Professional Documents

Culture Documents

Inspection of Valves

Uploaded by

Anand KesarkarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection of Valves

Uploaded by

Anand KesarkarCopyright:

Available Formats

SBU-Quality Services

Valves

May 5, 2010

Meeting the Challenges of Time & Technology

Inspection of Valves

Valve:

A Valve is a component in a fluid flow or pressure system which regulate either the flow or the pressure of the fluid, by: Stopping or starting the flow Controlling the flow rate Preventing back flow Controlling the pressure Relieving the pressure Flow or pressure regulation is done by adjusting the position of the closure member of the valve. The closure member of the valve is called Disc or Rotor

Meeting the Challenges of Time & Technology

Inspection Valves Application:

Valves are used in:

Industrial Military Commercial Residential Transportation applications

Meeting the Challenges of Time & Technology

Inspection Valves Types of Valves:

Valves can be categorized into following design types based on the design of the closure member: Gate Globe Ball Check Butterfly Plug Diaphragm Needle

Meeting the Challenges of Time & Technology

Inspection Valves

Types of Valves: GATE

Meeting the Challenges of Time & Technology

Inspection Valves

Types of Valves: GLOBE

Meeting the Challenges of Time & Technology

Inspection Valves

Types of Valves: BALL

Meeting the Challenges of Time & Technology

Inspection Valves

Types of Valves: CHECK

Meeting the Challenges of Time & Technology

Inspection Valves

Types of Valves: Butterfly

Meeting the Challenges of Time & Technology

Inspection Valves Types of Valves: Based on Function

Valves Operating Manually: Starting / Stopping the flow Regulating the Flow Valves Operating Automatically: Controlling the Flow Preventing Back Flow Relieving Pressure

Meeting the Challenges of Time & Technology

Inspection Valves

MANUALLY OPERATED VALVES

Meeting the Challenges of Time & Technology

Inspection Valves

Parts of Valve:

Meeting the Challenges of Time & Technology

Inspection Valves Parts of Valve:

Body / Bonnet: Thickness of the body / bonnet should not be less than minimum specified. Disc/Gate: The movable part of the valve that is positioned in the flow path to modify the rate of flow through the valve Seat: The part of the body which contacts the disc/gate for making a sealing. Seat may be integral to the body of the valve or can be removable. A removable seat is called renewable seat. Advantage of renewable seat is that it can be removed in case of any wear and tear without destroying the body. Meeting the Challenges of Time & Technology

Inspection Valves Parts of Valve:

Backseat: Prevents leakage along the stem Gland packing can be removed without de-pressurizing the system Trim:

Stem, seating surfaces of the body and the disc, internal keys, pins and small internal components that come in contact with the contained fluid. Screws and bushes in contact with the contained fluid are also considered as trim

Meeting the Challenges of Time & Technology

Inspection Valves End Connections of Valve:

Flanged Ends Welded Ends Socket Welded Ends (Up to NPS 2) Butt Welding Ends (> NPS 2) Threaded Ends (Up to NPA 2)

Meeting the Challenges of Time & Technology

Inspection Valves Valve Manufacturing Standard:

ASME/ANSI 16.34: Steel Valves - Flanged &

Butt welding Ends

ASME/ANSI B16.10:Face-to-Face Dimensions of Ferrous Valves API 600: Steel Valves - Flanged & Butt welding Ends API 602: Compact Steel Gate Valves- Flanged, Threaded, Welding and Extended-Body Ends API 603: Class 150, Cast, Corrosion-Resistant, Flanged- End Gate Valves API 608: Metal Ball Valves-Flanged and Butt-Welding Ends

Meeting the Challenges of Time & Technology

Inspection Valves Valve Manufacturing Standard:

API 609: Butterfly Valves, Lug-Type and Wafer API 6D: Specification for Pipeline Valves (Gate, Plug, Ball and Check Valves) MSS SP-55Quality Standard for Steel Castings for Valves, Flanges and Fittings and Other Piping Components API 598Valve Inspection & Testing BS 6755-1:1986:Testing of Valves - Part 1: Specification for Production Pressure Testing Requirements

Meeting the Challenges of Time & Technology

Inspection Valves Materials (Sample):

