Professional Documents

Culture Documents

Hobart Self-Shield Wire Presen

Uploaded by

alefeli26Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hobart Self-Shield Wire Presen

Uploaded by

alefeli26Copyright:

Available Formats

Self Shielded Flux Core Pipeline

Welding

ITW Hobart Brothers, Troy, OH

Fundamentals of Self Shielded

FCAW

Porosity Formation

Oxygen & Nitrogen

Carbon Monoxide (CO)

Nitrogen solubility in liquid iron (0.045%)

> solid iron (0.012%)

Preventing Porosity

Generate sufficient shielding gas

Fix the Oxygen & Nitrogen through the

formation of stable oxides and nitrides

Shielding Gas Generation

Flux ingredient (Carbonates & Fluorides)

CaCO

3

and MgCO

3

decompose at 350 - 900C

and provide CO

2

Metallic Oxide contributes to slag volume

Generates spatter during decomposition reaction

BaCO

3

& Li

2

CO

3

Shielding Gas Generation

Fluorides produce shielding gas & slag

Shielding gas produced through either

vaporization or dissociation of fluorides

CaF

2

used to scavenge O

2

, N, H

2

and reduce

sulfur & phosphorous

LiF

2

reduces nitrogen

De-oxidation and De-nitriding

Al, Ti, Zr, Mn, Si, Mg

Stub Loss

Parameters F/S 81N1, 5/64" E7010, 3/16"

A. Wire/Electrode Unit Cost 1.00 1.00

B. Deposit Efficiency 75% 50%

C. Labour Cost $/hr 10 10

D. Deposition Rate lbs/hr 4.10 3.50

E. Operating Factor 50% 30%

F. Material Cost Unit/lb = A/B/(1-H) 1.40 2.67

G. Labour Cost $/lb = C*((1/D)/E) 4.88 9.52

H. Stub Loss/ Waste 5% 25%

Total Unit Cost Per Lb 6.28 12.19

Self Shielded FCAW vs SMAW

New Generation

Self Shielded Wires

Low Spatter Level

Excellent Slag Detachability

Excellent Properties

Improved

Quality

Productivity

Overall Fabrication Cost

E71T8-Ni1 in market

Slag

New Generation Wire

NO SLAG

E71T8-Ni1 in Market

Large and high

spatter level

New Generation Wire

Small and low

spatter level

Quantitative Spatter Generation

Comparison

0

5

10

15

20

25

%

S

p

a

t

t

e

r

G

e

n

e

r

a

t

e

d

200 A 250 A

Current

a

a

b

c b c

a - Current Wire

b,c - New Wire

Recommendations

X65, X70 E71T8 - K6 FS 71K6

X65, X70: E71T8 - Ni1 FS 81N1

X80: E81T8 - Ni2 FS 81N2

CVN Transition Curve

0

50

100

150

200

250

300

350

400

450

-120 -100 -80 -60 -40 -20 0

Testing Temperature (F)

C

V

N

T

o

u

g

h

n

e

s

s

(

F

t

-

L

b

s

)

Historical Tensile Strength Data

50000

52500

55000

57500

60000

62500

65000

67500

70000

72500

75000

77500

80000

Samples

T

e

n

s

i

l

e

S

t

r

e

n

g

t

h

(

p

s

i

)

Historical Impact Toughness

0

50

100

150

200

250

300

350

400

450

500

Samples

A

v

g

.

C

V

N

V

a

l

u

e

s

@

-

4

0

F

(

f

t

-

l

b

s

)

China Pipeline Bureau

State owned Company responsible for oil and gas

pipeline construction in China as well as overseas.

Used E6010 (EN) for root run and Self Shielded

FCAW (EN) for remaining passes - process

developed in late 80s

West East Pipeline Project

4000 km (2500 miles) main pipeline to transport gas from

Xinjiang gas field, North-West China to Shanghai, East

coast of China.

API 5LX-70, 67 Joules impact, 1 meter diameter, 15 to

25mm wall thickness, 12lb of weld metal per joint.

West East Pipeline Project

China Pipeline Bureau welding X-70 Pipe for the first

time.

New wires excellent CVN impact toughness exceeded

requirements and was the first wire to be qualified for the

project !!!

New wire preferred due to low spatter level and easy slag

removal over competitive wire !!!

China welders complete approximately 250 joints per day

for a 50 man welding crew.

Shanghai

China Pipeline

China Pipeline

China Pipeline

Shanghai

ITW Companies supplied over 1000 tons of Self Shielded Flux

Core Wire in 2002 !!!

