Professional Documents

Culture Documents

The Quality Improvement Model: Is Process Capable?

Uploaded by

shafie_buangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Quality Improvement Model: Is Process Capable?

Uploaded by

shafie_buangCopyright:

Available Formats

8-1

Is

Process

Capable

?

The

Quality

Improvement

Model

Use SPC to

Maintain

Current

Process

Collect &

Interpret

Data

Select

Measures

Define

Process

Is

Process

Capable

?

Improve

Process

Capability

Is

Process

Stable

?

Investigate &

Fix Special

Causes

No

Yes

No

Yes

Is Process Capable?

Purpose: Determine the adequacy

of the process with

respect to customer

/management needs.

8-2

Is

Process

Capable

?

Capable Process

A stable process that meets customer requirements.

8 22 24 2 4 6 10 12 14 16 18 20 26 28 30 32

Run Order

UCL

CL

LCL

Control Chart

Lower Spec Upper Spec

Target

Histogram

Capability assessments for unstable processes, may not be indicative of

how the process is actually performing.

8-3

Is

Process

Capable

?

Assessing Process Capability

Counting Measures

The average percent defectives.

The average number of defects.

Instrument Measures

Comparing both the center of the process and the process

variation

8-4

Is

Process

Capable

?

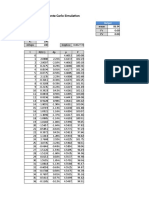

Capability Assessment for Counting Measures

Order Entry Process

Is this process adequate as is?

Should it be improved?

Week

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Total

# Errors

15

22

18

10

13

9

27

12

24

22

8

8

26

16

20

10

16

9

15

20

320

0

5

10

15

20

25

30

35

5 10 15 20

Avg=16.0

LCL=4.0

UCL=28.0

Week

Number

of Errors

Control Chart

8-5

Is

Process

Capable

?

Measures of Process Capability

C p =

Specification Range

True Process Range

=

USL - LSL

6s

c

C pk =

Distance from process average

to closest specification limit

1

2

True Process Range

=

min (USL - x , x - LSL)

3s

c

Problem: We are assuming the process has a target that is

in the center of the specification range, and that

the process is in fact centered on that target.

Note: a negative result is possible if the process average is outside specifications

Benefits: Optimal values are attained by running exactly

between specs.

Can (must) be used for 1-sided specifications

C p < 1.0

Process is not capable of meeting specs

C

p

= 1.0

Process is marginally capable

C

p

> 1.0

Process is capable of meeting specs

C

pk

< 1.0

Process is not capable of meeting specs

C pk = 1.0

Process is marginally capable

C

pk

> 1.0

Process is capable of meeting specs

Warning: Capability assessments for unstable processes, may not be

indicative of how the process is actually performing.

8-6

Is

Process

Capable

?

How much material is out of spec?

In the short term?

In the long term?

USL

LSL

Process Capability

8-7

Is

Process

Capable

?

Process Capability Ratios

Voice of The Customer

Voice of The Process

USL

LSL

8-8

Is

Process

Capable

?

8-9

Is

Process

Capable

?

Process Capability - The Strategy

Centering The Process Is On Target

Spread Reduce The Variation

LSL

USL

Defects

Defects

8-10

Is

Process

Capable

?

2 Key Metrics for Measuring Capability

C Min(

X - LSL

3

USL - X

3

pk

, )

c

LSL USL

Cp

s 6

c s

c s

Process Capability Ratios

8-11

Is

Process

Capable

? Process Capability Ratios - Concept

Total Tolerance

C

Process Spread

p

c

LSL USL

Cp

s 6

8-12

Is

Process

Capable

?

A Short-term Capability study covers a relatively

short period of time (days, weeks) generally

consisting of 30 to 50 data points. The actual

number depends on the subject under study.

Is The Process

In Control ?

Is It Producing

Defects ?

35 30 25 20 15 10 5 0

39

34

29

24

Observation Number

I

n

d

i

v

i

d

u

a

l

V

a

l

u

e

I Chart for C1

X=30.60

3.0SL=37.36

-3.0SL=23.84

C

P

& C

PK

Measure Short-term

Capability

8-13

Is

Process

Capable

?

