Professional Documents

Culture Documents

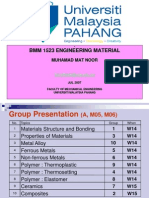

Eng Mat Chapter 2

Uploaded by

VC Chua Yee LeongOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eng Mat Chapter 2

Uploaded by

VC Chua Yee LeongCopyright:

Available Formats

lecture #1c

lecture #1c

3 basic subatomic particles: Proton, electrons and neutrons

Atomic structure

lecture #1c

"GOD is the ONE who created the night, the day, the

sun, and the moon. Each one is travelling in an orbit

with its own motion" (21:33)

lecture #1c

Atomic structure

What is atom?

Basic structural unit of all engineering materials

Atoms = Nucleus (protons+neutrons) + electrons

Electrons:

Smallest mass (1/1836 of proton) compare to neutrons

(1.675x10

-24

g) and protons (1.673x10

-24

g).

Determine most of the electrical, mechanical, chemical

and thermal properties of the atoms.

lecture #1c

The Qur'an states, "Whoso doeth ill

(Al Sharr) an atom`s weight, will

see it then." (Sura 99:8)

lecture #1c

Foundation of materials science and engineering,William F. Smith,McGrawHill, 2004, pg19-58

The Periodic Table Inert Gas (s

2

p

6

)

Halogen (s

2

p

5

)

Alkali (s

1

)

Alkaline Earth (s

2

)

Transition Metals (incomplete d subshell)

lecture #1c

Atomic Bonding

lecture #1c

Valence Electrons

Valence electrons are the electrons that occupy the

outermost filled shell.

These electrons are extremely important as they

participate in the bonding between atoms to form

atomic and molecular aggregates.

Most of the electrical, mechanical, chemical and

thermal properties of the atoms of solids are based

on these valence electrons.

lecture #1c

Primary Atomic Bonds

1. Ionic Bonding

2. Covalent Bonding

3. Metallic bonding

Types of Bonding

Secondary Atomic Bonds

1. Permanent dipole bonds

2. Fluctuating dipole

lecture #1c

Ionic Bonding

Occurs in compounds that are composed of both metallic

and nonmetallic elements which are in the horizontal

extremities of the periodic table

lecture #1c

Ionic Bonding

Metallic elements transfer the valence electrons to

nonmetallic atoms

To produce ions that are bonded together by coulombic

forces

(attraction of positively and negatively charged ions).

In the process, all the atoms acquire stable or inert gas

configurations.

Ionic bonding is termed strong and nondirectional, i.e. the

magnitude of the bond is equal in all directions around an

ion

lecture #1c

Foundation of materials science and engineering,William F. Smith,McGrawHill, 2004, pg19-58

Examples: NaCl, MgO

The properties of ionic materials are:

i. hard and brittle

ii. electrically and thermally insulative

Ionic Bonding

lecture #1c

Give up electrons Acquire electrons

He

-

Ne

-

A r

-

Kr

-

Xe

-

Rn

-

F

4.0

Cl

3.0

Br

2.8

I

2.5

A t

2.2

Li

1.0

Na

0.9

K

0.8

Rb

0.8

Cs

0.7

Fr

0.7

H

2.1

Be

1.5

Mg

1.2

Ca

1.0

Sr

1.0

Ba

0.9

Ra

0.9

Ti

1.5

Cr

1.6

Fe

1.8

Ni

1.8

Zn

1.8

A s

2.0

C sC l

MgO

C aF

2

N aC l

O

3.5

Ionic Bonding

lecture #1c

Ionic materials are poor electrical conductors

When voltage is applied to an ionic material, the entire ions must

move to cause a current flow.

However, the ion movement is slow and therefore, the electrical

conductivity is poor.

lecture #1c

Metallic Bonding

Occurs in the solid metals and alloys.

In solid state, atoms are packed relatively close

together in a systematic pattern or crystal structure.

The valence electrons of metallic materials are

not bound to any particular atom in the solid and are

more or less free to drift throughout the entire metal.

Valence electrons belong to the metal as a whole,

or forming a sea of electrons.

lecture #1c

Metals have low ionization energies, thus they

do not have a tight hold on their valence electrons.

These outer electrons easily move around, as they

do not "belong" to any one atom, but are part of

the whole metal crystal

Metallic Bonding

lecture #1c

lecture #1c

The remaining non-valence electrons and atomic nuclei

form ion cores, which possess a net positive charge

equal in magnitude to the total valence electron charge

per atom.

