Professional Documents

Culture Documents

Trends in Aerospace Engineering

Uploaded by

Rodriguez ArthursCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trends in Aerospace Engineering

Uploaded by

Rodriguez ArthursCopyright:

Available Formats

Trends in Aerospace Engineering

12 December 2007

Stork Fokker AESP B.V.

DCED symposium

Contents

Introduction

The requirements for new aircraft Looking back: the historical challenges and the recent achievements

of Aerospace Engineering

The changes in the supply base of new Aircraft programs

The new challenges for Engineering and Design

Conclusions

2 Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

Ours vs Competition: "DESIGN EFFICIENCY"

Performance

Range M 0.8 VMO - 3% + 9%

Flexibility

Climb = MLW/MTOW +15% Short Field =

Comfort Cabin Vol. - 10% Headroom = Width + 5% Noise - 4dB SIL

Cost Drivers MTOW & Fuel - 25% MZFW - 25% Eng. Thrust - 45%

3 Trends in Aerospace Engineering

The challenge in Aircraft Engineering: Integrate disciplines

Stork Fokker AESP B.V.

DCED symposium

Old challenge: Integration of disciplines

The challenge of Aircraft

design has always been to achieve multi-diciplinary optimization New regulatory requirements resulted in additional disciplines In the past 10 years Design for Manufacturing with 3D tools has achieved tremendous improvements

5 Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

Challenge: Apply new materials Properties of Aerospace Carbon Fibers

1000 900

G40-800 IM7 T-700SC AS4 T-1000GB

Fiber

G30-500 12K G30-700 12K G40-800 24K T-300 6K T-400 HB 6K T-700 SC 12K T-800 HB 12K T-1000 GB 12K M46J 6K M55J 6K T300 12K T650/35 12K T40/800 12K AS-4 12K M55J IM7 12K

Tensile KSI

580 710 810 512 640 710 795 925 610 540 560 625 800 625 800

Modulus MSI

34 35 40 33 36 33 40 42 63 78 32 35 40 33 40

Tensile Strength, KSI

800 700 600 500 400 300 200 0 10

T-800HB T40/800

G30-700

T-300

T-400HB T650/35 G30-500 T-300

M46J

Toho Toray Hexcel Cytec

20

30 40 50 Modulus, MSI

60

70

80

90

6

Trends in Aerospace Engineering

Stork Fokker AESP B.V.

CFI Composite Materials Performance

DCED symposium

Cytec offers line performance High Performance Epoxy Materials CytecFiberite Fiberite offersthe themost mostcomplete complete lineof ofhigh high performancecomposite composite products for the aerospace industry and set the standard in many applications.

350 325

products for the aerospace industry and set the standard in many applications. Cycom 5250-4(BMI)

IM7/8552 Hexcel IM7/8551-7 Hexcel

Use Temperature (F, wet) Use Te mpera ture(F, wet)

300 275 250 225 200 175 20

Cycom 977-3

1st Generation Epoxy

Cycom 997 Cycom 977-2 Cycom 5276-1 Cycom 970

30 35 40 45 After Impact ComCompression press ion After Impact - KS (ksi) I (1500 in-lbs/in) Cytec (150 Fiberite 0 in-lb/in) Proprietary

25

50

7 Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

Certification: test plans

Buckling test plan 16 test panels will be tested: -> test panels with/without foam -> test panels with/without impact damage -> different failure modes (shear/compression loading)

Compression (local buckling)

Trends in Aerospace Engineering

Shear

Compression (Euler buckling)

8

Stork Fokker AESP B.V.

DCED symposium

Additional requirements: Lightning strike protection 25.581

The metallic tips of the horizontal stab and the non-structural trailing edges cover the

Zone 1B / 2B areas from SAE ARP5414.

Hence Zone 1A / 2A are to be considered for the torque boxes.

