Professional Documents

Culture Documents

9 - Primary DeNOx Measures in Large Pulverized Coal and Lignite Units Practical Solutions For Existing Uni

Uploaded by

Stefanos GabalacOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9 - Primary DeNOx Measures in Large Pulverized Coal and Lignite Units Practical Solutions For Existing Uni

Uploaded by

Stefanos GabalacCopyright:

Available Formats

International CAFENOx Symposium

Primary DeNOx Measures in Large Pulverized Coal and Lignite Units Practical Solutions for Existing Units

Jacques BLONDIN

Tel : +33 3 21 72 8432 Fax : +33 3 21 72 8351 jacques.blondin@snet-electricite.fr

FP5 CAFENOx project - NNE5-2001-830 2003 mid 2005

June 23 & 24th, 2005

International Symposium June 23rd 24th, 2005

1

International CAFENOx Symposium

INTRODUCTION

Main objectives of the CERCHAR study Large SNET coal fired units

NOx emission reduction strategy Financial impact of 900650500 mg/Nm3 primary NOx emission reduction

Primary DeNOx measure experiments

3MW CERCHAR furnace 2 x 600 MWe pulverized coal fired SNET units

Practical approach for existing units

June 23 & 24th, 2005 2

International CAFENOx Symposium

Main objectives of the CERCHAR study

From semi-industrial tests (3 MWth furnace pilot facility) and industrial tests (1500 MWth commercial units) : A wide range of simple and cheap primary DeNOx measures were carried out with a collection of continuous data (up to 200 measurements/analysis 5 min refreshment Implog software Excel files) during long periods of time in different configurations Combustion and NOx models were developed thanks to accurate and various data collection

Economical measures were selected for reducing NOx emission in 2 x 600 MWe units having their own specificities clearly identified, confirmed and explained to the operators

June 23 & 24th, 2005 3

International CAFENOx Symposium

Large SNET coal fired units NOx emission reduction strategy

2 x 600 MWe coal fired F units once through Alstom boiler Provence unit 5 at Meyreuil E. Huchet unit 6 at Carling (Lorraine) Concerned by Directive 2001/80 as far as these 2 units will be operated after 2015 and dont yet fulfill NOx emission limit values DeNOx technique implementation became compulsory 2 x Alstom-Lurgi CFBC units : Concerned by Directive 2001/80 but 125 MWe SODELIF unit 4 at Carling already fulfill NOx emission limit values 250 MWe SOPROLIF unit 4 at Meyreuil Nothing to be done regarding NOx emission in flue gas (EDF main shareholder) 1 x 343 MWe coal + gas combined cycle at Decision taken on June 30th 2004 to stop Carling these units 20000 h after January 1st 2008 E. Huchet unit 5 Nothing to be done regarding NOx emission in flue gas 2 x 250 MWe coal fired units Hornaing unit 3 at Hornaing (North) Lucy unit 3 at Montceau les Mines

4

June 23 & 24th, 2005

International CAFENOx Symposium

Financial impact of primary NOx emission reduction for SNET 600MWe units

Taxes and penalties linear to NOx emitted Primary DeNOx technique implementation implies : pay off in 7 years a long period of shunt down for modifications no clear interest as far as SCR is compulsory after 2015 technical risks for the boiler Temporary measures (< 200 h/yr) linear to effective application (the shorter, the cheaper) clearly correlated to coal selection 900 650 mg/Nm NOx at 900 500 mg/Nm NOx at 6% O2 6% O2 0.20 0.27 M/yr 0.15 0.21 M/yr about 0.7 0.9 M/yr about 1.1 1.3 M/yr

3 3

0.1 M/yr to 1 M/yr maximum for max 200 h/yr but the costs may be dissuasive for a continuous application (3000 h/yr)

impossible without primary DeNOx technique implementation

Based on that analysis, SNET decided at the end of 2001 to invest (2 x 25-30 M) in SCR equipments for its 2 x 600 MWe units

