Professional Documents

Culture Documents

ISO Numero Control Contaminacion

Uploaded by

Octavio MoralesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO Numero Control Contaminacion

Uploaded by

Octavio MoralesCopyright:

Available Formats

TC Training 2005

TC Training 2005

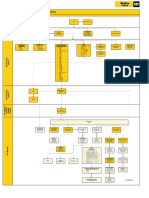

Providing World-Class

Dealer Support

Undercarriage Service Training

Service Tooling Training

Tooling & Process Development

Undercarriage Shop Reviews

Service Information

Technical Consultation

Train Dealers to identify salvageable

parts using scrap-barrel analysis

Undercarriage

Hydraulics & CHS,

Contamination Cleaning

Custom Hydraulic Service Program

Hydraulic Components Repair Training

Dealer Shop/Operations Reviews

Parts Reuse and Salvage

Contamination Control Guidelines

Pump and Motor Testing

Hose & Coupling Assembly Training

Train Dealers to identify salvageable

parts using scrap-barrel analysis

Applied Failure Analysis

Teaches a Logical, Fact-Based

Method of Analyzing Product

Failures

Determines the Problems Root

Cause

Reduces Repetitive Failures

Reduces Repair Costs

Increases Customer Satisfaction

Consulting Services

Repair Process

Engineering

Drive Train & Metal Restoration

Drive Train Support

Transmission Test Procedures

Thermal Spray Technology

High Velocity Oxygen Fuel

(HVOF) Technology

Arc Spray Technology

Abrasion Resistant Material

Train Dealers to identify salvageable

parts using scrap-barrel analysis

Engine Rebuild

Facility Planning & Development

Engine Component Reuse &

Salvage Guidelines

Provide Dealer Training on Engine

Repair Processes

Train Dealers to identify salvageable

parts using scrap-barrel analysis

Site Concepting

Cost Estimates

Sizing Studies

Location

Management

Implementation

Bar Coding /

RF Technology

Implementation

Detailed Facility Design

Specialized Repair Areas

Bin Sizing Analysis

Warehouse Layouts

Customer Equipment

Maintenance Facility

TC Training 2005

Pump and Motor

Bench Test Procedures

TC Training 2005

Where Available

SEBF8810 New Pump, Motor and Cylinder Testing Manual

Available by subscription only.

SIS Web

Bench Test Procedures

Example (992G, S/N: ADZ)

TC Training 2005

TC Training 2005

Transmission

Bench Test Procedures

TC Training 2005

Where Available

SEBF8760 Transmission, Torque Converter & Relief Valve

Test Bench Procedures

Available by subscription only

SIS Web

Bench Test Procedures

Example (992G, S/N: ADZ)

TC Training 2005

TC Training 2005

Reuse and Salvage

Guidelines

TC Training 2005

Where Available

SEBF8000 Guideline for Reusable Parts Library

SEBF8029 Index of Reusability & Salvage Publications

SEBF8052 Automatic Subscription List

SIS Web

Example (D11R, S/N: AAF)

TC Training 2005

Arc Spraying a OHT Rear Spindle

Bearing Journals

Use Again

Do Not Use Again

TC Training 2005

Undercarriage

Reconditioning Bulletins

https://sis.cat.com/sisweb/servlet/cat.cis.sis.PController.CSSISMainS

ervlet

TC Training 2005

Where Available

SEBF8599 Undercarriage Reconditioning Guide

Available by subscription only

SERF8890 Undercarriage Service CD

Available by subscription only

SIS Web

Undercarriage Reconditioning

Guide

Example (D11R, S/N: AAF)

TC Training 2005

Contamination

Control Guidelines

TC Training 2005

Where Available

SIS Web

Contamination Control Guidelines

Example (992G, S/N: ADZ)

TC Training 2005

TC Training 2005

The training covers hydraulics from basics

to testing. Both web based & instructor led

curriculums are offered.