Fokker has recently tested both 140 g/m copper screen and 72 g/m copper mesh on

various thicknesses to support a helicopter certification program:

9 Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

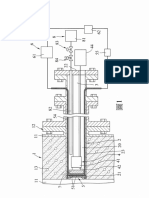

New industrialisation Proposed manufacturing flow welding tools

10 Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

Product Support: Repairs in the Full-scale test approach

After the test with level 3 / category 3 damage, the proposal is to repair detectable

damages and to continue cycling to substantiate repairs. Structural repairs will be needed in-service, especially for components which are too expensive to replace.

11 Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

Dilemmas in Aerospace design

Requirement: low weight for low DOC

Achieve low weight with low cost manufacturing

(10,10)

Achieve lowest unit cost for ROS of supplier

12 Trends in Aerospace Engineering

The new challenge: The changing role in the Supply Chain

Stork Fokker AESP B.V.

DCED symposium

The position in the supply chain

Tier 3

Many Nu veel Tier Tier 1s 1s : Boeing ~4000 Airbus 3500? ?

Tier 2

Tier 1

Tier 0

(Integrator) PositionFokker Situatie Fokker: soms Tier 1, sometimes Tier 1, meestal Tier sometimes Tier 2 (of 2 3)

Analyse en graphics door Joost 14 List

Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

The number of Tier 1 suppliers will reduce

Changes in the Supply Chain

Tier 1 will grow : - investment capability - outsourcing/partnering - sub -integration - responsibility

Small Tier 1 ? Tier 2 - focus on product posities - technology development - price competition

15 Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

The new Tier 1 will have some capabilities of the current integrator

Required competences for a Tier 1 position

Industrialization Lean Manufacturing Low Cost Facilities

Supply Chain Management Six Sigma, CAIV

Political cloud Offset credits Markt analysis

Engineering capabilites Design delegation Design Organization

Technology position Wolrd class performance

Trends in Aerospace Engineering

Analyse en graphics door Joost List

Investments Joint Ventures Partnerships

16

Stork Fokker AESP B.V.

DCED symposium

The Challenge of Stork Fokker

Have the best specialist knowledge and expertise in:

Advanced materials Innovative production methods and industrialization thereof Innovative product concepts and Combined with Integrated and Global Product Development (Integrator know how)

approach based on Smart and reliable Engineering and industrialization processes and tools

To achieve for our customers A global supply base of Innovative products to:

improve the performance (safety, operational costs, greener) and to reduce the cost of newly developed aircraft

17 Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

What are the consequences for Engineering and Design?

The knowledge challenge must continue to be a priority

The integration of this knowledge in Product Designs

Use KBE also for knowlegde to get everybody at the same level

Install Configuration Management to manage the iterative design

process

Have excellent project leaders to manage the integration within budget,

schedule and technical contraints

18 Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

Requirement: focussed and Lean Structures Engineering process

Overall design process has to be 40% shorter and 20% cheaper Optimization of concept design phase is key in order to exploit

influence on product quality and cost to the maximum Full Scale Development (FSD) has to start as late as possible (i.e. shorter lead-time) in order to have robust and stable requirements from customer Focus of concept phase is effectiveness, focus of FSD is efficiency Effective knowledge build up and transfer between projects is becoming vital Engineering process has to be resilient w.r.t. late configuration changes

19 Trends in Aerospace Engineering

Stork Fokker AESP B.V.

DCED symposium

Conclusion

The Engineering and Design Disciplines have delivered great results in

the past decade The globalization of the Supply base will deliver a new challenge

Apart from the required improvements from a product performance

point of view these challenges are: Spread basic knowledge over the supply base by increased and smart application of KBE Manage the date stream and baseline developments by smart Configuration management, supported by new PLM type applications

20 Trends in Aerospace Engineering

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Number Go Up - PrologueDocument5 pagesNumber Go Up - PrologueOnPointRadioNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- What Child Is This: Cello SoloDocument8 pagesWhat Child Is This: Cello SoloSylvia Abigail Vargas SánchezNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Course 1 Anchor Instalation inDocument39 pagesCourse 1 Anchor Instalation inViktorMarkuletsNo ratings yet

- Skill Development Program for Employability EnhancementDocument15 pagesSkill Development Program for Employability EnhancementRodriguez ArthursNo ratings yet

