Professional Documents

Culture Documents

SSP 020 Common - Rail

Uploaded by

venkateshyadav2116Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SSP 020 Common - Rail

Uploaded by

venkateshyadav2116Copyright:

Available Formats

COMMON RAIL FUEL INJECTION

SYSTEM

;JL";L\U V[g0 VMJZ CM,L\U VMO

VM8MDMAF., s 0Lh, f]

,[XG G\AZ : 15

Demand On Modern Diesel Engine

Development

Low fuel consumption

Low pollutant emissions

Quiet running engines

Improved engine performance

Common rail fuel injection system and its

function

Provide the diesel engine with fuel

Generate the high pressure needed for fuel

injection and distribute the fuel to the

individual cylinders

Inject precisely correct amount of fuel at

exactly the right moment in time.

In contrast to other injection system Common

rail fuel injection system is an accumulator

injection system.

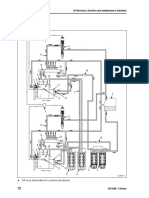

How does a CR system function?

Sub functions of a CRFI system

Low pressure circuit High pressure circuit ECU with sensors

COMMON RAIL FUEL INJECTION SYSTEM

Low pressure circuit comprises of:

Fuel tank ,Pre-supply pump, Fuel filter, And the

respective connection lines.

The Common Rail Sub functions

Low pressure circuit

The low pressure circuit is responsible for

transporting the fuel to the high pressure circuit

High pressure circuit comprises:

High pressure pump with pressure control valve

The high pressure accumulator (Rail )with the rail

pressure sensor

Injectors, and

The respective high pressure connection lines.

The Common Rail Sub functions

The high pressure circuit

It is the responsibility of the high

pressure circuit to generate a constant

unvarying high pressure in the high

pressure accumulator (the rail) and to

inject the fuel through the injectors into

the engines combustion chambers.

ECU and sensors

The common rail ECU evaluates the signals from the

following sensors.

Crankshaft speed sensor, Camshaft sensor,

Accelerator-pedal travel sensor

The Common Rail Sub functions

The common rail ECU evaluates the signals from the

following sensors:

Boost pressure sensor, Air temperature sensor,

Air mass meter, and Rail pressure sensor.

The Common Rail Sub functions

The Common Rail Sub functions

ECU and sensors

The sensor are responsible for measuring important

physical quantities. The ECU calculates injected fuel

quantity, start of injection, duration of injection, and

rate of discharge curve, as well supervises the correct

functioning of the injection system as a whole.

PRE SUPPLY PUMP

Transports fuel from the fuel tank to the high pressure

pump.

An electric fuel pump is used for this purpose in the

CRFIS.

When the electric fuel pump is switched off, the supply

of fuel is interrupted and the engine stops.

COMMON RAIL FUEL INJECTION SYSTEM

DESIGN

PRE SUPPLY PUMP

The electric fuel pump comprises of:

1.Electric Motor

2.Roller-Cell Pump

3.Non Return Valve

The roller cell is

driven by an electric

motor.

Its rotor is mounted

eccentrically and

provided with slots

in which movable

rollers are free to

travel.

PRE SUPPLY PUMP

The rollers are forced

against the base plate

by rotation and by fuel

pressure .

The fuel is

transported to the

outlet openings on the

pumps pressure side.

PRE SUPPLY PUMP

Gear type fuel pump

The drive gear wheel

is driven by the engine

.

Delivery quantity is

directly proportional

to engine speed .

Shut off is by means

of an electromagnet..

PRE SUPPLY PUMP

variants

High- pressure pump

The pump plunger moves downwards

The inlet valve opens

The fuel is drawn in to the pumping element

chamber(suction stroke)

At BDC, the inlet valve closes

The fuel in the chamber can be compressed by

the upward moving plunger.

High- pressure pump

An electromagnet is

used for pumping

element switch-off.

High- pressure pump

High- pressure accumulator (Rail)

Store fuel

Prevent pressure fluctuations

Rail is a forged-steel tube.

ID is approx.. 10mm

Length is between 280 and 600mm

The volume must be as small as possible,

as large as necessary

High- pressure accumulator (Rail)

Pressure-control valve (DRV)

Responsible for

maintaining the

pressure in the

rail at a

constant level.

Rail-pressure sensor (RDS)

Measures the

pressure in the rail

inputs the information

to the ECU

RDS should provide

extremely precise

measured values.

RDS is mounted

directly on the rail.

