Professional Documents

Culture Documents

Cool Treat

Uploaded by

Vasudevan Krishnan0 ratings0% found this document useful (0 votes)

14 views31 pagescooling water treatement for power plant

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcooling water treatement for power plant

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views31 pagesCool Treat

Uploaded by

Vasudevan Krishnancooling water treatement for power plant

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 31

CHEMICAL TREATMENT IN

COOLING WATER SYSTEMS

BY P.K.VASUDEVAN

JUNIOR CHEMIST/MTPS

What is cooling water system?

It is the most important system in any Power

Station predominantly decides the efficiency of

stations

Heat Transfer: ( e.g. Boiler)

Hotter (source) cooler ( receiver)

Cooling water System:

Process ( source) Cool water(receiver )

Cooling water does not contact the source

directly. A Barrier that allows heat pass from

source to receiver

Water completes it job and cools the

source

This heat should be transferred to the

environment

Types of system

Once through system

Open recirculation system

Closed recirculation system

Source of water

Sea, River, Pond, etc.

Controlling Factors

1. The heat transfer characteristics

(thermal conductivity) of the barrier

2. The thickness of the heat transfer barrier

3. The surface area of the barrier

4. The temperature difference between the

source and the receiver ( cool. Water)

5. Insulating deposits on the either side of

the barrier

Types of Problems

Corrosion

Corrosion is function of water characteristics and the

metals in the system

Scale

Precipitation of compounds that become insoluble at

higher temperature

Fouling

Settling out of suspended solids, buildup corrosion

products, growth of microbial masses

Chemical treatments Corrosion Scaling Fouling Microbes

Chromates X

Zinc X

Molybates X

Silicates X

Polyphosphates X X

Polyolesters X

Phosphonates X X

All organics X X X

Natural organics X

Synthetic polymers X X

Non oxidizing

biocides

X X

Chlorine / Bromine X

Ozone X

Some of the major chemical components available for

cooling water treatment

CORROSION

Galvanic corrosion,

cell corrosion,

Dissolved gases

Stress corrosion

Corrosion fatigue cracking

Dezincification

Dissolved solids ( Chloride & Sulphate)

UNTANGLE THE TRIANGLE

The arms of the triangle encompass the

microbiological process in the centre.

Bio film contributes significantly to

microbiologically influenced corrosion and

under deposit corrosion

Bio film also possible nucleation sites for

mineral scale growth

Corrosion inhibitors

Principally

anodic

Principally

Cathodic

Both anodic &

Cathodic

Chromate

Calcium

Carbonate

Organic filming

amines

Orthophosphate Polyphosphate Phosponates

Nitrite Zinc

Silicate

Problem due to bio film

Increase microbiological influenced

corrosion

Reduction in heat transfer

Increase chemical cost

Cooling water chlorination

Dosing gaseous chlorine in cooling water

will control the organic matter growth

Cl2 + H2O HCl + HOCl

HOCL H

+

+ OCl

The above components are the primary

Toxicants that destroys microorganisms

A residual chlorine value of 0.2 to 0.4 ppm

will provide control

Continuous presence of residual chlorine

will increase contact time

In recent development HOBr , ( bromine

biocide) are available in liquid form are

used for continuous dosing .

Bromine is often a more practical

treatment than chlorine because it

remains effective at higher PH

Material % of Cl

2

Chlorine gas (Cl

2

) 100

Chlorine dioxide ( Cl O

2

) 263

Hypo chlorites ( Na or Ca)

Calcium Ca(OCl)

2

70

Sodium (NaOCl)

Industrial 12 - 15

Domestic 3 - 5

Lithium, LiOCl, laundry grade 35

Chlorinated isocyanuric acid ( CONCl)

3

85

SCALE CONTROL

Tendency to form inorganic deposits ( CaCO3,

MgCO3) on heat transfer surfaces due to cycles

of concentration

Scales are formed when inorganic constituents

are concentrated and super saturated solutions

are formed

When further concentrated in recirculation,

whereby reaching maximum concentration of

hardness (Ca,Mg) salts.

