Professional Documents

Culture Documents

Hansen Aise Im Ch16

Uploaded by

norsiah_shukeriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hansen Aise Im Ch16

Uploaded by

norsiah_shukeriCopyright:

Available Formats

1

PowerPoint Presentation by

Gail B. Wright

Professor Emeritus of Accounting

Bryant University

Copyright 2007 Thomson South-Western, a part of The

Thomson Corporation. Thomson, the Star Logo, and

South-Western are trademarks used herein under license.

MANAGEMENT

ACCOUNTING

8

th

EDITION

BY

HANSEN & MOWEN

1 INTRODUCTION

16 LEAN ACCOUNTING, TARGET

COSTING, & BALANCED SCORECARD

2

LEARNI NG GOALS

After studying this

chapter, you should be

able to:

LEARNING OBJ ECTIVES

3

1. Describe the basic features of lean

manufacturing.

2. Describe lean accounting.

3. Explain the basics of life-cycle cost

management & target costing.

4. Discuss the basic features of the Balanced

Scorecard & its role in lean manufacturing.

LEARNING OBJ ECTIVES

Click the button to skip

Questions to Think About

4

QUESTIONS TO THINK ABOUT:

Allen Autoparts, Inc.

How does lean manufacturing

change cost accounting &

management?

5

QUESTIONS TO THINK ABOUT:

Allen Autoparts, Inc.

What are the similarities

between JIT & lean

manufacturing?

6

QUESTIONS TO THINK ABOUT:

Allen Autoparts, Inc.

How are products assigned

costs in a lean manufacturing

environment?

7

QUESTIONS TO THINK ABOUT:

Allen Autoparts, Inc.

Why are processes so important

to performance management?

8

QUESTIONS TO THINK ABOUT:

Allen Autoparts, Inc.

Are lean manufacturing and the

Balanced Scorecard compatible

approaches?

9

1

Describe the basic

features of lean

manufacturing.

LEARNING OBJ ECTIVE

10

ALLEN AUTOPARTS: Background

Allen Autoparts is concerned about

competition in an environment that

changes rapidly. They need to exercise

better control, reduce costs, become more

efficient, and gain operating efficiencies.

Can lean manufacturing help?

LO 1

11

LEAN MANUFACTURING:

Definition

Is an approach designed to

eliminate waste & maximize

customer value.

LO 1

12

DIMENSIONS OF LEAN

MANUFACTURING

Delivering the right product

Right quantity

Right quality (zero defect)

At time needed

At lowest possible cost

A cost reduction strategy that redefines

activities performed

LO 1

13

5 PRINCIPLES OF LEAN

THINKING

1. Precisely specify value by each particular

product

2. Identify the value stream for each

3. Make value flow without interruption

4. Let customer pull value from producer

5. Pursue perfection

LO 1

14

VALUE BY PRODUCT: Definition

Is when only value-added

features should be produced;

non-value-added activities

should be eliminated.

LO 1

15

VALUE STREAM: Definition

Is all activities, both value-added

& non-value-added, required to

bring product group or service from

starting point to finished product in

hands of customer.

LO 1

16

VALUE STREAM

Types of value streams

Order fulfillment

New product

Value stream activities

Non-value-added

Activities avoidable in the short run

Unavoidable activities due to current technology or

production method

Value added

LO 1

17

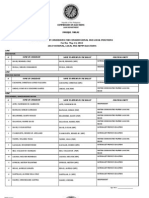

ORDER FULFILLMENT VALUE

STREAM

LO 1

EXHIBIT 16-1

Order fulfillment

provides current

products to current

customers.

18

VALUE FLOW

Changes the traditional manufacturing setup

for batches to a cellular approach in

order to:

Reduce setup time

Reduce changeover time

LO 1

19

MANUFACTURING CELL:

Definition

Contains all operations in close

proximity that are needed to

produce a family of products.

LO 1

20

TRADITIONAL BATCH SYSTEM

LO 1

EXHIBIT 16-3A

Note time lost

in moving &

waiting.

21

CELLULAR SYSTEM

LO 1

EXHIBIT 16-3B

Time saved

over traditional

manufacturing

is 90 minutes

(150 60).

22

PULL VALUE

Lean manufacturing uses a demand pull

system to reduce waste.

JIT inventory

Reduces inventory levels

Requires close relations with suppliers

Suppliers benefit from

Long term relations

Better competitive position

LO 1

23

2

Describe lean

accounting.

