIRARCMohdNajib Mahmud75% (4)

- LNG Process Selection Considerations For Future DevelopmentsDocument9 pagesLNG Process Selection Considerations For Future Developmentsromdhan88No ratings yet

- Hazard and Risk Analysis Lls 9-22-2011Document34 pagesHazard and Risk Analysis Lls 9-22-2011AlberipaNo ratings yet

- Combined Shear and TensionDocument16 pagesCombined Shear and TensionDAN MARK OPONDANo ratings yet

- 1970 - Transformer FMEA PDFDocument7 pages1970 - Transformer FMEA PDFSing Yew Lam0% (1)

- Risk Assessment: A Practical Guide to Assessing Operational RisksFrom EverandRisk Assessment: A Practical Guide to Assessing Operational RisksNo ratings yet

- Flare Modeling ParametersDocument26 pagesFlare Modeling Parametersromdhan88No ratings yet

- FINAL WEEK 4 - Personnel ManagementDocument23 pagesFINAL WEEK 4 - Personnel ManagementKenneth SibonghanoyNo ratings yet

- ATTACHMENT 2-4 - Risk Assessment Report Template1521105902Document4 pagesATTACHMENT 2-4 - Risk Assessment Report Template1521105902martahan manurungNo ratings yet

- Risk Assessment - Chapter 1Document26 pagesRisk Assessment - Chapter 1Alexandre Hugen50% (2)

- Risk Assessment - Chapter 2Document29 pagesRisk Assessment - Chapter 2Alexandre HugenNo ratings yet

- Risk Analysis InstructionsDocument26 pagesRisk Analysis Instructionsaborder-06-sonnetNo ratings yet

- Hazard Management: 1. PurposeDocument9 pagesHazard Management: 1. Purposebmwm31996bmwNo ratings yet

- Ipc2012 90237Document11 pagesIpc2012 90237Marcelo Varejão CasarinNo ratings yet

- Process of Development of Safety Critical ElementsDocument5 pagesProcess of Development of Safety Critical ElementsClarence LoganathanNo ratings yet

- Hazard & Risk Assessment ManualDocument7 pagesHazard & Risk Assessment ManualMohamed FaroukNo ratings yet

- 18001our Next Mission!!!Document23 pages18001our Next Mission!!!babyfish1No ratings yet

- KAHLIDr Yehia45 PDFDocument36 pagesKAHLIDr Yehia45 PDFLuiz Rubens Souza CantelliNo ratings yet

- ISO14001 Implementation & Operation, Checking and Management ReviewDocument45 pagesISO14001 Implementation & Operation, Checking and Management ReviewVIRGILIO MANANGANNo ratings yet

- Hazards Risk Analysis N ScankDocument51 pagesHazards Risk Analysis N ScankpotatoteddyNo ratings yet

- Unit III: Life Cycle Testing ApproachDocument28 pagesUnit III: Life Cycle Testing ApproachSanthosh NaniNo ratings yet

- CombinepdfDocument105 pagesCombinepdfKenneth SibonghanoyNo ratings yet

- Deviation WHODocument28 pagesDeviation WHOk.p.No ratings yet

- Case Study RMWG-05 - Packaging Line OptimizationDocument4 pagesCase Study RMWG-05 - Packaging Line Optimizationtito1628No ratings yet

- Unit 5 ICH GuidelinesDocument35 pagesUnit 5 ICH Guidelinesvidusha9727No ratings yet

- Eia Implementation and Follow Up-Slide PresentationDocument18 pagesEia Implementation and Follow Up-Slide PresentationHenry KoechNo ratings yet

- An Introduction Lecture To Environmental Impact Assessment (EIA) CourseDocument12 pagesAn Introduction Lecture To Environmental Impact Assessment (EIA) CourseFales HauleNo ratings yet

- Risk Management in Product Development - Current MethodsDocument8 pagesRisk Management in Product Development - Current MethodsGerome NavarroNo ratings yet

- RiskmanagementDocument18 pagesRiskmanagementAmirul 'Ariff Abdul ManafNo ratings yet

- IUM-Safety Risk Management Concept (1635)Document2 pagesIUM-Safety Risk Management Concept (1635)Risad ChoudhuryNo ratings yet

- Unit III: Life Cycle Testing ApproachDocument27 pagesUnit III: Life Cycle Testing ApproachmadhanNo ratings yet

- TQM, Lecture-11+12Document18 pagesTQM, Lecture-11+12Shakeel AhmadNo ratings yet

- TQM Unit 4 FMEA Lecture 6Document17 pagesTQM Unit 4 FMEA Lecture 6tamilselvansambathNo ratings yet

- Risk Assessment Protocol MaterialsDocument36 pagesRisk Assessment Protocol MaterialsJorge MaldonadoNo ratings yet