This will result precipitation of dense ,

adherent scale

These Scale act as a thermal insulator it

causes reduction in heat transfer

Scaling also increases roughness there by

increasing turbulence and pressure drop

To prevent scaling the concentration

factor is kept in the range of 1.25 to 2.0

C.F. = Concentration in cooling water

Concentration in Raw water

Calcium Carbonate solubility will decrease

while increase in temperature (inverse)

Ca( HCO

3

) CaCO

3

+ CO

2

+ H

2

O

Cooling Tower expels CO

2

from the water

To find the tendency of deposit Langlier

Index and Ryznar index are used

In recent technologies software packages

are available which are significantly more

powerful than the above methods

Control of Scaling

Scaling potential is mitigated by use of

polyphosponates or polymers

These are act as crystal modifier rather

than scale inhibitor

i.e they change the morphology of scale

not to bind each other and to precipitate

They help to keep the contaminants

suspended in bulk space

CONTROL DEPOSITS

Threshold inhibitors

Delay in precipitation / increase solubility

Dispersants

Disperse suspended solids ,adding charges, causing

mutual repulsion

Surface active agents

Penetrate and disperse biomasses. Some of them are

biocides kill slime organism

Crystal modifiers

modify the crystal structure of scale resultant will be

weak in structure will not stick on the surfaces.

Makeup

water

Condenser

Cooling

water pumps

Cooling Tower

Blow

Down

Evaporation & Drift

loss

Calcium

Magnesium

Sodium

Carbonates

Bicarbonates

Chlorides

sulphates

Pure water

Cooling water cycle

MASS BALANCE

This is the technique used to find out the

whether the system is In Balance or not

Concentration in circulation water

Concentration Ratio [ CR] = --------------------------------------------

[non precipitating ion( Cl)] Concentration of in Makeup water

From the CR the value of Calcium is calculated as follows

C.R X Calcium in make up water

Mass balance = Calculated calcium --- Actual Calcium in Cir.water

Example calculation:

Chloride in Makeup water = 22 ppm

Chloride in Circulating water = 34 ppm

Concentration Ratio = 34 / 22 == 1.545

Calcium in Makeup is = 86 ppm

Calculated calcium is = 86 X 1.545 = 133

If Actual calcium in Circulating water is:

Case (i)133 then 133 133 = 0 [ no deposition]

Case (ii) 131 then 133 131 = + 2 [Deposition ]

Case (iii) 135 then 133 135 = - 2 [ Calcium

dissolved]

Fouling

Fouling can be considered as deposition of

hardness salts and of other inorganic

particulate matter

This occurs usually in the areas where

water velocity is low

It has same effect as scale bet it promotes

severe corrosion under deposition

Sources of fouling deposits

Raw

water

Air borne Recirculation

water

Colloidal

organics

Dirt Scale: CaCO

3

,

CaSO

4

Silt, Dirt Reactive gases

H

2

S, SO

2

, NH

3

Corrosion

products: Fe

2

O

3

Microbial

contamination

Microbial

Contamination

Microbial deposits

Fouling control

Deposition fouling can be controlled

by

Filtering of makeup water

Addition of good dispersant

Controlling of scaling

Controlling of bio film formation

Latest development

Controlling the cooling water system

through latest software packages

Monitoring through on-line and real-time

Dosing chemicals and biocides according

to demand and performance based

SOME OF THE ONLINE

INSTRUMENTS

Bio film Analyser

Deposit Analyser

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Filtration TutorialDocument12 pagesFiltration TutorialSher Ahmad100% (1)

- Cpu PPTDocument10 pagesCpu PPTVasudevan KrishnanNo ratings yet

- Cpu PPTDocument10 pagesCpu PPTVasudevan KrishnanNo ratings yet

- Cool TreatDocument31 pagesCool TreatVasudevan KrishnanNo ratings yet

- Generator ChemisDocument86 pagesGenerator ChemisVasudevan Krishnan100% (6)

- Generator ChemisDocument86 pagesGenerator ChemisVasudevan Krishnan100% (6)

- Cool TreatDocument31 pagesCool TreatVasudevan KrishnanNo ratings yet

- TRansformer OilDocument28 pagesTRansformer OilVasudevan Krishnan100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Wind Energy Unit-EEEDocument6 pagesWind Energy Unit-EEEpfalencarNo ratings yet

- Check List For Chilled Water Secondary Pump: Sl. No Description RemarksDocument2 pagesCheck List For Chilled Water Secondary Pump: Sl. No Description Remarkssiruslara6491No ratings yet