LEARNING OBJ ECTIVE

24

LEAN ACCOUNTING: A Comparison

LO 2

Traditional cost management systems may

not be compatible with Lean

Accounting. Lean Accounting makes

product costs more simple & direct.

More labor and overhead costs are

assigned to products through direct

tracing rather than allocation.

25

FOCUSED VALUE STREAMS:

Definition

Allow overhead costs to be

assigned through driver tracing

of costs in a lean accounting

system.

LO 2

26

FOCUSED VALUE STREAMS

Are more simple & accurate in product costing

Have limitations

Initially, labor costs may be difficult to assign if

people are employed in several value streams

Labor costs should assigned proportionately

Are organized around a family of products

LO 2

27

FORMULA: Multiple Products

Costs are assigned proportionately when

multiple products are produced.

LO 2

Value stream product cost:

= Total value stream cost of period

Units shipped of period

= $600,000 / 5,000 = $120 per unit

28

VALUE STREAM REPORTING

LO 2

EXHIBIT 16-6

Costs are

collected,

reported by

value stream;

outside costs

reported

separately.

29

VALUE STREAM DECISIONS

May lead to

Short term decisions

May not reflect long term consequences

LO 2

30

PERFORMANCE

MEASUREMENT: A Comparison

LO 2

Lean accounting replaces standard cost

system measurements with a Box

Scorecard that compares a) operational,

b) capacity, & c) financial metrics with

prior week performances. A mixture of

financial & nonfinancial measures are

used.

31

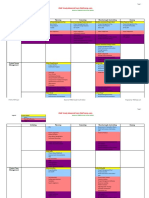

BOX SCORECARD

LO 2

EXHIBIT 16-7

Comparison

measures point

to future

desired goals.

32

3

Explain the basics

of life-cycle cost

management &

target costing.

LEARNING OBJ ECTIVE

33

What are product life cycle

& life cycle costs?

Product life cycle is the time a

product exists from conception

to abandonment. Life cycle

costs are all costs associated

with a product for its life cycle.

LO 3

34

VALUE CHAIN: Definition

Is the set of activities required

to design, develop, produce,

market, and service a product.

LO 3

35

When are most costs

incurred?

During the development stage.

This is also the time costs

should best be managed.

LO 3

36

WHOLE-LIFE PRODUCT COST

Product cost is

Nonrecurring costs

Planning,

Designing,

Testing

Manufacturing costs

Logistic costs

Customers postpurchase costs

LO 3

37

TARGET COST: Definition

Is the difference between sales

price needed to capture a

predetermined market share &

desired per-unit profit.

LO 3

38

TARGET COSTING

Uses 1 of 3 methods

Reverse engineering

Tearing down a competitors product to discover

design features that create cost reductions

Value analysis

Attempting to assess the value placed on product

functions by customers

Process improvement

LO 3

39

TARGET COSTING MODEL

LO 3

EXHIBIT 16-9

When desired profit

not met, target product

costing to redesign

product, process.

40

OTHER ISSUES

Short life cycles

Life cycle cost management even more important

when life cycle is short

LO 3

41

LIFE CYCLE COSTING: A

Comparison

LO 3

Life cycle costing includes development

costs unlike conventional cost systems.

Inclusion of more cost information can

be useful for assessing effects on costs

and benefit future design.

42

PERFORMANCE REPORT: Life

Cycle Costing

LO 3

EXHIBIT 16-11

Variances are

computed

between actual &

budgeted costs.

43

4

Discuss the basic

features of the

Balanced Scorecard

& its role in lean

manufacturing.

LEARNING OBJ ECTIVE

44

BALANCED SCORECARD:

Definition

Translates an organizations

mission & strategy into

operational objectives &

performance measures.

LO 4

45

BALANCED SCORECARD

PERSPECTIVES

Financial perspective

Economic consequences of actions taken in other 3

perspectives

Customer perspective

Defines customer & market segments where the business

unit will compete

Internal business process perspective

Describes internal processes needed to provide value for

customers, owners

Learning & growth (infrastructure) perspective

Defines capabilities that an organization must have to

create long term growth & improvement

LO 4

46

STRATEGY + TRANSLATION

Is the ways in which a company

implements it strategy for profit & growth

within the balanced scorecard framework.

It includes choices of type of customer,

product, market, internal & business

processes, etc. Strategy translation means

specifying objectives, measures, targets

& initiatives.