You might also like

- Basc QB 2Document3 pagesBasc QB 2prabhakaran.SNo ratings yet

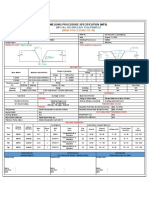

- NCTL Project: Proposal Welding Procedure SpecificationDocument4 pagesNCTL Project: Proposal Welding Procedure SpecificationRotimi Shitta-BeyNo ratings yet

- BPVC Ix Qw-484aDocument1 pageBPVC Ix Qw-484aTC Capulcu Mustafa MNo ratings yet

- Appendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Document14 pagesAppendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Jobaer ShaonNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCDocument1 page22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforNo ratings yet

- Defects and Discontinuities: Boiler and Mechanical PowerDocument78 pagesDefects and Discontinuities: Boiler and Mechanical PowerthejusNo ratings yet

- Specifications For Plates: Chemical Composition Mechanical PropertiesDocument7 pagesSpecifications For Plates: Chemical Composition Mechanical Propertiesprajakt_pieNo ratings yet

- ARTICLE - Advancements in The Hardness Testing of Welds (2010)Document3 pagesARTICLE - Advancements in The Hardness Testing of Welds (2010)Sangameswaran RamarajNo ratings yet

- Mathematical Modelling of GTAW and GMAWDocument240 pagesMathematical Modelling of GTAW and GMAWpatriciatavares2009100% (2)

- Study On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationDocument7 pagesStudy On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationManuel CarreñoNo ratings yet

- Inconal625 - SAW Study - Final ReportDocument21 pagesInconal625 - SAW Study - Final ReportshibumbNo ratings yet

- 6082 T6 Aluminum Plate SuppliersDocument9 pages6082 T6 Aluminum Plate Supplierssanghvi overseas incNo ratings yet

- GTAW Welding of CP Titanium and Ti6Al4VDocument1 pageGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarNo ratings yet

- P Q R - 005Document2 pagesP Q R - 005Courtney DukeNo ratings yet

- 100% Stainless: The Avesta Welding ManualDocument0 pages100% Stainless: The Avesta Welding ManualFlorin SoicuNo ratings yet

- ARTICLE - Destructive Testing Basics (2012)Document4 pagesARTICLE - Destructive Testing Basics (2012)Sangameswaran RamarajNo ratings yet

- KEMPPI Welding Technology Course: R.BanerjeeDocument78 pagesKEMPPI Welding Technology Course: R.BanerjeeAnoop KushwahaNo ratings yet

- Mock-Up Block Drawings Fro AUTDocument14 pagesMock-Up Block Drawings Fro AUTSiddiqui Abdul KhaliqNo ratings yet

- PreheatDocument2 pagesPreheatScott TrainorNo ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- Microstructure Properties: I Sensitivity of Properties To Thermal History?Document35 pagesMicrostructure Properties: I Sensitivity of Properties To Thermal History?MadhusudanNo ratings yet

- Modul Tambahan Kualifikasi Las (KL)Document27 pagesModul Tambahan Kualifikasi Las (KL)Nurhamsyah Susianto0% (1)

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- TWI - FAQ - Can One Company Use Welding Procedures Qualified by Another CompanyDocument3 pagesTWI - FAQ - Can One Company Use Welding Procedures Qualified by Another CompanytuanNo ratings yet

- AWS April 2014Document44 pagesAWS April 2014Mohamed FaragNo ratings yet

- Marching Chart JHBDPL, DAPL Section - II, ORISSA Region (118.23 To 206.59 KM)Document2 pagesMarching Chart JHBDPL, DAPL Section - II, ORISSA Region (118.23 To 206.59 KM)Gururaj P Kundapur100% (1)

- Wps MainlineDocument5 pagesWps MainlineAlfian FebriansyahNo ratings yet

- 1.2 Resistance and Special WeldingDocument14 pages1.2 Resistance and Special WeldingnikhilbathamNo ratings yet

- SSIS Visual Examination Report FormatDocument1 pageSSIS Visual Examination Report FormatSalman KhanNo ratings yet

- Tolerances For Pressure VesselsDocument2 pagesTolerances For Pressure VesselsolekNo ratings yet

- Helling Katalog NDTDocument43 pagesHelling Katalog NDTjeyaselvanmNo ratings yet

- ARTICLE - Considerations When Selecting An NDE Method (2010)Document2 pagesARTICLE - Considerations When Selecting An NDE Method (2010)Sangameswaran RamarajNo ratings yet