Body/Bonnet: IS 210 (Cast Iron) ASTM A 216 Gr. WCB, WCC (Cast Steel) ASTM A 217 Gr. WC6, WC9 (Cast Steel) ASTM A 352 Gr. LCB, LCC (Cast Steel-Low Temperature Service) ASTM A 351 Gr. CF8, CF8M, CF3, CF3M (Cast-Austenitic Stainless Steel) ASTM A 182 Gr. 304, 304L, 316, 316L (Forged-Austenitic Stainless Steel) Stem: ASTM A 479 Gr. 316, ASTM A 182 Gr.316 Seat/Seat Ring: Contact Surface Stellited Packing: PTFE, Graphite Meeting the Challenges of Time & Technology

Inspection Valves Valve: Size and Rating

Designation: NPS ASME Pressure Classes: 150, 300, 600, 900, 1500, 2500

Meeting the Challenges of Time & Technology

Inspection Valves

Inspection & Testing

Material Certification Visual & Dimensional Inspection Pressure Test Calibration (Control Valves) Functional Test (Automatically operated valves) Painting Inspection Final Inspection for Marking/Tagging/Identification Packing and Preparation for Shipment Review of Final Documentation Inspection Release

Meeting the Challenges of Time & Technology

Inspection Valves

Inspection & Testing: API-598

Applicable for Non-Metallic Seated, Resilient Seated and metalto-metal seated valves of the Gate, Globe, Plug, Ball, Check, Butterfly types. Applicable Tests: Visual Examination of Casting Shell Test Backseat Test Low Pressure Closure Test High Pressure Closure Test High Pressure Pneumatic Shell Test

Meeting the Challenges of Time & Technology

Inspection Valves

Inspection & Testing: API-598

Visual Examination Of Casting: MSS SP 55 Pressure Test: Backseat Test Shell Test High Pressure Closure Test (seat test) Low Pressure Closure Test (Pneumatic) High Pressure Shell Pneumatic Test (Optional)

Meeting the Challenges of Time & Technology

Inspection Valves

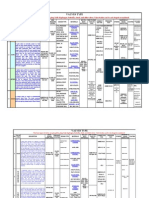

Pressure Tests as per API-598:

Valves NPS 4and smaller with pressure rating up to and including ASME Class 1500 and valves larger than NPS 4 having pressure rating up to and including ASME Class 600, shall be tested in accordance with Table 1-A Valves NPS 4and smaller with pressure rating greater than ASME Class 1500 and valves larger than NPS 4 having pressure rating greater than ASME Class 600, shall be tested in accordance with Table 1-B

Meeting the Challenges of Time & Technology

Inspection Valves

Pressure Tests as per API-598:

Test Fluid: Shell, backseat, high pressure closure test: Air, inert gas, kerosene, water or a non-corrosive liquid with a viscosity not higher than water. Temperature of test fluid should not exceed 125 Deg. F (52 Deg C) Low pressure closure test: Air or inert gas.

Meeting the Challenges of Time & Technology

Inspection Valves

Pressure Tests as per API-598:

Quality of Water: Should contain a water soluble oil or a rust inhibitor For testing austenitic stainless steel valves, the chloride content should not exceed 100 PPM (water analysis report is required)

Meeting the Challenges of Time & Technology

Inspection Valves

Pressure Tests as per API-598:

Test Pressure: In line with Table-2 and Table-3 Test Duration: In line with Table-4 Maximum Allowable Leakage for Closure Test: Table-5

Meeting the Challenges of Time & Technology

Inspection Valves

Pressure Tests as per API-598:

Leakages: For shell and backseat test, no visible leakage is permitted. If the testing medium is a liquid, there shall be no visible evidence of drops or wetting of the external surfaces. If the test medium is air or gas, no leakage will be revealed by established method of detection.

