Professional Documents

Culture Documents

General Piping and Valves

Uploaded by

facebookshopOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Piping and Valves

Uploaded by

facebookshopCopyright:

Available Formats

ME 514 INDUSTRIAL PLANT DESIGN

1.1 Pipe and Tube

The fundamental difference between pipe and

tube is the dimensional standard to which each

is manufactured. A pipe is a tube with a round

cross section conforming to the dimensional

requirements for nominal pipe size as tabulated

in table for Pipe Schedules.

A tube is a hollow product of round or any other

cross section having a continuous periphery.

Round tube size maybe specified with respect to

any two, but not all three of the following:

outside diameter or internal diameter or

nominal diameter.

1.2 Black pipe steel pipe that has not been

galvanized.

1.3 Bell and Spigot Joint the commonly

used joint in cast-iron pipe. Each piece is

made with an enlarged diameter or bell at

one end into which the plain or spigot end of

another piece is inserted when laying. The

joint is then made tight by cement, oakum,

or rubber caulked into the bell around the

spigot.

1.4 Bull Head Tee a tee the branch of

which is larger than the run.

1.5 Butt Weld Joint a welded pipe joint made

with the ends of the two pipes butting each

other, the weld being around the periphery.

1.6 Carbon Steel Pipe steel pipe which owes

its properties chiefly to the carbon which it

contains.

1.7 Check Valve a valve designed to allow a

fluid to pass through in one direction only. A

common type has a plate so suspended that the

reverse flow aids gravity in forcing the plate

against a seat, shutting off reverse flow.

1.8 Compression Joint a multi-piece joint with

cup shaped threaded nuts which, when tightened

compress tapered sleeves so that they form joint

on the periphery of the tubing they connect.

1.9 Cross-Over a small fitting with a double

offset, or shaped like the letter U with the ends

turned out. It is only made in small sizes and

used to pass the flow of one pipe past another

when the pipes are in the same plane.

1.10 Expansion Loop a large radius bend in a

pipe line to absorb longitudinal expansion in the

pipe line due to heat.

1.11 Galvanized Pipe steel pipe coated with

zinc to resist corrosion.

1.12 Gate Valve a valve employing a gate, often

wedge-shaped, allowing fluid to flow when the

gate is lifted from the seat. Such valves have

less resistance to flow than globe valves.

1.13 Globe Valve one with a somewhat globe

shaped body with a manually raised or lowered

disc which when closed rests on a seat so as to

prevent passage of a fluid.

1.14 Header a large pipe or drum into which

each of a group of boilers is connected. Also

used for a large pipe from which a number of

smaller ones are connected in line and from the

side of the large pipe.

1.15Malleable Iron cast iron heat-treated to

reduce its brittleness. The process enables

the materials to stretch to some extent and

to stand greater shock.

1.16Manifold a fitting with a number of

branches in line connecting to smaller pipes.

Used largely as an interchangeable term with

header.

1.17Medium Pressure when applied to

valves and fittings, implies they are suitable

for a working pressure of from 862 to 1207

kPa (125 to 175 psi).

1.18Mill Length also known as random

length. Run-of-mill pipe is 4880 mm to 6000

mm (16 ft to 20 ft) in length. Some pipe are

made in double lengths of 9150 mm to

10,675 mm (30 ft to 35 ft).

1.19Relief Valve one designed to open

automatically to relieve excess pressure.

1.20Run a length of pipe made of more

than one piece of pipe; a portion of a fitting

having its ends in line or nearly so, in

contradistinction to the branch or side

opening, as of a tee.

1.21 Saddle Flange a flange curved to fit a

boiler or tank and to be attached to a threaded

pipe. The flange is riveted or welded to an

adjoining pipe.

1.22 Socket Weld a joint made by use of a

socket weld fitting which has a prepared female

end or socket for insertion of the pipe to which

it is welded.

1.23 Standard Pressure formerly used to

designate cast-iron flanges, fittings, valves, etc.,

suitable for a maximum working steam pressure

of 862 kPa.

1.24 Street Elbow an elbow with male thread

on one end , and female thread on the other

end.

1.25Stress-Relieving uniform heating of a

structure or portion thereof to a sufficient

temperature to relieve the major portion of

the residual stresses, followed by uniform

cooling.

1.26Wrought Iron iron refined to a plastic

state in a puddling furnace. It is

characterized by the presence of about 3

percent of slag irregularly mixed with pure

iron and about 0.5 percent carbon.

1.27Wrought Pipe this term refers to both

wrought steel and wrought iron. Wrought in

this sense means worked, as in the process of

forming furnace-welded pipe from skelp, or

seamless pipe from plates or billets. The

expression wrought pipe is thus used as a

distinction from cast pipe. When wrought-

iron pipe is referred to, it should be

designated by its complete name.

2.1 All piping shall be run parallel to

building walls.

2.2 Grouped piping shall be supported on

racks either on horizontal or vertical planes.

2.3 All piping to headers shall come from

below rack.

2.4 All piping from headers shall go up above

rack.

2.5 All piping above or below racks shall be

supported on separate racks.

2.6 All piping should run with slight

inclination for drainage of main headers.

2.7 All piping on racks shall have a sufficient

spacing for pipe or chain wrenches so that any

single line can be altered without disturbing the

rest of the piping on rack.

2.8 All piping 63.5 mm (2 in) and above shall

be flanged while smaller sizes can be screwed.

2.9 On long headers a pair of flanges shall be

provided for every three lengths of 6000 mm (20

ft) of pipes 63.5 mm (2 in ) and above.

2.10 On long headers a pair of unions shall be

provided for every three lengths of 6000 mm (20

ft) of pipes smaller than 63.5 mm (2 in).

2.11All piping subject to varying temperature

shall be provided with expansion joints or

expansion loops to take care of expansion.

2.12No galvanized piping shall be used of

steam.

2.13No piping material shall be used that is

easily corroded by material passing thru.

2.14All piping shall be clamped by U bolts

or clamps to supporting racks except steam

piping.

2.15Piping supports shall be placed on a 3000

mm (10 ft) intervals or less.

2.16 All steam piping shall be supported on

rollers or sliding support for expansion.

2.17 All piping carrying pressure shall be of

sufficient bursting strength for the pressure

applied. A minimum factor of safety of 4 for

working pressure applied shall be used.

2.18 A minimum factor of safety of 4 for working

applied shall be used.

2.19 For conveying liquids subject to water

hammer additional safety factor of a minimum of

100% of working pressure shall be used.

2.20 Piping supports shall be placed on a 3000

mm (10 ft) intervals or less.

2.21All piping carrying steam, hot water or

hot liquids shall be insulated to prevent

accidental contact and loss of heat.

2.22Drains for steam piping shall be provided

with steam traps.

2.23On all screwed joints the threaded

portion shall enter fittings with three threads

by hand before a pipe wrench is applied.

2.24Pipe threads shall be lubricated by white

lead, red lead graphite and oil or other

approved thread lubricants before

tightening.

2.25 No rubber or rubberized gasket shall be

used for steam or hot liquids.

2.26 A shut-off valve shall be installed to every

branch from headers.

2.27 All piping shall be reasonable cleaned

before installation.

2.28 All piping shall be free from burns or

protruding metals inside.

2.29 No piping carrying steam or hot liquids shall

be imbedded in concrete walls or floors.

2.30 Where piping has to be located in trenches

the pipes shall be supported on steel benches on

floor of trench.

2.31 Where piping has to be located in trenches a

suitable drainage or sump for removal of liquid

accumulations shall be provided for trench.

2.32 Where piping carrying steam or hot liquids

have to pass walls of concrete suitable sleeves

made of pipes one size bigger shall be imbedded

in concrete before piping is laid.

2.33 Piping to all equipments shall not impose

any stress on equipment being connected.

2.34 Pipe carrying liquids with solids shall use

long radius elbows or tees with plugs in the

direction of flow.

Identification of piping by color, or color

bands at convenient locations shall be as

follows:

In addition to color coding, the specific

contents of piping must be identified by

sticker, stencil, tag, etc.

Color bands and pipe flow identifications

shall be as specified and installed as shown.

In practice, the average fluid flow velocities may

be as follows:

a. Water - - - - - - - - - - 1.5 3.0 meters/sec.

b. High Pressure Saturated Steam ----- 25 50

meters/sec.

c. High Pressure Superheated Steam --- 50 77

meters/sec.

d. Atmospheric Exhaust Steam ---- 40 60

meters/sec.

e. Low Pressure Exhaust Steam --- 100 120

meters/sec.