The metallic bonding is also nondirectional.

Metallic bonding may be strong or weak.

The properties of metallic materials are:

i. Good ductility

ii. Good electrical conductivity

iii.Lustrous

iv.Malleable

lecture #1c

(a) Atomic arrangement in metallic copper crystal. Each copper atom

is coordinated with 12 other copper atoms, producing a crystal

structure called face-centered-cubic.

(b) Two dimensional schematic diagram of metallically bonded atoms.

The circles with the inner positive ion cores, and the charge clouds

around the iron cores represent the dispersed valence electrons.

Foundation of materials science and engineering,William F. Smith,McGrawHill, 2004, pg19-58

lecture #1c

Materials Structure

and Bonding

Crystal Structure of Metals

lecture #1c

SOLIDS

CRYSTALLINE AMORPHOUS

Short-range order (SRO)

of the positions

of the atoms.

Examples:

ceramic - common window glass,

polymers polystyrene & plastic

and food - cotton candy

The constituent atoms,

molecules, or ions are

packed in a regularly

ordered.

Examples:

Metals, alloys, minerals,

sand, clay, limestone,

carbon, and salts (NaCl, KCl)

Long-range order (LRO)

of the positions

of the atoms.

Random orientation of

particles.

lecture #1c

Crystalline Solids

Quartz crystal

Properties:

Relate to orientation and are

dependent on the crystals axes

(anisotropic).

Crystals become liquids at a

specific temperature (melting point)

Crystal

Liquid

Melting

T

m

Volume

Temperature

Single crystals

Poly-crystals

lecture #1c

Amorphous Solids

Wax

Properties:

Identical in all directions along

any axis (isotropic).

A relatively wide temperature

range for the melting point.

Soften gradually when they

are heated.

Amorphous

solid

Liquid

Softening

T

m

Volume

Temperature

lecture #1c

CRYSTALLINE

STRUCTURE

The orderly arrangement

of atoms in three

dimensional space.

Space lattice

-infinite 3D array of

points.

-repeating unit cells

Each point in the space

lattice has identical

surroundings.

Size & shape of unit cell

can be described by 3

lattice vectors (a,b,c).

Lattice constants:

Axial lengths (a,b,c)

Interaxial angles (,,).

lecture #1c

The arrangement of the atoms is called

crystalline structure

Space Lattice Unit cell

lecture #1c

CRYSTAL SYSTEMS

14 standard unit cells

(Bravais)

4 basic types of unit cells:

1. Simple

2. Body-centered

3. Face-centered

4. Base-centered

7 different types of unit cells

(specify the lattice constants):

1. Cubic

2. Tetragonal

3. Orthorhombic

4. Rhombohedral

5. Hexagonal

6. Monoclinic

7. Triclinic

lecture #1c

14 Bravais Conventional Unit Cell

lecture #1c

The Structure of Metal

What is metal?

What makes metals immediately recognizable?

What are the properties of metals that make

them such useful materials?

What simple experiments can be carried out to

distinguish metals from other materials?

lecture #1c

The Structure of Metal

Why are some metals hard and other soft?

Why some metals can withstand high temperatures, while some

others not?

Structure - arrangement of atoms

Influence the behavior and structure

lecture #1c

LIQUID

METAL

SOLIDIFICATION

UNIT CELL

(0.1 nm)

BCC

FCC

HCP

CRYSTALS

Lattice

imperfections

Dislocations

SINGLE

CRYSTALS

POLY-

CRYSTALS

Grain boundaries

Plastic deformation

Anisotropy

Products:

Solid state devices

Turbine blades

Products:

Paper clips, bolts,

springs, aircraft fuselage

Metallic Crystal Structures

lecture #1c

Metallic Crystal Structures

Metals crystallize in the dense-packed

structures because energy is released.

(atoms come close together & bond more

tightly with each other)

Body centered

cubic (BCC)

Face centered

cubic (FCC)

Hexagonal centered

cubic (HCP)

lecture #1c

a=b=c=0.287nm

The cube side of the unit cell of BCC iron at

room temperature is 0.287nm. If unit cells of

pure iron are lined up side by side, in 1mm

there will be:

1mm x 1 unit cell = 3.48 x 10

6

unit cells

0.287nm x 10

-6

mm/nm

lecture #1c

Body centered cubic

(BCC)

Face centered cubic

(FCC)

Hexagonal centered

cubic (HCP)

Metallic Crystal Structure

3 densely packed crystal structures:

lecture #1c

Body Centered Cubic (BCC)

Atomic-site unit

cell

Hard-sphere unit

cell

Isolated unit cell

How many atoms ?