June 23 & 24th, 2005 5

International CAFENOx Symposium

Primary DeNOx measure experiments 3MW CERCHAR furnace

June 23 & 24th, 2005

International CAFENOx Symposium

3MW CERCHAR flame furnace ATC coal Low NOx combustion test

low NOx = 500 ppm C N VM ash distance from the burner

ATC coal 72.62 1.63 25.7 13.4 0

char 1 72.95 1.45 12.3 21.35 100

char 2 72.21 1.34 3.02 24.88 300

char 3 56.1 0.39 5.61 42.09 500

char 4 34.08 0.4 4.89 64.9 1000

fly ash 7.42 0.41 5.3 91.98 > 7000

June 23 & 24th, 2005

International CAFENOx Symposium

3MW CERCHAR flame furnace ATC coal High NOx combustion test

High NOx = 1000 ppm C N VM ash distance from the burner

ATC coal 72.62 1.63 25.7 13.4 0

char 1 55.9 0.63 5.89 42.51 100

char 2 54.62 0.48 3.75 44.02 300

char 3 62.36 0.54 2.72 45.03 500

char 4 18.12 0.22 78.66 1000

fly ash 5.96 0.15 3.55 92.19 > 7000

June 23 & 24th, 2005

International CAFENOx Symposium

3MW CERCHAR flame furnace N combustion in ATC coal

C & N - coal combustion

100 90

ignition in reducing Char 1 at conditions 1380C at 1380C Low NOx ignition in Char 1 at oxidizing 1570C conditions atHigh 1570C NOx

residual N in char (%)

80 70 60 50 40 30 20 10 0 20 40

% residual N low NOx % residual N high NOx

end of volatile matters combustion

60

80

100

C coal burn out (%)

June 23 & 24th, 2005

International CAFENOx Symposium

3MW CERCHAR flame furnace N combustion in ATC coal

N behaviour along ATC coal combustion process

1600 1550

oxidizing ignition zone CO = 900 ppm O2 = 7.5 % reducing ignition zone CO = 55000 ppm O2 = 0.5 %

TC of the flame

1500 1450 1400 1350 1300 30 40 50

TC - low NOx TC - high NOx

final 1000 ppm NO in flue gas final 500 ppm NO in flue gas

60

70

80

90

100

percent of burnt N from coal

June 23 & 24th, 2005

10

International CAFENOx Symposium

Synthesis of 3 MW CERCHAR combustion tests Char, temperatures and gas composition measurements possible along a 5 m in length flame having different NOx emission configurations available for other experiments (e.g. O2 enriched flame) Selection/classification of low NOx coals and fuel blends, when no information available at industrial scale Data collection available for modeling Training of thermal plant operators and probe/analyser testing

June 23 & 24th, 2005 11

International CAFENOx Symposium

2 SNET 600 MWe pulverized units

June 23 & 24th, 2005

12

International CAFENOx Symposium

Comparison of the 2 SNET 600 MWe units

Provence 5 designed for Gardanne lignite 7 mills A to G furnace section 19.9 x 19.9 m2 now fed with imported coal 4/3 mills in use for PC max/mid OFA possibilities by switching off the upper burners SCR to be implemented between ECO and Air Reheater (too cold zone) SCR designed for 1000 mg/Nm3 at 6% O2 NOx inlet CEH 6 designed for Freyming hard coal 6 mills 61 to 66 furnace section16.6 x 16.6 m2 now fed with a mixture of imported coal + ashy colliery residues 5/4 mills in use for PC max/mid lack of flexibility for OFA SCR to be implemented between ECO2 and ECO1 (too hot zone) SCR designed for 800 mg/Nm3 at 6% O2 NOx inlet

June 23 & 24th, 2005

13

International CAFENOx Symposium

Design of tangential burners

Provence unit 5

ABCE configuration

Air II-1

Huchet unit 6

62-63-64-65 configuration

Air II-2

coal burner + air I

oil fuel burner

June 23 & 24th, 2005

14

International CAFENOx Symposium

Critical limits Provence unit 5

1000

Provence 5 - NOx versus reheated steam temperatures as a function of fuel ratio of differents coals 1.47