5.1 Scope.

Power piping systems include all steam,

water and oil piping and the component

parts such as the pipe, flanges, bolting,

gaskets, valves, and fittings for steam

generating plants, central heating plants and

industrial plants.

5.2 Materials.

Materials used shall conform to Table 11.6.2

(PSME Code 2008). Any material other than

those specified should meet the physical &

chemical requirements & test of the latest

revision of the respective specifications in

Table 11.6.2.

5.3 Valves

It is mandatory that valves be (a) of the

design or equal to the design which the

manufacturer thereof recommends for the

service, and (b) of materials allowed by the

code for the pressure & temperature.

All valves in nominal sizes:

80 mm (3 in) and smaller for pressure above

1724 kPa (250 psig) but not above 2758 kPa

(400 psig).

50 mm (2 in) smaller for pressures above

25787 kPa (400 psig) not above 4137 kPa (600

psig).

40 mm ( 1 in) and smaller for pressures

above 4137 kPa (600 psig) may have screwed,

flanged, or welding ends.

For all valves, larger than sizes specified in

the preceding paragraph, flanged or welding

ends shall be used.

5.4 Wall Thickness.

The following formula shall be used to determine

pipe wall thickness:

Where

t

m

= minimum pipe wall thickness in mm

P = maximum internal service pressure in kPa

t = nominal pipe wall thickness in mm

D = outside diameter of pipe in mm

S = allowable stress in materials in kPa

C = allowance for threading, mechanical strength

of corrosion in mm, see Table 11.6.4a

Y = co-efficient for values, Table 11.6.4b

C

YP S

PD

t

m

+

+

=

2

Since all pipe

furnished by the

mill is subject to 12

% variation in

wall thickness, the

thickness tm should

be multiplied by

8/7 to obtain the

nominal wall

thickness.

5.5 Variations in presure and temperature.

Either pressure or temperature, or both, may

exceed the nominal design values if the

computed stress in the pipe wall calculated for

the pressure does not exceed the allowable S

value in Table 11.6.5 and 11.6.5a for the

expected temperature by more than the

following allowances for the period of duration

indicated:

a. Up to 15 percent increase above the S value

during 10 percent of the operating period.

b. Up to 20 percent increase above the S value

during one percent of the operating period.

5.6 Pressure reducing and relief valves.

a. Where pressure reducing valves are used, one or

more relief or safety valves shall be provided on the

low pressure side of the reducing valve in case the

piping or equipment on the low pressure side does

not meet the requirements for the full initial

pressure. The relief or safety valve shall be located

adjoining or as close as possible to the reducing

valve. Proper protection shall be provided to prevent

injury or damage caused by escaping fluid from relief

or safety valves if vented to the atmosphere. The

vents shall be of ample size and as short and direct as

possible. The combined discharge capacity of the

relief valves shall be such that the pressure rating of

the lower pressure piping and equipment will not be

exceeded if the reducing valves sticks open.

b. It is mandatory that a pressure gage is

installed on the low pressure side of a

reducing valve.

5.7 Pipe

a. For pressure above 4,137 kPa (600 psig) ,

the pipe shall be:

1. Seamless steel meeting ASTM

specification A-106, A-312, A-335 or A-376; or

2. Forged and bored steel meeting A-369 or

3. Automatic welded steel meeting A-312 or

4. Electric-fusion welded steel pipe

meeting with ASTM specification A-155

b. For pressure above 1724 kPa (250 psig), but

not above 4137 kPa (600 psig) , pipe shall be:

1. Electric-fusion welded steel of ASTM

specification A-134 or A-139

2. Electric-resistance welded steel pipe of

ASTM specification A-135

3. Forged or bored steel meeting A-380; or

4. Automatic welded steel meeting A-312

5. Electric-fusion welded steel pipe meeting

with ASTM specifications A-155

6. Seamless steel in accordance with ASTM

specification A-106

7. Seamless or electric-resistance welded steel

pipe of ASTM specification of A-53

c. For service up to 400 C (750 F) and

pressure of not over 1724 kPa (250 psig), any

of the following classes of pipe may be used:

1. Electric-fusion welded steel of ASTM

specification A-134 or A-139

2. Electric-resistance welded steel pipe of

ASTM specification A-135

3. Wrought-iron pipe of ASTM specification

A-72

d. Grade A seamless steel pipe of ASTM

specification A-106, wrought-iron pipe of

ASTM A-72, Grade A seamless steel pipe of

ASTM A-53, or grade A electric welded pipe

of ASTM A-53, A-135 or A-139 shall be used

for close coiling, cold bending or other uses.

5.8 Boltings

a. The following standards shall apply to

bolting:

For steam service pressure in excess of 1724

kPa (250 psig) or for steam or water service

temperature exceeding 232 C (450 F), the

bolting material shall conform to ASTM

specifications A-193. For temperature

exceeding 400 C (750 F), only bolts studs are

recommended. When cast iron flanges are

used, bolting material shall be of carbon

steel conforming to ASTM specification A-

307, Grade B, or A-107, Grade 1120.

b. Flange bolts or bolt-studs shall be of the

dimensions and material specified for the

purpose in the corresponding American

flange standards. Bolts or bolt-studs shall

extend completely through the nuts and if

desired may have reduced shank of a

diameter not less than the diameter at root

of threads.

c. Nuts shall conform to ASTM specification

A-194.

5.9 Flanges

a. Flanges shall conform to the American

Standard B 16.5 for respective pressures and

temperature or to the specifications set by the

manufacturer.

b. 1724 kPa (250 psig) and class 862 kPa (125

psig) cast-iron integral or screwed companion

flanges may be used with a full dace gasket or

with a ring gasket extending to the inner edge of

the bolt holes. When using a full face gasket, the

bolting maybe of heat-treated carbon steel

(ASTM-A261), or alloy steel (ASTM A-193). When

using a ring gasket, the bolting shall be of

carbon steel equivalent to ASTM A-307, Grade B,

without heat-treatment other than stress relief.

c. When bolting together two Class 1724

kPa (250 psig) integral or screwed

companions cast-iron flanges, having 1.6 mm

(1/16 in) raised faces, the bolting shall be of

carbon steel equivalent to ASTM A-307,

Grade B. Without heat-treatment other than

the stress relief.

d. 1034 kPa (150 psig) steel flanges may be

bolted to cast-iron valves, fittings or other parts

having either integral Class 862 kPa (125 psig)

cast-iron flanges or screwed Class 862 kPa (125

psig) companion flanges. When such construction

is used, the 1.6 mm (1/16 in) raised face on the

steel flange shall be removed. When bolting such

flanges together using a ring gasket extending to

the inner edge of the bolt holes, the bolting shall

be of carbon steel equivalent to ASTM A-307

Grade B, without heat-treatment other than

stress relief. When bolting such flanges together

using full face gasket, the bolting may be heat

treated carbon steel (ASTM A-261) or alloy steel

(ASTM A-193).

e. 2069 kPa (300 psig) steel flanges may be

bolted to cast-iron valves, fittings, or other

parts having either integral Class 1724 kPa

(250 psig) cast iron flanges or screwed Class

1724 kPa (250 psig) cast-iron companion

flanges without any changes in the raised

faces on either flange. Where such

construction is used, the bolting shall be of

carbon steel equivalent to ASTM A-307 Grade

B, without heat treatment other than stress

relief.

5.10 Fittings

a. The minimum mill thickness of all flange or

screwed fittings and the strength of factory-

made welding fittings shall not be less than that

specified for the pressure and temperatures in

the respective American Standards.

b. All fittings in nominal sized above; 80 mm

for pressures above 1724 kPa (250 psig) but not

above 2758 kPa (400 psig); 50 mm for pressures

above 2758 kPa (400 psig) but not above 4137

kPa (600 psig), and 40 mm for pressures above

4137 kPa (600 psig) but not above 17238 kPa

(2500 psig) shall have flanged ends or welding

ends.

5.11 Gaskets

a. Gaskets where required, shall be of

material that resists attack by the fluid

carried in the pipe line, shall be strong

enough to hold the pressure, and perform

the purpose intended throughout the

temperature range encountered. Gaskets

shall be as thin as the finish of the surface

that will permit to reduce possibility of

blowing out.

b. Paper, vegetable fiber, rubber or rubber

inserted gaskets shall not be used for

temperatures in excess of 121 C (250 F).