Meeting the Challenges of Time & Technology

Inspection Valves Pressure Tests as per API-598:

Test Procedure-Backseat Test:

Gland Bolts / Nuts Loose

Meeting the Challenges of Time & Technology

Inspection Valves

Pressure Tests as per API-598:

Test Procedure-Shell Test:

Meeting the Challenges of Time & Technology

Inspection Valves

Pressure Tests as per API-598:

Test Procedure-Shell Test:

Closure member partially open

Meeting the Challenges of Time & Technology

Inspection Valves

Pressure Tests as per API-598:

Shell Test: Failure (Example)

Gate,

2 Class 600, ASTM A 352 Gr. LCB

Meeting the Challenges of Time & Technology

Inspection Valves

Pressure Tests as per API-598:

Test Procedure-High Pressure Closure Test (Gate):

Meeting the Challenges of Time & Technology

Inspection Valves

Pressure Tests as per API-598:

Test Procedure-Low Pressure Closure Test:

Meeting the Challenges of Time & Technology

Inspection Valves

Pressure Tests as per API-598:

Post Testing Activities: Valve should be cleaned off the test fluid Any components dismantled for testing should be re-assembled and tightened. Rust preventive should be applied Protection of ends and closing of the openings with end caps to be ensured

Meeting the Challenges of Time & Technology

Inspection Valves

Dimensional Inspection:

Reference: Customer approved drawings ASME B 16.10 ASME B16.5/16.47/16.11/1.20.1 ASME B16.25

Meeting the Challenges of Time & Technology

Inspection Valves

Dimensional Inspection:

To include but not limited to: Identification of Valve Size and Rating of the Valve Verification of all the parts of the assembled valve with respect to BOM/Part list (Completeness) Verification of Name Plates/Tag for Identification / Marking Verification of Material Grade on different parts Any special requirements of material (like NACE compliance) End to end dimension End Connections

Contd.

Meeting the Challenges of Time & Technology

Inspection Valves Dimensional Inspection:

Flanged Ends: OD/Thickness/No. of holes/PCD/ Staggering of Holes with respect to axis of the valve/Flange Facing/Finish RTJ Flanged Ends Socket Welded Ends: Socket dimension (checking by gauge) Bevel Welded Ends: Bevel Edge, Bevel Angle Threaded Ends: Checking of the Threads with GO/NO GO gauges, extent of threading Flow direction marker in case of unidirectional valves Torque to open and close the valve (if required by the specification)

Meeting the Challenges of Time & Technology

Inspection Valves

SAFETY RELIEF VALVES

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Relief Valves are designed to prevent internal fluid pressure from rising above a predetermined maximum pressure in a vessel or a system exposed to emergency or abnormal conditions.

In other words, relief valves provide overpressure protection to a vessel or a system.

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Safety Valve: An automatic pressure relieving device actuated by the static pressure upstream of the valve and characterized by rapid full opening or pop action. It is used for gas or vapor service. In the petroleum industry it is used also for steam and air Relief Valve: An automatic pressure-relieving device actuated by the static pressure upstream of the valve, and which opens in proportion to the increase in pressure above set pressure. It is used primarily for liquid service.

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Safety Relief Valve: An automatic pressure-relieving device suitable for use as either a safety or relief valve. It is used in gas or vapor service or for liquid

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves: Parts

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves: Parts

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves: Types

Conventional Type

The set pressure affected by changes in the superimposed backpressure

Meeting the Challenges of Time & Technology

Inspection Valves Safety Relief Valves: Types

Balanced Type

Incorporates a bellows having effective area equal to that of the valve seat Eliminates the effect of backpressure on the set pressure of the valve, and which effectively prevents the discharging fluid entering the bonnet space Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Governing Standard: ASME Sec-VIII, Div.1 API-526: Flanged Steel Pressure Relief Valves API-527: Seat Tightness of Pressure Relief Valves NOTE: The above description is guide lines only and does not cover IBR and any other manufacturing standard

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves: Materials (Sample)

Base/Bonnet: ASTM A 210 (Cast Iron) ASTM A 216 Gr. WCB, WCC (Cast Steel) ASTM A 217 Gr. WC6, WC9 (Cast Steel) ASTM A 352 Gr. LCB, LCC (Cast Steel-Low Temperature Service) ASTM A 351 Gr. CF8, CF8M, CF3, CF3M (Cast-Austenitic Stainless Steel) ASTM A 182 Gr. 316, 316L (Forged-Austenitic Stainless Steel)

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves: Materials

Nozzle: ASTM A 479 Gr.316, 316L ASTM A 351 Gr. CF8, CF8M, CF3, CF3M (Cast-Austenitic Stainless Steel) ASTM A 182 Gr. 316, 316L (Forged-Austenitic Stainless Steel)

DISC: ASTM A 565 Gr. 616 ASTM A 479 Gr. 316, 316L All the parts are to verified with respect to approved drawing / data sheet

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Applicable Tests: Pressure Test (Base and Bonnet) Set Pressure Test Seat Tightness Test Back Pressure Test (Bellow type valves)

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Test Medium: Hydrostatic Test: Water having a corrosion inhibitor, temperature not exceeding 125 Deg. F. Seat Tightness Test: Air, Steam or Water, the same medium that has been used for determining the set pressure of the valve.