- UAV Design TrainingDocument17 pagesUAV Design TrainingPritam AshutoshNo ratings yet

- Lab - Researching Network Attacks and Security Audit ToolsDocument4 pagesLab - Researching Network Attacks and Security Audit ToolsAlvaro Avila QuirosNo ratings yet

- Access Global Online Research Ag ResourcesDocument2 pagesAccess Global Online Research Ag ResourcesRodriguez ArthursNo ratings yet

- Cost Report Template PDFDocument1 pageCost Report Template PDFEzekiel Eljay MacatangayNo ratings yet

- Combustion and Flame: Kyung Ju Kim, Myung Hoon Cho, Soo Hyung KimDocument9 pagesCombustion and Flame: Kyung Ju Kim, Myung Hoon Cho, Soo Hyung KimRodriguez ArthursNo ratings yet

- National Cheng Kung University student examines causes and impacts of landslides in IndiaDocument17 pagesNational Cheng Kung University student examines causes and impacts of landslides in IndiaRodriguez ArthursNo ratings yet

- A356.0 Alloy DetailDocument2 pagesA356.0 Alloy DetailAdrian LimantoNo ratings yet

- Ijsetr Vol 3 Issue 5 1453 1457Document5 pagesIjsetr Vol 3 Issue 5 1453 1457Rodriguez ArthursNo ratings yet

- Mems Report JournalDocument4 pagesMems Report JournalRodriguez ArthursNo ratings yet

- 3D Printing TechnologyDocument5 pages3D Printing Technologyvasu088No ratings yet

- Implementation of A Skating Motion On A Spider Robot: Bachelor ThesisDocument55 pagesImplementation of A Skating Motion On A Spider Robot: Bachelor ThesisRodriguez ArthursNo ratings yet

- SP19416圖式20161104Document3 pagesSP19416圖式20161104Rodriguez ArthursNo ratings yet

- Mos Fabrication Content BsDocument11 pagesMos Fabrication Content BsarumugamNo ratings yet

- Polyjet Materials Data SheetDocument2 pagesPolyjet Materials Data SheetRodriguez ArthursNo ratings yet

- Automobile Crank ShaftDocument8 pagesAutomobile Crank ShaftRodriguez ArthursNo ratings yet

- Optimization CrankShaft MechanismDocument22 pagesOptimization CrankShaft MechanismLakshman ReddyNo ratings yet

- Aiaa 2010 1018Document11 pagesAiaa 2010 1018Rodriguez ArthursNo ratings yet

- Volume 3 Issue 9 Paper 1Document21 pagesVolume 3 Issue 9 Paper 1Rodriguez ArthursNo ratings yet

- Nafems Conference BroucherDocument4 pagesNafems Conference BroucherRodriguez ArthursNo ratings yet

- FIBER OPTICS Workshop BrouchureDocument15 pagesFIBER OPTICS Workshop BrouchureRodriguez ArthursNo ratings yet

- Solar Power Pesticides SprayerDocument4 pagesSolar Power Pesticides SprayerRodriguez Arthurs100% (1)

- Design Optimization TutorialDocument13 pagesDesign Optimization TutorialRodriguez ArthursNo ratings yet

- Report ProjectDocument53 pagesReport ProjectRodriguez ArthursNo ratings yet

- CAEA v145 Update ACTDocument22 pagesCAEA v145 Update ACTRodriguez ArthursNo ratings yet

- V Tail MAV ReportDocument46 pagesV Tail MAV ReportRodriguez ArthursNo ratings yet

- XFLR5 Tut v1Document40 pagesXFLR5 Tut v1spandaglis0% (1)

- Ramesh S TalkDocument21 pagesRamesh S TalkRodriguez ArthursNo ratings yet

- LS-PrePost Forming Aug1stDocument240 pagesLS-PrePost Forming Aug1stRodriguez ArthursNo ratings yet

- ABAQUS Tutorial Schedule and Access InfoDocument2 pagesABAQUS Tutorial Schedule and Access InfoAmit RajputNo ratings yet