LO 4

47

STRATEGY TRANSLATION

PROCESS

LO 4

EXHIBIT 16-12

Vision & strategy

works through 4

perspectives to reach

targets & initiatives.

48

PERFORMANCE MEASURES

Must be balanced between:

Lead measures (performance drivers)

Lag (outcome) measures

Objective (quantifiable & verifiable) measures

Subjective (more judgmental) measures

Financial & nonfinancial measures

External & internal measures

LO 4

49

LINKING PERFORMANCE

MEASURES & STRATEGY

Testable strategy

Using cause & effect

Link objectives to overall goal

Double loop feedback

Managers receive information on effectiveness of

strategy & its underlying assumptions

Single loop feedback

Emphasizes only effectiveness of strategy

LO 4

50

TESTABLE STRATEGY

LO 4

EXHIBIT 16-13

Strategy map

illustrates quality

improvement

strategy.

51

FINANCIAL PERSPECTIVE

Flows from other 4 perspectives

Revenue growth

Cost reduction

Asset utilization

LO 4

52

CUSTOMER PERSPECTIVE

Source of revenue component within the

financial perspective

Core objectives & measures

Customer value

Difference between what customers receive and what

they have given up

Delivery reliability

LO 4

53

PROCESS PERSPECTIVE

Process value chain made up of 3 processes

Innovation process

Operations process

Cycle time & velocity

Manufacturing cycle efficiency

Day-by-hour report

Post sales service process

LO 4

54

LEARNING & GROWTH

PERSPECTIVE

Source of capabilities that enable the

accomplishment of other 3 perspectives

Employee capabilities

Motivation, empowerment, alignment

Information systems capabilities

LO 4

55

THE END

CHAPTER 16

You might also like

- Financial Planning & Analysis and Performance ManagementFrom EverandFinancial Planning & Analysis and Performance ManagementRating: 3 out of 5 stars3/5 (1)

- PPCRV OrientationDocument3 pagesPPCRV OrientationRhusselleNo ratings yet

- Cost Reduction Techniques and StagesDocument40 pagesCost Reduction Techniques and StagesXMBA 24 ITM Vashi100% (2)

- Example of Annual Audit Planning Work ProgramDocument2 pagesExample of Annual Audit Planning Work Programrindwa100% (1)

- Chapter 8Document8 pagesChapter 8Shenne Minglana50% (4)

- Discipline Procedures WorkplaceDocument27 pagesDiscipline Procedures Workplacenorsiah_shukeriNo ratings yet

- The Balanced Scorecard: Turn your data into a roadmap to successFrom EverandThe Balanced Scorecard: Turn your data into a roadmap to successRating: 3.5 out of 5 stars3.5/5 (4)

- Strategic Cost ManagementDocument25 pagesStrategic Cost ManagementPriAnca GuptaNo ratings yet

- Cost Reduction Strategies for the Manufacturing Sector With Application of Microsoft ExcelFrom EverandCost Reduction Strategies for the Manufacturing Sector With Application of Microsoft ExcelNo ratings yet

- Safety Training For Managers & Supervisors p1Document47 pagesSafety Training For Managers & Supervisors p1Herry PrakosoNo ratings yet

- Answer To Questions: Strategic Cost Management - Solutions ManualDocument8 pagesAnswer To Questions: Strategic Cost Management - Solutions ManualKyla Roxas67% (6)

- Performance Management NoteDocument229 pagesPerformance Management NoteRam Manoj YendruNo ratings yet

- Strategic Cost Management and The Value ChainDocument19 pagesStrategic Cost Management and The Value ChainInney SildalatifaNo ratings yet

- Cost ManagementDocument41 pagesCost Managementsuperdole83No ratings yet

- Cost Reduction and ControlDocument25 pagesCost Reduction and Controlparthasadhak100% (1)

- Target Costing PDFDocument44 pagesTarget Costing PDFAnonymous dPkadxxNo ratings yet

- Martinez V HRET - GR189034Document1 pageMartinez V HRET - GR189034Michael Oliver BarrientosNo ratings yet

- PMO Maturity AssessmentDocument3 pagesPMO Maturity AssessmentPMI South Florida ChapterNo ratings yet

- Understanding Production and Operations ManagementDocument23 pagesUnderstanding Production and Operations ManagementMohammed MohiuddinNo ratings yet

- Financial Management: Partner in Driving Performance and ValueFrom EverandFinancial Management: Partner in Driving Performance and ValueNo ratings yet