Training includes:

Basic hydraulics Hydraulic information systems

D&A procedures Parts reuse & failure analysis

Work processes Contamination Control

Component testing

Hose & Coupling training improves dealer

technician assembly skills, efficiency,

quality, and opens market focus through

part identification and application. The

training includes classroom & lab

instruction and provides:

Hose & Coupling identification

CAT-approved hose assembly

procedures

Reference material availability

New products & tooling review

Machine operator safety

Hydraulic Technician Training Hose & Coupling Training

Test Bench Training

Bench Testing ensures correct assembly and

operation of the component. This allows the dealer

to ensure that the component will operate properly

in the machine. The training includes on-site test

bench instruction and provides:

Efficient Test Bench Development

Up-to-Date Test Methods

Field/Lab Validated Test Procedures

Engine Repair Process Training

Engine Repair Process Training provides

dealers with up-to-date information on the

processes and procedures used for the

reuse and salvage of used engines and

their components. The training helps the

technician to identify salvageable parts

using scrap-barrel analysis.

Undercarriage Service Training

Undercarriage Service Training provides a four-day

course that covers servicing rollers, idlers, and track,

as well as roller and idler welding. This training class

offers the following:

Classroom instruction on recommended processes

and procedures

Hands-on application of instruction

Production facility tours to verify methods and

processes

Reuse & Salvage Training

Reuse & Salvage Training covers all

components of CAT equipment. It enables

the technician to determine whether or not

the parts are reusable during repair/rebuild

procedures. The training offers the

following:

Modules that are created from a

global perspective

Discusses the different failure

modes

Applied Failure Analysis Training

AFA teaches a logical, fact based method of

analyzing product failures to determine the root cause

of the problem.

This training reduces repetitive failures, reduces

repair costs, and increases product availability.

TC Training 2005

Additional Training Classes

Schedule through the Global Manpower Development (DLMS) Web

Site:https://dlms.logicbay.com/dlms/login/landing.jsp

Hose and Coupling Assembler Training

Pump and Motor D&A and Parts Reuse I (Rexroth A2, A4, A8, A11 Models)

Pump and Motor D&A and Parts Reuse II (Caterpillar Proprietary and Sauer

Danfoss Series 46 & 90)

Test Bench Training (Schematics & Pump Operation/Testing)

Undercarriage Service Training

Applied Failure Analysis Training

For the following training contact Dave Haney, in Repair Process Engineering,

at 309-636-5941. There is no set curriculum and the training is tailored for the individual

dealer needs.

Engine Repair Process Training

Reuse & Salvage Training

TC Training 2005

TC Training 2005

Shop Reviews

Hydraulic Shop

Reviews

Rob Aldrich

Dealer Service Shop

Reviews

Dave Haney

Machine Shop

Reviews

-Dave Haney

Undercarriage Shop

Reviews

Doug Thacker

TC Training 2005

Facility Planning and Development

Facility Layouts and Design

Contacts

Mike Rabe

https://dealer.cat.com/cda/layout?m=422598&x=7

TC Training 2005

Section 8

04/08 (1)

Facility Planning and Development

TC Training 2005

Sources For Help Self-Help Sources

8-2

Cat Facility Planning Web Site

Facility Planning Questionnaires

Available from Facility Planning Web Site

Cat Facility Planning Guide

Available upon request

Web-Based E-Learning Module

Dealers local & regional Caterpillar offices

TC Training 2005

TC Training 2005

TC Training 2005

Anything in a fluid that doesnt belong

The #1 enemy of fluid systems

What is Contamination?

TC Training 2005

Effects of Contamination

Hydraulic System experts attribute

75 to 85%

of all component failures to particle contamination in the

fluid and not a weakness in the system components.

-- Hydraulics & Pneumatics, June 2005

-- Equipment Today, August 1997

TC Training 2005

Under 40 Microns

40 Microns & Larger

Two Types of Contamination

TC Training 2005

Design

Manufacturing & Assembly

New Fluids

Machine Operation

Maintenance and Service

Sources of Contamination

TC Training 2005

What is a Micron?

1 Millionth of a Meter

100 microns (m) - grain of table salt

80 microns (m) - diameter of a

human hair

TC Training 2005

Cat Hydraulic

System Clearances

MICRONS

(m)

5

30

40

80

Smallest

Visible

to the Eye

Human Hair

Particles You Cant See Are Harmful!