5.12 Hangers, supports,anchors

a. Piping and equipment shall be supported in

a thoroughly substantial and workman like

manner, rigid enough to prevent excessive

vibration and anchored sufficiently to prevent

undue strains on boilers and the equipment

served. Hangers, supports, and anchors shall be

made of durable materials in tunnels and

buildings of permanent fire proof construction,

piping may be supported on or hung from wood

structures if all piping used for conveying fluid at

temperatures above 121 C (250 F) is spaced or

insulated from such wooden members to prevent

dangerous heating.

b. Hangers and supports shall permit free

expansion and contraction of the piping

between anchors. All piping shall be carried

on adjustable hangers properly levelled

supports, and suitable springs, sway bracing,

vibration dampeners, etc. shall be provided

where necessary.

5.13 Pipe sleeves

a. Where steam pipe pass through walls,

partitions, floors, beams, etc., construction of

combustible material, protecting metal sleeves

or thimbles shall be provided to give a clearance

of not less than 6.35 mm (1/4 in) under hot and

cold conditions all around the pipe, or pipe and

covering. When steam pipes pass through metal

partitions, etc., a clearance of at least 6.35 mm

(1/4 in) under hot and cold conditions shall be

left all around the pipe, or pipe covering. In any

cases, if the fluid temperature exceeds 121 C

(250 F), the pipe shall be insulated inside the

sleeve with a covering of at least standard

thickness.

b. Walls, floors, partitions, beams, etc.,

shall not be cast solidly to or built up around

and in contact with a steam, hot water, or

hot oil pipe. Where such pipe must be

installed in a concrete floor or other building

member, it shall be protected for the entire

buried length with a suitable protecting pipe

sleeve of steel, cast iron, wrought iron, or

tile; exception maybe taken to the preceding

rules where pipes pass through walls, floors,

partitions, etc., that must be kept water

tight.

5.14 Drains,drips, and steam traps

a. Suitable drains or drips shall be provided

wherever necessary to drain the condensate

from all sections of the piping and equipment

whenever it may collect. Suitable drains shall

also be provided to empty water lines, water

storage tanks, equipment containing water,

etc., when such piping and equipment is out

of service. At least one valve shall be placed

in each drip or drain line.

b. Drip lines from steam headers, mains,

separators, and other equipment shall be

properly drained by traps installed in

accessible locations and below the level of

the apparatus drained. Drip pumps, drip

(preferably with orifice control) maybe used

in lieu of traps, if they are safely installed

protected and operated under regular

supervision. All drain lines shall have drip

valves for free blow to the atmosphere.

c. Drip lines from steam headers, mains,

separators, and other equipment operating

at different pressures shall not be connected

to discharge through the same trap. Where

several traps discharge into one header

which is or maybe under pressure, a stop

valve and a check valve shall be placed in

the discharge line from each trap.

d. Trap discharge piping shall have the

same thickness as the inlet piping unless it is

vented to atmosphere or operated under low

pressure and has no stop valves. The trap

discharge piping shall have at least the

pressure rating of the maximum discharge

pressure to which it maybe subjected against

freezing where necessary. Drainage from

steam traps, if open to atmosphere, shall be

safeguarded to prevent accidents from hot

discharge.

5.15 Hydrostatic tests

a. Before Erection

All valves, fittings, etc., shall be capable of

withstanding a hydrostatic shell test made

before erection equal to twice the primary

steam service pressure, except that steel fittings

and valves shall be capable of withstanding the

test pressure as given in the American Standard

for Steel Pipe Flanges and Flanged Fittings for

the specific material, pressure standard and

facing involved (ring joint facing for welding

ends.) Pipe shall be capable of meeting the

hydrostatic test requirements contained in the

respective specification in Table 11.6.2, under

which it is purchased.

If a hydrostatic mill test pressure for pipe is

not stated in any of the specifications

enumerated in Table 11.6.2, the pipe shall be

capable of meeting a minimum internal

hydrostatic test pressure determined from

the formula.

Where:

P = test pressure in kPa

t = nominal pipe wall thickness in mm.

D = pipe outside diameter in mm, and

D

St

P

2

=

S = allowable stress in material in kilopascal

and which shall be taken as not less than 50

percent of the specified yield point of the

material except that hydrostatic tests shall

not exceed 17,238 kPa (2500 psig) for sized

80 mm (3 in) and below, or 19,306 kPa (2800

psig) for size over 80 mm (3 in) nor shall the

stress produced exceed 80 percent of the

specified yield point.

b. After Erection

All piping systems shall be capable of

withstanding a hydrostatic test pressure of one

and one-half times the design pressure, except

that the test pressure shall in no case exceed

the adjusted pressure-temperature rating for 38

C (100 F) as given in the American Standard for

Steel Pipe Flanges and Flange Fittings for the

material and pressure standard involved. For

systems joined wholly with welded joints the

adjusted pressure rating shall be that for ring

joint facing for systems joined wholly or partly

with flanged joints adjusted pressure rating shall

be that for ring joint facing. For systems joined

wholly or partly with flanged joints the adjusted

pressure rating shall be that for the type of

facing used. .

5.16 Expansion and flexibility.

a. Piping systems are subject to a diversity

of loadings creating stresses of different

types and patterns, of which only the

following more significant ones need

generally be considered in piping stress

analysis:

1. Pressure, internal or external

2. Weight of pipe, fittings and valves,

containing fluid and insulation, and other

external loadings such as wind.

3 Thermal expansion of the line.

The first two loadings produce sustained

stresses which are evaluated by conventional

methods. The stresses due to thermal

expansion on the other hand, if of sufficient

initial magnitude will be relaxed as a result

of local flow in the form of yielding or in the

form of creep. The stress reduction which

has taken place will appear as a stress or

reversed sign in the cold condition.

b. Materials

The thermal expansion range shall be

determined from the Table 11.6.16.2 as the

difference between the unit expansion shown for

the maximum normal-operating metal

temperature and that for the minimum normal-

operating metal temperature (for hot lines this

may usually be taken as the erection

temperature). For materials not included in this

table, reference shall be made to authority

source data, such as publication of the National

Bureau of Standards. The cold and hot moduli of

elasticity, E

c

and E

h

, and the moduli of torsional

rigidity, G

c

and G

h

, respectively, may be taken as

the values shown for the minimum and maximum

normal operating metal temperatures in Table

11.6.16.2a for ferrous and Table 11.6.16.2b for

non-ferrous materials.

c. For flexibility calculations, Poissons

ratio may be taken as 0.3 at all temperatures

for all ferrous materials.

d. The S values, S

c

and S

h

at the minimum

and maximum operating metal temperatures,

respectively, to be used for determining the

allowable expansion stress range SA shall be

taken for the type of piping system involved

from the applicable tables in the respective

sections of the code. In the case of welded

pipe, the longitudinal joint efficiency maybe

disregarded in calculating expansion

5.17 General.

a. Piping systems shall be designed to have

sufficient flexibility to prevent thermal

expansion from causing:

1. Failure from over-stress of the piping

material or anchors

2. Leakage at joints

3. Detrimental distortion of connected

equipment resulting from excessive thrusts

and moments.

b. Flexibility shall be provided by changes

of direction in the piping through the use of

bends, loops, and off-sets; or provision shall

be made to absorb thermal strains by

expansion joints of the slip joints or bellows

type. If desirable, flexibility may be provided

by increasing or corrugating portions or all of

the pipe. In this case, anchors or ties of

sufficient strength and rigidity shall be

installed to provide for end force due to fluid

pressure and other causes..

c. Basic Assumptions and Requirements

1. Formal calculations or model tests shall

be required when reasonable doubt exists as

to the adequate flexibility of a system. Each

problem shall be analyzed by a method

appropriate to the conditions.

No hard and fast rule can be given as to when as

analysis should be made. However, in the

absence of better information the need for a

formal stress analysis for a two-anchor system of

uniform pipe size is indicated when the following

approximate criterion is not satisfied:

Where:

D = nominal pipe size, mm

Y = resultant of movements to be absorbed by

pipe line, mm

U = anchor distance (length of straight line

joining anchors), meter.

L = developed length of line axis, meter.

