Professional Documents

Culture Documents

Basic Refinery

Uploaded by

Khairatun NisaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Refinery

Uploaded by

Khairatun NisaCopyright:

Available Formats

REFINING

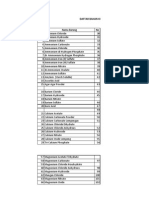

Outline

Crude Oil Basics

Refining Concepts

Flowcharts of Petroleum Refineries

Basic Refinery Operations and Optimization

Conversion

Refinery Overview

What is Crude Oil?

Crude oil is a mixture of

hydrocarbons formed from

organic matter.

Crude varies significantly in

color and composition

Composition varies

Sulfur content

Density varies

Contains sediment and

water

Crude Oil Characteristics

Crude density is commonly measured by API gravity

API gravity provides a relative measure of crude oil

density. The higher the API number, the lighter the

crude

Sulfur content measures if a crude is sweet (low

sulfur) or sour (high sulfur)

Typically less than 0.5% sulfur content = sweet

Typically greater than 1.5% sulfur content = sour

High sulfur crudes require additional processing to

meet regulatory specs

Crude Types Versus Demand

Gasoline Gasoline Gasoline

5 - 15 %

20 - 30 % 40 - 45%

Distillate

20 - 25%

Distillate Distillate

25 - 35% Heavy Fuel 30 - 35%

Oil Heavy Fuel

60 - 75% Oil

Heavy Fuel ~10%

Oil

35 - 55% Asphalt ~5%

Other ~5 -10%

Light Crude Heavy Crude Example

Product Product Product

Composition Composition Demand

Naturally occuring

hydrocarbon molecules do

not meet customer needs.

The refining processes must

adjust the molecules, reshape

them and remove contaminants

to ensure they meet

requirements for:

- end use performance

- environmental performance

Supply and Demand

California

CA now consumes 44 to 45 million gallons of gasoline

and 10 million gallons of diesel fuel per day.

Demand for transportation fuels increased nearly 50%

in last 20 years

Number of refineries producing gasoline in California

dropped from 32 in mid-1980s to 14 today

California now imports 3.5 million gallons of gasoline

per day.

Source: California Energy Commission

Basic Refining Concepts

Crude Separation

Basic Refining Concepts

Basic Flowchart of Petroleum Refinery (1915)

Simplified Flowchart of a Complex Refinery

Basic Refinery Operations

Separation Distillation

Conversion Changing the size or shape of molecules

Re-shape molecules to improve product quality

Catalytic Reforming Unit

Upgrading breaking large molecules into smaller

Coking

Hydrocraking

Treatment / Blending Making on specification products

Removal of impurities desalting, desulfurization,

denitrofication

Mixtures of components to meet specifications

Refinery Optimization

Two areas can not be compromised

Safety

Reliability

Ecomonic optimization is a series of trade-offs

Feedstocks

Availability (crude, Intermediate products), Yields, Cost

Refinery Complexity, Flexibility + Constraints

Crude rate

Maximize to spread fixed costs

Products

Meet market demands

Value added and margins

Operations

Maximize yields, minimize giveaway / inventories

Optimize energy use

Conversion

REFINERY OVERVIEW

Distillation Cracking Treating Reforming

(Separation) (Changing Size) (Changing Shape)

LPG

Raw Fuel gas

LPG C4

I-C4

Naptha Gasoline

Diesel Diesel

Gas Gas

Oil Oil

Resid. Coke

Coker

MHCU

HCU

HDS

CRU

Utilities

For More Information

www.bigwestca.com

www.energy.gov

www.energy.ca.gov

www.pipeline101.com

www.wspa.org

Thank you

You might also like

- What Is Statistics IntroDocument16 pagesWhat Is Statistics IntroKomala RangarauNo ratings yet

- ABC Refinery Brochure Web 1Document28 pagesABC Refinery Brochure Web 1Leon MutambalaNo ratings yet

- Refinery Corrosion - Review SummaryDocument2 pagesRefinery Corrosion - Review SummarycastilloehxNo ratings yet