Pamas

2: 18032

5: 2036

10: 754

15: 155

20: 92

25: 36

50: 2

100: 1

TC Training 2005

ISO Cleanliness Code

Explained in ISO Standard 4406

Expressed Amount of Contamination in one mL of Fluid

2m / 5m / 15m

TC Training 2005

X

Y

First number represents number of particles

equal to or greater than 5 microns

Second number represents number of particles

equal to or greater than 15 microns

Why were these sizes selected?

>5 micron particles indicate wear particles

that cause "silting" or clogging of oil flow

>15 micron particles indicate the presence of

wear and potential early failure

Metrics

TC Training 2005

ISO Code

23

22

21

20

19

18

17

16

15

14

13

12

11

ISO Code Chart

Pamas

ID: Hydro Oil

3/16/02 21/18/14

2: 18032

5: 2036

10: 754

15: 155

20: 92

25: 36

50: 2

100: 1

Number of Particles / mL

40,000 - 80,000

20,000 - 40,000

10,000 - 20,000

5000 - 10,000

2500 - 5000

1300 - 2500

640 - 1300

320 - 640

160 - 320

80 - 160

40 - 80

20 - 40

10 - 20

Dirty

Clean

Cleaner

TC Training 2005

Non-Pressurized, Non-Filtered Compartments

Target To Be Established

Recommended Cleanliness Targets

Fill Oil .... ISO16/13

Hydraulic Systems (Implement & Steering)..... ISO18/15

Hydraulic Oil Extension IRM # FLU01-02... PELE0824

Transmission Systems

Electronic ..ISO18/15

Mechanical Transmissions.. ISO21/17

Component Rebuild

Engines (Roll-off) ....Pending.. ISO18/15

Transmission, Pumps, Governors Etc .... ISO16/13

Fuel ??? ISO18/16/13

Injector Testing Equipment Calibration Fluid.. ISO15/13

TC Training 2005

How Much of a Difference Will Cleaning Your Oil from

ISO 21/17 to ISO 16/13 Really Make?

32 GPM Pump Working 8 Hours / day for 200 Days

Example:

?

Contamination Control

TC Training 2005

(.52 or 2.08 or 16.64)mg/L x 3.785 L/gal x 32 GPM = 93.3 mg/min

x 60 min/hr x 8 hr/day for 200 days/year =

193,481,933 mg/year divided 1000 mg/gal divided 454 gal/lb =

Amount of Dirt Flowing

Amount of Dirt in Oil Through Pump in One Year

ISO 21/17

ISO 18/15

ISO 16/13

426.2 lb/yr

53.2 lb/yr

Contamination Control

13.3 lb/yr

TC Training 2005

Dirt Samples

TC Training 2005

Pump Manufacturer

Component Life Over Time

C

o

n

t

a

m

i

n

a

t

i

o

n

ISO

22/19

21/17

20/15

19/16

18/15

17/14

16/13

15/12

14/11

13/10

12/09

----

------------

-----

Clean New Oil

Component Life

10,000

2,500

25,000

TC Training 2005

Batu Hijau

Newmont

Indonesia

18,000hrs

4000hr Oil

Chg

13,000hrs

1200hr Oil

Chg

TC Training 2005

Thank You

Any Questions?

You might also like

- Sebd0809 02 01 AllDocument68 pagesSebd0809 02 01 AllMiguel Gutierrez100% (1)

- Cat Hydraulic Systems Management GuideDocument16 pagesCat Hydraulic Systems Management GuideSetiawan Tuhu BasukiNo ratings yet

- Komatsu AfterMarket - E PDFDocument6 pagesKomatsu AfterMarket - E PDFtehsintariqNo ratings yet

- Recommended Free Courses Caterpillar UniversityDocument3 pagesRecommended Free Courses Caterpillar Universityمعلومة على الماشىNo ratings yet

- Hydraulic Shovel Vs Wheel Loader - September 2006Document71 pagesHydraulic Shovel Vs Wheel Loader - September 2006Jacques Van NiekerkNo ratings yet

- Pedp7028 02Document20 pagesPedp7028 02atulnalawade1980No ratings yet

- D10R - AKT - Hose Management Guide PDFDocument43 pagesD10R - AKT - Hose Management Guide PDFAla Eddine BarhoumiNo ratings yet

- TDTO Pehp7506Document4 pagesTDTO Pehp7506ngilaNo ratings yet

- Oil Sampling IntervalsDocument3 pagesOil Sampling IntervalsshivNo ratings yet

- Hydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionDocument24 pagesHydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionMiguel Angel RodriguezNo ratings yet