( )

03 . 0

2

s

U L

DY

2. In calculating the flexibility of a piping

system between anchor points, the system

shall be treated as a whole. The significance

of all parts of the line and of all restraints

such as solid hangers or guides including

intermediate restraints introduced for the

purpose of reducing moments and forces on

equipment or small branch lines shall be

recognized.

3. Calculations shall take into account

stress-intensification factors found to exist in

components other than plain straight pipe.

Credit may be taken for the extra flexibility

of such components. In the absence of more

directly applicable data, the flexibility

factors shown in Fig. 11.6.17.3(c) may be

used.

4. Dimensional properties of pipe and

fittings as used in flexibility calculations,

shall be based on nominal dimensions. The

pressure stresses for services subject to

severe condition shall be based on the

reduced thickness of the pipe.

5. The total expansion range from the

minimum of the maximum normal-operating

temperature shall be used in all calculations,

whether piping is cold sprung or not. Not

only the expansion of the line itself, but also

linear and angular movements of the

equipment to which it is attached, shall be

considered.

6. Calculations for the expansion stresses S

E

shall be based on the modulus of elasticity E

c

at room temperature.

5.18 Stresses and reactions.

a. Using the foregoing assumptions, the

stresses, and reactions due to the expansion

shall be investigated at all significant points.

The expansion stresses shall be combined in

accordance with the following formula.

Where:

S

b

= iM

b

/Z = resultant bending stress kPa

S

t

= M

t

/2Z = torsiional stress kPa

M

b

= resultant bending moment,n Newton-meter.

M

t

= torsional moment, Newton-meter.

Z = section modulus of pipe (m3),

i = stress intensification factor

2 2

4

t b E

S S S + =

b. The maximum computed expansion stress,

S

E

based on 100 per cent of the expansion and E

c

for the cold condition shall not exceed the

allowable stress range, S

A

:

Where:

In the above formula

S

C

= allowable stress (S value) in the cold

condition

S

h

= allowable stress (S value) in the hot

condition

S

C

and S

h

are to be taken from the table in the

applicable date, the values of f shall be taken

from the following table:

Attach Fig. 11.6.1.7.3(c) and Fig. For graph for k

and i.

( )

h C A

S S f S 25 . 0 25 . 1 + =

Expected life is meant the total number of

years during which system is expected to be

in active operation.

The sum of the longitudinal stresses due to

pressure, weight and other sustained

external loadings shall not exceed Sh.

Where the sum of these stresses is less than

Sh the difference between Sh and this sum

may be added to the term 0.25 Sh in the

above formula.

The longitudinal pressure stress Sep shall be

determined by dividing the end force due to internal

pressure:

By the cross-sectional area of the pipe wall

Or

In which

S

ep

= longitudinal pressure stress, kPa

p = internal pressure, kPa

d = nominal outside diameter of the pipe m inus two

times the normal wall thickness in mm

D = nominal outside diameter of pipe, mm

2

2

d p

F

t

=

( )

2 2

4

d D A =

t

2 2

2

d D

pd

S

F

S

ep

= =

The reactions (forces and moments) Rh and

Rc in the hot and cold conditions,

respectively, shall be obtained as follows

from the reactions R derived from the

flexibility calculations based on the modulus

of elasticity at room temperature Ec.

or

Whichever is greater, and with the further

condition that:

c

c

h

h

R

E

E

C R

|

|

.

|

\

|

|

.

|

\

|

=

3

2

1

CR R

c

=

R

E

E

S

S

R

h

c

c

h

c

|

|

.

|

\

|

= 1

Where:

C = cold spring factor varying from zero for

no cold spring to one for 100 percent cold

spring

S

e

= maximum computed expansion stress

E

c

= modulus of elasticity in the cold

condition

E

h

= modulus of elasticity in hot condition

R = range of reactions corresponding to the

full expansion range based on E

C

.

R

c

and R

h

represent the maximum reactions

estimated to occur in the cold and hot

conditions, respectively.

c. The design and spacing of support shall

be checked to assure that the sum of the

longitudinal stress due to the weight,

pressure, and other sustained external

loading does not exceed S

h

.

6.1 This is industrial air and gas in mines,

power plants, industrial and gas

manufacturing plants.

a. Piping with metal temperature above

232 C (450 F) or below -2.9 C (27 F).

b. Air piping systems operating at pressures

of 207 kPa (30 psig) or less.

c. Piping lines with firebrick or other

refractory material used for conveying hot

gases.

6.2 Wall thickness of Pipe

The minimum thickness of pipe wall required

shall be determined by the following formula

for the designated pressure and for

temperature not exceeding 232 C (450 F).

C

P S

PD

t

m

+

+

=

8 . 0 2

Where:

P = maximum allowable, operating pressure in

kPa. The value obtained maybe rounded to the

next higher unit of 10. The maximum allowable

operating pressure computed with S values

permitted under this paragraph, shall not exceed

two-thirds of the mill test pressure for a service

temperature of 38 C (100 F) or less and five-

ninths of the mill test pressure for a service

temperature of 232 C (450 F).

S = maximum allowable hoop stress in kPa, see

Table 11.7.2.

For steel or wrought-iron pipe (except butt

welded-manufactured under a specification not

listed in Table 11.7.2) the value of S shall be

0.6K for a service temperature of 38 C (100 F) or

less or 0.52K for a service temperature of 232 C

(450 F) where K is the stipulated minimum

effective yield strength calculated in the manner

described in Section 11.7.3.

t

m

= minimum pipe wall thickness in mm, i.e.,

nominal wall thickness less the manufacturing

tolerance for the thickness. Where available

from on hand or in stock, the actual measured

wall thickness maybe used to calculate the

maximum allowable operating pressure.

C = corrosion in millimetre obtained from the

following:

D = outside diameter of pipe in inches (mm).

6.3 Effective Yield Strength (K)

The effective yield strength K of steel or

wrought-iron pipe maybe determined by

taking the product of Y, the stipulated

minimum yield strength, and E, efficiency of

the longitudinal joint. The value of E shall

be taken from the following:

Alternatively, the effective yield strength

maybe determined by internal hydrostatic

pressure tests on finished lengths of pipe or

on cylindrical samples cut from the results of

such tests in accordance with the following

formula:

Where:

K = effective yield strength in kPa.

P

y

= pressure at the yield strength of the pipe

in kPa.

t

D P

K

y

2

=

This maybe taken as the pressure required to

cause a volumetric offset of 0.2 per cent of

as the pressure required to cause a

permanent increase in circumference of 0.1

per cent at any point, but other suitable

methods of determining that the stress in the

steel has reached the yield strength may be

used, provided such methods conform in all

respects to recognized engineering practices.

t = stipulated nominal pipe wall thickness in

mm. D = stipulated outside diameter of pipe

in mm.

7.1 Refrigeration piping shall be understood

to comprise all refrigerant and brine piping,

whenever used and whether erected on the

premise or factory assembled.

7.2 Minimum Design Pressures for

Refrigerant Piping

a. Piping Systems for refrigerants shall be

designed for not less than the pressures given

in Table 11.8.2.1.

b. For refrigerants not listed in Table 11.8.2.1

the design pressure for the high-pressure side

shall be not less than the saturated vapour

pressure of the refrigerant at 54 C (130 F). The

design pressure for the low-pressure side shall

be not less than the saturated vapour pressure of

the refrigerant at 32 C (90 F). For refrigerant not

listed in Table 11.8.2.1 and having a critical

temperature below 54 C (130 F), the design

pressure for the high pressure side shall be not

less than 1.5 times the critical pressure and the

design pressure for the low-pressure side shall

be not less than the critical pressure. In no case

shall be design pressure be less than 270 kPa (39

psig).

c. Piping systems for brine shall be

designed for the maximum pressure which

can be imposed on the system in normal

operation, but not less than 689.5 kPa (100

psig) including for cast-iron pipe, the water

hammer allowance as shown in Table

11.8.2.3.

d. For working temperatures below 18 C (65

F), an allowance for brittleness of castings,

forgings, bolting, and pipe shall be made as

follows:

Cast Iron, Wrought-Iron, and Carbon Steel

ferrous materials shall have the design

pressure including allowance for water

hammer increased 2 percent for each degree

below 18 C (65 F) and shall not be used

below -73 C (-100 F).

Copper, brass, bronze. No adjustment.

