Professional Documents

Culture Documents

F13 CE470Ch5 Beam Shear Design

Uploaded by

zainabcomOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F13 CE470Ch5 Beam Shear Design

Uploaded by

zainabcomCopyright:

Available Formats

Shear Design of Beams

CE 470 - Steel Design Class

By:

Amit H. Varma

Shear Strength

Beam shear strength is covered in Chapter G of the AISC

specifications. Both rolled shapes and welded built-up shapes

are covered.

Rolled shapes is the focus here. Built-up shapes, commonly

referred to as plate-girders are beyond the scope of our course.

Consider the behavior of beams in shear

Shear Strength

The web will completely yield long before the flanges begin

to yield. Because of this, yielding of the web represents one

of the shear limit states.

Taking the shear yield stress as 60% of the tensile yield

stress.

This will be the nominal strength in shear provided there is

no shear buckling of the web.

Shear buckling of the web depends on its h/t

w

ratio.

If the ratio is too large, then then web can buckle in shear

elastically or inelastically.

f

v

=

V

n

A

w

= 0.6 F

y

V

n

= 0.6 F

y

A

w

Shear Buckling

Shear

yielding

Elastic shear

buckling

Shear Buckling

in. stiffners, ansverse between tr distance clear a where

260

a/h or 3.0 a/h when 5

) / (

5

5

5

260 /

2

2

=

(

(

(

(

|

.

|

\

|

> > =

+ =

-

=

< -

w

v

v

w

t

h

h a

k

webs stiffened for

k

t h with webs d unstiffene for

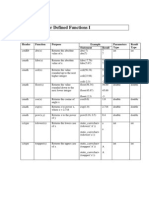

Shear Design Equations

Shear Design Equations

Shear Design Equations

Shear Design Equations

= area of web, the overall depth times the web thickness,

,

.

2

h= for rolled shapes, the clear distance between flanges less the

fillet or corner radii, in.

= for built-up welded sections, the clear distance between the

flanges, in.

= for built-up bolted sections, the distance between fastener

lines, in.

= for tees, the overall depth, in.

= thickness of web, in.

Shear Design Equations

The web plate shear buckling co-efficient,

, is determined as

follows:

For webs without transverse stiffeners and with

< 260:

= 5

except for the stem of tee shapes where

= 1.2.

For webs with transverse stiffeners:

= 5 +

5

2

(G2-6)

=5 when a/h >3.0 or a/h >

260

2

where

a= clear distance between transverse stiffeners, in.

Shear Design Equations

2. Transverse Stiffeners:

Transverse stiffeners are not required where

2.46

, or

where the available shear strength provided in accordance with

Section G2.1 for

= 5 is greater than the required shear strength.

The moment of inertia,

, of the transverse stiffeners used to develop

the available web shear strength, as provided in Section G2.1, about an

axis in the web center for stiffener pairs or about the face in contact

with the web plate for single stiffeners, shall meet the following

requirement

3

(G2-7)

where

=

2.5

2

2 0.5 (G2-8)

and b is the smaller of the dimensions a and h.

Shear Design Equations

Block Shear Failure of Beam

Block shear failure was considered earlier in tension member

connections.

To facilitate the connections of beams to other beams so that

the top flanges are at the same elevation, a short length of

the top flange of one of the beams may be cut away, or

coped.

If a coped beam is connected with bolts as shown, segment

ABC will tend to tear out.

Block shear failure of beam ends

The applied load in the case of the beam will be the vertical

reaction, so shear will occur along line AB and there will be

tension along BC. Thus, the block shear strength will be a

limiting value of the reaction.

Failure is assumed to occurred by rupture (fracture) on the

tension area and rupture or yielding on the shear area.

R

n

= 0.6 F

u

A

nv

+ U

bs

F

u

A

nt

s 0.6 F

y

A

gv

+ U

bs

F

u

A

nt

Where, phi =0.75

Example

Determine the maximum reaction, based on block shear, that

can be resisted by the beam shown below. Treat the bolt end

distance of 1.25 in. as standard.

The effective hole diameter is 3/4 + 1/8 = 7/8 in.