- Thickness ProbesDocument4 pagesThickness ProbesRodrigoNo ratings yet

- Liquid Penetrant Testing IntroductionDocument68 pagesLiquid Penetrant Testing IntroductionMuhammad ZariqNo ratings yet

- Confidence You Can See: Omniscan X3 Phased Array Flaw Detector With TFMDocument5 pagesConfidence You Can See: Omniscan X3 Phased Array Flaw Detector With TFMWayneNo ratings yet

- Interpretation of EN 1712 Acceptance CriteriaDocument4 pagesInterpretation of EN 1712 Acceptance CriteriaYuzi VengamNo ratings yet

- FAQ - What's New in ISO 15614-1 - 2017Document2 pagesFAQ - What's New in ISO 15614-1 - 2017tomasinkaNo ratings yet

- UT SlidesDocument58 pagesUT SlidesY ShameyaNo ratings yet

- ASME Code Case 2600 PDFDocument2 pagesASME Code Case 2600 PDFrotero_pujolNo ratings yet

- Iso 14096 1 2005Document18 pagesIso 14096 1 2005RONALD ALFONSO PACHECO TORRESNo ratings yet

- Example Slide of User Functions: Time Guide The Slide Should Be Finished byDocument71 pagesExample Slide of User Functions: Time Guide The Slide Should Be Finished byzahidwahla1No ratings yet

- Difference Between Law and Ethics: First Chapter Cont. Introduction To Business EthicsDocument8 pagesDifference Between Law and Ethics: First Chapter Cont. Introduction To Business EthicsAmrertaNo ratings yet

- An Application of Six Sigma in Service Sector-A Case StudyDocument9 pagesAn Application of Six Sigma in Service Sector-A Case StudyblitzkrigNo ratings yet

- The Eddy Current Inspection Method Pt4Document4 pagesThe Eddy Current Inspection Method Pt4vrapciudorianNo ratings yet

- Inspection Technologies Brochure English 5Document19 pagesInspection Technologies Brochure English 5Agus WiyantoNo ratings yet

- DATASHEET Up1542rDocument17 pagesDATASHEET Up1542rjoao doisssNo ratings yet

- U.T ProcedureDocument10 pagesU.T ProceduretreyX67No ratings yet

- G-08 KAN Guide On Application of SNI ISO 17020 For Accreditaion of Inspection Bodies (EN) PDFDocument15 pagesG-08 KAN Guide On Application of SNI ISO 17020 For Accreditaion of Inspection Bodies (EN) PDFDimas Arief SetiawanNo ratings yet

- Magnetic Particle Examination ProcedureDocument5 pagesMagnetic Particle Examination ProcedureShankey JAlanNo ratings yet

- Introduction To NDT BasicDocument27 pagesIntroduction To NDT BasicAngela WalkerNo ratings yet

- Ultrasonic Thickness Gaging GuideDocument4 pagesUltrasonic Thickness Gaging GuideCarlos BustamanteNo ratings yet

- Lecture - 2 (Book-Keeping, Accounting and Accountancy) PDFDocument24 pagesLecture - 2 (Book-Keeping, Accounting and Accountancy) PDFShivati Singh KahlonNo ratings yet

- Ultra Sound Testing: Opic:-Test Methods and TechniquesDocument23 pagesUltra Sound Testing: Opic:-Test Methods and TechniquesVarun MalanNo ratings yet

- Astm A435Document2 pagesAstm A435Mostafa MehrjerdiNo ratings yet

- 7002mfh Module HandbookDocument11 pages7002mfh Module HandbookRaviteja NvrNo ratings yet

- Reducing The Risk of High Temperature Hydrogen Attack (HTHA) FailuresDocument5 pagesReducing The Risk of High Temperature Hydrogen Attack (HTHA) FailuresAgustin Fabian HaddadNo ratings yet

- Sonatest CompletoDocument131 pagesSonatest CompletogabrielNo ratings yet

- Corrosion MappingDocument17 pagesCorrosion MappingJuliog100% (1)