7.3 Thickness of Pipe

The minimum thickness of pipe wall required

shall be determined by the following

formula:

Where:

t

m

= minimum pipe wall thickness in mm

C

P S

PD

t

m

+

+

=

8 . 0 2

P = maximum internal service pressure in kPa

(plus allowance for temperatures as provide in

Sec. 11.8.2.4 (7.2.d) and water hammer

allowance for cast-iron pipe as provided in Sec.

11.8.2.3 (7.2.c)). The value of P shall not be

taken at less than 689.5 kPa (100 psig) for any

condition of service or material.

D = outside diameter of pipe in mm

S = allowable stress in material due to internal

pressure, kPa, Table 11.8.3.

C = allowance for threading, mechanical

strength, and/or corrosion, in mm obtained from

the following list.

7.4 Piping of Pressure Relieving Devices

The most important design factor about

pressure relieving devices is the underlying

principle of intrinsic safety. They must fail

safe or not at all. Therefore, the solution to

problems in pressure relied piping must be

based on sound design practices. Because

failure is intolerable, simplicity and

directness of design should be encouraged as

a mass to reliability.

There are at least four good reasons why the

installation of pressure safety valves and disc

should be engineered with care:

a. The inlet and outlet piping can reduce the

capacity of the device below a safe value.

b. The operation of the device maybe

adversely affected to the point where the

opening or closing pressure is altered. In the

case of safety valves, premature leaking or

simmering may occur at pressures less than

the set pressure or chattering may occur after

the valve opens.

c. The reaction thrust at the same time the

device starts to discharge can cause mechanical

failure of the piping.

d. Good design saves maintenance pesos.

7.5 Safety Valve Inlet Piping

In order to operate satisfactorily, a safety

valve must be mounted vertically. It should

be directly on the vessel nozzle or on a short

connection fitting that provides direct and

unobstructed flow between the vessel and

the valve. Safety valves protecting piping

systems should of course be mounted in a

similar manner. The device may never be

installed on a fitting having a smaller inside

diameter than the safety valve inlet

connection.

7.6 Pressure Drop

The pressure drop between the vessel and

safety valve inlet flange should not be so

large that the valve is starved or

chattering will result. The following

limitations are suggested:

a. The pressure drop due to friction should

not exceed 1 percent of the accumulated

relieving pressure.

b. The pressure drop due to velocity head

loss should not exceed 2 percent of the

accumulated relieving pressure.

Some safety valve manufacturer suggested a

maximum total pressure drop of 2 percent of

set pressure. In the absence of test data, it is

recommended that this more conservative

limit be used.

These recommendations are based on a

blowdown of a 4 percent. Within this limits, if

the blowdown setting is increased, the pressure

drop maybe increased proportionately.

Remember however, that pressure lost in the

inlet piping must be taken into consideration

when sizing the safety valve. Pressure loss in the

discharge piping should be minimized by running

the line as directly as possible. Use long-radius

bends and avoid close-up fittings. In no case may

the cross-sectioned area of the discharge pipe be

less than that of the valve outlet.

7.7 Piping Supports

Safety valves, although they may not be

included under heading of delicate

instruments, nonetheless instruments. They

are required to measure within three percent

and to perform a specific control function.

Excessive strain on the valve body adversely

affects its ability to measure and control.

Supports for discharge piping should be designed

to keep the load on the valve to a minimum. In

high temperature service, high loads will cause

permanent distortion of the valve because of

creep in the metal. Even at low temperature,

valve distortion will cause the valve to leak at

pressures lower than the set pressure and result

in faulty operation. The discharge piping should

be supported free of the valve and carefully

aligned so that the forces acting on the valve

will be at minimum when the equipment is under

normal operating conditions. Expansion joints or

long radius bends of proper design and cold

spring should be provided to prevent excessive

strain.

The major stresses to which the discharge

pipe is subjected are usually due to thermal

expansion and discharge reaction forces. The

sudden release of compressible fluid into a

multi-directional discharge pipe produces an

impact load and bourdon effect at each

charge of direction. The piping must be

adequately anchored to prevent sway or

vibration while the valve is discharging.

NOTES:

A. The maximum weight per span is based on

bigger steel pipe size weight full of water

fittings and insulated.

1. The copper tubing and fittings (for

instrument air lines) shall be supported not

more than 5 feet on centers or as shown on the

drawings.

2. Vertical risers shall be supported from the

building construction by means of approved pipe

clamps of U-bolts at every floor. Provide slide

guides for pipes subject to thermal expansion.

Supports shall be of adequate size structural

steel shapes or sections where pipe clamps are

too short to connect to the building.

2. Piping restraints shall be provided to

prevent unnecessary pipe movements due to

vibration and seismic forces and damage to

pipe joints such as cast iron pipe soldered

copper pipes and others as required.

7.8 Reaction Forces

The total stress imposed on a safety valve or its

piping is caused by the sum of these forces:

a. Internal pressure

b. Dead weight of piping

c. Thermal expansion or contraction of either

the discharge line of the equipment upon which

the valve is mounted and

d. The bending moment cause by the reaction

thrust of the discharge.

All of these stresses except the latter are

common to practically every problem in piping

stress analysis.

The magnitude of the reaction force resulting from

the instantaneous release of a compressible fluid

maybe calculated from the two simple formulas given

below.

For safety valve:

For safety disc:

Where:

F

1

= Reaction force, kg

A = Area of valve orifice or disc., sq. Mm.

P

1

= inlet pressure at time of opening, kPa (set

pressure plus 14.7)

K = ratio of specific heats, Cp/Cv

Note: Psi x 6.895 = kPa

( )

1 1

2 . 0 AP K F + =

( )

1 1

2 . 0 63 . 0 AP K F + =

If it is possible for air to be relieved from the

system under special conditions, use a

minimum value of K = 1.4 for design.

Calculation of the reaction force for liquid

service demonstrates that this force is

negligible. However, since it is usually

possible to trap air or gas in any pressure

system, it is recommended that K = 104 be

used in the above formulas as a basis design

for liquid service.

7.9 Compressor Piping

Piping in a compressor circuit should connect

directly point to point; bends instead of

elbows give less friction loss and less

vibration; angular branch connections

eliminate hard tees and give a smoother

flow; double offsets for directional change

should be avoided;

closely integrated intercoolers with the

machine minimizes piping; pulsation

dampeners should be located on the

cylinders without any interconnecting pipe;

knockout drums should be adjacent to the

machine; several aftercoolers or exchangers

in the circuit should be stacked as much as

possible for a direct gas flow; and equipment

in the circuit should be in process flow

sequence.

Because of the ever present vibration

problems of reciprocating compressors, pipe

supports have a very important role in piping

design. Supports independent of any other

foundation or structure is almost mandatory.

Pipe systems nailed down close to grade is

a much preferred arrangement. If badly

designed compressor piping has to be

corrected after start-up of the plant, it can

become very expensive.

INTRODUCTION

Valves are mechanical devices designed to

direct, start, stop, mix or regulate the flow,

pressure or temperature of a process fluid. The

common types of valves available are gate

valves, globe valves, butterfly valves etc. the

materials commonly used for construction are

iron, steel, plastic, brass or a mixture of special

alloys.

According to their function valves may be

classified as on-off valves, non-return valves,

and control valves. The on-off valves are used to

start or stop the flow through the process. Gate

valves and pressure relief valves are examples of

on-off type of valves to mention a few. The non-

return valves allow the fluid to flow in one

particular direction only. The control valves are

used to regulate flow, temperature or pressure

through a system.

ON-OFF VALVES:

GATE VALVES

Gate valves are linear motion valves having a

closure element perpendicular to the process

flow that slides into the main stream to provide

shut off. These are used in low-pressure systems.

The problem with these valves is that they

cannot handle throttling operations, are easily

fouled and cannot be used in systems having

high-pressure drops. It is difficult to obtain tight

shut off with these valves and they take longer

to open or close than any other manual valves.

The different types of gate valves are parallel

gate valves knife edged gate valves and through

conduit gate valves.

BUTTERFLY VALVES

These valves are mainly used as an onoff valve.

It is mainly a rotary motion valve that uses a

rotating round disk as a regulating element.

There are two types of butterfly valves

concentric and eccentric butterfly valves. These

valves can be directly installed in between two

flanges without any special end connections

owing to their very narrow face-to-face

dimensions.