TC must be > 525C at MP turbine inlet possible compromise

NOx mg/Nm3 - 6% O2

900 800 700 600 500

2.27 1.5 2.1 1.8 1.46 1.42

"Low NOx" coal selected 400 480 490 500 510 520 530 540 550

threshold

TC reheated steam

OFA through BOOS induced a dramatic decrease of reheated steam temperatures and a subsequent reduction of global efficiency

June 23 & 24th, 2005 15

International CAFENOx Symposium

Critical limits Huchet unit 6

CEH 6 - Low NOx possibilities

NOx mg/Nm3 - 6% O2

900 850 800 750 700 650 600 550 500 1.6

goal for optimizing SCR 1.82 2.16 goal

but 4 mills + OFA

1.8 2 2.2 2.4

Fuel ratio

OFA through BOOS was only possible with 4 mills in service when pure imported coal was burnt instead of cheaper blends of coals with old ashy colliery residues

June 23 & 24th, 2005 16

International CAFENOx Symposium

Synthesis of combustion tests carried out on the 2 SNET 600 MWe PF units

Primary DeNOx measures based on OFA through BOOS allowed an emission reduction from about 800-1100 to an absolute minimum 600 mg/Nm3 NOx at 6% O2 without any investments, but with determinal impact on operating costs NOx emission reduction possible at full load, but very poor at middle load Selection of low NOx coals would rather be made through industrial scale tests carried out on the concerned units than based on index such fuel ratio or N content Temporary reduction methods of NOx emission were defined for both units : they are available for local Authority requirements before SCR commissioning date in 2007-2008 At Huchet unit 6, SCR will have to be completed with moderate but continuous primary DeNOx measures (target : 700 800 mg/Nm3 at 6% O2)

June 23 & 24th, 2005

17

International CAFENOx Symposium

Practical approach for existing units

Return of experience

normal NOx emission hard coals lignites 800 - 1200 400 - 600 with primary low NOx measures 500 - 700 250 - 350 with SCR < 200 < 200

Fractional conversion of char-N into NO and N2O at total char burnout (de Soete)

Char from Low and high volatiles bituminous coals Lignite FNO (range) 0.35 0.67 0.084 FN2O (range) 0.013 - 0.057 0.006 0.012

SCR more or less compulsory after 2015

June 23 & 24th, 2005 18

International CAFENOx Symposium

Mechanisms of SCR catalyst deterioration Thermal reaction : rapid and irreversible deterioration when temperatures > 450C, even locally and on a quite short period of operating time Mechanical plugging up : by ultra-fine and coarse particles > 1/3 honeycomb pitch (6.4 9.2 mm for coal from Cormetech) Chemical plugging up including :

Ammonia-sulfur compounds, especially when temperatures < 320C Alkaline metals from fuel (e.g. As) Non metals, such Ca, P

June 23 & 24th, 2005 19

International CAFENOx Symposium

Data collection of measurements in a view of SCR equipment implementation

Measurements and analysis in various configurations having an impact on Coal, fuel oil and secondary fuels characteristics, including Duration life of SCR catalyst (poisons) trace-elements Limestone or lime injection when primary DeSO2 is Duration life of SCR catalyst (poisons) implemented Flue gas characteristics (average and extreme values) at the SCR catalyst design, dimension and location point of SCR implementation Detailed mapping: implementation flow rate (dry and wet), local velocity Probes, instrumentation, control temperatures regulation NOx, SO2, O2, CO2, CO Geometric design of the unit SCR casing implementation including a possible hopper to trap coarse particles By-pass of SCR Maintenance of NH3 injection Fly ash at the point of SCR implementation : Dimension of catalyst channel flow rate, including peaks during soot blowing section size dimension distribution popcorn Risk of catalyst channels or cells chemistry and mineralogy slagging detection plugging up Additional hopper to trap coarse particles

June 23 & 24th, 2005 20

International CAFENOx Symposium

Consequences of SCR equipment implementation

Modification induced by having an incidence on SCR implementation Pressure drop : Pressure profile of downstream flue gas pass-by normal Mechanical strength resistance of flue gas duct, ESP accidental (plugging up) Fan design and dimension Safety equipments Reinforcement of structures Decrease of global efficiency due to the rise of auxiliary consumption Leakage of NH3 in fly ash Fly ash quality, market, smelliness Additional cost of disposal SO3 in flue gas Risk of acidic corrosion of metallic components Atmospheric SO3 release in flue gas Acidic attack of concrete chimney (in case of DeSO2 wet scrubber without final flue gas reheater) Weight and dimension Whole installation stability Maintenance design especially when SCR catalyst modules should be changed