- WeldingDocument21 pagesWeldingprabhatkumar_6657012No ratings yet

- Class P6A6Document24 pagesClass P6A6SalimNo ratings yet

- What Is Peening?: Frequently Asked QuestionsDocument2 pagesWhat Is Peening?: Frequently Asked QuestionstuanNo ratings yet

- Aws WJ 201402Document150 pagesAws WJ 201402aperezm361No ratings yet

- WIC-WPS-01 Rev. 00 - FCAW - 1.2Document2 pagesWIC-WPS-01 Rev. 00 - FCAW - 1.2murshid badshahNo ratings yet

- Is 7310 RequirementsDocument4 pagesIs 7310 RequirementsRavichandran Tirupattur SubramaniamNo ratings yet

- ConsumablesDocument28 pagesConsumablesadeoye_okunoyeNo ratings yet

- Scenario 1 S: Lamelar Tearing Occur in Set In? orDocument6 pagesScenario 1 S: Lamelar Tearing Occur in Set In? orBeny ZulNo ratings yet

- Cordon Off - 4 (00000003)Document1 pageCordon Off - 4 (00000003)Anonymous PlyxbQ3tNo ratings yet

- WPQ TemplateDocument1 pageWPQ Templatejoshrathburn1980No ratings yet

- Ajay Dimri: (Certificate No - 84801.)Document8 pagesAjay Dimri: (Certificate No - 84801.)muhammadazharNo ratings yet

- ASNT Calculator GuideDocument14 pagesASNT Calculator GuidevasanthNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- Wel 13 HDocument8 pagesWel 13 HWilly Uio100% (1)

- RT Pratical Exam FormulasDocument2 pagesRT Pratical Exam FormulasKartik SharmaNo ratings yet

- WI & CERT Kelas EDocument22 pagesWI & CERT Kelas EKevin ArmandoNo ratings yet

- UAE-CSWIP Visual Welding Inspector Level 1 (3.0)Document2 pagesUAE-CSWIP Visual Welding Inspector Level 1 (3.0)adeoye_okunoyeNo ratings yet

- Twi Impact TestingDocument17 pagesTwi Impact TestingchungndtNo ratings yet

- Spec Sheet - Handler 187Document4 pagesSpec Sheet - Handler 187Hobart Welding ProductsNo ratings yet

- SF188 Rev 1 - Welder Qualification Test CertificateDocument1 pageSF188 Rev 1 - Welder Qualification Test CertificateMike BoyesNo ratings yet

- QAP For PQR'S - For Impact TestingDocument3 pagesQAP For PQR'S - For Impact TestingDries VandezandeNo ratings yet

- AlokJain JindalDocument76 pagesAlokJain JindalArunprasad Murugesan100% (1)

- Graaf Welding Consumables For Girth Welding of PipelinesDocument33 pagesGraaf Welding Consumables For Girth Welding of PipelinesRavjManjunathNo ratings yet

- Welding Stainless SteelDocument4 pagesWelding Stainless SteelJohan ZraghozNo ratings yet

- Flux Cored Arc Welding Equipment Setup and OperationDocument70 pagesFlux Cored Arc Welding Equipment Setup and OperationMuhammailNo ratings yet

- Fabcor 86 RDocument2 pagesFabcor 86 RAnonymous fj4iRr1No ratings yet

- (Welding) Ansi-Aws Standard d9 1-90 Sheet Metal Welding Code (Ebook, 59 Pages)Document4 pages(Welding) Ansi-Aws Standard d9 1-90 Sheet Metal Welding Code (Ebook, 59 Pages)markosdistefanoNo ratings yet

- Simulacion Parte BDocument10 pagesSimulacion Parte Balefeli26No ratings yet

- Aws A1.1Document30 pagesAws A1.1alefeli26No ratings yet

- Practica 1Document5 pagesPractica 1alefeli26No ratings yet

- FW0061Document7 pagesFW0061alefeli26No ratings yet

- QC4 89Document14 pagesQC4 89alefeli26No ratings yet

- FW0007Document5 pagesFW0007alefeli26No ratings yet

- Simulacion Parte C Parte CDocument17 pagesSimulacion Parte C Parte Calefeli26No ratings yet

- AWS Part BDocument32 pagesAWS Part Balefeli260% (2)

- QC4 89Document14 pagesQC4 89alefeli26No ratings yet

- QC17-2008 Especificacion para Certificacion de Fabricacion de SoldadurasDocument18 pagesQC17-2008 Especificacion para Certificacion de Fabricacion de Soldadurasalefeli26No ratings yet

- Preguntas Al Comite API 1104Document12 pagesPreguntas Al Comite API 1104alefeli26No ratings yet