- ECHOGRAPH Ultrasonic Probes Brochure SummaryDocument4 pagesECHOGRAPH Ultrasonic Probes Brochure Summarycarlos100% (1)

- Iso 4386 1 2019 en PDFDocument6 pagesIso 4386 1 2019 en PDFZorianny Garcia LopezNo ratings yet

- DGS DGS MethodDocument6 pagesDGS DGS MethodAlzaki AbdullahNo ratings yet

- Ultrasonic Testing Training (UT) : Level-IIDocument8 pagesUltrasonic Testing Training (UT) : Level-IIAn IkhrandiNo ratings yet

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFDocument11 pagesInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014No ratings yet

- Inspection Programs For Internal Corrosion in PipingDocument6 pagesInspection Programs For Internal Corrosion in PipingsajimaliNo ratings yet

- Weld Scanning ProcedureDocument5 pagesWeld Scanning ProcedureLutfi IsmailNo ratings yet

- Multifilm Techinique PDFDocument7 pagesMultifilm Techinique PDFamitNo ratings yet

- How Oil Refining Works: From Crude to ProductsDocument7 pagesHow Oil Refining Works: From Crude to ProductsmuraliNo ratings yet

- Lecture 7 Intergranular CorrosionDocument18 pagesLecture 7 Intergranular Corrosionprakush01975225403No ratings yet

- Echo To Echo (Holloway NDT Article)Document4 pagesEcho To Echo (Holloway NDT Article)pjhollowNo ratings yet

- NIST SPECIFICATIONS AND TOLERANCES FOR FIELD STANDARD WEIGHTSDocument14 pagesNIST SPECIFICATIONS AND TOLERANCES FOR FIELD STANDARD WEIGHTSDiego TobrNo ratings yet

- Ultrasonic 4Document3 pagesUltrasonic 4nsbirwalNo ratings yet

- Handbook 1 A29Document31 pagesHandbook 1 A29srgokuNo ratings yet

- Liquid Penetrant Testing Module 1Document6 pagesLiquid Penetrant Testing Module 1Weld Bro SandeepNo ratings yet

- Assignment CSRDocument20 pagesAssignment CSRMohammad Tosif Nur Zahin ,151442No ratings yet

- B-Scan Buggy Demo ProcedureDocument12 pagesB-Scan Buggy Demo ProcedureJuan Ricardo Villanueva ReañoNo ratings yet

- IITS SAFERAD PROCEDUREDocument34 pagesIITS SAFERAD PROCEDUREasikurNo ratings yet

- Visual TestingDocument1 pageVisual TestingGulfnde Industrial ServicesNo ratings yet

- API 934 Minutes Fluor ATT CDocument28 pagesAPI 934 Minutes Fluor ATT CAnonymous rUs4PjYo5No ratings yet

- ANDTBF - 06 NDT Training SyllabusDocument34 pagesANDTBF - 06 NDT Training SyllabusHeidi CoxNo ratings yet

- Study of The Factors Affecting The Sensitivity of Liquid PenetrantDocument59 pagesStudy of The Factors Affecting The Sensitivity of Liquid PenetrantfallalovaldesNo ratings yet

- The Complete Guide to Telephone Interview Questions and AnswersFrom EverandThe Complete Guide to Telephone Interview Questions and AnswersNo ratings yet

- Petroleum Refining & PetrochemicalsDocument32 pagesPetroleum Refining & PetrochemicalsprasoonNo ratings yet

- Refining - VALERODocument35 pagesRefining - VALERORoozbeh P100% (1)

- Refinery Overview ModificationDocument108 pagesRefinery Overview ModificationChakravarthy BharathNo ratings yet

- Diesel Fuel Refining and Its AdvancementDocument21 pagesDiesel Fuel Refining and Its Advancementvivek20072008No ratings yet

- 1007469Document27 pages1007469ger80No ratings yet

- SubseaUK News NOV14 ISSUU 2 PDFDocument32 pagesSubseaUK News NOV14 ISSUU 2 PDFKhairatun NisaNo ratings yet