Injector

Injects exactly the correct amount of fuel in

to the combustion chamber at precisely

the right moment in time

The injector is equipped with:

2/2 electromagnetic servo valve

Nozzle

Valve control chamber

Return line

Injector

The essential forces for correct functioning are:

Nozzle-spring force

Valve spring force

Electromagnet force

Force due to the pressure in the valve-control

chamber

Force due to the pressure in the nozzle needle

Injector

ECU with sensors

Common Rail is an EDC controlled injection

system

The ECU controls & monitors the complete

injection process

The sensors delivers all the measured values

which are required in the process

Summary

Components of CRFIS

are:

Pre-supply pump

High-pressure pump

High-pressure

accumulator(rail)

Pressure-control valve

Rail-pressure sensor

Injectors

ECU with sensors

COMMON RAIL FUEL INJECTION SYSTEM

COMMON RAIL FUEL INJECTION SYSTEM

SUMMAR

1.The basic functional groups of the common rail are : low

pressure circuit , high pressure circuit ECU and

sensors.

2.In the low pressure circuit, the fuel is cleaned by a filter

and then transported to the high pressure circuit

COMMON RAIL FUEL INJECTION SYSTEM

SUMMARY

3.In the high pressure circuit , the maximum

pressure of 1,350 bar is generated in the high

pressure accumulator (Rail).

The pressure is maintained at a constant

level , and the fuel is taken from the rail every

time an injection takes place.

4.The ECU controls and monitors the complete

injection system. Using the signals from the

sensors, the ECU calculates all the values for

the injection process and triggers the

components in high-pressure circuit (pressure

control valve, injectors).

You might also like

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Common RailDocument30 pagesCommon RailrowanNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Common Rail SystemDocument30 pagesCommon Rail SystemJunaidi Juna Westborneo100% (3)

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- CRDIDocument31 pagesCRDIJawahar Raj100% (3)

- Common RailDocument30 pagesCommon RailRowan CorneliusNo ratings yet

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Common RailDocument30 pagesCommon RailAnonymous 9QkTHFNo ratings yet

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Electronic Diesel Fuel System (Common Rail)Document30 pagesElectronic Diesel Fuel System (Common Rail)Katu2010100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Denso CR - Hp2 NissanDocument31 pagesDenso CR - Hp2 NissanMarcelo Diesel86% (7)

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsFrom EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNo ratings yet

- Saa6d140e-3 Shop ManualDocument18 pagesSaa6d140e-3 Shop Manualjannievanstaden783No ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Libro InstructorDocument62 pagesLibro InstructorTHOMAS NGNo ratings yet

- Hino j08c j05c Type EngineDocument29 pagesHino j08c j05c Type EngineNaseer Ahmed Awan88% (8)

- Vehicle Electrical ActuatorsDocument40 pagesVehicle Electrical ActuatorsBence M Zoltan100% (1)

- Common Rail Direct Injection: By: Sahal M Mansuri AND Joshi MaulikDocument19 pagesCommon Rail Direct Injection: By: Sahal M Mansuri AND Joshi MaulikTanvir KatariaNo ratings yet

- Fuel Injection SystemDocument24 pagesFuel Injection SystemDevendra Pratap SinghNo ratings yet

- Fuel Injection SystemDocument9 pagesFuel Injection SystemJM PraveenNo ratings yet

- Group 13E Electronically Controlled Fuel SystemDocument57 pagesGroup 13E Electronically Controlled Fuel Systemandleralfonso7308No ratings yet

- Multi Point Fuel InjectionDocument15 pagesMulti Point Fuel Injectionಶಿವರಾಜ್ ಎನ್No ratings yet

- 2.fuel Inj Compresion IgnitionDocument19 pages2.fuel Inj Compresion IgnitionJo VialNo ratings yet

- CHAPTER 2 (Common Rail Diesel)Document48 pagesCHAPTER 2 (Common Rail Diesel)Muhd Nasri100% (3)

- Isuzu 6HK1Document23 pagesIsuzu 6HK1Ihsanul HudaNo ratings yet

- 1 Gasoline Electronic Direct Injection System1Document40 pages1 Gasoline Electronic Direct Injection System1EZHILARASAN RNo ratings yet

- CRI Sytem PDFDocument21 pagesCRI Sytem PDFAdi SNo ratings yet

- Gasoline EFIDocument97 pagesGasoline EFIAnteneh MesfinNo ratings yet

- HINO J08C J05C Type Engine PDFDocument29 pagesHINO J08C J05C Type Engine PDFDiego Cadena100% (3)