It has a large flow coefficient and due to rotary

motion of shaft the friction forces generated are

far less than a linear motion valve. They have a

high pressure recovery factor. These valves are

used in low pressure applications. Cavitation and

choked flow can occur easily with these valves

when installed in an application with high

pressure drop.

PLUG COCKS AND BALL VALVES

For temperature below 250 C, metallic plug

cocks are useful in chemical process lines. As in

laboratory stopcock, a quarter turn of the stem

takes the valve from fully open to fully closed,

and when fully open, the channel through the

plug may be as large as the inside of the pipe

itself, and the pressure drop is minimal. In a ball

valve the sealing element is spherical, and the

problems of alignment and freezing of the

element are less than with a plug cock.

In both plug cocks and ball valves the area of

contact between moving element and the seat is

large, and both can therefore be used in

throttling service. Ball valves find occasional

application in flow control.

NON RETURN (CHECK) VALVES

Non-return valves allow the fluid to flow only in

the desired direction. The design is such that any

flow or pressure in the opposite direction is

mechanically restricted from occurring. All check

valves are non return valves.

Non return valves are used to prevent back flow

of fluids, which could damage equipment or

upset the process. Such valves are especially

useful in protecting a pump in a liquid

application or compressed gas applications from

back flow when pump or compressor is shut

down . Non return valves are also used in process

systems that have varying pressure which must

be kept separate.

There are two types of check(non-return) valves,

swing types and spring types.

In the swing type, the pressure of the water

forces the valve gate to 'swing' open, but once

the flow stops, gravity causes the gate to fall

closed , preventing a reversal of the flow. This

type of valve must be mounted vertically or

horizontally to work properly.

In contrast, the gate in a spring check valve is

spring loaded. Water pressure forces the gate

open just as in the swing type, but when the

flow stops, the spring, not gravity, forces the

gate closed. This enables the valve to be

mounted in any position and at any angle..

GLOBE VALVES

A globe valve is a linear motion valve

characterized by a globe style body with a long

face to face dimension that accommodates

smooth, rounded flow passages sufficiently long

enough to ensure smooth flow through the valve

without any sharp turns. These valves can be

used in both gas as well as liquid applications

and can handle severe conditions of temperature

and pressure.

The majority of the globe valves have a top

entry design thus permitting a easier servicing of

the internal parts and allowing the valves to

remain in line when maintenance is taking place.

But these valves have certain disadvantages also.

They have a high cost and a large size factor and

cannot be used for unclean liquids. They are

mainly used for flow control and in cases

involving vacuum or high temperature extremes.

SOLENOID VALVE:

Solenoid valves are best suited for small, short-

stroke on-off operations requiring very high

speed of response. These valves can open or

close in 8 to 12 milliseconds. However, they are

limited to pressure drops below 20.7 bars

although when pivoted with pilot levers or

double seats, they can handle higher pressure

drops. A solenoid valve contains a valve body, a

magnetic core attached to the stem and disc,

and a solenoid coil. A small spring assists the

release and initial closing of the valve. The valve

is electrically energized to open.

When an electrical signal is input to a solenoid

valve (magnetic changeover valve), the drawing

force of the solenoid moves the spool, changing

the direction of flow. Because the electrical

signal is switched at the valve, remote control

and automatic control are simple. Stronger

springs are used to overcome the friction of the

packing when it is required. Reversing the valve

plug causes reverse action (open when de-

energized). These valves are quite expensive.

Bellow Seal Valve

Bellow seal valves are a special type of globe

valves which are used for fine control of flow.

The main difference between the ordinary globe

valves and the bellow seal valve is that in the

globe valve there is gland packing along the stem

but in the bellow seal valve, a bellow is used to

prevent leakage instead of the packing. Bellow

seal valves are totally leak-proof. They are used

to handle corrosive liquids. This type of valve

has been used in the butadiene extraction unit.

MATERIAL OF CONSTRUCTION OF VALVES

The selection of the valve body material is

usually based on pressure, temperature,

corrosive properties and erosive properties of

the flow media. Also the choice of the materials

depends on economic factors. Majority of control

valves involve non corrosive fluids at reasonable

temperatures and pressure. Therefore cast iron

and cast carbon steel are most commonly used

valve body materials.

The purpose of the pipe schedule standards

is for all industries that use pipes to use the

same standards. Pipe schedules are a means

of categorizing pipe and identifying the

strengths and characteristics of its

capabilities. For all pipe sizes and outside

diameter (O.D.) remains relatively constant.

The variations in wall thickness affects only

the inside diameter (I.D.).

Pipe schedule is an American definition to

define pipe thickness and how much pressure

can the pipe stand. The most commonly used

schedules today are 40, 80, and 160. There is

a commonly held belief that the schedule

number is an indicator of the service

pressure that the pipe can take.

The Iron pipe size (IPS) is an older system

still used by some manufacturers and legacy

drawings and equipment. The IPS number is

the same as the NPS, but the schedules were

limited to Standard Wall (STD), Extra Strong

(XS), and Double Extra Strong (XXS). STD is

identical to SCH 40 for NPS 1/8 to NPS 10,

inclusive, and indicates 0.375 wall thickness

for NPS 12 and larger. SX is identical to SCH

80 for NPS 1/8 to NPS 8, inclusive, and

indicates 0.500 wall thickness for NPS 8 and

larger. Different definitions exist for XXS, but

it is generally thicker than schedule 160.

Industrial pipe thickness follow a set

formula, expressed as the schedule

number as established by the American

Standard Association (ASA) now re-organized

as ANI the American National Standard

Institute. Eleven schedule number are

available for use: 5, 10, 20, 30, 40, 60, 80,

100, 120, 140, & 160.

A schedule number indicate the

approximate value of

Sch. No. = 1000P/S

Where

P = service pressure (psi)

S = allowable stress (psi)

The higher the schedule number is, the

thicker the pipe is. Since the outside

diameter of each pipe size is standardized, a

particular nominal pipe size will have

different inside pipe diameter depending on

the schedule specified.

Welded and Seamless Wrought Steel Pipe

To distinguish different weights of pipe. It is

common to use the Schedule terminology

from ANSI/ASME B36.10 Welded and Seamless

Wrought Steel Pipe:

Light Wall

Schedule 10 (Sch/10, S/10)

Schedule 20 (Sch/20, S/20)

Schedule 30 (Sch/30, S/30)

Schedule 40 (Sch/40, S/40)

Standard Weight (ST, Std, STD)

Schedule 60 (Sch/60, S/60)

Extra Strong (Extra Heavy, EH, XH, XS)

Schedule 80 (Sch/80, S/80)

Schedule 100 (Sch/100, S/100)

Schedule 120 (Sch/120, S/120)

Schedule 140 (Sch/140, S/140)

Schedule 160 (Sch/160, S/160)

Double Extra Strong (Double extra heavy,

XXH, XXS)

Note that many of the schedules are

identical in certain sizes.

Stainless Steel Pipe

For stainless steel pipe thru 12-inch,

schedule numbers from Schedule 5S to

schedule 80S are used as published in

ANSI/ASME 36.19M Stainless Steel Pipe.

Schedule 5S (Sch/5S, S/5S)

Schedule 10S (Sch/10S, S/10S)

Schedule 40S (Sch/40S, S/40S)

Schedule 80S (Sch/80S, S/80S)

Copper pipe and tube comes in a variety of

types, with different wall thicknesses,

ductility and intended used. The difference

between copper pipe and copper tube is the

the way the diameter of the pipe is

measured. Copper tube is measured by

outside diameter (OD) whereas copper pipe

is measured by inside diameter (ID).

Depending on the plumbing job you are

doing, local and national plumbing codes will

dictate which type of copper pipe is

acceptable.

Type L copper pipe

Type L copper pipe and tube has a thicker

wall than type M and DWV pipes making it

the preferred choice for longevity. There are

two kinds of type L; Hard, and soft temper.

Type L will be marked with blue along the

pipe or tubing.

Hard temper type L plumbing applications

include:

Above ground water distribution

Above and below ground drainage and venting

systems

Building sewer

Soft temper type L plumbing applications

include:

Water service pipe

Water distribution above and below ground

Type M copper pipe

Type M copper pipe and tubing is commonly

used in residential plumbing because it has

thin walls and can be produced and sold at a

much lower cost. For water distribution

longevity type M is not recommended. Type

M copper is also better for heating

applications because of the thin wall

thickness. Type M is identified with RED

markings along the pipe.