- Risk Management for Engineering Projects: Procedures, Methods and ToolsFrom EverandRisk Management for Engineering Projects: Procedures, Methods and ToolsNo ratings yet

- Advanced Safety Management: Focusing on Z10 and Serious Injury PreventionFrom EverandAdvanced Safety Management: Focusing on Z10 and Serious Injury PreventionNo ratings yet

- Agma 6000 Spec Vibration For GearDocument16 pagesAgma 6000 Spec Vibration For Gearromdhan88100% (1)

- IEC 60034 Pt.11 Ch.3 (Thermal Protection)Document2 pagesIEC 60034 Pt.11 Ch.3 (Thermal Protection)romdhan88No ratings yet

- IEC 60034 Pt.11 Ch.2 (Thermal Protection)Document2 pagesIEC 60034 Pt.11 Ch.2 (Thermal Protection)romdhan88No ratings yet

- Heat and Material Balance of Gas Stripping Deaerator ColumnDocument1 pageHeat and Material Balance of Gas Stripping Deaerator Columnromdhan88No ratings yet

- Water97 v12Document9 pagesWater97 v12Kathryn CottonNo ratings yet

- FlareDocument10 pagesFlareromdhan88No ratings yet

- Emergency ShowerDocument8 pagesEmergency Showerromdhan88No ratings yet

- Specification For Fire MonitorDocument4 pagesSpecification For Fire Monitorromdhan88No ratings yet

- Hirsch Velocity Guide SpecificationsDocument27 pagesHirsch Velocity Guide Specificationsromdhan88No ratings yet

- Air Tool Consumption ChartDocument4 pagesAir Tool Consumption Chartromdhan88No ratings yet

- Lafarge Interior Building Solutions BrochureDocument24 pagesLafarge Interior Building Solutions BrochuretwinpixtwinpixNo ratings yet

- World's Standard Model G6A!: Low Signal RelayDocument9 pagesWorld's Standard Model G6A!: Low Signal RelayEgiNo ratings yet

- Updated Factory Profile of Aleya Apparels LTDDocument25 pagesUpdated Factory Profile of Aleya Apparels LTDJahangir Hosen0% (1)

- DR PDFDocument252 pagesDR PDFa_ouchar0% (1)

- Catalogo GatesDocument255 pagesCatalogo GatesBenjamin HedoneweNo ratings yet

- Sales 20: Years Advertising Expense (Millions) X Sales (Thousands) yDocument8 pagesSales 20: Years Advertising Expense (Millions) X Sales (Thousands) ybangNo ratings yet

- Presentation On 4G TechnologyDocument23 pagesPresentation On 4G TechnologyFresh EpicNo ratings yet

- HCPL 316J 000eDocument34 pagesHCPL 316J 000eElyes MbarekNo ratings yet

- Cynosure Starlux 500 Palomar Technical Service ManualDocument47 pagesCynosure Starlux 500 Palomar Technical Service ManualJF SilvaNo ratings yet

- JKJKJDocument3 pagesJKJKJjosecarlosvjNo ratings yet

- SSDsDocument3 pagesSSDsDiki Tri IndartaNo ratings yet

- Semi Finals in Tle 2015Document3 pagesSemi Finals in Tle 2015LoraineTenorioNo ratings yet

- Assessment Questions: 1: Wash - Rinse and SanitizeDocument3 pagesAssessment Questions: 1: Wash - Rinse and SanitizeAna Margarita AycochoNo ratings yet

- Fundamentals of Pain Medicine: Jianguo Cheng Richard W. RosenquistDocument346 pagesFundamentals of Pain Medicine: Jianguo Cheng Richard W. RosenquistMayNo ratings yet

- Surface TensionDocument13 pagesSurface TensionElizebeth GNo ratings yet

- Kindergarten Math Problem of The Day December ActivityDocument5 pagesKindergarten Math Problem of The Day December ActivityiammikemillsNo ratings yet

- Math COT 3Document18 pagesMath COT 3Icy Mae SenadosNo ratings yet

- Proefschrift T. Steenstra - tcm24-268767Document181 pagesProefschrift T. Steenstra - tcm24-268767SLAMET PAMBUDINo ratings yet

- Assignment 1Document3 pagesAssignment 1farhang_tNo ratings yet

- CapstoneDocument23 pagesCapstoneA - CAYAGA, Kirby, C 12 - HermonNo ratings yet

- Schneider Pressure Switch XMLDocument2 pagesSchneider Pressure Switch XMLhaoNo ratings yet

- NF en Iso 5167-6-2019Document22 pagesNF en Iso 5167-6-2019Rem FgtNo ratings yet

- G1CDocument12 pagesG1CKhriz Ann C ÜNo ratings yet