- Excel 2010 Cheatsheet PDFDocument2 pagesExcel 2010 Cheatsheet PDFVinith VimalNo ratings yet

- Wire Diagram Complete Elevator - SL ELEVATOR 20190805Document23 pagesWire Diagram Complete Elevator - SL ELEVATOR 20190805Eka Rama100% (2)

- Dynamic Arrays With The Arraylist Class Chapter Xii TopicsDocument38 pagesDynamic Arrays With The Arraylist Class Chapter Xii TopicsRocket FireNo ratings yet

- Legend:-: General Arrangement ACS550-124A-4 YN3A205086-GAADocument12 pagesLegend:-: General Arrangement ACS550-124A-4 YN3A205086-GAANeeraj SharmaNo ratings yet

- Bansilal Ramnath Agarwal Charitable Trust'sDocument2 pagesBansilal Ramnath Agarwal Charitable Trust'sJennifer WaltonNo ratings yet

- CharanDocument25 pagesCharanCharan KumarNo ratings yet

- Spirent TestCenter Automation Obj RefDocument3,210 pagesSpirent TestCenter Automation Obj Refokie11No ratings yet

- Ultrasonic Atomizing Nozzle SystemsDocument40 pagesUltrasonic Atomizing Nozzle SystemsAnonymous H8hysGxA100% (1)

- BSM BWMP - D1 and D2Document34 pagesBSM BWMP - D1 and D2Adnan DjamalNo ratings yet

- Bolts TheoryDocument30 pagesBolts TheoryIbrahim Mesfin100% (1)

- Digital Signal Processing R13 Previous PapersDocument5 pagesDigital Signal Processing R13 Previous PapersPrasannaKumar KaraNam100% (1)

- Sigma Marine Coatings Manual - Part44Document2 pagesSigma Marine Coatings Manual - Part44EngTamerNo ratings yet

- Apollo Experience Report Electronic Systems Test Program Accomplishments and ResultsDocument70 pagesApollo Experience Report Electronic Systems Test Program Accomplishments and ResultsBob AndrepontNo ratings yet

- Data Structures NotesDocument9 pagesData Structures NotesMohammed JeelanNo ratings yet

- Week4 Divide and ConquerDocument15 pagesWeek4 Divide and ConquerHg0% (1)

- 13 Ijee2962nsDocument15 pages13 Ijee2962nspurvakul10No ratings yet

- Upload Photosimages Into Custom Table & Print in Adobe FormDocument14 pagesUpload Photosimages Into Custom Table & Print in Adobe FormEmilSNo ratings yet

- Gear Trains ProblemsDocument9 pagesGear Trains Problemsa c s Kumar100% (1)

- Curriculam Vitae: ObjectiveDocument4 pagesCurriculam Vitae: ObjectiveSachin DeoNo ratings yet

- Assign 3Document9 pagesAssign 3Yudha PP0% (1)

- Handling An Maintenance of Construction Machineries, Equipments and InstrumentsDocument13 pagesHandling An Maintenance of Construction Machineries, Equipments and InstrumentsVelmurugan BalasubramanianNo ratings yet

- Bernette Ramirez Mariano Bernette Ramirez MarianoDocument1 pageBernette Ramirez Mariano Bernette Ramirez Marianomia palacioNo ratings yet

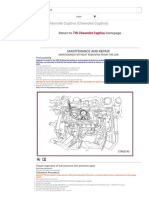

- Chevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.Document57 pagesChevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.krisdiarto@gmail.com96% (23)

- MH16 Series ROOFTOP AC Manual REV 2013Document19 pagesMH16 Series ROOFTOP AC Manual REV 2013caleb perezNo ratings yet

- Datasheet 783Document2 pagesDatasheet 783veertulNo ratings yet

- Building Applications in C# - InTLDocument682 pagesBuilding Applications in C# - InTLMustehsan Armaghan Ghouri Magkacgck100% (1)

- Led Linear Emergency 2021Document4 pagesLed Linear Emergency 2021Sugumaran LakshmananNo ratings yet

- Astm B446 - 2003 - 2008Document5 pagesAstm B446 - 2003 - 2008isaque300984No ratings yet