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Pressure Test: Base, Bonnet and Nozzle (Hydrostatic) Nozzle: Primary Side Base and Bonnet: Secondary Side Test Pressure: For set pressure >50PSI: test pressure=0.9Xset pressure For set pressure < 50 PSI: test pressure=5 PSI(34.5 KPa)

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Set Pressure Test: The pressure at the inlet of the valve at which the Valve is expected to discharge at the outlet (based on the data sheet) Cold Differential Set Pressure (CDSP): The pressure at which the valve is to be tested, taking the service temperature into account. Temperature correction factor is to be applied for calculating the CDSP.

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Set Pressure Test: Gas Service

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Set Pressure Test: Liquid Service

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Seat Leakage Test:

90% of set pressure for metallic seat 95% of set pressure for resilient seat

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Back Pressure Test:

Applicable for Balanced Valves (below type) Test Pressure: Super Imposed Back Pressure

Meeting the Challenges of Time & Technology

Inspection Valves

Safety Relief Valves:

Visual & Dimensional Inspection:

Identification of the valve Size & Rating at Inlet and outlet Material of parts of valve Accessories per Data Sheet Name plate marking

Meeting the Challenges of Time & Technology

Inspection Valves

CONTROL VALVES

Meeting the Challenges of Time & Technology

Inspection Valves

Control Valve:

Meeting the Challenges of Time & Technology

Inspection Valves

Control Valve:

Meeting the Challenges of Time & Technology

Inspection Valves

Control Valve:

Meeting the Challenges of Time & Technology

Inspection Valves

Control Valve: Components

Body Bonnet Disc Stem Yoke Actuator Positioner Limit Switches Solenoid Valves Air Filter Regulator Quick Exhaust Valve Volume Boosters

Meeting the Challenges of Time & Technology

Inspection Valves Control Valve:

Flow Coefficient (Cv): No. of US Gallons per minute of 60 Deg. F water that will flow through a valve with one pound per square inch pressure drop.

(A constant, Cv, related to the geometry of a valve, for a given travel, that can be used to establish flow capacity)

Meeting the Challenges of Time & Technology

Inspection Valves Control Valve: Inspection & Tests

Visual Inspection: Verification of, assemblies / components as per drawing Name Plate Accessories, Sr. No. & Make, with respect to data sheet Flow Direction Marker Scale for stroke length Materials, heat No. etc. Fasteners for specific application

Meeting the Challenges of Time & Technology

Inspection Valves

Control Valve: Inspection & Tests

Pressure Test: Shell Test Seat Leakage Test (based on leakage class) Packing Leakage Test Actuator Leakage Test (pneumatic) Pneumatic Test of Tubing Calibration Functional check for Valve Failure Mode

Meeting the Challenges of Time & Technology

Inspection Valves

Control Valve: Calibration

Meeting the Challenges of Time & Technology

Inspection Valves

Control Valve: Calibration

Meeting the Challenges of Time & Technology

Inspection Valves

Control Valve:

Valve Failure Mode: Open Closed Locked in the Last Position

Meeting the Challenges of Time & Technology

Inspection Valves

POSITIVE MATERIAL IDENTIFICATION (PMI)

Meeting the Challenges of Time & Technology

Inspection of Valves Positive Material Identification (PMI):

Intended for identification of:

Pressure-retaining alloy material components, flange bolting, welds, weld overlays and cladding.