June 23 & 24th, 2005 21

International CAFENOx Symposium

Practical approach for existing units

higher NOx at SCR inlet NOx at SCR inlet (mg/Nm3 at 6% O2) initial percent of SCR abatement SCR Catalyst operating NH3 slip potential hours ppm K/Ko initial NOx at SCR outlet (mg/Nm3 at 6% O2) normal design lower NOx at SCR inlet

1 000

800

600

90

90

90

Primary DeNOx measures may reduce SCR costs by postponing SCR catalyst module replacements

June 23 & 24th, 2005

5 000 10 000 15 000 20 000 25 000 30 000 35 000

0.29 0.57 0.86 1.14 1.43 1.71 2.00

1.00 0.95 0.90 0.85 0.80 0.75 0.70 0.65

100 105 111 118 125 133 143 154

80 84 89 94 100 107 114 123

60 63 67 71 75 80 86 92

reinvestment of a catalyst module

22

International CAFENOx Symposium

Primary DENOx measure application possibilities

Small PF units (50 < P < 500 MWth) may fulfill 600 mg/Nm3 at 6% O2 without any problems and at moderate costs thanks to existing primary DeNOx techniques Large pulverized lignite fired units (P > 500 MWth) should fulfill 200 mg/Nm3 at 6% O2 in due time (before 2015) thanks to further technical enhancements of primary DeNOx measures Think about NOx emission expression (mg/Nm3 at 6% O2 mg/MWh at 6% O2) Large pulverized coal fired units (P > 500 MWth) should need SCR, but SCR operating costs may be reduced Think about end of life of unit without any SCR catalyst module replacement thanks to primary DeNOx measures

June 23 & 24th, 2005 23

International CAFENOx Symposium

Thanks for your attention

The final report of the CAFENOx project will be available before the end of 2005 after its approval by the Commission

June 23 & 24th, 2005 24

You might also like

- The Royal Marines Tennis ModuleDocument39 pagesThe Royal Marines Tennis ModuleSteve Russel Regua100% (2)

- Radial Stockpile CalculationDocument1 pageRadial Stockpile CalculationSai KrishNo ratings yet

- Heat Requirement Calculations For ReepDocument8 pagesHeat Requirement Calculations For ReeplkchoudhuryNo ratings yet

- Conversion Table and WeavingDocument4 pagesConversion Table and WeavingAbu AlaynaNo ratings yet

- Furnace EfficiencyDocument1 pageFurnace EfficiencySteve WanNo ratings yet

- Insulation HandbookDocument8 pagesInsulation HandbookSanket PujariNo ratings yet

- Nox Impacts On Environment and Human HealthDocument5 pagesNox Impacts On Environment and Human HealthnaikNo ratings yet

- Raw Mix Empat Komponen PerhitunganDocument7 pagesRaw Mix Empat Komponen Perhitunganarmadi harisNo ratings yet

- The Shot-Firers Guide 1000195986Document258 pagesThe Shot-Firers Guide 1000195986waynefishingaustinNo ratings yet

- CSA z32 Section 51Document8 pagesCSA z32 Section 51Matt ThomasNo ratings yet

- WIS 5 Qu paper MSR-WI-1Document8 pagesWIS 5 Qu paper MSR-WI-1Shankar Gurusamy100% (1)

- Clinker Cooler Queching Best PracticeDocument1 pageClinker Cooler Queching Best PracticeShukor AzNo ratings yet

- Study of The Grinding Balls Distribution Inside The MillDocument2 pagesStudy of The Grinding Balls Distribution Inside The Millsempatik721No ratings yet

- Air PropertyDocument1 pageAir Propertykunju1234No ratings yet

- 320k VLCC Spec Rev 5 No SignatureDocument333 pages320k VLCC Spec Rev 5 No SignatureStefanos Gabalac100% (2)