- TA-2 Visual & Technical Inspection for Skid Steer LoadersDocument17 pagesTA-2 Visual & Technical Inspection for Skid Steer LoadersHebert TrujilloNo ratings yet

- 793 793b 793cDocument8 pages793 793b 793cJulio Elias Mayta RamosNo ratings yet

- Dealer Repair Options Webinar 12-15Document38 pagesDealer Repair Options Webinar 12-15Henry Monteagudo100% (1)

- 385C Cat Vs 385B CatDocument69 pages385C Cat Vs 385B CatKolo BenduNo ratings yet

- Business Awareness: Student GuideDocument62 pagesBusiness Awareness: Student GuidePutra JawaNo ratings yet

- Diagnostico y TroubleshootingDocument40 pagesDiagnostico y Troubleshootinggabriel pacovilca arhuataNo ratings yet

- Earth Moving MachineDocument29 pagesEarth Moving Machinejillianix100% (1)

- PSSR ToolsDocument34 pagesPSSR Toolseng100% (2)

- Hydraulic Excavator OverhaulsDocument3 pagesHydraulic Excavator OverhaulsLody100% (1)

- PEO002 - SGD - V4 (Customer Relation)Document50 pagesPEO002 - SGD - V4 (Customer Relation)Jela ParadiseNo ratings yet

- 345B II Prod Bulletin (TEJB6083)Document24 pages345B II Prod Bulletin (TEJB6083)suwarjitechnic100% (1)

- Service Courses - Final VersionDocument1 pageService Courses - Final VersionDanuth Yashantha IllukkumburaNo ratings yet

- Level 1 Rebearing/Reseal: Provides New Component Life Guaranteed Price Reduces Costs Reduces DowntimeDocument2 pagesLevel 1 Rebearing/Reseal: Provides New Component Life Guaranteed Price Reduces Costs Reduces DowntimeAbdelbagiNo ratings yet

- Machine Profiles: D10R Track-Type TractorsDocument5 pagesMachine Profiles: D10R Track-Type TractorsJavier Pagan TorresNo ratings yet

- 005 - Cat-6060 - Tank, Pump, Drive Controller - Without XLRDocument23 pages005 - Cat-6060 - Tank, Pump, Drive Controller - Without XLRJorby CuadrosNo ratings yet

- CAT Reference Materials (Oil, Fuel, Coolant, Etc)Document1 pageCAT Reference Materials (Oil, Fuel, Coolant, Etc)victor.ciprianiNo ratings yet

- Hydraulic System Inspection: Service Data SheetDocument2 pagesHydraulic System Inspection: Service Data SheetAnonymous alQXB11EgQNo ratings yet

- PEO003 - SGD - V4 (Personal Devt)Document60 pagesPEO003 - SGD - V4 (Personal Devt)Jela ParadiseNo ratings yet

- 374FHydEx Intro EN TXT-InstructorDocument56 pages374FHydEx Intro EN TXT-InstructorJavier Pagan TorresNo ratings yet

- 776d Tractors 777d TrucksDocument7 pages776d Tractors 777d TrucksJavier Pagan TorresNo ratings yet

- Service Brake Wear TestDocument14 pagesService Brake Wear TestsatyaNo ratings yet

- Electronic FundamentalsDocument76 pagesElectronic FundamentalsErnie Ronsable100% (1)

- Caterpillar - System Selection GuideDocument11 pagesCaterpillar - System Selection GuidefvmattosNo ratings yet

- Optimizing Oil (Caterpillar Engine) PDFDocument8 pagesOptimizing Oil (Caterpillar Engine) PDFKurniadi Setyanto100% (1)

- Hose Inspection - All Cat MachinesDocument12 pagesHose Inspection - All Cat MachinesSixto Guarniz Anticona100% (1)

- Componentes de Maquina de Oruga D10RDocument152 pagesComponentes de Maquina de Oruga D10RJesús Abreu100% (1)

- Peep7212 11Document2 pagesPeep7212 11Erick Alarcon100% (1)

- 4 - Interp I Training For Tier 4 v2Document27 pages4 - Interp I Training For Tier 4 v2DAniel100% (1)