A long-term capability study covers a relatively long

period of time (weeks, months) generally consisting of

100-200 data points. Again, the actual amount depends

on the subject under study.

Is The Process

In Control ?

Is It Producing

Defects ?

100 50 0

50

40

30

20

Observation Number

I

n

d

i

v

i

d

u

a

l

V

a

l

u

e

I Chart for C3

X=33.80

3.0SL=47.12

-3.0SL=20.49

Long Term Performance

Short term

Capability

8-14

Is

Process

Capable

?

A Further Look at Capability

Compare the estimates of the process deviations

from the short-term and long-term data

What is the difference between the short-term and the

long-term data?

What implication does this have in doing capability

studies?

Descriptive Statistics

Variable N Mean StdDev

short term 30 30.6 2.23

long term 180 33.8 4.44

8-15

Is

Process

Capable

?

Measures of Process Performance

P

p

=

Specification Range

True Process Range

=

USL - LSL

6s

s

P

pk

=

Distance from process average

to closest specification limit

1

2

True Process Range

=

min (USL - x , x - LSL)

3s

s

Problem: We are assuming the process has a target that is

in the center of the specification range, and that

the process is in fact centered on that target.

Note: a negative result is possible if the process average is outside specifications

Benefits: Optimal values are attained by running exactly

between specs.

Can (must) be used for 1-sided specifications

P

p

< 1.0

Process Performance is not meeting specs

P

p

= 1.0

Process Performance is marginally meeting specs

P

p

> 1.0

Process Performance is meeting specs

P

pk

< 1.0

Process Performance is not meeting specs

P

pk

= 1.0

Process Performance is marginally meeting specs

P

pk

> 1.0

Process Performance is meeting specs

8-16

Is

Process

Capable

?

Performance vs. Capability

These data show that the process, if well controlled can

perform much better than it currently is

50 40 30 20 10

14

13

12

11

10

Index

C

O

2

-

S

h

r

t

CO2 Levels for 55 Time Points Days Sales Outstanding for 55 Days

D

S

O

8-17

Is

Process

Capable

?

Capability vs. Performance

50 40 30 20 10

14

13

12

11

10

Index

C

O

2

-

S

h

r

t

CO2 Levels for 55 Time Points Days Sales Outstanding for 55 Days

D

S

O

Process Performance:

Total Variation including

shifts and drifts

(Pp & Ppk)

Capability: Only

random or short

term variability

(Cp & Cpk)

8-18

Is

Process

Capable

?

Process Performance Ratios

The P-family of indices are computationally the same as

the C-family of capability indices, but use the observed

long-term standard deviation.

P Min(

X - LSL

3

USL - X

3

pk

, )

s

LSL USL

p P

s 6

s s s s

8-19

Is

Process

Capable

?

WARNING!!!

Statistical Assumptions Made In Capability Studies

1. Data Comes From a Stable Process

If not, work towards getting the process in

control

Dont despair, you can still make some

assumptions about your process in the mean

time

You might also like

- MeasurementSystemsAnalysis PDFDocument37 pagesMeasurementSystemsAnalysis PDFJorge MartinezNo ratings yet

- Satistical Process Control Study: Data Collections:-Sample D2 A2 D4Document1 pageSatistical Process Control Study: Data Collections:-Sample D2 A2 D4cqi9nNo ratings yet

- 14 Variable Sampling Plan - StudentDocument17 pages14 Variable Sampling Plan - Studentsoonvy100% (1)

- World Class Quality To Achieve Zero PPM 231111Document108 pagesWorld Class Quality To Achieve Zero PPM 231111Gyanesh_DBNo ratings yet

- QC Tool - Control Chart Sieve Agg. 0.150mm 200diaDocument3 pagesQC Tool - Control Chart Sieve Agg. 0.150mm 200diachinhon0% (1)

- 4 Introduction To Minitab JJTDocument75 pages4 Introduction To Minitab JJTPankaj VishwakarmaNo ratings yet