- ORJIP Bird Collision Avoidance Study April-2018Document248 pagesORJIP Bird Collision Avoidance Study April-2018Lorry69No ratings yet

- LAMPIRAN B: PERHITUNGAN NERACA MASSADocument18 pagesLAMPIRAN B: PERHITUNGAN NERACA MASSASatria Muliya PutraNo ratings yet

- 645e3 Turbocharged Engine Maintenance Manual Emd645-TitleDocument6 pages645e3 Turbocharged Engine Maintenance Manual Emd645-TitleJorge Yuro100% (1)

- Points Temperature © Temperature K Pressure (Mbar) Desired Density (Kg/m3)Document2 pagesPoints Temperature © Temperature K Pressure (Mbar) Desired Density (Kg/m3)hmaza shakeelNo ratings yet

- Small Wind Energy Systems 110702042021 Small Wind GuideDocument25 pagesSmall Wind Energy Systems 110702042021 Small Wind GuideAsad IqbalNo ratings yet

- Pyro Heat Balance 8000TPD @23.03.2023Document2 pagesPyro Heat Balance 8000TPD @23.03.2023harikrushnaNo ratings yet

- Scrcostmanualchapter7thedition 2016revisions2017Document107 pagesScrcostmanualchapter7thedition 2016revisions2017Dave KevinNo ratings yet

- Introduction To Aspen Plus-2012Document243 pagesIntroduction To Aspen Plus-2012Virgilio2009100% (1)

- NOx Reduction TA Study v1 - December2005Document70 pagesNOx Reduction TA Study v1 - December2005Dilnesa Ejigu100% (1)

- Thermal design of a 2-effect forward-feed evaporatorDocument4 pagesThermal design of a 2-effect forward-feed evaporatorAristya KurniawanNo ratings yet

- Specific Stoichiometric - Combustion Air CalculationDocument2 pagesSpecific Stoichiometric - Combustion Air CalculationVijay BhanNo ratings yet

- CCPP Cycling PDFDocument20 pagesCCPP Cycling PDFStefanos GabalacNo ratings yet

- CalculationDocument19 pagesCalculationJunhao XiaNo ratings yet

- AWE Kiln Gas DensityDocument2 pagesAWE Kiln Gas DensityNadia AbesNo ratings yet

- Hot AirDocument6 pagesHot AirElancheran RengaNo ratings yet

- CV Calculation for Talcher CoalDocument2 pagesCV Calculation for Talcher CoalirfanNo ratings yet

- Major Accidents On ShipsDocument61 pagesMajor Accidents On ShipsGonçalo Cruzeiro100% (1)

- IncinerationDocument11 pagesIncinerationPhyu Mar Thein KyawNo ratings yet

- Coal Feeder-03 Calibration 04 Feb2020Document20 pagesCoal Feeder-03 Calibration 04 Feb2020Muhummad Tanzeel RanaNo ratings yet

- 1X 66 Mwkohinoor Power Pvt. Ltd. CNT 5110122 Stack Height SizingDocument4 pages1X 66 Mwkohinoor Power Pvt. Ltd. CNT 5110122 Stack Height SizingPriyanathan ThayalanNo ratings yet

- Fuel Energy Equivalents ChartDocument1 pageFuel Energy Equivalents Chartruhul010% (1)

- WE 12742 Grasim Rawan Table: Mixing Calculation Mixture With Coal B As FuelDocument1 pageWE 12742 Grasim Rawan Table: Mixing Calculation Mixture With Coal B As FuelKenny RuizNo ratings yet

- Solid Fuel PreperationDocument1 pageSolid Fuel PreperationvvijaybhanNo ratings yet

- S by C and S by G Calculation Energy Calculation in Gcals Feed To Reformer / DayDocument2 pagesS by C and S by G Calculation Energy Calculation in Gcals Feed To Reformer / DaynavNo ratings yet

- Identification Data: Description Fan - 1 Fan - 2 Fan - 3 Fan - 4 CommentsDocument13 pagesIdentification Data: Description Fan - 1 Fan - 2 Fan - 3 Fan - 4 CommentsAngel CarvajalNo ratings yet