- Rumus AntoineDocument7 pagesRumus AntoineGaluh ChynintyaNo ratings yet

- VDMS Scholarships for Talented Indonesian Students 2015-2016Document1 pageVDMS Scholarships for Talented Indonesian Students 2015-2016Khairatun NisaNo ratings yet

- APLIKASI SS 2015 Fix PDFDocument3 pagesAPLIKASI SS 2015 Fix PDFKhairatun NisaNo ratings yet

- Rumus AntoineDocument7 pagesRumus AntoineGaluh ChynintyaNo ratings yet

- Contoh 3Document6 pagesContoh 3Ardy Anto SupardiNo ratings yet

- Vessel DesignDocument12 pagesVessel DesignJefry Soclin SianiparNo ratings yet

- Steam Generation Theory & DevelopmentDocument8 pagesSteam Generation Theory & DevelopmentKhairatun NisaNo ratings yet

- VLE Acetone MethanolDocument15 pagesVLE Acetone MethanolKhairatun NisaNo ratings yet

- Bahan KimiaDocument4 pagesBahan KimiaKhairatun NisaNo ratings yet

- Rumus AntoineDocument7 pagesRumus AntoineGaluh ChynintyaNo ratings yet

- Steam Generation Theory & DevelopmentDocument8 pagesSteam Generation Theory & DevelopmentKhairatun NisaNo ratings yet

- Bod For WebsiteDocument2 pagesBod For WebsiteHarith MuhammadNo ratings yet

- Msds CresolDocument6 pagesMsds CresolArya Bima Aji KusumaNo ratings yet

- Bahan KimiaDocument4 pagesBahan KimiaKhairatun NisaNo ratings yet

- Bod For WebsiteDocument2 pagesBod For WebsiteHarith MuhammadNo ratings yet

- Contoh 12.3 "Optimization of Chemical Processes" A 1.958661 A 1.689446 X X P P P P P - PDocument6 pagesContoh 12.3 "Optimization of Chemical Processes" A 1.958661 A 1.689446 X X P P P P P - PGapuk MaboekNo ratings yet

- 1377 3809 1 PBDocument2 pages1377 3809 1 PBArma Sari TrgnNo ratings yet

- Unilever Tablets Reduce Detergent ImpactDocument6 pagesUnilever Tablets Reduce Detergent ImpactKhairatun NisaNo ratings yet

- WB Npdes BiochemicalOxygenDemand 247231 7Document2 pagesWB Npdes BiochemicalOxygenDemand 247231 7ginga716No ratings yet

- 02 Dasar2 Perancangan Chp1 FoglerDocument14 pages02 Dasar2 Perancangan Chp1 FoglerAdun DudunNo ratings yet

- Refrigeration Gas CatalogDocument92 pagesRefrigeration Gas Catalogildiko1234No ratings yet

- Khairatun Nisa - Humidity ChartDocument1 pageKhairatun Nisa - Humidity ChartKhairatun NisaNo ratings yet

- Refrigeration CyclesDocument17 pagesRefrigeration CyclesKhairatun NisaNo ratings yet

- LeachingDocument16 pagesLeachingKhairatun NisaNo ratings yet

- Hysys in Energy BalanceDocument14 pagesHysys in Energy BalanceKhairatun NisaNo ratings yet

- Processflowdiagrampg 130810211631 Phpapp01Document14 pagesProcessflowdiagrampg 130810211631 Phpapp01Khairatun NisaNo ratings yet

- Khairatun Nisa - Humidity ChartDocument1 pageKhairatun Nisa - Humidity ChartKhairatun NisaNo ratings yet

- NHDT FoulingDocument6 pagesNHDT FoulingJulio RamirezNo ratings yet

- Optimization of Biodiesel Production From Caster Seed Oil ThroughDocument86 pagesOptimization of Biodiesel Production From Caster Seed Oil ThroughyascheNo ratings yet

- Interpretation of Total Petroleum Hydrocarbon (TPH) Results With Rapid Assay KitsDocument5 pagesInterpretation of Total Petroleum Hydrocarbon (TPH) Results With Rapid Assay Kitsraghavan89No ratings yet