- Ayuda Técnica - VW - Particularidades de La Transmisión CFC 348VDocument38 pagesAyuda Técnica - VW - Particularidades de La Transmisión CFC 348VMEKATRONIKA ARGENTINANo ratings yet

- Weber Injection-Ignition SystemDocument27 pagesWeber Injection-Ignition SystemjohnvandurenNo ratings yet

- Control FuellDocument51 pagesControl FuellGuadalupe GuerreroNo ratings yet

- HINO Riel Comun J08C-J05C (Ingles)Document29 pagesHINO Riel Comun J08C-J05C (Ingles)Carlos Pabon Salom100% (1)

- 6 Gasoline Electronic Fuel Injection SystemsDocument34 pages6 Gasoline Electronic Fuel Injection Systemsloganathanpalani100% (1)

- Isuzu 6hk1 6sd1 Type EngineDocument23 pagesIsuzu 6hk1 6sd1 Type Engineابن حمزة الخدري الخدريNo ratings yet

- Unit Injectors: Unit Injector Hold-Down Clamp Rack Plunger Injector NozzleDocument14 pagesUnit Injectors: Unit Injector Hold-Down Clamp Rack Plunger Injector NozzleGovea HeduNo ratings yet

- Ae 1 Module PDFDocument113 pagesAe 1 Module PDFUnni HaridasNo ratings yet

- Fuel Injection System Bosch AfcDocument28 pagesFuel Injection System Bosch AfcShivam TandonNo ratings yet

- Electronic Fuel Injection by Dr.S.John AlexisDocument32 pagesElectronic Fuel Injection by Dr.S.John AlexisJ Naveen KumarNo ratings yet

- Isuzu Common RailDocument40 pagesIsuzu Common RailManos Stavrou100% (25)

- Common Rail Diesel InjectionDocument13 pagesCommon Rail Diesel InjectionDejan Matic100% (1)

- Gasoline Electronic Fuel Injection SystemsDocument35 pagesGasoline Electronic Fuel Injection SystemsatulsemiloNo ratings yet

- Common Rail Diesel InjectionDocument13 pagesCommon Rail Diesel InjectionDejan Matic67% (3)

- Common RailDocument11 pagesCommon RailnitishghosalNo ratings yet

- Prepared By: Amanuel Gebisa May 2015Document69 pagesPrepared By: Amanuel Gebisa May 2015Yalew MekonnenNo ratings yet

- Diesel Engine ManagementDocument56 pagesDiesel Engine Managementbravo6dNo ratings yet

- MPFI Vs Carburetor Technology For Multi Cylinder EnginesDocument14 pagesMPFI Vs Carburetor Technology For Multi Cylinder EnginesDipak Kumar100% (1)

- Fuel 1Document1 pageFuel 1bernabasNo ratings yet

- High PressureDocument9 pagesHigh Pressurezozo0424No ratings yet

- Bomba de Alta Presion Denso Hp0pdfDocument4 pagesBomba de Alta Presion Denso Hp0pdfMarcelo DieselNo ratings yet

- Engine Management Common Rail Diesel Fuel SystemDocument53 pagesEngine Management Common Rail Diesel Fuel SystemBiruk TilahunNo ratings yet

- Back To Basics With Auto-SolveDocument3 pagesBack To Basics With Auto-SolveKar GayeeNo ratings yet

- Ic Engine AssignmentDocument7 pagesIc Engine AssignmentMuhammad Fahad Khan 51-FET/BSCMET/F19No ratings yet

- 8.edc 17 9 Aug 2016Document34 pages8.edc 17 9 Aug 2016iqbal husseinNo ratings yet

- 164 TWSM0814R 4M5 enDocument71 pages164 TWSM0814R 4M5 enClaudio Rene Silva HernandezNo ratings yet

- Fuel SystemDocument99 pagesFuel SystemPaulus Saing100% (5)

- Training Process: 4 StagesDocument1 pageTraining Process: 4 Stagesvenkateshyadav2116No ratings yet

- STAGE 1for CollegesDocument1 pageSTAGE 1for Collegesvenkateshyadav2116No ratings yet

- Jominy Hardness TessDocument3 pagesJominy Hardness TessIqbal BashiruNo ratings yet

- Assembly DrawingsDocument1 pageAssembly Drawingsvenkateshyadav2116No ratings yet

- CAD 2D ContentDocument3 pagesCAD 2D Contentvenkateshyadav2116No ratings yet

- Catia V5: DR Ahmed KovacevicDocument60 pagesCatia V5: DR Ahmed KovacevicYunus YanarNo ratings yet