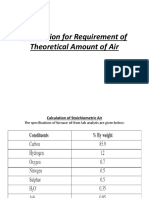

- Calculation For Requirement of Theoretical Amount of AirDocument13 pagesCalculation For Requirement of Theoretical Amount of AirDivya Bharathi RavuriNo ratings yet

- Calculation of Max. Ball Size: Plant: Mill Nr. Mill SizeDocument1 pageCalculation of Max. Ball Size: Plant: Mill Nr. Mill SizeAbul QasimNo ratings yet

- What Are The Factors Affecting The Number of Cyclone Stages in Preheater Kiln System?Document4 pagesWhat Are The Factors Affecting The Number of Cyclone Stages in Preheater Kiln System?hmaza shakeelNo ratings yet

- Combustion CalcsDocument8 pagesCombustion CalcsZhaqir HusseinNo ratings yet

- Merged Heat BalanceDocument56 pagesMerged Heat Balancehmaza shakeel100% (2)

- Volume CalculationDocument6 pagesVolume CalculationAnup DoluiNo ratings yet

- Combustion CalculationDocument2 pagesCombustion CalculationRamachandran VenkateshNo ratings yet

- Lampiran 2 Perhitungan Neraca PanasDocument19 pagesLampiran 2 Perhitungan Neraca PanasWali YudinNo ratings yet

- Coal Drying (Dry Basis)Document9 pagesCoal Drying (Dry Basis)billyNo ratings yet

- Upl HBDSDocument32 pagesUpl HBDSSuparna BhoseNo ratings yet

- Denox DesoxDocument20 pagesDenox DesoxArzu AkarNo ratings yet

- Lower and Higher Heating ValuesDocument1 pageLower and Higher Heating ValuesPierangelo CarozzaNo ratings yet

- Heat BalenceDocument544 pagesHeat BalenceSantanu PachhalNo ratings yet

- Evaluasi % Moisture Terhadap GHV & Harga: Serbuk GergajiDocument6 pagesEvaluasi % Moisture Terhadap GHV & Harga: Serbuk GergajiTIRIANTONo ratings yet

- Heat Calculation by SGDocument42 pagesHeat Calculation by SGaaa100% (1)

- Triplex BoilerDocument53 pagesTriplex Boilershahroze mustafaNo ratings yet

- CID FanDocument2 pagesCID FanIrfan AhmedNo ratings yet

- Raw Mix Oxide Calculation: Coke Need For 100 KG Clinker LS Need For 100 KG Clinker LOI Clay Need For 100 KG ClinkerDocument2 pagesRaw Mix Oxide Calculation: Coke Need For 100 KG Clinker LS Need For 100 KG Clinker LOI Clay Need For 100 KG ClinkerMahla Raj KumarNo ratings yet

- Brayton Cycle (Cold Air Standard) : Equations Used: RT V P T P Ss CLN RLN T P T P V T P VDocument6 pagesBrayton Cycle (Cold Air Standard) : Equations Used: RT V P T P Ss CLN RLN T P T P V T P VCarlaGuzmánNo ratings yet

- Coal CV 6000Document2 pagesCoal CV 6000AnGahBasHaNo ratings yet

- FAD and NTP Calculations for Air FlowDocument1 pageFAD and NTP Calculations for Air FlowDurjoy ChakrabortyNo ratings yet

- Cooler-2 DiagramDocument3 pagesCooler-2 DiagramPraveen Singh Chouhan100% (1)

- Cast Astimaton For Local CoalDocument1 pageCast Astimaton For Local Coalirfan100% (1)

- Balance Model Low Alumina NDocument2 pagesBalance Model Low Alumina NngrajanbdvtNo ratings yet

- Understanding LEL, UEL and PPMDocument8 pagesUnderstanding LEL, UEL and PPMSherwin Delfin CincoNo ratings yet

- Tromp Curve v2Document4 pagesTromp Curve v2safwat hassanNo ratings yet

- Specific Heat CPDocument2 pagesSpecific Heat CPPrabhakar Reddy PeramNo ratings yet

- Williams Mill Diagnostic and DesignDocument12 pagesWilliams Mill Diagnostic and DesignIrshad HussainNo ratings yet