- Final Reporting GuidelinesDocument183 pagesFinal Reporting GuidelinesAkhmad NuzulNo ratings yet

- CI OverviewDocument41 pagesCI OverviewGilmer PatricioNo ratings yet

- D11T Dozer SMCS Job Codes Dealer Guidebook 14MAR2017Document17 pagesD11T Dozer SMCS Job Codes Dealer Guidebook 14MAR2017AMLOHRI PROJECTNo ratings yet

- DX 340 Operational ManualDocument288 pagesDX 340 Operational ManualJoakimindarno100% (1)

- TA-2 Visual & Technical Inspection ChecklistDocument22 pagesTA-2 Visual & Technical Inspection ChecklistWilliams ArayaNo ratings yet

- TA1 English - Articulated TruckDocument15 pagesTA1 English - Articulated Truckcarlos angelNo ratings yet

- RH200 Cooling SystemDocument14 pagesRH200 Cooling SystemLuis jopi100% (3)

- Engine Life Optimization Final Document Version 00 8-9-21Document20 pagesEngine Life Optimization Final Document Version 00 8-9-21shiv100% (1)

- Hydraulic Mining Shovel Cat 6020B: 09. Hydraulic Oil Cooling SystemDocument8 pagesHydraulic Mining Shovel Cat 6020B: 09. Hydraulic Oil Cooling SystemSatrio Teguh0% (1)

- Global Service Learning: 320D-336D Series Hydraulic Excavators - Tier Iii EnginesDocument3 pagesGlobal Service Learning: 320D-336D Series Hydraulic Excavators - Tier Iii EnginesLea7herfaceNo ratings yet

- Diagrama Hidraulico 777FDocument4 pagesDiagrama Hidraulico 777Ffabioalbor100% (1)

- TA1 Visual Inspection Form Master - Track-Type TractorDocument11 pagesTA1 Visual Inspection Form Master - Track-Type TractorCarlosNo ratings yet

- 006 - CAT-6040 - RH170B - Servo SystemDocument28 pages006 - CAT-6040 - RH170B - Servo SystemJorby CuadrosNo ratings yet

- TechDocument37 pagesTechmahadevbNo ratings yet

- 004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFDocument12 pages004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFMiguel RodriguezNo ratings yet

- 740 Artiiculated Truck Power TrainDocument37 pages740 Artiiculated Truck Power TrainFabrizio Jesús100% (1)

- Turbo ChargerDocument93 pagesTurbo ChargerradytamaNo ratings yet

- BP Publication - CRC Component TurnaroundDocument6 pagesBP Publication - CRC Component Turnaroundleaw81No ratings yet

- 950H-962H Marketing BulletinDocument6 pages950H-962H Marketing BulletinWilbort Encomenderos Ruiz100% (1)

- Mechanical Engineering For Static and Rotating Equipment: The Delegates Will CoverDocument4 pagesMechanical Engineering For Static and Rotating Equipment: The Delegates Will CoverRashedNo ratings yet

- Reduce Hydrocarbon Leaks Through Improved Training StandardsDocument12 pagesReduce Hydrocarbon Leaks Through Improved Training StandardsbharathaninNo ratings yet

- Induction Motor Failure AnalysisDocument8 pagesInduction Motor Failure AnalysisMunazar HussainNo ratings yet

- Mantenimiento 789CDocument264 pagesMantenimiento 789COctavio Morales100% (1)

- Digital Camera CATDocument38 pagesDigital Camera CATOctavio MoralesNo ratings yet

- Fotografias PDFDocument14 pagesFotografias PDFOctavio MoralesNo ratings yet

- How To Communicate Effectively SEBD0522Document28 pagesHow To Communicate Effectively SEBD0522Octavio MoralesNo ratings yet

- Digital Camera CATDocument38 pagesDigital Camera CATOctavio MoralesNo ratings yet

- Rating Pocket Size LEXE2576-08Document21 pagesRating Pocket Size LEXE2576-08Octavio Morales0% (1)

- Communicate With PicturesDocument11 pagesCommunicate With PicturesOctavio Morales0% (1)

- Battery MaintenanceDocument1 pageBattery MaintenanceLily MimbelaNo ratings yet

- Simulador MotorgraderDocument10 pagesSimulador MotorgraderOctavio MoralesNo ratings yet