It is intended to ensure that the nominal composition of the alloy components and associated welds have been correctly supplied and installed as specified

Meeting the Challenges of Time & Technology

Inspection of Valves Positive Material Identification (PMI):

Meeting the Challenges of Time & Technology

Inspection of Valves Positive Material Identification (PMI):

Programme Covers: Alloy materials Shop and field-fabricated pressure-retaining components (base metal, welds and cladding) Materials used for repair or replacement of pressureretaining components

Meeting the Challenges of Time & Technology

Inspection of Valves Positive Material Identification (PMI):

Coverage in Valves: Body Bonnet/Base Trim Materials Nozzle (Safety Relief Valve)

Meeting the Challenges of Time & Technology

Inspection of Valves Positive Material Identification (PMI):

Equipment:

X-ray Fluorescence type-Unable to detect carbon content Optical Emission Spectrometer-can detect carbon content

Meeting the Challenges of Time & Technology

Inspection of Valves Positive Material Identification (PMI):

Operator Qualification:

Operator should be qualified to operate the PMI test equipment.

Equipment Calibration: Should be done before testing Calibration should be done with standard calibration alloy sample, representative of the base material/weld being tested.

Meeting the Challenges of Time & Technology

Inspection of Valves Positive Material Identification (PMI):

Elements to be verified

Meeting the Challenges of Time & Technology

Inspection of Valves Preparation for shipment:

Marking / Labeling Colour Coding Tagging Packing End Protection

Meeting the Challenges of Time & Technology

Inspection of Valves Preparation for shipment:

Marking & Labeling Meeting the Challenges of Time & Technology

Inspection of Valves Preparation for shipment:

Colour Coding & Flanged End Protection Meeting the Challenges of Time & Technology

Inspection of Valves Preparation for shipment:

Packing under Progress Meeting the Challenges of Time & Technology

Inspection of Valves Preparation for shipment:

Packing under Progress Meeting the Challenges of Time & Technology

Inspection of Valves Preparation for shipment:

Valves Packed Meeting the Challenges of Time & Technology

Inspection of Valves

Review of Final Documentation & Issue of Inspection Release

Meeting the Challenges of Time & Technology

Inspection of Valves

Finally :

VISUAL INSPECTION IS BEST FORM OF INSPECTION

Meeting the Challenges of Time & Technology

Inspection of Valves

Meeting the Challenges of Time & Technology

You might also like

- API 598 Testing Procedure-20130720-032647Document2 pagesAPI 598 Testing Procedure-20130720-032647JOMAGUES100% (1)

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- Inspect ValvesDocument124 pagesInspect ValvesMohd Idris Mohiuddin100% (2)

- Heat Exchanger InspectionDocument11 pagesHeat Exchanger InspectionVivek Bhangale100% (1)

- Sa (Valves and Fittings Exam)Document6 pagesSa (Valves and Fittings Exam)rajaksekar100% (2)

- Heat Exchanger InspectionDocument7 pagesHeat Exchanger InspectionHamid Albashir100% (1)

- PSV TestingDocument26 pagesPSV Testingmanoj thakkar100% (1)

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- 23 Piping InspectorDocument79 pages23 Piping InspectorBukty Siahaan100% (3)

- Inspection Manual For PipingDocument184 pagesInspection Manual For Pipingzula74No ratings yet

- Valve Testing ProcedureDocument9 pagesValve Testing ProcedureFaiz Zainudin83% (6)

- Piping Inspector QuestionsDocument10 pagesPiping Inspector QuestionsRichard Periyanayagam100% (1)

- Pressure Vessel InspectionDocument44 pagesPressure Vessel Inspectionأحمد صبحى100% (4)

- DOW VISUAL INSPECTION Check CHECKLIST PDFDocument2 pagesDOW VISUAL INSPECTION Check CHECKLIST PDFDanny Boysie100% (1)

- Pressure Vessel Inspection PDF FreeDocument44 pagesPressure Vessel Inspection PDF FreemabroukNo ratings yet

- Piping QC Guide (For Saudi Aramco Project)Document11 pagesPiping QC Guide (For Saudi Aramco Project)HengNo ratings yet

- Valves and Valves Inspection & TestingDocument36 pagesValves and Valves Inspection & TestingSathish P Sathish PalanichamyNo ratings yet

- API 570 - Asme B31.3 Q&ADocument29 pagesAPI 570 - Asme B31.3 Q&AShaalan Ali100% (1)

- 07 PPP TTE Heat Exchanger InspectionDocument38 pages07 PPP TTE Heat Exchanger InspectionAlfredo Del Rio Lambis100% (4)