- Lean Project Management PDFDocument55 pagesLean Project Management PDFMaryam KhushbakhatNo ratings yet

- Mas 10Document12 pagesMas 10Christine Jane AbangNo ratings yet

- Redundancy, Retrenchment and Termination GuideDocument15 pagesRedundancy, Retrenchment and Termination Guidenorsiah_shukeriNo ratings yet

- Redundancy, Retrenchment and Termination GuideDocument15 pagesRedundancy, Retrenchment and Termination Guidenorsiah_shukeriNo ratings yet

- Seven common misconceptions about HR practices: Research findings vs beliefsDocument13 pagesSeven common misconceptions about HR practices: Research findings vs beliefsnorsiah_shukeriNo ratings yet

- Etl Toolkit by Ralph Kimball PDFDocument2 pagesEtl Toolkit by Ralph Kimball PDFStephen0% (2)

- Chapter 13 - Cost planning for product life cycleDocument51 pagesChapter 13 - Cost planning for product life cycleRenard100% (1)

- Ch13 000Document44 pagesCh13 000cirujeffNo ratings yet

- Lean Accounting, Costs of Quality & Target Costing ExplainedDocument47 pagesLean Accounting, Costs of Quality & Target Costing ExplainedrikiNo ratings yet

- FAST Diagram Technique ExplainedDocument7 pagesFAST Diagram Technique ExplainedTharayilJamesNo ratings yet

- Hansen Aise Im Ch16Document55 pagesHansen Aise Im Ch16Daniel NababanNo ratings yet

- Hansen Aise Im Ch16Document55 pagesHansen Aise Im Ch16Maharani KumalasariNo ratings yet

- MAHM8e Chapter16.Ab - AzDocument28 pagesMAHM8e Chapter16.Ab - AzOkta SelregaNo ratings yet

- Management Accounting: Student EditionDocument24 pagesManagement Accounting: Student EditionerrikprabowoNo ratings yet

- Strategic Planning and Control True/False QuestionsDocument28 pagesStrategic Planning and Control True/False QuestionsReneeNo ratings yet

- Management accounting information for decision makingDocument7 pagesManagement accounting information for decision makingReenalNo ratings yet

- CH 13Document40 pagesCH 13Ehab hobaNo ratings yet

- Chap 010Document38 pagesChap 010Tendy WatoNo ratings yet

- AKMEN CH 15 - Hansen MowenDocument29 pagesAKMEN CH 15 - Hansen MowenStella Tralalatrilili100% (1)

- Hansen Aise Im Ch02Document39 pagesHansen Aise Im Ch02FirlanaSubekti100% (1)

- Lean Accounting, Target Costing, BSCDocument19 pagesLean Accounting, Target Costing, BSCfranco radisNo ratings yet

- Operations Management: (Operations Strategy) Teacher: Ismatullah Butt PHD (Candidate)Document31 pagesOperations Management: (Operations Strategy) Teacher: Ismatullah Butt PHD (Candidate)Ismatullah ButtNo ratings yet

- Accountant's Role in The OrganizationDocument17 pagesAccountant's Role in The OrganizationTapas TiwariNo ratings yet

- Sol10 4eDocument44 pagesSol10 4eCalvin NguyễnNo ratings yet

- Cost Planning For The Product Life Cycle: Target Costing, Theory of Constraints, and Strategic PricingDocument44 pagesCost Planning For The Product Life Cycle: Target Costing, Theory of Constraints, and Strategic PricingMuhamad SyofrinaldiNo ratings yet

- Chapter 10 Cost Planning For The ProductDocument44 pagesChapter 10 Cost Planning For The ProductMuhamad SyofrinaldiNo ratings yet

- Production & Operation StrategyDocument22 pagesProduction & Operation StrategyGolam Morshed100% (3)

- Managerial Accounting Chapter 1Document21 pagesManagerial Accounting Chapter 1Ikhlas WauNo ratings yet

- Opman SoftDocument72 pagesOpman SoftEllen MaskariñoNo ratings yet

- Management Accounting Tutorial SolutionsDocument7 pagesManagement Accounting Tutorial SolutionsOmisha SinghNo ratings yet

- Cost Analysis Through Life Cycle Analysis and Target CostingDocument35 pagesCost Analysis Through Life Cycle Analysis and Target CostingSunny KhsNo ratings yet

- Theory Questions of Advance Management Accounting (CA Final)Document7 pagesTheory Questions of Advance Management Accounting (CA Final)Lawrence Maretlwa33% (3)