- Strategy Diagram ExamplesDocument8 pagesStrategy Diagram ExamplesmanuelNo ratings yet

- SPCDocument12 pagesSPCalpanakaurNo ratings yet

- Six Sigma Control PDFDocument74 pagesSix Sigma Control PDFnaacha457No ratings yet

- GR&R Training DraftDocument53 pagesGR&R Training DraftLOGANATHAN VNo ratings yet

- SPC Chart BlankDocument1 pageSPC Chart BlankbowlinglmNo ratings yet

- CPK GuidelinesDocument2 pagesCPK GuidelinesNavnath Tamhane100% (1)

- Advanced Process CapabilityDocument11 pagesAdvanced Process Capabilitycheqjieja100% (1)

- GM Apqp Manual PDFDocument57 pagesGM Apqp Manual PDFBenito GerardoNo ratings yet

- MSA Case StudiesDocument10 pagesMSA Case StudiesMuthuswamyNo ratings yet

- MSA WorksheetDocument33 pagesMSA WorksheetSandrawarman BalasundramNo ratings yet

- Msa PDFDocument35 pagesMsa PDFRajesh SharmaNo ratings yet

- Chapter 3 - Control Chart For VariablesDocument66 pagesChapter 3 - Control Chart For VariablesSultan Almassar100% (1)

- SPC Basics: Presented By: Tariq KhurshidDocument50 pagesSPC Basics: Presented By: Tariq Khurshidtkhurshid3997No ratings yet

- DOE Taguchi Basic Manual1 PDFDocument121 pagesDOE Taguchi Basic Manual1 PDFMaduraveluNo ratings yet

- Msa-R&R Training Program: DateDocument25 pagesMsa-R&R Training Program: DateHarshad KulkarniNo ratings yet

- MSA Training Material - 18 - 04 - 2018Document10 pagesMSA Training Material - 18 - 04 - 2018Mark AntonyNo ratings yet

- Root Cause Analysis - ShaininapproachDocument6 pagesRoot Cause Analysis - ShaininapproachRaghavendra KalyanNo ratings yet

- Training in MSA PQ Systems Training Material PDFDocument109 pagesTraining in MSA PQ Systems Training Material PDFsaby aroraNo ratings yet

- HDS Manual PDFDocument73 pagesHDS Manual PDFsunkissedchiffon100% (1)

- Statistical Process Control Chart KjashdDocument5 pagesStatistical Process Control Chart Kjashdanon_216770716No ratings yet

- DMAIC Project ExampleDocument18 pagesDMAIC Project Examplejesus peralNo ratings yet

- PPXV An Elegant and Fast Method To Predict The Slow Crack Growth Behaviour of High Density Polyethylene Pipe MaterialsDocument7 pagesPPXV An Elegant and Fast Method To Predict The Slow Crack Growth Behaviour of High Density Polyethylene Pipe MaterialsMehboob ulHaqNo ratings yet

- How To Design, Analyze and Interpret The Results of An Expanded Gage R&R StudyDocument10 pagesHow To Design, Analyze and Interpret The Results of An Expanded Gage R&R Studymassman02143No ratings yet

- CpkGuide 0211 TECH1Document11 pagesCpkGuide 0211 TECH1d_flamarich7358No ratings yet

- 4 Aa Process CapabilityDocument30 pages4 Aa Process CapabilityAniket Jain100% (2)

- Shainin Methodology An Alternative or An EffectiveDocument14 pagesShainin Methodology An Alternative or An EffectiveMarco SánchezNo ratings yet

- PEBC-Calculation QuestionsDocument24 pagesPEBC-Calculation QuestionsHal Edwards100% (8)

- Process Capability and Capability IndexDocument18 pagesProcess Capability and Capability IndexBhavesh Rana100% (2)

- Quality Control and Acceptance SamplingDocument15 pagesQuality Control and Acceptance SamplingMark Ortiz Luis OllerNo ratings yet