The shear areas are:

A

gv

= t

w

(2+3+3+3) = 0.30 (11) = 3.3 in

2

A

nv

= 0.300 [11 -3.5 (7/8)] = 2.381 in

2

Block shear example

The net tension area is:

A

nt

= 0.300 [1.25 - 1/2 (7/8) ] = 0.2438 in

2

Since the block shear will occur in a coped beam with

standard bolt end distance U

bs

= 1.0.

R

n

= 0.6 F

u

A

nv

+ F

u

A

nt

= 108.7 kips

With an upper limit of

R

n

= 0.6 F

y

A

gv

+ F

u

A

nt

= 114.85 kips

Therefore, nominal block shear strength = 108.7 kips

Factored block shear strength for design = 0.75 x 108.7 =

81.5 kips.

You might also like

- Wastewater Characteristics Physical ChemicalDocument31 pagesWastewater Characteristics Physical ChemicalzainabcomNo ratings yet

- Gaza Concrete Structures Recycled Aggregate PerformanceDocument98 pagesGaza Concrete Structures Recycled Aggregate Performancefandhiejavanov2009No ratings yet

- Design of Members For Combined ForcesDocument27 pagesDesign of Members For Combined ForceszainabcomNo ratings yet

- Ve 23Document40 pagesVe 23zainabcomNo ratings yet

- Chapter 9 - Arrays - Handout 5Document5 pagesChapter 9 - Arrays - Handout 5zainabcomNo ratings yet

- Nut & Bolt Connection DesignDocument16 pagesNut & Bolt Connection DesignChandana KumaraNo ratings yet

- F13 - CE470Ch 2 - Tension MembersDocument39 pagesF13 - CE470Ch 2 - Tension MemberszainabcomNo ratings yet

- VE DefinitionDocument136 pagesVE DefinitionzainabcomNo ratings yet

- Ce470 Hw2 SolDocument6 pagesCe470 Hw2 SolzainabcomNo ratings yet

- Ce470 Hw1 SolDocument8 pagesCe470 Hw1 SolzainabcomNo ratings yet

- BIS202 Test Bank NewDocument589 pagesBIS202 Test Bank NewNaveed Karim BakshNo ratings yet

- Applying VE ConceptDocument164 pagesApplying VE ConceptzainabcomNo ratings yet

- Selected Solutions - 1Document2 pagesSelected Solutions - 1zainabcomNo ratings yet

- Chapter 9 - Arrays - Handout 3Document4 pagesChapter 9 - Arrays - Handout 3zainabcomNo ratings yet

- Excercises - SolutionDocument2 pagesExcercises - SolutionzainabcomNo ratings yet

- 212-Chpt 8Document5 pages212-Chpt 8zainabcomNo ratings yet

- Chapter 9 - Arrays - Handout 1Document4 pagesChapter 9 - Arrays - Handout 1zainabcomNo ratings yet

- Chapter 6 - HandoutDocument5 pagesChapter 6 - HandoutzainabcomNo ratings yet

- General Equations of PlaneDocument2 pagesGeneral Equations of PlanezainabcomNo ratings yet

- Selected Solbookutions - 2Document4 pagesSelected Solbookutions - 2Jeremie YoungNo ratings yet

- الإكسير في برمجة السي بلس بلسDocument285 pagesالإكسير في برمجة السي بلس بلسأكبر مكتبة كتب عربية100% (3)

- Selected Solutions - 3Document3 pagesSelected Solutions - 3zainabcomNo ratings yet

- Sample Mt2 KeyDocument10 pagesSample Mt2 KeyzainabcomNo ratings yet

- 212-Chpt 9Document5 pages212-Chpt 9zainabcomNo ratings yet

- Quiz 2Document4 pagesQuiz 2zainabcomNo ratings yet

- 212-Chpt 7Document6 pages212-Chpt 7zainabcomNo ratings yet

- Econ Sp04 PDFDocument6 pagesEcon Sp04 PDFzainabcomNo ratings yet

- 212-Chpt 5Document8 pages212-Chpt 5zainabcomNo ratings yet

- 212-Chpt 4Document6 pages212-Chpt 4zainabcomNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Normal Distribution & Z-ScoresDocument82 pagesNormal Distribution & Z-Scoresgela tinNo ratings yet