- Inspection and Welding Repairs of Pressure VesselsDocument8 pagesInspection and Welding Repairs of Pressure VesselsAlper Çakıroğlu100% (1)

- Thickness Range For Welder Qualification and Procedure QualificationDocument4 pagesThickness Range For Welder Qualification and Procedure QualificationvirajNo ratings yet

- Pressure Vessel Inspection and DesignDocument48 pagesPressure Vessel Inspection and DesignMohammed Raje100% (2)

- Pressure Vessel InspectionsDocument29 pagesPressure Vessel InspectionsStephanie Webb100% (2)

- 4) Piping Interview QuestionnaireDocument2 pages4) Piping Interview QuestionnaireAjaz Malik33% (3)

- Valve StandardsDocument14 pagesValve StandardskandhasamykarthickNo ratings yet

- Valve Material SpecsDocument112 pagesValve Material Specsjoseph.maquez24No ratings yet

- 13 - Piping Sample ReportDocument5 pages13 - Piping Sample ReportS Surya Dharma100% (3)

- Pipe Inspection & TestingDocument10 pagesPipe Inspection & TestingRobert MichaelrajNo ratings yet

- PQR Asme Ix - CompletedDocument3 pagesPQR Asme Ix - CompletedCarlos Nombela Palacios100% (1)

- Pressure Vessel CertificationDocument4 pagesPressure Vessel CertificationalokbdasNo ratings yet

- Mechanical Interview Rev 1Document86 pagesMechanical Interview Rev 1Syed Mohamed Gani GaniNo ratings yet

- Feild Inspection of Shell and Tube Heat ExchangersDocument4 pagesFeild Inspection of Shell and Tube Heat ExchangersMatthew BennettNo ratings yet

- ASME 2 Related Post Construction Codes and StandardsDocument38 pagesASME 2 Related Post Construction Codes and StandardsInstech Premier Sdn BhdNo ratings yet

- Welding Inspector Interview ReviewDocument5 pagesWelding Inspector Interview ReviewLuttpiNo ratings yet

- Inspection Of: Piping Systems (In-Service) 570Document36 pagesInspection Of: Piping Systems (In-Service) 570g_jeyasankar100% (2)

- Piping Inspection-MTDocument73 pagesPiping Inspection-MTInstech Premier Sdn BhdNo ratings yet

- Heat Exchanger InspectionDocument43 pagesHeat Exchanger Inspectionabdul aziz100% (6)

- Basic Type of ValvesDocument2 pagesBasic Type of ValvesbharathaninNo ratings yet

- Pipe Repair Case StudyDocument15 pagesPipe Repair Case StudyAnyanele Nnamdi Felix100% (1)

- API Inspectors Toolbox EE - User GuideDocument273 pagesAPI Inspectors Toolbox EE - User Guidekirans60100% (3)

- Butterfly Valve Info PDFDocument14 pagesButterfly Valve Info PDFCS100% (1)

- Vessel Pressure TestingDocument3 pagesVessel Pressure Testingalokbdas100% (1)

- Hydro Test Preparation.Document22 pagesHydro Test Preparation.Santosh Kumar BogelaNo ratings yet

- Piping Engineers Interview QuestionsDocument16 pagesPiping Engineers Interview Questionsashish2086100% (2)

- TOP 250+ QC Welding Inspector Interview Questions and Answers 11 February 2021 - QC Welding Inspector Interview Questions - Wisdom Jobs India1Document1 pageTOP 250+ QC Welding Inspector Interview Questions and Answers 11 February 2021 - QC Welding Inspector Interview Questions - Wisdom Jobs India1kokaanilkumarNo ratings yet

- To Commissioning Manual: Appendix No. 1Document7 pagesTo Commissioning Manual: Appendix No. 1Bassem BalghouthiNo ratings yet

- Piping Training CourseDocument446 pagesPiping Training CourseJose Luis Roca CordovaNo ratings yet

- Valves: Training Centre Thursday, August 4, 2016Document77 pagesValves: Training Centre Thursday, August 4, 2016Tolstoy LeoNo ratings yet

- ValveDocument82 pagesValveSumon VargheseNo ratings yet

- Types of Ball Valves (Floating, Trunnion)Document11 pagesTypes of Ball Valves (Floating, Trunnion)swapnil PATILNo ratings yet