- Fastener TrainingDocument20 pagesFastener TrainingJesus Barragán Ramos100% (2)

- Yamaha Motor Company ProjectDocument64 pagesYamaha Motor Company Projectnavitsh1084% (19)

- B737NG76T1T2L3Document29 pagesB737NG76T1T2L3MedaNo ratings yet

- Liebherr 312 LitronicDocument22 pagesLiebherr 312 LitronicBore Bernaldo de QuirosNo ratings yet

- Hydrostatic Transmissions for Heavy VehiclesDocument128 pagesHydrostatic Transmissions for Heavy Vehicles113BOANo ratings yet

- Ford E40D Solenoid and Transmission SettingsDocument2 pagesFord E40D Solenoid and Transmission SettingsmilerkNo ratings yet

- Automatict RansmissionDocument34 pagesAutomatict RansmissionGanapati HegdeNo ratings yet

- Service Training PDFDocument270 pagesService Training PDFLenin Valderrama Segura100% (2)

- GD511A 1PdfDocument32 pagesGD511A 1PdfDanar PrasastyoNo ratings yet

- 590 Super R 695 Super R: Section 17 - Torque ConvertersDocument12 pages590 Super R 695 Super R: Section 17 - Torque ConvertersTeknik MakinaNo ratings yet

- L120e 03 PDFDocument38 pagesL120e 03 PDFGilbert OliveiraNo ratings yet

- Safety Tips for Operating Construction EquipmentDocument159 pagesSafety Tips for Operating Construction Equipmentazze bouzNo ratings yet

- English Translate 1 - 质量证明书Document12 pagesEnglish Translate 1 - 质量证明书Kiki Kiko KikoNo ratings yet

- Faizan Khan Ayub KhanDocument22 pagesFaizan Khan Ayub KhanGani GaneyanNo ratings yet

- SM 5 PDFDocument147 pagesSM 5 PDFLeandro VialNo ratings yet

- Eschmann MR, MRS Operation Table - Service Manual 0Document32 pagesEschmann MR, MRS Operation Table - Service Manual 0perla_canto_1No ratings yet

- Mercedes Trans 7G Tronic PlusDocument6 pagesMercedes Trans 7G Tronic PlusEdwin C. Walke100% (1)

- Product Recommendation JCB Fastrac Fastrac 135 - 636.000 (1991-1997)Document4 pagesProduct Recommendation JCB Fastrac Fastrac 135 - 636.000 (1991-1997)glino santanaNo ratings yet

- CEB1053Document30 pagesCEB1053oscar horacio floresNo ratings yet

- Shimpo VRL SeriesDocument48 pagesShimpo VRL SeriesElectromateNo ratings yet

- Conditions For Implementing Trolleybuses in Public Urban TransportDocument8 pagesConditions For Implementing Trolleybuses in Public Urban TransportSorin ScutarasuNo ratings yet

- 999 Product GuideDocument83 pages999 Product GuideWesley Delai CruzNo ratings yet

- ZF BWDocument26 pagesZF BWAlex100% (1)

- Unit 1-At6402 Automotive ChassisDocument39 pagesUnit 1-At6402 Automotive ChassisSathis KumarNo ratings yet

- Test Walking-Type Agricultural TractorsDocument20 pagesTest Walking-Type Agricultural TractorsSukiyanti SukirNo ratings yet

- Agitator Vessel (Design&Costing)Document34 pagesAgitator Vessel (Design&Costing)imrancenakk100% (2)

- I GTH-4013 EX From SN 20615Document202 pagesI GTH-4013 EX From SN 20615sixin93551No ratings yet

- Ducati 750-860 ServiceDocument73 pagesDucati 750-860 ServicetricolormonsterNo ratings yet

- How To Drive An Automatic CarDocument4 pagesHow To Drive An Automatic CarPaul KarijaNo ratings yet

- MICROMAT single-shaft shredder efficiently granulates plasticsDocument2 pagesMICROMAT single-shaft shredder efficiently granulates plasticskarnakesNo ratings yet

- Mercedes-Benz Tractor HeadDocument9 pagesMercedes-Benz Tractor HeadRudi KurniawanNo ratings yet