- Opman SoftDocument72 pagesOpman SoftEllen MaskariñoNo ratings yet

- Operations Strategy and CompetitivenessDocument35 pagesOperations Strategy and CompetitivenessJeewika PareekNo ratings yet

- Assignment 1 - Darshan BhavsarDocument5 pagesAssignment 1 - Darshan BhavsarDarshan BhavsarNo ratings yet

- System Lock-In Strategic FrameworkDocument15 pagesSystem Lock-In Strategic FrameworkvanderbylrouxNo ratings yet

- Relevant Cost&cost Planning For Product Life CycleDocument4 pagesRelevant Cost&cost Planning For Product Life CycleFerial FerniawanNo ratings yet

- Pom PDFDocument19 pagesPom PDFKomal SinghNo ratings yet

- Management Accounting: Student EditionDocument27 pagesManagement Accounting: Student EditionDinda OktavianiNo ratings yet

- Benchmarking & BPR for Optimal Business ProcessesDocument34 pagesBenchmarking & BPR for Optimal Business Processesvkvivekvk1No ratings yet

- MACS Assess Performance Across Value ChainDocument51 pagesMACS Assess Performance Across Value ChainRandy CavaleraNo ratings yet

- Maf635 UitmDocument31 pagesMaf635 UitmAtiqah AzhariNo ratings yet

- Ankita Emerging Concepts in Cost & MNGT AcingDocument21 pagesAnkita Emerging Concepts in Cost & MNGT AcingAnkita NirolaNo ratings yet

- The Utilization of Target Costing in The Telecom IndustryDocument6 pagesThe Utilization of Target Costing in The Telecom IndustryThe IjbmtNo ratings yet

- CA Inter Cost & Management Accounting Theory Book by CA Purushottam AggarwalDocument125 pagesCA Inter Cost & Management Accounting Theory Book by CA Purushottam Aggarwalabhinesh243No ratings yet

- 6 Cost ManagementDocument9 pages6 Cost ManagementZenCamandangNo ratings yet

- Target Costing and Life Cycle Costing - 305951881Document14 pagesTarget Costing and Life Cycle Costing - 305951881SaurabhBagdeNo ratings yet

- TargetcostingfinalfinalprjctDocument43 pagesTargetcostingfinalfinalprjctapi-3701467No ratings yet

- CHAPTER 2 - Key NotesDocument14 pagesCHAPTER 2 - Key NotesLuna RosieNo ratings yet

- Maf 635 Q&ADocument19 pagesMaf 635 Q&Atia87No ratings yet

- CH 7 - CFcapinvestdec - 1Document24 pagesCH 7 - CFcapinvestdec - 1norsiah_shukeriNo ratings yet

- CFfinstat&PlanningDocument53 pagesCFfinstat&Planningnorsiah_shukeriNo ratings yet

- S4 Economics, Demand and Supply2Document8 pagesS4 Economics, Demand and Supply2norsiah_shukeriNo ratings yet

- Redundancy, Layoff and Retrenchment GuideDocument16 pagesRedundancy, Layoff and Retrenchment Guidenorsiah_shukeriNo ratings yet

- Using MIS 3e: David KroenkeDocument40 pagesUsing MIS 3e: David Kroenkenorsiah_shukeriNo ratings yet

- Kroenke Umis3e ch11Document31 pagesKroenke Umis3e ch11norsiah_shukeriNo ratings yet

- Intro to Corporate Finance in 40 CharactersDocument16 pagesIntro to Corporate Finance in 40 Charactersnorsiah_shukeriNo ratings yet

- Trade Dispute Settlement MethodDocument26 pagesTrade Dispute Settlement Methodnorsiah_shukeriNo ratings yet

- Hansen Aise Im Ch11Document73 pagesHansen Aise Im Ch11norsiah_shukeriNo ratings yet

- Chapter 6Document53 pagesChapter 6norsiah_shukeriNo ratings yet

- Chapter 3Document35 pagesChapter 3norsiah_shukeriNo ratings yet

- Chapter 4Document30 pagesChapter 4norsiah_shukeriNo ratings yet

- Kroenke Umis3e Ch08.EdiDocument28 pagesKroenke Umis3e Ch08.Edinorsiah_shukeriNo ratings yet

- Chapter 5Document35 pagesChapter 5norsiah_shukeriNo ratings yet

- Lecture Objectives: The Organization of ProductionDocument6 pagesLecture Objectives: The Organization of Productionnorsiah_shukeriNo ratings yet