- Pre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)Document3 pagesPre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)saji kumarNo ratings yet

- Simulation An OptimizationDocument28 pagesSimulation An Optimizationalmoanna97100% (1)

- Performance Driven Maintenance Feb 52013Document25 pagesPerformance Driven Maintenance Feb 52013recaiNo ratings yet

- 4 - Oxygen-Enrichment For NOx Control in Pulverised Coal-Fired Boilers - PresentationDocument15 pages4 - Oxygen-Enrichment For NOx Control in Pulverised Coal-Fired Boilers - PresentationStefanos GabalacNo ratings yet

- 2 - Application of NOx Emissions Control Technologies To Achieve NOx Emission Less Than 200 MgNm3 On CoalDocument15 pages2 - Application of NOx Emissions Control Technologies To Achieve NOx Emission Less Than 200 MgNm3 On CoalStefanos GabalacNo ratings yet

- Coal Pyrolysis (Gavalas)Document175 pagesCoal Pyrolysis (Gavalas)Stefanos GabalacNo ratings yet

- Cornemuse Apartments Features Stunning ViewsDocument13 pagesCornemuse Apartments Features Stunning ViewsPrabartak DasNo ratings yet

- Essay SEGDocument9 pagesEssay SEGEM Rifqi Wilda PradanaNo ratings yet

- 1 Site ViewDocument1 page1 Site Viewapi-302117883No ratings yet

- Secoroc Underground Rock DrillsDocument4 pagesSecoroc Underground Rock DrillsRodrigo Cortés Castillo100% (1)

- PV SystemDocument10 pagesPV SystemVictor ImehNo ratings yet

- Increase Performance and Flexibility with GT26 MXL2 UpgradeDocument4 pagesIncrease Performance and Flexibility with GT26 MXL2 UpgradeMai DangNo ratings yet

- Research PaperDocument9 pagesResearch PapercroprobosNo ratings yet

- Coal Combustion Theory - Electrical4uDocument11 pagesCoal Combustion Theory - Electrical4uAarthi JayakumarNo ratings yet

- GSR 2020 - Full Report PDFDocument367 pagesGSR 2020 - Full Report PDFd_macuraNo ratings yet

- Does Renewable Electricity Supply Match With Energy Demand 1-S2.0-S0306261921014914-MainDocument20 pagesDoes Renewable Electricity Supply Match With Energy Demand 1-S2.0-S0306261921014914-MainCarlos PintoNo ratings yet

- Tellerette InformationDocument1 pageTellerette InformationAdriana HernandezNo ratings yet

- Solar Bankers White PaperDocument40 pagesSolar Bankers White PaperCarlo MaraglianoNo ratings yet

- SHR22500 Liquid Ring Pump Datasheet - SHR22500895Document2 pagesSHR22500 Liquid Ring Pump Datasheet - SHR22500895Ranjit RjtNo ratings yet

- Problem-Solution Essay OutlineDocument2 pagesProblem-Solution Essay OutlineThrowaway TwoNo ratings yet

- Enhanced Electricity Generation by Using Algae Biomass and Activated Sludge in PDFDocument4 pagesEnhanced Electricity Generation by Using Algae Biomass and Activated Sludge in PDFAlex Julio Quincho RojasNo ratings yet

- NSHP Forms 1Document3 pagesNSHP Forms 1sandyolkowskiNo ratings yet

- ComAp Protection Relay - Solar RelayDocument20 pagesComAp Protection Relay - Solar RelayProtection RelaysNo ratings yet

- Parts YamahaDocument63 pagesParts YamahahuguslourNo ratings yet

- RPT 1810 DominionEnergyProfile-FNEMBDocument40 pagesRPT 1810 DominionEnergyProfile-FNEMBLowell FeldNo ratings yet

- The X Jet BookDocument4 pagesThe X Jet Bookmarkrobertza0% (1)

- Compair Pokretni KatalogDocument14 pagesCompair Pokretni Katalogjelcam106No ratings yet

- Power Qualty ConditionersDocument20 pagesPower Qualty ConditionersRavinder RangaNo ratings yet