- NAL Workshop April8 VeenaDocument37 pagesNAL Workshop April8 VeenaRodriguez ArthursNo ratings yet

- MTU Computer Graphics Course Covers BasicsDocument98 pagesMTU Computer Graphics Course Covers BasicsETHIO FIRST MUSICNo ratings yet

- mPro-200-V2 CatalogDocument20 pagesmPro-200-V2 CatalogAmol BhaleraoNo ratings yet

- A Randomized Controlled Trial of An Intelligent Robotic Response To Joint Attention Intervention SystemDocument13 pagesA Randomized Controlled Trial of An Intelligent Robotic Response To Joint Attention Intervention SystemTaciany SantosNo ratings yet

- Appuse Userguide v2-2Document31 pagesAppuse Userguide v2-2AshwiniNo ratings yet

- Hikvision Smart Functions and Applications: Hikvision Certified Security AssociateDocument48 pagesHikvision Smart Functions and Applications: Hikvision Certified Security AssociateMiri HasanovNo ratings yet

- R1-7-10K5-DS CE-LVD CertificateDocument2 pagesR1-7-10K5-DS CE-LVD CertificateJosé DaniloNo ratings yet

- Ujian Tengah Semester Genap TA 2020/2021 Fakultas Ekonomi dan SosialDocument4 pagesUjian Tengah Semester Genap TA 2020/2021 Fakultas Ekonomi dan SosialAchmad VidyNo ratings yet

- Grade 12 Mathematics Important Question CollectionDocument9 pagesGrade 12 Mathematics Important Question Collectionaashishdevkota185No ratings yet

- CCC: Current Carrying Capacity tables for cablesDocument3 pagesCCC: Current Carrying Capacity tables for cablesMeera DeviNo ratings yet

- Final Article Review For BRMDocument5 pagesFinal Article Review For BRMSelemon BerihunNo ratings yet

- Solar Water HeatersDocument16 pagesSolar Water HeatersKRUPA.SNo ratings yet

- Scraper SiteDocument3 pagesScraper Sitelinda976No ratings yet

- Casual Leather Backpack: PDF Pattern & TutorialDocument33 pagesCasual Leather Backpack: PDF Pattern & TutorialCosmin Daniel ComanNo ratings yet

- Fig 1: Ground Distribution Circuit, CaterpillarDocument2 pagesFig 1: Ground Distribution Circuit, Caterpillarluis eduardo corzo enriquezNo ratings yet

- BMS Wiring DaigramDocument8 pagesBMS Wiring DaigramChukwuma OnukuNo ratings yet

- Test DSC VHF MF-HFDocument1 pageTest DSC VHF MF-HFDario RomeoNo ratings yet

- 2M H.265 Network 32x Zoom Camera: Key FeaturesDocument2 pages2M H.265 Network 32x Zoom Camera: Key Featuresnot jappeningNo ratings yet

- 1st Review Report - Smart Distribution SystemDocument54 pages1st Review Report - Smart Distribution SystemretechNo ratings yet

- Crowdstrike Support OfferingsDocument4 pagesCrowdstrike Support OfferingsRemicheNo ratings yet

- 42 - 21 Rotational, Well Test Supervisor JobDocument25 pages42 - 21 Rotational, Well Test Supervisor JobRizwan FaridNo ratings yet

- Step by Step Process For Creating AdobeDocument23 pagesStep by Step Process For Creating AdobeGL1254No ratings yet

- Algorithm Design and Analysis (CS60007) Assignment 1: 1 Interval SchedulingDocument6 pagesAlgorithm Design and Analysis (CS60007) Assignment 1: 1 Interval SchedulingBraj SehraNo ratings yet

- VNX Operating Environment For Block 05.33.021.5.266Document122 pagesVNX Operating Environment For Block 05.33.021.5.266molym moNo ratings yet

- Install Java on Ubuntu with AptDocument19 pagesInstall Java on Ubuntu with AptNavneet HoodaNo ratings yet

- Lab - Convert Data Into A Universal Format PDFDocument9 pagesLab - Convert Data Into A Universal Format PDFNi Made ArtiniNo ratings yet