1(at the center)+ 8 x 1/8 = 2 atoms per unit cell

lecture #1c

BCC

Prove the relation between the

lattice constant a and the atomic

radius R..

Prove it!

lecture #1c

Face Centered Cubic (FCC)

Atomic-site unit

cell

Hard-sphere unit

cell

Isolated unit cell

How many atoms ?

6 x + 8 x 1/8 = 4 atoms per unit cell

lecture #1c

FCC

Prove it?

a

2

a

2

2a

lecture #1c

Hexagonal Close-Packed (HCP)

Atomic-site unit

cell

Hard-sphere unit

cell

Isolated unit cell

How many atoms?

6 x + 2 x 6 x 1/6 + 2 x 1/2 = 6 atoms per unit cell

lecture #1c

HCP

The ratio of the height c to its basal a called c/a ratio

Ideal c/a ratio consisting of uniform spheres: 1.633

Atomic-site unit cell Base of Hcp unit cell Triangle ABC removed

from base of unit cell

Problem:

Calculate the volume of the zinc crystal structure unit cell by using the

following data; pure zinc has the Hcp crystal structure with lattice

constants a = 0.2665 nm and c= 0.4947 nm.

lecture #1c

Answers..

1 2 base height Area of triangle ABC =

=

1 2 a asi n60

o

From Fig. c

Total area of Hcp base =

=

6 1 2a

2

si n60

o

3a

2

si n60

o

From Fig. b

Volume of zinc Hcp unit cell =

=

=

3a

2

si n60

o

c

3 0.265nm

2

0.8660 0.4947nm

0.0913nm

3

From Fig. a

lecture #1c

Atom Positions in Cubic Unit Cells

Rectangular x,y,z axes Atom position in BCC unit cell

lecture #1c

Comparison of FCC, HCP & BCC Crystal

Structures.

Crystal Structure BCC FCC

(close packed)

HCP

(close-packed)

Atom position Atoms are

positioned at

each corner of

the cube and one

at the center of

the cube

Atoms are

positioned at each

corner of the cube

and one at the

center of each

cube face

?

Atomic Packing

Factor

=vol

atoms

/vol

unit cell

0.68 0.74 0.74

Examples: Iron, tungsten,

chromium,

molybdenum,

vanadium

Aluminum, copper,

lead, nickel, and

iron (at 912-

1394

o

C)

Cadmium, zinc,

magnesium,

cobalt, zirconium,

titanium, beryllium

lecture #1c

Polymorphism / Allotropy

Elements and

compounds which exist

more than one crystalline

form under different

conditions of temperature

and pressure

Examples: iron, titanium

and cobalt (at elevated

temp. and atmospheric

pressure).

Temperature Crystal

structure

Alpha

iron

-273-912

o

C BCC

Gamma

iron

912-1394

o

C FCC

Delta

iron

1394-1539

o

C FCC

lecture #1c

Materials Structure

and Bonding

Deformation and Strength of

Single Crystal

lecture #1c

Deformation and Strength

of Single Crystal

Elastic

deformation

The lattice structure is shifted, stretched,

and distorted but returns to the materials

original shape when force removed.

Plastic

deformation

Atoms change positions and slip past one

another because the atomic bond is

broken material does not return to

original shape when force removed

lecture #1c

Metallic bonding allows for slip, the basic

mechanism by which metals deform plastically

when subjected to high stresses

The properties of materials are a function of

their:

1. Atomic Structure

2. Bonding Structure

3. Crystal Structure

4. Imperfections

If these various structures are known then the

properties of the material can be determined.

lecture #1c

Crystalline Imperfections

Crystals contain various types of

imperfections and defects that affect their

physical and mechanical properties.

Crystal lattice imperfections are classified

according to their geometry and shape.

Strength of a material also depends on

crystal imperfections, alloying agents, and

impurities.

lecture #1c

May be intentional or unintentional.

May be present because of an added alloy.

Steel is an alloy of Iron (Fe) and Carbon

(C).

Carbon atoms are much smaller than the

iron atoms and appear as interstitial.

Crystalline Imperfections

lecture #1c

Types of Imperfections in the Crystal

Structure

1. Zero dimensional / Point defects

e.g.: vacancy, interstitialcy (atom or impurity)

2. One dimensional / Line defects

e.g.: dislocations

3. Two dimensional / Planar defects

e.g.: grain boundaries, twin boundaries, low

angle boundaries, high angle boundaries, twists,

and stacking faults.