- Using MIS 3e: David KroenkeDocument40 pagesUsing MIS 3e: David Kroenkenorsiah_shukeriNo ratings yet

- Kroenke Umis3e ch11Document31 pagesKroenke Umis3e ch11norsiah_shukeriNo ratings yet

- Seven Common Misconceptions About HR PracticesDocument22 pagesSeven Common Misconceptions About HR Practicesnorsiah_shukeri50% (2)

- Hansen Aise Im Ch08Document54 pagesHansen Aise Im Ch08norsiah_shukeriNo ratings yet

- Case Study 7 Process Cast in StoneDocument2 pagesCase Study 7 Process Cast in Stonenorsiah_shukeriNo ratings yet

- SEEG5013 Top 2Document11 pagesSEEG5013 Top 2Rabel KhokharNo ratings yet

- Human Resource MGMT (HR Planning at COMPTECH) - AzlinaBNM (Final)Document8 pagesHuman Resource MGMT (HR Planning at COMPTECH) - AzlinaBNM (Final)norsiah_shukeriNo ratings yet

- Bulmash SampleChapter2Document27 pagesBulmash SampleChapter2Raja ManiNo ratings yet

- Hansen Aise Im Ch04Document46 pagesHansen Aise Im Ch04norsiah_shukeriNo ratings yet

- Hansen Aise Im Ch06Document49 pagesHansen Aise Im Ch06norsiah_shukeriNo ratings yet

- Principles of Management and Organization at Calauan CampusDocument14 pagesPrinciples of Management and Organization at Calauan CampusDory Almendras50% (2)

- Industrial TrainingDocument7 pagesIndustrial TrainingAmar KumarNo ratings yet

- AP American Government Chapter 11 Congress With AnswersDocument9 pagesAP American Government Chapter 11 Congress With Answersbhr856100% (1)

- Thinking Responsibly About Responsible AI and The Dark Side of AIDocument13 pagesThinking Responsibly About Responsible AI and The Dark Side of AIRidm DNo ratings yet

- Indian Process IndustryDocument7 pagesIndian Process Industryankushgup_agNo ratings yet

- Certified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsDocument2 pagesCertified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsSunStar Philippine NewsNo ratings yet

- Promotional Activities Control and EvaluationDocument7 pagesPromotional Activities Control and EvaluationDevi AprianiNo ratings yet

- Itto For PMP ExamDocument10 pagesItto For PMP Exameager18No ratings yet

- TCSDocument14 pagesTCSRitubatra26No ratings yet

- Wheelen smbp12 PPT 09 ModDocument13 pagesWheelen smbp12 PPT 09 ModAbdul wadoodNo ratings yet

- WBS Structure ASAP 7.2 PublicDocument18 pagesWBS Structure ASAP 7.2 PublicdeddywijayaNo ratings yet

- Management Diploma & Certificate Exam QuestionsDocument6 pagesManagement Diploma & Certificate Exam QuestionsMr DamphaNo ratings yet

- 2) Project Management FrameworkDocument17 pages2) Project Management FrameworkMihai UngureanuNo ratings yet

- Systematic Approach To Successful Implementation of ITILDocument8 pagesSystematic Approach To Successful Implementation of ITILJuliano S.M. BatistelaNo ratings yet

- POLGOVDocument5 pagesPOLGOVLyka FrancessNo ratings yet

- ISO 9001:2008 & AS9100C Quality StandardsDocument1 pageISO 9001:2008 & AS9100C Quality StandardsRamses SalazarNo ratings yet

- Superpresidentialism and Political Party Developme PDFDocument16 pagesSuperpresidentialism and Political Party Developme PDFlacosNo ratings yet

- CV - Creagh WarrenDocument4 pagesCV - Creagh Warrenbob panicNo ratings yet

- SHRM Mod 3 Part 1Document25 pagesSHRM Mod 3 Part 1Vishal Singh JaswalNo ratings yet

- Angelo JonesDocument2 pagesAngelo Jonesapi-77532609No ratings yet

- Verified Official List of Watchers in Barangay Cutcut For Sangguniang Kabataan Election 2018Document2 pagesVerified Official List of Watchers in Barangay Cutcut For Sangguniang Kabataan Election 2018j guevarraNo ratings yet

- Case Study of HRMDocument6 pagesCase Study of HRMDrRahul ChopraNo ratings yet