Hard temper type M plumbing applications

include:

Above ground water distribution

Above ground drainage systems

Soft temper type M shall not be used in

plumbing systems.

Type K copper pipe

Type K copper pipe and tube is the most

robust of the four types because it has the

largest wall thickness. Type K comes in hard

and soft temper and will be identified by

green markings. Type K copper can be used

for many other applications such as: Fuel,

gasses, HVAC, fire protection systems and

vacuum systems to name a few.

Hard temper type K plumbing applications

include:

Above ground water distribution

Above and below ground drainage and venting

systems

Building sewer

Soft temper type K plumbing applications

include:

Water service pipe

Water distribution above and below ground

DWV copper pipe

DWV copper pipe is used for drainage waste

and vent (DWV), above ground only and is

identified by yellow markings.

1. Determine the specifications of material

and wall thickness for a 12 in pipe to carry

steam at a state selected from the following:

(a) 425 psig, 600 F; (b) 400 psig, saturated;

(c) 1275 psig, 950 F

(d) 850 psig, 850 F.

2. Would Schedule 120, 8 in pipe made to

A53-SA Specification be acceptable on a line

operating at 250 psig, 750 F?

3. Specify the pipe required to carry

600,000 lb steam per hr at 1255 psig, 1000 F,

with velocity approximating 10,000 fpm.

4. What maximum working pressure is

advisable in an 18 in OD, Schedule 40 pipe

A53-SA, operations not to exceed 450 F?

You might also like

- General Piping and ValvesDocument184 pagesGeneral Piping and ValvesChiheb KaanicheNo ratings yet

- Pipe Fittings PDFDocument164 pagesPipe Fittings PDFjlvega18No ratings yet

- Piping Fundamentals for EngineersDocument29 pagesPiping Fundamentals for Engineersmaneeshmsanjagiri100% (2)

- How To Select The Correct Valve For Wastewater Treatment Applications PDFDocument2 pagesHow To Select The Correct Valve For Wastewater Treatment Applications PDFNicat MammadovNo ratings yet

- Piping Fittings: Elbows or EllsDocument17 pagesPiping Fittings: Elbows or Ellsleading_aliNo ratings yet

- Pipes FittingsDocument37 pagesPipes Fittingsanand bandekarNo ratings yet

- Ductile Iron Fittings & Specials - by NeoDocument59 pagesDuctile Iron Fittings & Specials - by NeoSomu DahiyaNo ratings yet

- Scope of Work For Various Valve ServicingDocument3 pagesScope of Work For Various Valve ServicingSreekanthMylavarapu100% (1)

- Cci Valve 100DSVDocument8 pagesCci Valve 100DSVyg89No ratings yet

- 6.6 Control Valve Actuators and Positioners PDFDocument20 pages6.6 Control Valve Actuators and Positioners PDFdanpolymathNo ratings yet

- LT Pipeline Ball ValvesDocument19 pagesLT Pipeline Ball ValvessiswoutNo ratings yet

- Orifice Flowmeter Straight RunDocument4 pagesOrifice Flowmeter Straight RunMuhammad ImranNo ratings yet

- NTPC Project ReportDocument31 pagesNTPC Project ReportDeepak Ranjan ParidaNo ratings yet

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- Steam System of Power PlantDocument34 pagesSteam System of Power PlantEjaz AhmedNo ratings yet

- Orbit Valve - BrochureDocument12 pagesOrbit Valve - BrochureMohamed MeeranNo ratings yet

- Topic 1 Valve and Instrumentation SymbolsDocument8 pagesTopic 1 Valve and Instrumentation SymbolshatiniNo ratings yet

- Pressure Rating PDFDocument4 pagesPressure Rating PDFMohamed AdelNo ratings yet

- KF Check-Valves PDFDocument24 pagesKF Check-Valves PDFTaylor RamirezNo ratings yet

- Process Valv HandbookDocument14 pagesProcess Valv Handbookdenim89No ratings yet

- Guide To Design and Selection of Check Valves PDFDocument18 pagesGuide To Design and Selection of Check Valves PDFNareshNo ratings yet

- Flowserve Erpn PDFDocument8 pagesFlowserve Erpn PDFJaluk 1zinNo ratings yet

- Reaching 10,000+ Likes on Our Chemical Engineering Facebook PageDocument103 pagesReaching 10,000+ Likes on Our Chemical Engineering Facebook Pageebin_thankachan1988No ratings yet

- Guide To Steam Tracing and Condensate CollectionDocument34 pagesGuide To Steam Tracing and Condensate CollectionRAMNo ratings yet

- Weicco - Flexible ConnectorDocument2 pagesWeicco - Flexible ConnectorSundar RamasamyNo ratings yet

- Buttweld Fittings Accesorios SoldadosDocument5 pagesButtweld Fittings Accesorios SoldadosJuan CadenaNo ratings yet

- Piping NotesDocument33 pagesPiping NotesSyed FarhanNo ratings yet

- Project Standards and Specifications Piping Materials Rev01webDocument12 pagesProject Standards and Specifications Piping Materials Rev01webroy_b200933% (3)

- Pipes Spec & Pipe ClassDocument19 pagesPipes Spec & Pipe Classryo asg5No ratings yet

- Pipe Components PDFDocument179 pagesPipe Components PDFmatevzartacNo ratings yet

- Piping Design (Revised)Document22 pagesPiping Design (Revised)Yash PatelNo ratings yet

- Screwed Fitting - An Overview - ScienceDirect Topics PDFDocument47 pagesScrewed Fitting - An Overview - ScienceDirect Topics PDFSoran Salam Awlla100% (1)

- Basics of Pipe For Oil & Gas EngineerDocument12 pagesBasics of Pipe For Oil & Gas EngineerMannuddin KhanNo ratings yet

- Valves - Standard and Automatic Process ControlDocument90 pagesValves - Standard and Automatic Process ControlmordidomiNo ratings yet

- 2007 Catalog Constant SpringDocument36 pages2007 Catalog Constant Springinfo592No ratings yet

- Piping Components Classification GuideDocument45 pagesPiping Components Classification Guideindika sunarkoNo ratings yet

- 07 ValvesDocument33 pages07 Valvesshiva_ssk17No ratings yet

- L&T Cast Steel Gate, Globe & Check Valves Product CatalogDocument24 pagesL&T Cast Steel Gate, Globe & Check Valves Product Catalogaaa100% (1)

- Isometric Symbol KeysDocument91 pagesIsometric Symbol KeysAldo88% (17)

- Flange FacingDocument6 pagesFlange FacingDurjoy ChakrabortyNo ratings yet

- Implementation of Expansion LoopsDocument13 pagesImplementation of Expansion LoopsSSSNo ratings yet

- Pressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientDocument9 pagesPressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientRapee PuaksungnoenNo ratings yet

- Wavin PE Pressure Pipes Data SheetDocument2 pagesWavin PE Pressure Pipes Data SheetConspiracy_PTNo ratings yet

- Pipe RoutingDocument4 pagesPipe RoutingJaykumarNo ratings yet

- Piping Presentation MasterDocument61 pagesPiping Presentation MasterQC NGUYEN100% (2)

- Process Piping Fundamentals, Codes and Standards: Course No: M05-023 Credit: 5 PDHDocument5 pagesProcess Piping Fundamentals, Codes and Standards: Course No: M05-023 Credit: 5 PDHRaakze Movi100% (1)

- Session I - II - Power Cycle Piping PDFDocument122 pagesSession I - II - Power Cycle Piping PDFHema NandhNo ratings yet

- Chapter 11 FINAL NA I2Document9 pagesChapter 11 FINAL NA I2Kwinn EspinosaNo ratings yet

- Lecture 8 Plumbing MaterialsDocument49 pagesLecture 8 Plumbing Materialspepito manalotoNo ratings yet

- Pipe and Pipe JointsDocument11 pagesPipe and Pipe Jointsنور جمال عبدالحليمNo ratings yet

- Unit - II: Environmental Engineering-I: TopicDocument53 pagesUnit - II: Environmental Engineering-I: Topicbharatiya technologyNo ratings yet

- Chapter No.6: Design of Heat ExchangerDocument35 pagesChapter No.6: Design of Heat ExchangerGlacier RamkissoonNo ratings yet

- Piping DesignDocument122 pagesPiping Designfacebookshop100% (9)