4. Three dimensional macroscopic / Volume or bulk

imperfection

e.g.: voids or inclusion (nonmetallic such as

oxide,sulfide and silicates)

lecture #1c

1. Point Defects

Vacancy

Missing atoms

Produced during solidification as a result of:

local disturbances during crystal growth

Atomic rearrangements in an existing crystal

due to atomic mobility.

Additional vacancies in metals:

Plastic deformation

Rapid cooling from higher temperature to

lower temperature to entrap vacancies

lecture #1c

Defects in a Single-Crystal Lattice

Schematic illustration of types of defects in a single-crystal

lattice: self-interstitial, vacancy, interstitial, and substitutional.

lecture #1c

Self-Interstitial

Extra" atoms positioned between atomic sites.

Impurities

A foreign atom that has replaced an atom of the pure

metal.

lecture #1c

2. Line defects

Dislocations

Rows of unit cells that become shifted and upset the

orderly arrangement.

Types of dislocations:

Edge

Screw

Mixed

All crystalline materials contain dislocations introduced during:

Solidification

Plastic deformation

As a consequence of thermal stresses resulting from

rapid cooling.

lecture #1c

Types of dislocations in a single crystal: (a) edge dislocation; and (b)

screw dislocation.

lecture #1c

Movement of an Edge Dislocation

Movement of an edge dislocation across the crystal

lattice under a shear stress. Dislocations help explain

why the actual strength of metals is much lower than

that predicted by theory.

lecture #1c

Dislocations cause slip between crystal plane

when they move. They produce permanent

(plastic) deformation.

(a) Plastic deformation of a single crystal under a tensile load.

Note that the slip planes tend to align themselves in the

direction of the pulling force. This behavior can be simulated

using a deck of cards with a rubber band around them.

(b) Twinning in a single crystal in tension.

lecture #1c

Slip and Twinning

Plastic deformation of a single crystal subjected to a shear stress: (a)

structure before deformation; and (b) permanent deformation by slip. The

size of the b/a ratio influences the magnitude of the shear stress required to

cause slip.

Elastic deformation

Plastic deformation

lecture #1c

Slip Lines and Slip Bands

Schematic illustration of slip lines

and slip bands in a single crystal

(grain) subjected to a shear

stress.

A slip band consists of a number

of slip planes. The crystal at the

center of the upper illustration is

an individual grain surrounded

by other grains.

lecture #1c

3. Planar Defects

Boundaries having two dimensions and separate regions of

materials having different crystal structure and/or

crystallographic orientations.

Twin boundaries

Occur when two crystals of the same type intergrow, so that

only a slight misorientation exists between them.

Twin results from atomic displacements produced from

mechanical shear force (mechanical twin, found in BCC &

HCP) or annealing heat treatment (annealing twin, found in

FCC).

Responsible for many of the changes that occur in cold work of

metals with limited slip systems or at very low temperatures.

lecture #1c

Twin plane or boundary and the adjacent atom positions.

lecture #1c

lecture #1c

Atoms on one side of a plane (called the twinning plane)

are shifted to form a mirror image of the other side

Twinning, involving the formation of an atomic mirror image

(i.e., a "twin") on the opposite side of the twinning plane:

(a) before, and (b) after twinning

lecture #1c

Stacking Faults

Found in FCC when there is an interruption

in the ABC ABC stacking sequence of

closed-packed planes.

lecture #1c

4. Volume Defects

Form when a cluster of point defects join to form

a 3D void or pore.

Introduced during processing and fabrication

steps.

lecture #1c

Summary

Deformation may be elastic or plastic.

Elastic Deformation - lattice structure is

distorted but reorients.

Plastic Deformation occurs by slip along

lattice where atomic bonds are broken.

lecture #1c

DISLOCATION

A way of explaining two key observations about the plastic deformation

of crystalline material:

i. The stress required to plastically deform a crystal is much less

than the stress one calculates from considering a defect-free crystal

structure

ii. Materials work-harden: when a material has been plastically

deformed it subsequently requires a greater stress to deform further

A dislocation in a 2D close-packed plane can be described as an extra

'half-row' of atoms in the structure.

ADDITIONAL NOTES

lecture #1c

SLIP & DISLOCATION

Explain how plastic deformation of materials occurs through the

mechanism of slip.