- Six Sigma Green Belt TrainingDocument6 pagesSix Sigma Green Belt TrainingRajasekaran Thiyagarajan75% (4)

- Statistic ProcessDocument39 pagesStatistic ProcessxredjokerxNo ratings yet

- Measurement System Analysis LabDocument32 pagesMeasurement System Analysis LabAnonymous 3tOWlL6L0U100% (1)

- MSA-Gage RRDocument9 pagesMSA-Gage RRbmyertekinNo ratings yet

- MSA Example WorkbookDocument41 pagesMSA Example Workbookll vvNo ratings yet

- Attribute Gauge R&RDocument5 pagesAttribute Gauge R&Rhel2905No ratings yet

- MSA Presentation by M Negi 31.01.09Document76 pagesMSA Presentation by M Negi 31.01.09Mahendra100% (2)

- Msa PresentationsDocument17 pagesMsa PresentationsNarasimharaghavanPuliyurKrishnaswamyNo ratings yet

- Process and Measurement System Capability AnalysisDocument18 pagesProcess and Measurement System Capability AnalysisUtkarsh MittalNo ratings yet

- Statistical Process Control FundamentalsDocument32 pagesStatistical Process Control FundamentalsEd100% (1)

- Gage R&RDocument1 pageGage R&Rshobhit2310No ratings yet

- Core Tools: Measurement Systems Analysis (MSA)Document6 pagesCore Tools: Measurement Systems Analysis (MSA)Salvador Hernandez ColoradoNo ratings yet

- BS en 12697-12-2018Document24 pagesBS en 12697-12-2018Nguyễn văn ChínNo ratings yet

- A Study of Multiple Intelligence Among D.t.ed StudentsDocument14 pagesA Study of Multiple Intelligence Among D.t.ed StudentsAnonymous CwJeBCAXpNo ratings yet

- Process Capability Analysis and Process Analytical TechnologyDocument43 pagesProcess Capability Analysis and Process Analytical TechnologyPankaj VishwakarmaNo ratings yet

- Anova Gauge RR Repeatability ReproducibilityDocument3 pagesAnova Gauge RR Repeatability ReproducibilitysharkfsdfskjfsdfsfeNo ratings yet

- Measurement System Analysis (MSA) : Validating Your Measurement Systems Gy yDocument16 pagesMeasurement System Analysis (MSA) : Validating Your Measurement Systems Gy yHesham MahdyNo ratings yet

- Shain in TaguchiDocument8 pagesShain in TaguchisdvikkiNo ratings yet

- Presented By:: ASQ Section 0700 ASQ Section 0701Document35 pagesPresented By:: ASQ Section 0700 ASQ Section 0701fennyNo ratings yet

- Capability Analysis and MSA IntroductionDocument27 pagesCapability Analysis and MSA IntroductionJosé María MorenoNo ratings yet

- MSA TrainingDocument30 pagesMSA Trainingshukumar_24No ratings yet

- Plantilla R&R Variables-ANOVA Julio2013Document4 pagesPlantilla R&R Variables-ANOVA Julio2013Carlos Jose Sibaja CardozoNo ratings yet

- Process CapabilityDocument2 pagesProcess CapabilityrkshpanchalNo ratings yet

- Presentation On MSA by TS16949 Auditors From UL IndiaDocument16 pagesPresentation On MSA by TS16949 Auditors From UL Indiavish12321No ratings yet

- Advance Product Quality Planning-Matrix: LegendDocument1 pageAdvance Product Quality Planning-Matrix: Legendsumit_saraf_5No ratings yet

- Dynamic Control Plan - DCPDocument2 pagesDynamic Control Plan - DCPGabriel Caicedo RussyNo ratings yet

- How To Conduct A Measurement Systems AnalysisDocument5 pagesHow To Conduct A Measurement Systems AnalysisNavnath TamhaneNo ratings yet

- Measurement Systems: AnalysisDocument114 pagesMeasurement Systems: AnalysisAZIZ KUMARNo ratings yet

- STAT Exam 1 - Review SheetDocument2 pagesSTAT Exam 1 - Review SheetSamhitha BandiNo ratings yet