- Air-Cooled Heat Exchangers Fin-Fan: by M.M.SorourDocument64 pagesAir-Cooled Heat Exchangers Fin-Fan: by M.M.SorourNader GaafarNo ratings yet

- Plumbing Fitting Joints and FixtureDocument61 pagesPlumbing Fitting Joints and FixtureManjeet Cingh100% (1)

- Lab Session PDFDocument101 pagesLab Session PDFMuhammad Toseef ChohanNo ratings yet

- A Fitting: Pipe Tubing FluidDocument7 pagesA Fitting: Pipe Tubing FluidAliNo ratings yet

- Copper Water PipingDocument2 pagesCopper Water PipingNabil Rameh0% (1)

- Introduction to Piping SystemsDocument9 pagesIntroduction to Piping SystemsMohamed Al-OdatNo ratings yet

- Everything About Pipes in 38 CharactersDocument8 pagesEverything About Pipes in 38 CharactersMohit BauskarNo ratings yet

- Un 3790-44Document8 pagesUn 3790-44facebookshopNo ratings yet

- Process Piping Welding T-IDocument188 pagesProcess Piping Welding T-IfacebookshopNo ratings yet

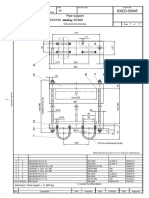

- KXEO-00045: CSC010A 25/460 Pipe SupportDocument1 pageKXEO-00045: CSC010A 25/460 Pipe SupportfacebookshopNo ratings yet

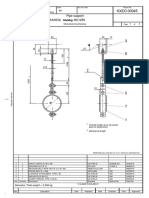

- HAX053A 80/1250 Pipe Support: KXEO-00045Document1 pageHAX053A 80/1250 Pipe Support: KXEO-00045facebookshopNo ratings yet

- Prediction of Standard Pipe PressureDocument5 pagesPrediction of Standard Pipe PressurefacebookshopNo ratings yet

- Pde Pip G00 Ec 0137 000 00 DPP 1Document3 pagesPde Pip G00 Ec 0137 000 00 DPP 1facebookshopNo ratings yet

- Un 3790-33Document10 pagesUn 3790-33facebookshopNo ratings yet

- Un 3790-41Document14 pagesUn 3790-41facebookshopNo ratings yet

- Un 3790-39Document8 pagesUn 3790-39facebookshopNo ratings yet

- Pressure Vessel Design CalculationsDocument127 pagesPressure Vessel Design Calculationsajayghosh314086% (22)

- Un 3790-31 PDFDocument9 pagesUn 3790-31 PDFfacebookshopNo ratings yet

- Practical Piping CurseDocument46 pagesPractical Piping Cursemsaad2100% (1)

- Un 3790-31 PDFDocument9 pagesUn 3790-31 PDFfacebookshopNo ratings yet

- 1.standard Drawing R01 PDFDocument1,690 pages1.standard Drawing R01 PDFfacebookshopNo ratings yet

- Metric Properties of Structural Shapes - AISCDocument52 pagesMetric Properties of Structural Shapes - AISCalmeteck100% (7)

- Stainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Document5 pagesStainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Utada HikaruNo ratings yet

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- Piping Training CourseDocument446 pagesPiping Training CoursefacebookshopNo ratings yet

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- Piping DesignDocument122 pagesPiping Designfacebookshop100% (9)

- Procedures of Plant Layout N Piping-RILDocument123 pagesProcedures of Plant Layout N Piping-RILfacebookshopNo ratings yet

- Piping SpecificationsDocument10 pagesPiping SpecificationssmithallenNo ratings yet

- Piping Application GuideDocument36 pagesPiping Application GuidefacebookshopNo ratings yet

- Piping and Pipe Support SystemsDocument178 pagesPiping and Pipe Support Systemssaisssms9116No ratings yet

- Pipeline BasicsDocument12 pagesPipeline Basicsgerrydl100% (2)

- Part 1 Piping SystemsDocument22 pagesPart 1 Piping SystemsfacebookshopNo ratings yet

- Maximum Piping Operating PressureDocument8 pagesMaximum Piping Operating PressurefacebookshopNo ratings yet

- SAE Flanges PDFDocument55 pagesSAE Flanges PDFG.SWAMI100% (2)

- Flange TypesDocument1 pageFlange TypesHadi UtomoNo ratings yet

- Membrane Element CPA2-4040: PerformanceDocument1 pageMembrane Element CPA2-4040: Performancecarlos pachecoNo ratings yet

- Rapport Esi SuwaDocument233 pagesRapport Esi SuwaEzzadin BabanNo ratings yet

- Heating and Cooling With Ground-Source Heat Pumps in Moderate and Cold Climates, Two-Volume Set 1Document397 pagesHeating and Cooling With Ground-Source Heat Pumps in Moderate and Cold Climates, Two-Volume Set 1Pavan Kalyan0% (1)

- How CCPPs Work to Generate Power EfficientlyDocument11 pagesHow CCPPs Work to Generate Power EfficientlyPGPalomaNo ratings yet

- Marine Bilge Water Treatment SystemDocument11 pagesMarine Bilge Water Treatment Systemrobjsimon100% (3)

- Safety Data Sheet: 1. IdentificationDocument15 pagesSafety Data Sheet: 1. IdentificationSaeed FNo ratings yet

- Case Study Mundra Thermal PlantDocument13 pagesCase Study Mundra Thermal PlantParth GhanekarNo ratings yet

- Tugas Alkohol 1 (3 Kelompok)Document39 pagesTugas Alkohol 1 (3 Kelompok)Galuh Eka WulandariNo ratings yet

- Microsoft PowerPoint - Open-Channel 1Document63 pagesMicrosoft PowerPoint - Open-Channel 1Eng Bagaragaza RomualdNo ratings yet

- Checklist ISO 22000 PDFDocument21 pagesChecklist ISO 22000 PDFkimkos2014No ratings yet

- List of Environmental DisastersDocument7 pagesList of Environmental DisastersCerise FranciscoNo ratings yet

- HIDRAULICA DE CANALES ABIERTOS - Editado-WordDocument87 pagesHIDRAULICA DE CANALES ABIERTOS - Editado-WordLuis Zambrana0% (1)

- Eor Potential For Dulang FieldDocument8 pagesEor Potential For Dulang FieldnikenanthaNo ratings yet

- 16AGS - Groundwater Control in Design and Construction of Deep Basement Excavation in Singapore (150910)Document15 pages16AGS - Groundwater Control in Design and Construction of Deep Basement Excavation in Singapore (150910)krainajackaNo ratings yet

- Application of Radiation and Radioisotopes in BiotechnologyDocument7 pagesApplication of Radiation and Radioisotopes in Biotechnologyraanja2No ratings yet

- Sample - MapDocument3 pagesSample - MapAnh ThảoNo ratings yet

- The Rise of Antibiotic-Resistant Infections: A Warning from Canada's Cod CollapseDocument8 pagesThe Rise of Antibiotic-Resistant Infections: A Warning from Canada's Cod CollapseRavi ZaiminNo ratings yet

- Echnology Rief: Autoclaved Aerated Concrete Masonry UnitsDocument4 pagesEchnology Rief: Autoclaved Aerated Concrete Masonry UnitsJayakumar AnanthaNo ratings yet

- Definition of Terms:: Harvesting MethodsDocument5 pagesDefinition of Terms:: Harvesting MethodsHero DiasNo ratings yet

- Sampling and Analysis Plan for DOE Legacy SitesDocument224 pagesSampling and Analysis Plan for DOE Legacy SitesCharmi HediNo ratings yet

- Soil Stabilization: With PolyurethaneDocument26 pagesSoil Stabilization: With Polyurethanedilaalvi100% (1)

- AC Generator Manual Safety PrecautionsDocument65 pagesAC Generator Manual Safety PrecautionsDadung PrakosoNo ratings yet

- Sevilla ProcessDocument4 pagesSevilla ProcessIrem KocaturkNo ratings yet

- Ballast Water Reporting FormDocument2 pagesBallast Water Reporting FormanilNo ratings yet

- Jgl710 30 CondenserDocument37 pagesJgl710 30 CondenserVaibhav SarinNo ratings yet

- Ship Hull Coatings PDFDocument36 pagesShip Hull Coatings PDFNur Hidayatul Nadhirah75% (4)