- Robustness of The QAL2 Calibration EN14181 UncertaDocument10 pagesRobustness of The QAL2 Calibration EN14181 UncertaAnaibar TarikNo ratings yet

- Eurovent Energy Efficiency CalculatorDocument1 pageEurovent Energy Efficiency CalculatorPradeep Sukumaran100% (1)

- HoneywellDocument2 pagesHoneywellzenerdiodeNo ratings yet

- AND From AND: FOR Rhodium, For Their GravimetricDocument13 pagesAND From AND: FOR Rhodium, For Their GravimetricshahinNo ratings yet

- PIC Lab Exp#02 - Analysis of Group II CationsDocument3 pagesPIC Lab Exp#02 - Analysis of Group II CationsNight RaveNo ratings yet

- Characterization of Iron Oxide Thin Film Prepared by The Sol-Gel MethodDocument2 pagesCharacterization of Iron Oxide Thin Film Prepared by The Sol-Gel MethodBryan Anders AguilarNo ratings yet

- 1 Lab Handout PDFDocument5 pages1 Lab Handout PDFKhud SarNo ratings yet

- Hexweb CR Iii: Corrosion Resistant Specification Grade Aluminum HoneycombDocument6 pagesHexweb CR Iii: Corrosion Resistant Specification Grade Aluminum Honeycombsahiljain_146No ratings yet

- Metal Spinning PDFDocument86 pagesMetal Spinning PDFloosenut100% (1)

- X-Ray Pipeline CrawlerDocument4 pagesX-Ray Pipeline CrawlerBala SingamNo ratings yet

- Ampho 149Document18 pagesAmpho 149Luis Andre SilvaNo ratings yet

- Tunnelling in Soft GroundDocument19 pagesTunnelling in Soft Groundiman safiyaNo ratings yet

- Lecture 5 2slidesDocument84 pagesLecture 5 2slidesAhmad BurqanNo ratings yet

- Target Iit-Jee: DATE: 12-12-2014Document8 pagesTarget Iit-Jee: DATE: 12-12-2014asuhassNo ratings yet

- I - Grades & Materilas InfoDocument32 pagesI - Grades & Materilas InfoEswara ReddyNo ratings yet

- Element Fe O: Find The Empirical Formula For A Compound Containing 40.6% Carbon, 5.1% Hydrogen, and 54.2% OxygenDocument8 pagesElement Fe O: Find The Empirical Formula For A Compound Containing 40.6% Carbon, 5.1% Hydrogen, and 54.2% OxygenLEENA HingNo ratings yet

- Zhang Et Al. 2010Document6 pagesZhang Et Al. 2010Aizat HawariNo ratings yet

- Light Transmitting Concrete Panels A New Innovation in Concrete Technology PDFDocument4 pagesLight Transmitting Concrete Panels A New Innovation in Concrete Technology PDFنور أزلينNo ratings yet

- Chemistry Period 8 Ben & Calum Honors Chem Hydrate LabDocument4 pagesChemistry Period 8 Ben & Calum Honors Chem Hydrate Labapi-239596021No ratings yet

- Section 9 Introduction To Welding ProcessesDocument16 pagesSection 9 Introduction To Welding ProcessesS GoudaNo ratings yet

- MISC - MSDS - 3 in 1 Oil PDFDocument4 pagesMISC - MSDS - 3 in 1 Oil PDFFifi UmmahNo ratings yet

- Fluoride Toxicity SeminarDocument27 pagesFluoride Toxicity SeminarNikhil BhandariNo ratings yet

- Stress Strain Curve ExplanationDocument8 pagesStress Strain Curve ExplanationGptc Chekkanurani0% (1)

- DNV Structure Steel Fabrication PDFDocument0 pagesDNV Structure Steel Fabrication PDFmastorfaizalNo ratings yet

- The Zeeman EffectDocument11 pagesThe Zeeman EffectAlex TarrNo ratings yet

- CRI Carpet Installation Standard 2011Document36 pagesCRI Carpet Installation Standard 2011Mykel VelasquezNo ratings yet

- Asme SB466Document9 pagesAsme SB466Stéphane LevasseurNo ratings yet

- Elution and Carbon Reactivation BasicsDocument19 pagesElution and Carbon Reactivation BasicsdiegovergaraNo ratings yet

- Enzyme Virtual LabDocument4 pagesEnzyme Virtual LabSamuel Morales NavarroNo ratings yet

- Sierra Megonnell and Kyle Lovisone ExpDocument1 pageSierra Megonnell and Kyle Lovisone Expapi-528179516No ratings yet