- Spring 12 ECON-E370 IU Exam 1 ReviewDocument27 pagesSpring 12 ECON-E370 IU Exam 1 ReviewTutoringZoneNo ratings yet

- Chapter 04 Asian Option PricingDocument9 pagesChapter 04 Asian Option Pricing8612959No ratings yet

- Laboratorymanual 135ALDocument182 pagesLaboratorymanual 135ALmollinedopinonNo ratings yet

- Forensic Toxicology Analysis of Self-Poisoning Suicidal Deaths in Tehran, Iran Trends Between 2011-2015Document10 pagesForensic Toxicology Analysis of Self-Poisoning Suicidal Deaths in Tehran, Iran Trends Between 2011-2015Fegi NugrahaNo ratings yet

- Unit 4 Lessson 1 Detailed Lesson PlanDocument14 pagesUnit 4 Lessson 1 Detailed Lesson PlanJenifer LapurgaNo ratings yet

- Aragon (2000) Evaluation of Four Vertical Jump Tests - Methodology, Reliability, Validity and Accuracy.Document16 pagesAragon (2000) Evaluation of Four Vertical Jump Tests - Methodology, Reliability, Validity and Accuracy.linoco1No ratings yet

- Deep Offshore Fracture Pressure Prediction in The Niger Delta - A New ApproachDocument16 pagesDeep Offshore Fracture Pressure Prediction in The Niger Delta - A New ApproachDaniel DamboNo ratings yet

- MODULE 8 One Sample Z-T - Test Population MeanDocument17 pagesMODULE 8 One Sample Z-T - Test Population MeanJanine LerumNo ratings yet

- C 577 - 99 AstmDocument4 pagesC 577 - 99 AstmLoan100% (1)

- Nhai Act 1988Document43 pagesNhai Act 1988Munaganti KiranNo ratings yet

- Normal Distribution ExcerciseDocument18 pagesNormal Distribution ExcercisePriyadarshini BAlakrishnan0% (1)

- Topic 2 - Chem 111Document68 pagesTopic 2 - Chem 111Toca TalezNo ratings yet

- Class 1 Chapter 14 Nuclear Counting Statistics: INME - Principles of Radiation Physics Chapter 14 - Page 1Document18 pagesClass 1 Chapter 14 Nuclear Counting Statistics: INME - Principles of Radiation Physics Chapter 14 - Page 1أحمدآلزهوNo ratings yet

- The Impact of REBT On AnxietyDocument11 pagesThe Impact of REBT On AnxietyMonica CiureaNo ratings yet

- Nutrients 10 00096Document11 pagesNutrients 10 00096OcZzNo ratings yet

- Easychair Preprint: B. Ismail Zabiullah, B. Eswar Sai and B. AmarendraDocument12 pagesEasychair Preprint: B. Ismail Zabiullah, B. Eswar Sai and B. AmarendraDIVYA PRIYA DARSHININo ratings yet

- L1 LM4 Probability Trees and Conditional Expectations - Study Notes (2024)Document9 pagesL1 LM4 Probability Trees and Conditional Expectations - Study Notes (2024)Thiago PlantholtNo ratings yet

- Stat 200 Week 5 HomeworkDocument3 pagesStat 200 Week 5 HomeworkldlewisNo ratings yet

- Assignment 1Document4 pagesAssignment 1Akash ShahNo ratings yet

- 4.3 - Propagation of UncertaintyDocument8 pages4.3 - Propagation of UncertaintyjahmanNo ratings yet

- Analysis of Organochlorine Pesticide Residues in Human and Cow's Milk in The Towns of Asendabo, Serbo and Jimma in South-Western Ethiopia (2013)Document6 pagesAnalysis of Organochlorine Pesticide Residues in Human and Cow's Milk in The Towns of Asendabo, Serbo and Jimma in South-Western Ethiopia (2013)EllyZaNo ratings yet

- Chapter 11 Test BankDocument46 pagesChapter 11 Test BankRujean Salar Altejar100% (1)