- Hydrocarbon Processing April 2013Document113 pagesHydrocarbon Processing April 2013asadashfaqlodhiNo ratings yet

- Risk Assessment of Sulphur RecoveryDocument6 pagesRisk Assessment of Sulphur RecoveryTejasNo ratings yet

- Crude Oil DistillationDocument64 pagesCrude Oil DistillationGautam SharmaNo ratings yet

- T 18Document10 pagesT 18khuramluck100% (2)

- Fuels & Combustion - Liquid Fuels TYBE COEP DR Vora 040123 FinalDocument199 pagesFuels & Combustion - Liquid Fuels TYBE COEP DR Vora 040123 FinalJaya NandeshwarNo ratings yet

- C P T T E M T F: Inal Nvestigation EportDocument99 pagesC P T T E M T F: Inal Nvestigation EportSurendar Veeraraj100% (1)

- HYSYS Course Level 1 PDFDocument52 pagesHYSYS Course Level 1 PDFRetno HardillahNo ratings yet

- Oil, Gas & PetrochemicalDocument54 pagesOil, Gas & Petrochemicalethanhunt37470% (1)

- World Energy MapDocument144 pagesWorld Energy Maplezz_coolNo ratings yet

- P S P C: Ilipinas Hell Etroleum OrporationDocument16 pagesP S P C: Ilipinas Hell Etroleum OrporationPaula VillarubiaNo ratings yet

- 3 2 2 0 Diploma Examination, 2010: 130. Petroleum Refinery EngineeringDocument2 pages3 2 2 0 Diploma Examination, 2010: 130. Petroleum Refinery EngineeringdhasdjNo ratings yet

- Module - 1 EIADocument91 pagesModule - 1 EIAHarsha ReddyNo ratings yet

- Reinforced Composite Piping (RCP)Document9 pagesReinforced Composite Piping (RCP)aslam2786No ratings yet

- Composition of Foreign TradeDocument10 pagesComposition of Foreign TradeNitish JoshiNo ratings yet

- Isom Unit SpecDocument5 pagesIsom Unit SpecMarlow Touch RugbyNo ratings yet

- Yash, M. (2015) .Re-Refining of Used Lubricating Oil PDFDocument4 pagesYash, M. (2015) .Re-Refining of Used Lubricating Oil PDFHenry PabonNo ratings yet

- Uop Unicracking Process For Hydrocracking: Donald AckelsonDocument12 pagesUop Unicracking Process For Hydrocracking: Donald AckelsonNguyễn Hoàng Bảo TrânNo ratings yet

- C2Document201 pagesC2AnecitoNo ratings yet

- API 982-Inspection & Assessment of Refractory LiningsDocument57 pagesAPI 982-Inspection & Assessment of Refractory Liningsmustaphakadiri100% (1)

- High Capacity Tray Reverse FlowDocument11 pagesHigh Capacity Tray Reverse Flowrvkumar61No ratings yet

- AssayManagementV8 8 RefDocument207 pagesAssayManagementV8 8 Refzubair1951No ratings yet

- 15.2 (6648-0600-5-PS-OM-0001) Offsite & Pipeline - enDocument114 pages15.2 (6648-0600-5-PS-OM-0001) Offsite & Pipeline - enouss blzNo ratings yet

- Alfa Laval Flexible Bleaching Solutions Application Brochure enDocument12 pagesAlfa Laval Flexible Bleaching Solutions Application Brochure enJotirmoy AichNo ratings yet

- Bangalore Metallurgy in AIM BrochureDocument7 pagesBangalore Metallurgy in AIM Brochurebhavesh solankiNo ratings yet

- Curriculum VitaeDocument2 pagesCurriculum VitaeobaroisaacNo ratings yet

- Tight OilDocument5 pagesTight OilmaheshlavandNo ratings yet

- Usm Stis 2011 - Bahasa InggrisDocument16 pagesUsm Stis 2011 - Bahasa InggrisAhmad Pique Baisuni100% (1)