- Mms Venky IntroductionDocument2 pagesMms Venky Introductionvenkateshyadav2116No ratings yet

- Engineering College: Course FileDocument2 pagesEngineering College: Course Filevenkateshyadav2116No ratings yet

- p111 Lecture13Document22 pagesp111 Lecture13venkateshyadav2116No ratings yet

- Chapter 7 Powerpoint 1225339266570076 9Document24 pagesChapter 7 Powerpoint 1225339266570076 9venkateshyadav2116No ratings yet

- Section 1 Momentum & Impulse - Phpapp01Document69 pagesSection 1 Momentum & Impulse - Phpapp01venkateshyadav2116No ratings yet

- Impulse Momentum Check ItDocument38 pagesImpulse Momentum Check Itvenkateshyadav2116No ratings yet

- Phys111 Lecture08Document54 pagesPhys111 Lecture08venkateshyadav2116No ratings yet

- Chapter 6 Momentum & Collisions Nice Check ItDocument67 pagesChapter 6 Momentum & Collisions Nice Check Itvenkateshyadav2116100% (1)

- Tyre Notes AeDocument16 pagesTyre Notes Aevenkateshyadav2116100% (2)

- Chapter 7Document32 pagesChapter 7venkateshyadav2116No ratings yet

- Academic Physics Chapter 5 Work EnergyDocument72 pagesAcademic Physics Chapter 5 Work Energyvenkateshyadav2116No ratings yet

- "View" "Slide Show.": Resources Chapter MenuDocument80 pages"View" "Slide Show.": Resources Chapter Menujlvmrbd777No ratings yet

- Mech 203 Term Project Automobile Differential and TransmissionDocument29 pagesMech 203 Term Project Automobile Differential and TransmissionYugi SupriatnaNo ratings yet

- Momentum, Impulse and CollisionDocument45 pagesMomentum, Impulse and CollisionBen TenederoNo ratings yet

- Important Question For Automobile EnggDocument2 pagesImportant Question For Automobile Enggvenkateshyadav2116No ratings yet

- Suspension System in AutomobilesDocument26 pagesSuspension System in AutomobilesAjay Singh BhadoriaNo ratings yet

- DomDocument151 pagesDomvenkateshyadav2116No ratings yet

- BrakesDocument16 pagesBrakesrautrajeshvNo ratings yet

- Brake System FundamentalsDocument32 pagesBrake System Fundamentalskumaras1No ratings yet

- Automobile EngineeringDocument4 pagesAutomobile Engineeringvenkateshyadav2116No ratings yet

- CSD 8 Automotive Brake Systems BasicsDocument14 pagesCSD 8 Automotive Brake Systems BasicsVijay Hassan KrishnappaNo ratings yet

- Friction Clutches Mmc1 April 20 2011Document24 pagesFriction Clutches Mmc1 April 20 2011venkateshyadav2116No ratings yet

- JNTU B.tech 3-2 MECH Syllabus BookDocument12 pagesJNTU B.tech 3-2 MECH Syllabus Bookvenkateshyadav2116No ratings yet

- Example Practical ReportDocument45 pagesExample Practical ReportMohd Zulhilmi84% (19)

- Castro Franklin ResumeDocument2 pagesCastro Franklin ResumeFrank CastroNo ratings yet

- CNSSAM - 01 - 13 - Red Black Installation GuidanceDocument43 pagesCNSSAM - 01 - 13 - Red Black Installation GuidanceTim_CNo ratings yet

- Nexans 500 KV CableDocument22 pagesNexans 500 KV CableFiras Atwan100% (1)

- Machine Learning Applications Used in Accounting and AuditsDocument6 pagesMachine Learning Applications Used in Accounting and AuditsVIVA-TECH IJRI100% (1)

- The Electrical Engineering HandbookDocument24 pagesThe Electrical Engineering HandbookKar GayeeNo ratings yet

- Project Report On Thermal EngineeringDocument14 pagesProject Report On Thermal EngineeringTanmay AmodkarNo ratings yet

- Bulk Sms End User GuideDocument46 pagesBulk Sms End User GuideMutiara HatiNo ratings yet

- Abid Hussain ResumeDocument1 pageAbid Hussain ResumeAbid HussainNo ratings yet

- WinRelay-V2 53Document2 pagesWinRelay-V2 53Gherib AlmoutassimbellahNo ratings yet

- Foerster Circoflux 2014 enDocument6 pagesFoerster Circoflux 2014 enamirlove206No ratings yet