- Teaching Quantum Mechanics On An Introductory Level PDFDocument10 pagesTeaching Quantum Mechanics On An Introductory Level PDF24263537No ratings yet

- The Evolution of Consciousness According to Bhagavad-GitaDocument14 pagesThe Evolution of Consciousness According to Bhagavad-Gitatrabajo mpdNo ratings yet

- Parameter Adaptation of Reduced Order Models For Three-Dimensional Flutter AnalysisDocument9 pagesParameter Adaptation of Reduced Order Models For Three-Dimensional Flutter AnalysisAtsis PapadopoulosNo ratings yet

- 0625 s07 Ms 3Document7 pages0625 s07 Ms 3Hubbak Khan50% (2)

- P Block - PDF 61Document6 pagesP Block - PDF 61SurajNo ratings yet

- Mcas Magnetism ElectricityDocument27 pagesMcas Magnetism ElectricityBea GonzalesNo ratings yet

- Finite Element Analysis of A Cracked Cantilever Beam: Research PaperDocument5 pagesFinite Element Analysis of A Cracked Cantilever Beam: Research PaperSanketNo ratings yet

- Operation Stages HDI SIEMENSDocument9 pagesOperation Stages HDI SIEMENSSergio SambuelliNo ratings yet

- Learning Objectives-2: Uniform MotionDocument7 pagesLearning Objectives-2: Uniform MotionBryanHarold BrooNo ratings yet

- Astm 1784Document4 pagesAstm 1784arifin rizalNo ratings yet

- Roxtec Product Catalogue GB FI RU SE IT 2011 2012Document252 pagesRoxtec Product Catalogue GB FI RU SE IT 2011 2012mmaleniNo ratings yet

- STRATEGIES TO IMPROVE TOEFL STRUCTURE EXERCISE PERFORMANCEDocument5 pagesSTRATEGIES TO IMPROVE TOEFL STRUCTURE EXERCISE PERFORMANCENIARAMLINo ratings yet

- Quantum Mechanics Module NotesDocument12 pagesQuantum Mechanics Module NotesdtrhNo ratings yet

- Magnetism and Electromagnetism - Electrical Multiple Choice Questions and AnswersDocument10 pagesMagnetism and Electromagnetism - Electrical Multiple Choice Questions and AnswersNagesh GillNo ratings yet

- Cooling PDFDocument656 pagesCooling PDFTrầnNgọcCườngNo ratings yet

- Homework 1Document6 pagesHomework 1Ahmet Kemal ÇetinNo ratings yet

- Rife Energy Medicine Cures DiseasesDocument5 pagesRife Energy Medicine Cures DiseasesOna OnićNo ratings yet

- Methods and Algorithms For Advanced Process ControlDocument8 pagesMethods and Algorithms For Advanced Process ControlJohn CoucNo ratings yet

- EdmDocument2 pagesEdmOmkar RahateNo ratings yet

- The Must-Have Guide to Centrifugal PumpsDocument24 pagesThe Must-Have Guide to Centrifugal PumpsStacy Wilson100% (1)

- $binder 1Document156 pages$binder 1fchem11No ratings yet

- Torque NotesDocument3 pagesTorque NotesKudzai MashayaNo ratings yet

- Science Sample Papers 2Document7 pagesScience Sample Papers 2api-281429068No ratings yet

- Solutions ManualDocument5 pagesSolutions ManualYoni BenshaharNo ratings yet

- Summary A PDFDocument3 pagesSummary A PDFAhmad TouqirNo ratings yet

- Fastener Process SimiulationDocument4 pagesFastener Process SimiulationMehran ZaryounNo ratings yet

- (ISRM Book Series) Shunsuke Sakurai - Back Analysis in Rock Engineering-Routledge - CRC Press (2016) PDFDocument241 pages(ISRM Book Series) Shunsuke Sakurai - Back Analysis in Rock Engineering-Routledge - CRC Press (2016) PDFJorge Cortez CampañaNo ratings yet

- Wireless Pick and Place RobotDocument26 pagesWireless Pick and Place RobotAshok GudivadaNo ratings yet

- Alternative Foundation Option by Jet Grouting Pile MethodDocument8 pagesAlternative Foundation Option by Jet Grouting Pile MethodVanDuongNguyenNo ratings yet