- Tank InspectionDocument3 pagesTank InspectionSubbarayan SaravanakumarNo ratings yet

- Inspection of ValvesDocument85 pagesInspection of ValvesChetan kharkarNo ratings yet

- Valves Valve LeakageDocument5 pagesValves Valve Leakagearson5646100% (1)

- Valve InspectionDocument6 pagesValve Inspectionrosid_alhusnaNo ratings yet

- Scope: PurposeDocument6 pagesScope: Purposezahid_497No ratings yet

- Valve Leakage: Home Glossary ResourcesDocument3 pagesValve Leakage: Home Glossary Resourcesarkan1976No ratings yet

- Valve TestingDocument6 pagesValve TestingjobertNo ratings yet

- All About ValvesDocument39 pagesAll About ValvesKarthik Naidu100% (1)

- Dynamic Print Solution: D P E PDocument8 pagesDynamic Print Solution: D P E PAnand KesarkarNo ratings yet

- Breakout Trading Strategies Quick GuideDocument10 pagesBreakout Trading Strategies Quick GuideAnand Kesarkar100% (1)

- The Truth About Fibonacci TradingDocument34 pagesThe Truth About Fibonacci TradingAnand KesarkarNo ratings yet

- Technology Developed by CoirBoard - 0Document16 pagesTechnology Developed by CoirBoard - 0Anand KesarkarNo ratings yet

- 21 CandlesticksDocument65 pages21 CandlesticksDxtr V Drn100% (1)

- Unit 8 - Week 7: Assignment 07Document3 pagesUnit 8 - Week 7: Assignment 07Anand KesarkarNo ratings yet

- Corona Kavach Policy-Oriental Insurance - Rate ChartDocument3 pagesCorona Kavach Policy-Oriental Insurance - Rate ChartAnand KesarkarNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- Change Address Contact Details Email IdDocument1 pageChange Address Contact Details Email IdAnand KesarkarNo ratings yet

- The Complete Guide To Trading PDFDocument116 pagesThe Complete Guide To Trading PDFvkverma352No ratings yet

- The Truth About Fibonacci TradingDocument34 pagesThe Truth About Fibonacci TradingAnand KesarkarNo ratings yet

- Manufacturing Processes UNIT Test-I - Series A With SolutionsDocument1 pageManufacturing Processes UNIT Test-I - Series A With SolutionsAnand KesarkarNo ratings yet

- Name Contact No. Location DOB Age SR No. Employee CodeDocument5 pagesName Contact No. Location DOB Age SR No. Employee CodeAnand KesarkarNo ratings yet

- A270Document6 pagesA270Anonymous O39pjWNo ratings yet

- Astm A70Document1 pageAstm A70Anand KesarkarNo ratings yet

- Let's Discuss Your Next Project.: Contact USDocument8 pagesLet's Discuss Your Next Project.: Contact USAnand KesarkarNo ratings yet

- Cap 3 Dse CutoffDocument614 pagesCap 3 Dse CutoffAnand KesarkarNo ratings yet

- Symbol of Weld PDFDocument28 pagesSymbol of Weld PDFSyarif IrwantoNo ratings yet

- 1.4 BG00381946 - ADocument1 page1.4 BG00381946 - AAnand KesarkarNo ratings yet

- M CR 601r1Document14 pagesM CR 601r1nazari123No ratings yet

- Dss 2205 Wps PQR WPQDocument8 pagesDss 2205 Wps PQR WPQAnand KesarkarNo ratings yet

- Pressure Testing (Hydrostatic Pneumatic) Safety GuidelinesDocument7 pagesPressure Testing (Hydrostatic Pneumatic) Safety GuidelinesSuleyman HaliciogluNo ratings yet

- MSRTC - Online Reservation SystemDocument1 pageMSRTC - Online Reservation SystemAnand KesarkarNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Cr10830005 - 3 Heat Exchanger 01Document1 pageCr10830005 - 3 Heat Exchanger 01Anand KesarkarNo ratings yet

- Appendix F - ESS 2.21 Hydrostatic Testing Procedures For Facilities - A4L3D7Document17 pagesAppendix F - ESS 2.21 Hydrostatic Testing Procedures For Facilities - A4L3D7prakash07343No ratings yet