- Unit 1: Review of Web TechnologiesDocument150 pagesUnit 1: Review of Web Technologiesdijon weilandNo ratings yet

- Graphic Design Assignment 1Document4 pagesGraphic Design Assignment 1Amita MaddhesiyaNo ratings yet

- Low-Loss, Broadly-Tunable Cavity Filter Operating at UHF FrequenciesDocument4 pagesLow-Loss, Broadly-Tunable Cavity Filter Operating at UHF FrequenciesDo SonNo ratings yet

- Virtual Reality: Sitaram ThripuralaDocument32 pagesVirtual Reality: Sitaram ThripuralaThripurala sitaramNo ratings yet

- Review If Transparent Solar Photovoltaic TechnologiesDocument13 pagesReview If Transparent Solar Photovoltaic TechnologiesSharonNo ratings yet

- Technology For Teaching and Learning Module 1Document11 pagesTechnology For Teaching and Learning Module 1Kim Roi CiprianoNo ratings yet

- (IJCST-V8I5P3) : Gajendra R. WaniDocument4 pages(IJCST-V8I5P3) : Gajendra R. WaniEighthSenseGroupNo ratings yet

- Editores de BlockDocument122 pagesEditores de Blockjesus lopezNo ratings yet

- KMSY (New Orleans, LA)Document47 pagesKMSY (New Orleans, LA)David PerinettiNo ratings yet

- Air-Cooled Aircraft Engine Cylinders: An Evolutionary OdysseyDocument9 pagesAir-Cooled Aircraft Engine Cylinders: An Evolutionary Odysseyyogi5guruNo ratings yet

- Applicability Guide PDFDocument2 pagesApplicability Guide PDFtriplbingaziNo ratings yet

- Ryoks-1644896915710 STKDocument2 pagesRyoks-1644896915710 STKRyoka SasakyNo ratings yet

- Excel Budget TemplateDocument5 pagesExcel Budget TemplateChiranjib BanerjeeNo ratings yet

- THYSSENKRUPP ElevatorDocument3 pagesTHYSSENKRUPP Elevatorhamid taher50% (2)

- Power Electronic TransformerDocument7 pagesPower Electronic TransformerNarendra TrivediNo ratings yet

- Airflow Chapter2Document35 pagesAirflow Chapter2massywebNo ratings yet

- MEO Class 4 Examination - Subjects, Syllabus, Courses, Eligibility EtcDocument10 pagesMEO Class 4 Examination - Subjects, Syllabus, Courses, Eligibility EtcRavi Viknesh67% (3)

- Managing Reverse LogisticsDocument14 pagesManaging Reverse LogisticsHarshit GajjarNo ratings yet

- DS-2CD3743G1-IZUHK 4 MP IR Varifocal Dome Network Camera: Key FeaturesDocument4 pagesDS-2CD3743G1-IZUHK 4 MP IR Varifocal Dome Network Camera: Key FeaturesSecurity STSNo ratings yet

- Automotive Electronic Diagnostics (Course 1)From EverandAutomotive Electronic Diagnostics (Course 1)Rating: 5 out of 5 stars5/5 (6)

- Why We Drive: Toward a Philosophy of the Open RoadFrom EverandWhy We Drive: Toward a Philosophy of the Open RoadRating: 4 out of 5 stars4/5 (6)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]From EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Rating: 5 out of 5 stars5/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceFrom EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVFrom EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVRating: 5 out of 5 stars5/5 (2)

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)From EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)No ratings yet

- The Official Highway Code: DVSA Safe Driving for Life SeriesFrom EverandThe Official Highway Code: DVSA Safe Driving for Life SeriesRating: 3.5 out of 5 stars3.5/5 (25)

- New Hemi Engines 2003 to Present: How to Build Max PerformanceFrom EverandNew Hemi Engines 2003 to Present: How to Build Max PerformanceNo ratings yet

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildFrom EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildRating: 5 out of 5 stars5/5 (1)

- Turbo: Real World High-Performance Turbocharger SystemsFrom EverandTurbo: Real World High-Performance Turbocharger SystemsRating: 5 out of 5 stars5/5 (3)

- Top 21 Hypercars: The Best and Fastest Car Ever MadeFrom EverandTop 21 Hypercars: The Best and Fastest Car Ever MadeRating: 3 out of 5 stars3/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Building Honda K-Series Engine PerformanceFrom EverandBuilding Honda K-Series Engine PerformanceRating: 5 out of 5 stars5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WFrom EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WRating: 4.5 out of 5 stars4.5/5 (6)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)