Slip involves dislocation glide on particular slip planes

Slip occurs when the shear stress acting in the slip direction on the slip

plane reaches some critical value.

This critical shear stress is related to the stress required to move

dislocations across the slip plane.

When a single crystal is deformed under a tensile stress, it is observed

that plastic deformation occurs by slip on well-defined parallel crystal

planes. Sections of the crystal slide relative to one another, changing the

geometry of the sample as shown in the diagram.

The tensile yield stress of a material is the applied stress required to

start plastic deformation of the material under a tensile load.

lecture #1c

lecture #1c

Thank You

You might also like

- Eng Mat Chapter 4Document126 pagesEng Mat Chapter 4VC Chua Yee LeongNo ratings yet

- The NLP GlossaryDocument8 pagesThe NLP GlossaryselfdevNo ratings yet

- Lab03 MetallographyDocument7 pagesLab03 MetallographyVC Chua Yee LeongNo ratings yet

- Cold Calling Success PDFDocument100 pagesCold Calling Success PDFAkin Akinmosin100% (1)

- Lab01 - Vickers Hardness Test - EacDocument8 pagesLab01 - Vickers Hardness Test - EacVC Chua Yee LeongNo ratings yet

- Attraction Formula - Paul JankaDocument88 pagesAttraction Formula - Paul JankaYashvir Savio Dalaya94% (35)

- Eng Mat Chapter 3Document155 pagesEng Mat Chapter 3VC Chua Yee Leong0% (1)

- Chap. 1 (Marking)Document15 pagesChap. 1 (Marking)VC Chua Yee LeongNo ratings yet

- Eng Mat Chapter 1Document26 pagesEng Mat Chapter 1VC Chua Yee LeongNo ratings yet

- Universiti Malaysia Pahang Faculty of Mechanical Engineering Tutorial 1 Infinite SeriesDocument2 pagesUniversiti Malaysia Pahang Faculty of Mechanical Engineering Tutorial 1 Infinite SeriesVC Chua Yee LeongNo ratings yet

- Chap. 1 (Marking)Document15 pagesChap. 1 (Marking)VC Chua Yee LeongNo ratings yet

- 2 PDFDocument6 pages2 PDFVC Chua Yee LeongNo ratings yet

- Chap 2 (Filing)Document23 pagesChap 2 (Filing)VC Chua Yee LeongNo ratings yet

- Week 1infinite SeriesDocument30 pagesWeek 1infinite SeriesVC Chua Yee LeongNo ratings yet

- Chap. 1 (Marking)Document15 pagesChap. 1 (Marking)VC Chua Yee LeongNo ratings yet

- Lect6 PhysicalDocument22 pagesLect6 PhysicalVC Chua Yee LeongNo ratings yet

- Lect4 HZD Mechanical11Document18 pagesLect4 HZD Mechanical11VC Chua Yee LeongNo ratings yet

- Chap 2 (Filing)Document23 pagesChap 2 (Filing)VC Chua Yee LeongNo ratings yet

- Lect4 HZD Mechanical11Document18 pagesLect4 HZD Mechanical11VC Chua Yee LeongNo ratings yet

- Lect4 HZD Mechanical11Document18 pagesLect4 HZD Mechanical11VC Chua Yee LeongNo ratings yet

- School of ArchitectureDocument2 pagesSchool of ArchitectureVC Chua Yee LeongNo ratings yet

- School of ArchitectureDocument2 pagesSchool of ArchitectureVC Chua Yee LeongNo ratings yet

- Ch02 StaticsDocument151 pagesCh02 StaticsVC Chua Yee LeongNo ratings yet

- Lect5 ChemicalDocument21 pagesLect5 ChemicalVC Chua Yee LeongNo ratings yet

- Chap. 1 (Marking)Document15 pagesChap. 1 (Marking)VC Chua Yee LeongNo ratings yet

- Deformation-Induced Phase Development in A Cobalt-Based Superalloy During Monotonic and Cyclic DeformationDocument3 pagesDeformation-Induced Phase Development in A Cobalt-Based Superalloy During Monotonic and Cyclic DeformationVC Chua Yee LeongNo ratings yet

- Deformation-Induced Phase Development in A Cobalt-Based Superalloy During Monotonic and Cyclic DeformationDocument3 pagesDeformation-Induced Phase Development in A Cobalt-Based Superalloy During Monotonic and Cyclic DeformationVC Chua Yee LeongNo ratings yet

- Eng Mat Chapter 8Document68 pagesEng Mat Chapter 8VC Chua Yee LeongNo ratings yet