- Symbol of Weld PDFDocument28 pagesSymbol of Weld PDFSyarif IrwantoNo ratings yet

- Symbol of Weld PDFDocument28 pagesSymbol of Weld PDFSyarif IrwantoNo ratings yet

- WPQ Is 2062 Haresh Shah W1Document1 pageWPQ Is 2062 Haresh Shah W1Anand KesarkarNo ratings yet

- Process Flow Chart - Heat ExchangerDocument7 pagesProcess Flow Chart - Heat ExchangerAnand KesarkarNo ratings yet

- Renishaw CMM Technology GuideDocument330 pagesRenishaw CMM Technology GuideGabi OnofreiNo ratings yet

- Engineered Packaging Center A Global ProviderDocument6 pagesEngineered Packaging Center A Global ProviderLTE002No ratings yet

- SailDocument52 pagesSailcitunairNo ratings yet

- Ime34070m 2 Far FR2835SDocument80 pagesIme34070m 2 Far FR2835Ssrinu1984No ratings yet

- Beam DesignDocument5 pagesBeam DesignAnonymous HJ7hmihh100% (1)

- Experiment 1 - Data SheetDocument4 pagesExperiment 1 - Data SheetApple PinpinNo ratings yet

- Project Proposal (Urban Gardening)Document2 pagesProject Proposal (Urban Gardening)Geanne Antoinette BasilioNo ratings yet

- Air Conditioning SystemsDocument14 pagesAir Conditioning Systemsarslan KhanNo ratings yet

- Triple Star Fire Catalogue Price List v2.5Document16 pagesTriple Star Fire Catalogue Price List v2.5pastorgeeNo ratings yet

- NUST Journal of Engineering Science (NJES) PDFDocument97 pagesNUST Journal of Engineering Science (NJES) PDFjasim aliNo ratings yet

- PlumbingDocument62 pagesPlumbingAnonymous iTzCnMNo ratings yet

- Building Composite TubesDocument3 pagesBuilding Composite TubesArmando Alvarado AraujoNo ratings yet

- Rotary Force Exciter Cell VZDocument4 pagesRotary Force Exciter Cell VZEduardo MendozaNo ratings yet

- Ebarra Pump SpecsDocument13 pagesEbarra Pump SpecsLiz BargolaNo ratings yet

- 5R110W Assembly PDFDocument16 pages5R110W Assembly PDFLuis VelazquezNo ratings yet

- DLL - Science 5 - Q1 - W5Document9 pagesDLL - Science 5 - Q1 - W5HEVER TORRESNo ratings yet

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Document2 pagesWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200kashyap_structuralNo ratings yet

- L-05 Critical Activities Anp-2Document11 pagesL-05 Critical Activities Anp-2SamNo ratings yet

- MUlecular Distilation UnitDocument6 pagesMUlecular Distilation UnitElly SufriadiNo ratings yet

- 10) Itp - Tank Fabrication PDFDocument6 pages10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- VD4 11ka Manual PDFDocument42 pagesVD4 11ka Manual PDFhonghoaso1100% (1)

- Aluminum Design Manual-24Document1 pageAluminum Design Manual-24Mohammed AyeshNo ratings yet

- Midea - Rooftop Package - 5-30 Ton - Creator - 20200928 - V1-b2cfdDocument18 pagesMidea - Rooftop Package - 5-30 Ton - Creator - 20200928 - V1-b2cfdsamorayNo ratings yet

- Paper On Curing Methods of GPCDocument17 pagesPaper On Curing Methods of GPCKUMAR RAJUNo ratings yet

- Homework - Equilibrium of ParticlesDocument15 pagesHomework - Equilibrium of ParticlesSivaprasad DusiNo ratings yet

- Oily Water Separator Safety DevicesDocument15 pagesOily Water Separator Safety DevicesMohammad Jahid Alam100% (6)

- GBDocument2 pagesGBRolando SoledadNo ratings yet

- Sonalika Training ReportDocument64 pagesSonalika Training Report3drohit100% (4)

- C1161 - 08 Flexural CeramicDocument16 pagesC1161 - 08 Flexural CeramicRedV1rusNo ratings yet

- Catalogo Fire 2009Document7 pagesCatalogo Fire 2009Benicio Joaquín Ferrero BrebesNo ratings yet