- Eng Mat Chapter 1Document26 pagesEng Mat Chapter 1VC Chua Yee LeongNo ratings yet

- Eng Mat Chapter 7Document167 pagesEng Mat Chapter 7VC Chua Yee LeongNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Shjohntec 2008218115733800771Document36 pagesShjohntec 2008218115733800771Kristin NgoNo ratings yet

- BPhO Round 1 2013 PRT 1Document6 pagesBPhO Round 1 2013 PRT 1Karn KumarNo ratings yet

- Antimicrobial Activity and Chemical Composition of Essential Oil FromDocument9 pagesAntimicrobial Activity and Chemical Composition of Essential Oil FromTrần Thuý QuỳnhNo ratings yet

- 1.1. Fossils: Picture 3.1 Cast and Mold FossilDocument6 pages1.1. Fossils: Picture 3.1 Cast and Mold Fossilsushan19No ratings yet

- Transparent WoodDocument7 pagesTransparent WoodArnab BhattacharyaNo ratings yet

- The Effect of LIGNOSULFONATE en The Flotability of TalcDocument9 pagesThe Effect of LIGNOSULFONATE en The Flotability of TalcjvchiqueNo ratings yet

- A Physical Absorption Process For The Capture of Co From Co - Rich Natural Gas StreamsDocument6 pagesA Physical Absorption Process For The Capture of Co From Co - Rich Natural Gas StreamssinhleprovietNo ratings yet

- Thin CylinderDocument5 pagesThin CylinderAngshuman BhardwajNo ratings yet

- As 4873.1-2005 Recommended Practice For Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) Principles andDocument8 pagesAs 4873.1-2005 Recommended Practice For Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) Principles andSAI Global - APACNo ratings yet

- Formulation and Evaluation of Gel Containing Econazole NitrateDocument9 pagesFormulation and Evaluation of Gel Containing Econazole NitrateSaiesh PhaldesaiNo ratings yet

- Chemical DosingDocument3 pagesChemical DosingMasoodyNo ratings yet

- RINA Desin&OperationDocument10 pagesRINA Desin&OperationmoubenNo ratings yet

- Understanding Underground Electric Transmission CablesDocument4 pagesUnderstanding Underground Electric Transmission CablesSebastianCicognaNo ratings yet

- SynopsisDocument4 pagesSynopsisyashaahmadNo ratings yet

- Shin 2016Document8 pagesShin 2016pur bNo ratings yet

- Group Two'S Seminar Work: Topic: Enzyme Regulation Allosteric Regulation and Models OutlineDocument13 pagesGroup Two'S Seminar Work: Topic: Enzyme Regulation Allosteric Regulation and Models OutlineOluwasegun ModupeNo ratings yet

- L2472 Rev 9Document4 pagesL2472 Rev 9Ignacio León CornejoNo ratings yet

- Metrology AND MeasurementsDocument56 pagesMetrology AND Measurementsvasanthmech092664No ratings yet

- Bongsuwan D 2008Document7 pagesBongsuwan D 2008Liona MargaritaNo ratings yet

- Photosynthesis in PlantsDocument5 pagesPhotosynthesis in Plantskay69max47No ratings yet

- Landau Ginzburg TheoryDocument16 pagesLandau Ginzburg TheoryMalik SaifNo ratings yet

- I - 6 Batch 2022 Project ReportDocument72 pagesI - 6 Batch 2022 Project Reportvilla srisuryaNo ratings yet

- Power CardDocument6 pagesPower CardArun SNo ratings yet

- 101-116 BergerDocument16 pages101-116 BergerBalaji GuruNo ratings yet

- Marine Enginnering SyllabusDocument3 pagesMarine Enginnering SyllabusRam Prasad YadavNo ratings yet

- 1995 Review - Aqueous Tape Casting of Ceramic PowdersDocument12 pages1995 Review - Aqueous Tape Casting of Ceramic PowdersFreudensteinitzNo ratings yet

- Excitation of Plasmons and Interband Transitions by Electrons PDFDocument2 pagesExcitation of Plasmons and Interband Transitions by Electrons PDFRobNo ratings yet

- BCS ClassificationDocument13 pagesBCS ClassificationSandeep SainiNo ratings yet

- Lecture26 PDFDocument4 pagesLecture26 PDFgautamNo ratings yet

- Tanker Cargo CalculationsDocument5 pagesTanker Cargo Calculationsutkarshgahtori83% (6)